Connecting structure of crossing type double trolleys

The technology of connecting structure and double trolley is applied in the direction of bottom support structure, traveling mechanism, walking bridge crane, etc., which can solve the problems of increasing the weight of the main girder, complicated processes such as processing and installation, increasing production cost and labor consumption, etc. To achieve the effect of simplifying the installation process and reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following embodiments will be used to further illustrate the present invention in conjunction with the accompanying drawings.

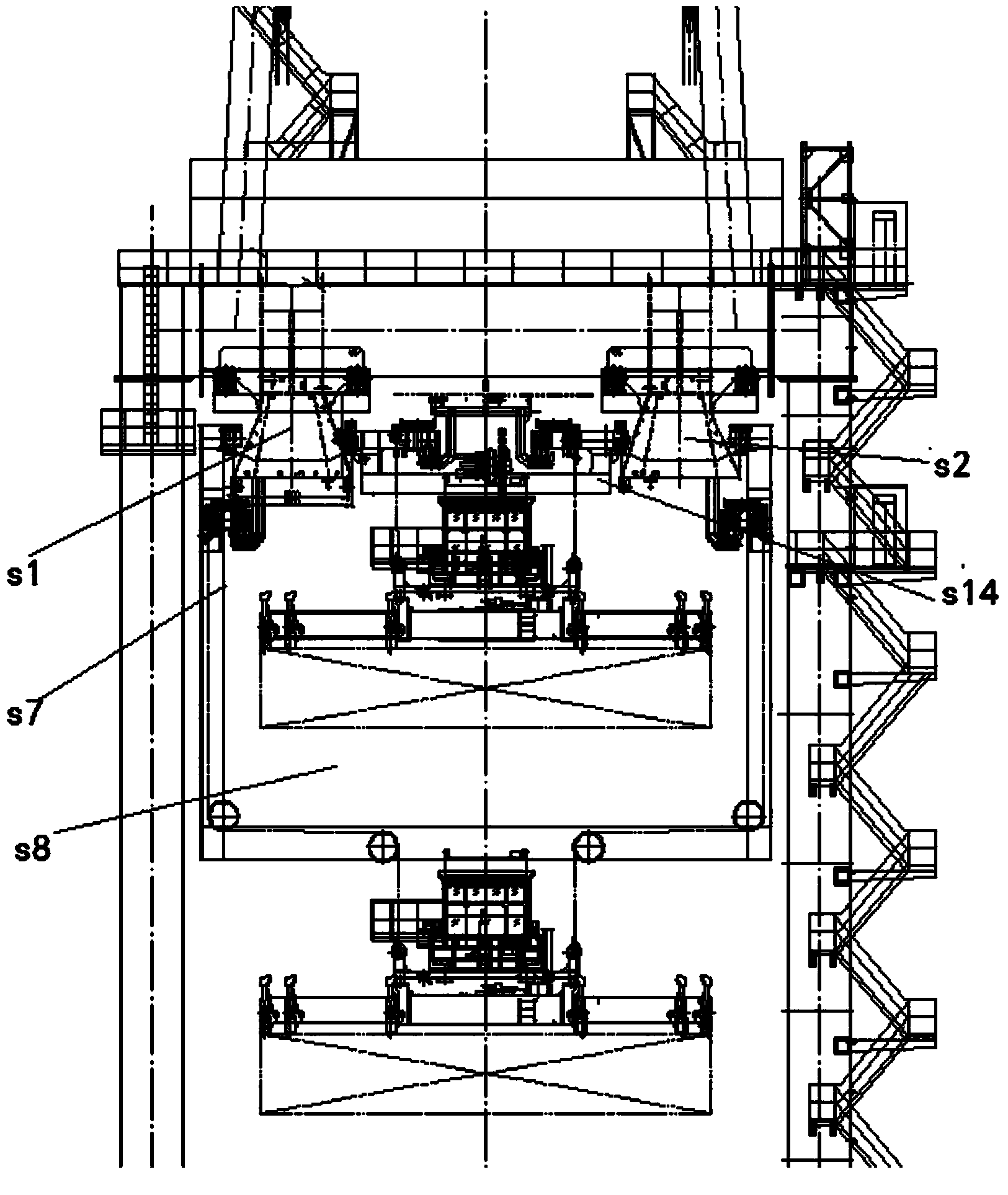

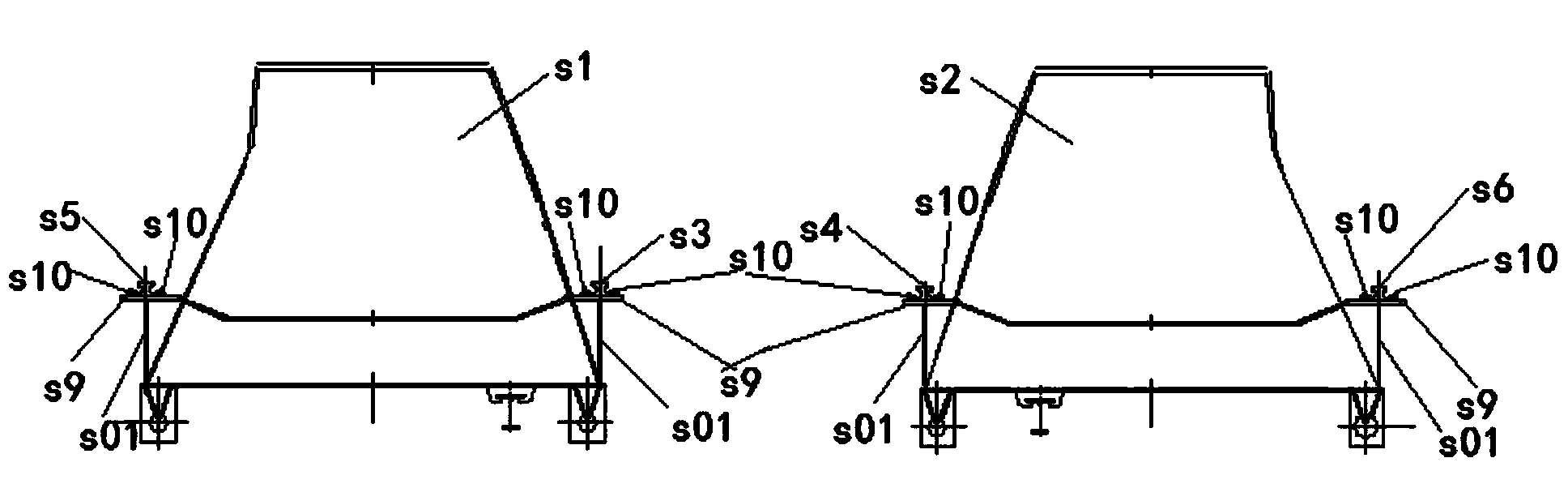

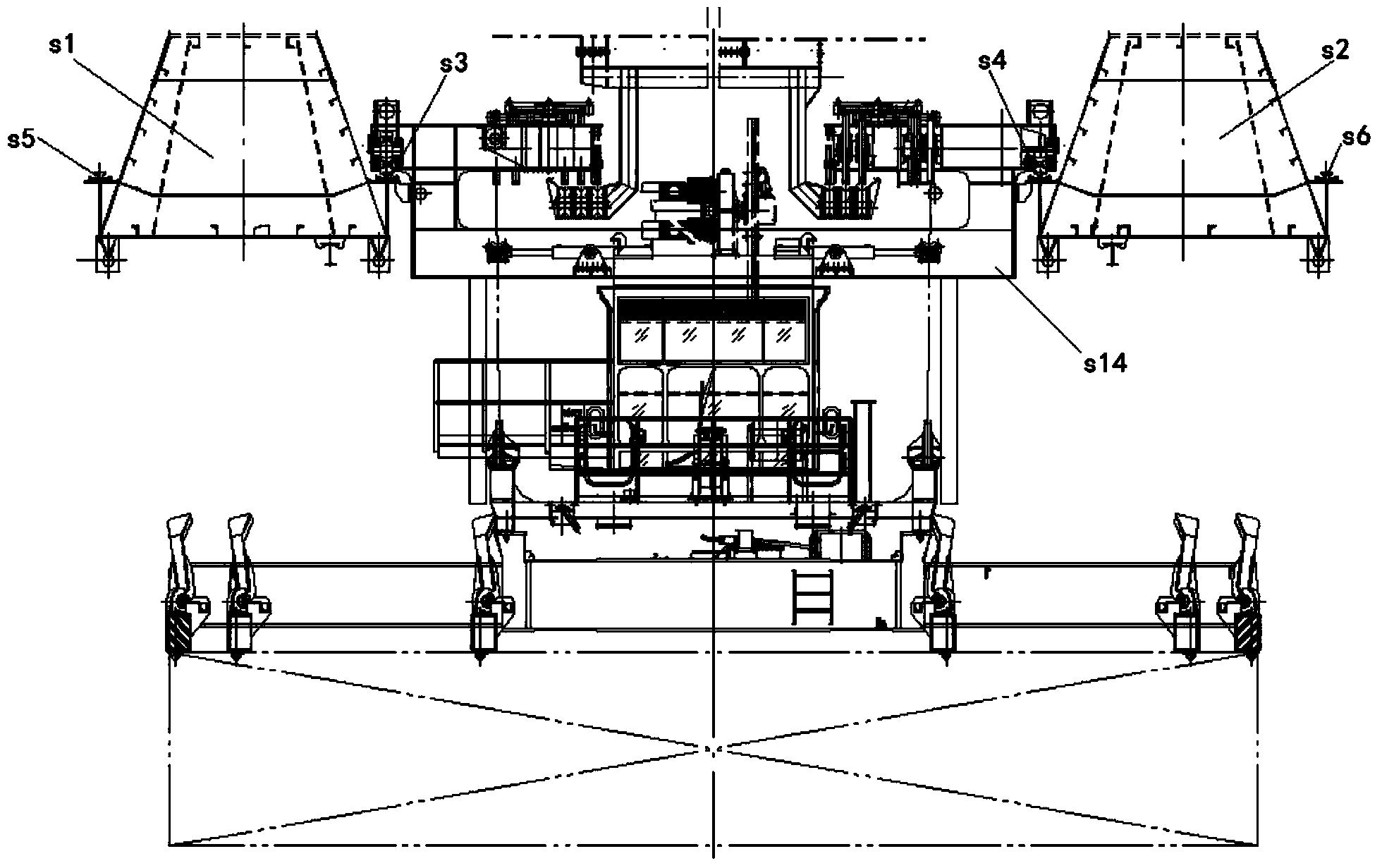

[0039] like Figure 1-Figure 4 As shown, a connection structure of cross-type double trolleys in this embodiment includes a first girder s1 and a second girder s2 arranged in parallel; A guide rail s3 and a second guide rail s4, the first guide rail s3 and the second guide rail s4 jointly form a first guide rail structure supporting the operation of the upper trolley s14; the outer side of the first girder s1 and the second girder s2 The third guide rail s5 and the fourth guide rail s6 are provided on the outside of the outer side, and the third guide rail s5 and the fourth guide rail s6 jointly form the second guide rail structure supporting the operation of the lower trolley; it also includes an anti-tilt mechanism, which supports the lower trolley The first traveling mechanism s12 and the second traveling mechanism s18 of the trolley ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com