Sealing structure of grinding head of wet ball mill

A technology of wet ball mill and sealing mechanism, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc. It can solve the problems of poor sealing, high labor intensity of workers, leakage of slurry, etc., achieve convenient replacement, solve serious wear problems, and connect The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

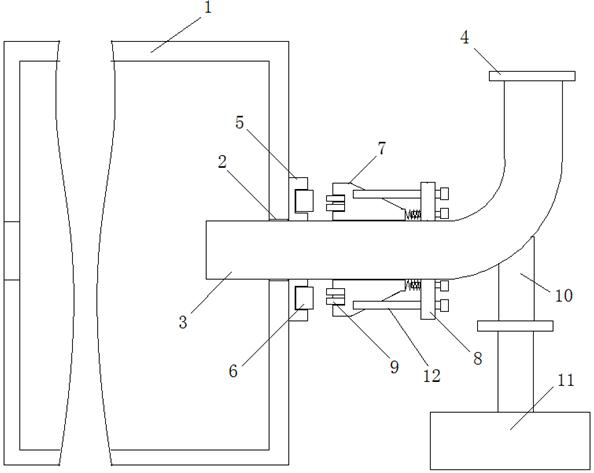

[0019] A sealing mechanism for the grinding head of a wet ball mill, in which a connection port 2 is provided on one side of the grinding head cylinder body, one end of the elbow 3 is inserted into the connection port 2, and the other end of the elbow 3 is connected to the mixer through a flange 4; Outside the connection port 2 between the cylinder body 1 and the elbow 3, a side motion base 5 of the cylinder body is arranged, and a groove around the elbow 3 is arranged on the side motion base 5 of the cylinder body. The dynamic sealing ring 6 is installed on the side motion of the cylinder body. In the groove of the base 5; the elbow side static base 7 and the static base pressing frame 8 that are set outside the feed end elbow 3, the elbow side static base 7 faces the side of the cylinder side moving base 5 A groove is set on the surface, and the static sealing ring 9 is installed in the groove of the static base 7 on the side of the elbow. The end face of the static seal rin...

Embodiment 2

[0021] As a specific preferred design, the side moving base 5 of the cylinder is made of metal material (such as: the side moving base 5 of the cylinder is made of 2205 stainless steel), the static base 7 of the elbow side is made of rubber, and the dynamic sealing ring 6 and The joint surface material of the static sealing ring 9 is silicon carbide.

[0022] As a preferred design, a positioning and fixing pipe 10 is installed on the elbow 3, and the other end of the positioning and fixing pipe 10 is provided with a positioning flange, and the positioning flange is connected with the base 11 installed on the ground.

[0023] As a specific structural design, the cylinder side moving base 5 has a thickness of 20mm, and a groove with a depth of 10mm and a width of 40mm is provided; the width*thickness of the dynamic sealing ring is 38mm*15mm.

[0024] As a preference, a 1mm rubber gasket is provided between the dynamic sealing ring 6 and the cylinder side dynamic base 5 to preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com