Constant-pressure friction driving trolley of hanging type hoisting equipment and method

A technology of friction drive and lifting equipment, which is applied in the direction of load block, traveling mechanism, transportation and packaging, etc., and can solve the problems of large motor heat generation, failure to satisfy customers, long running distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

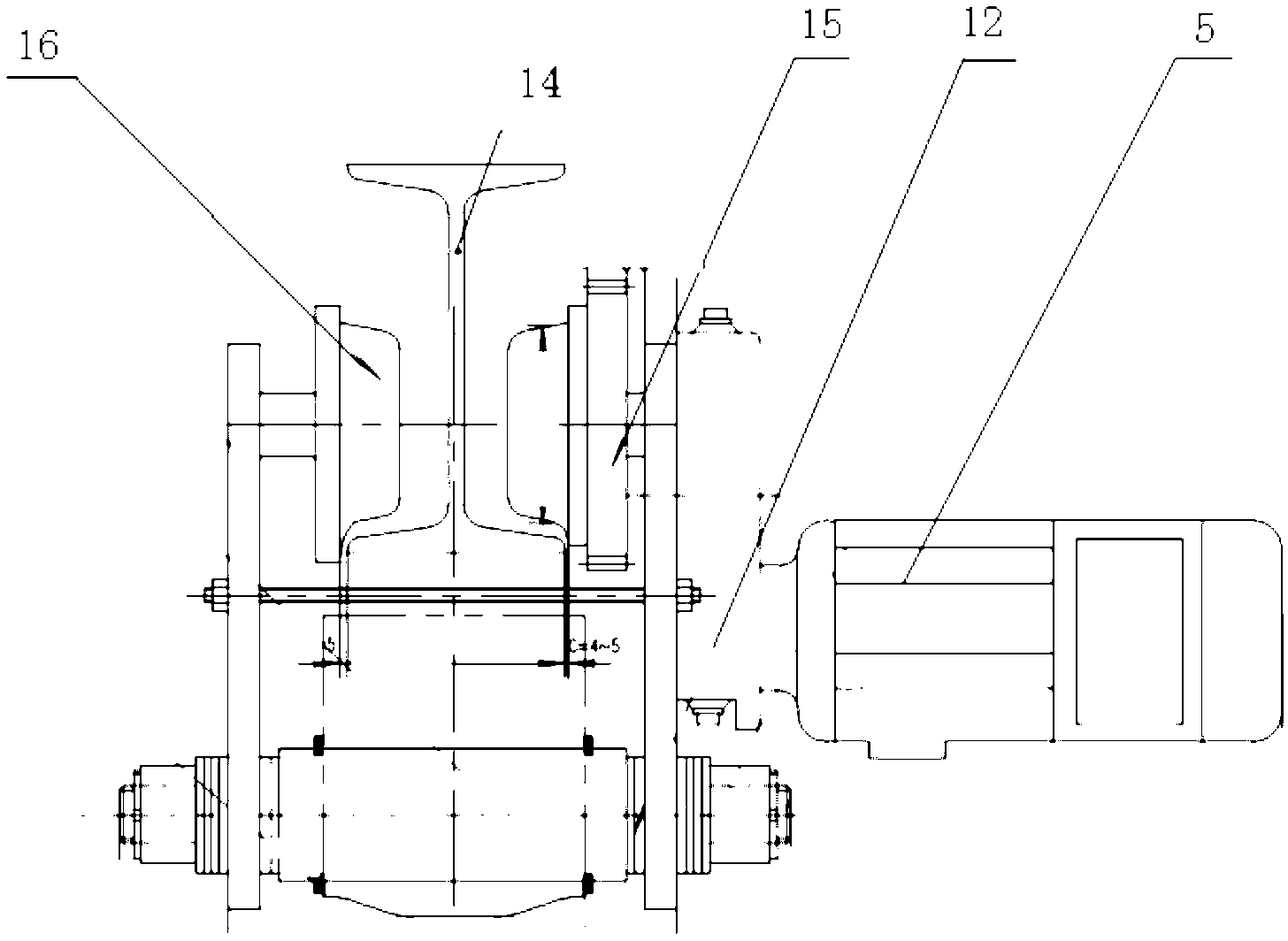

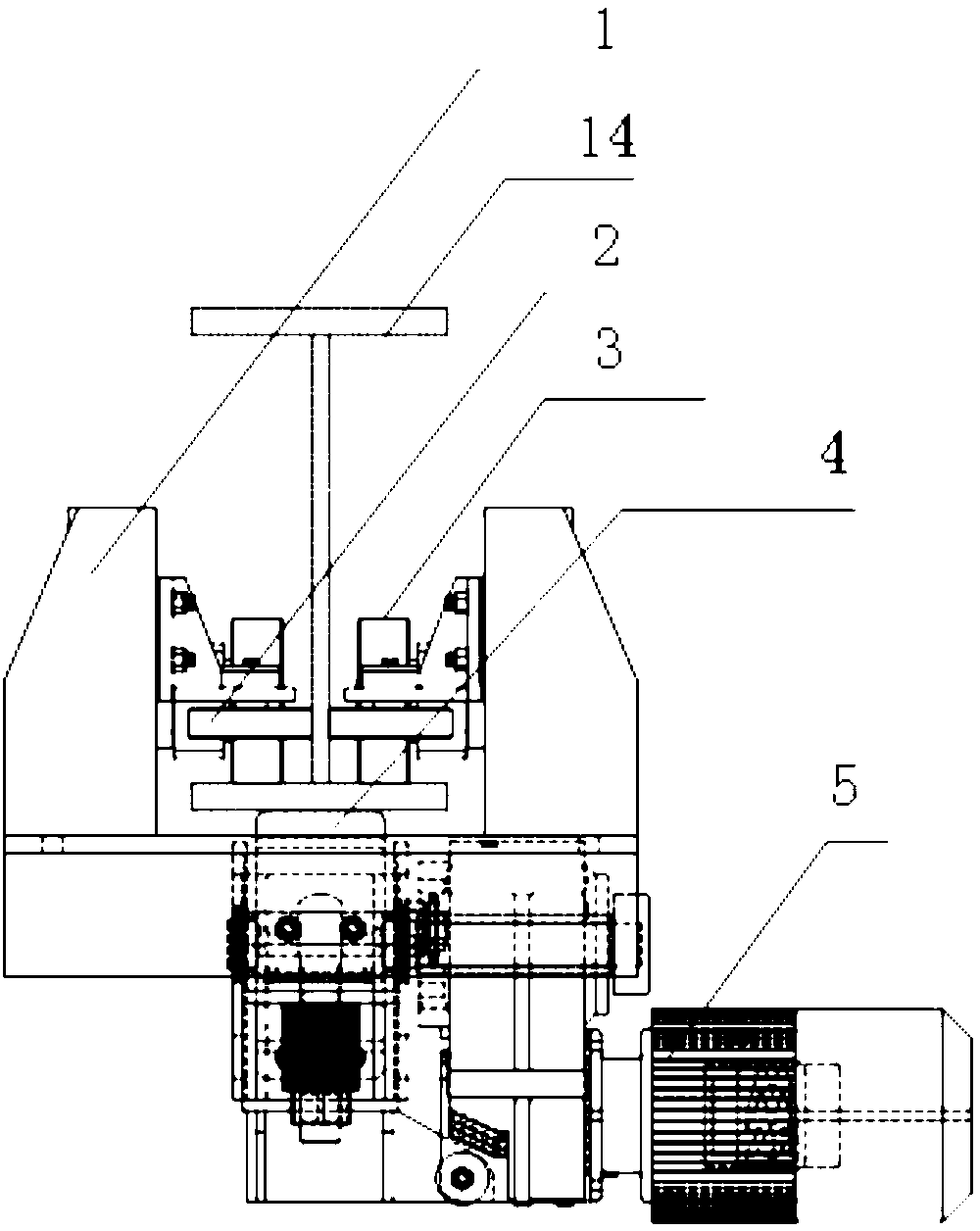

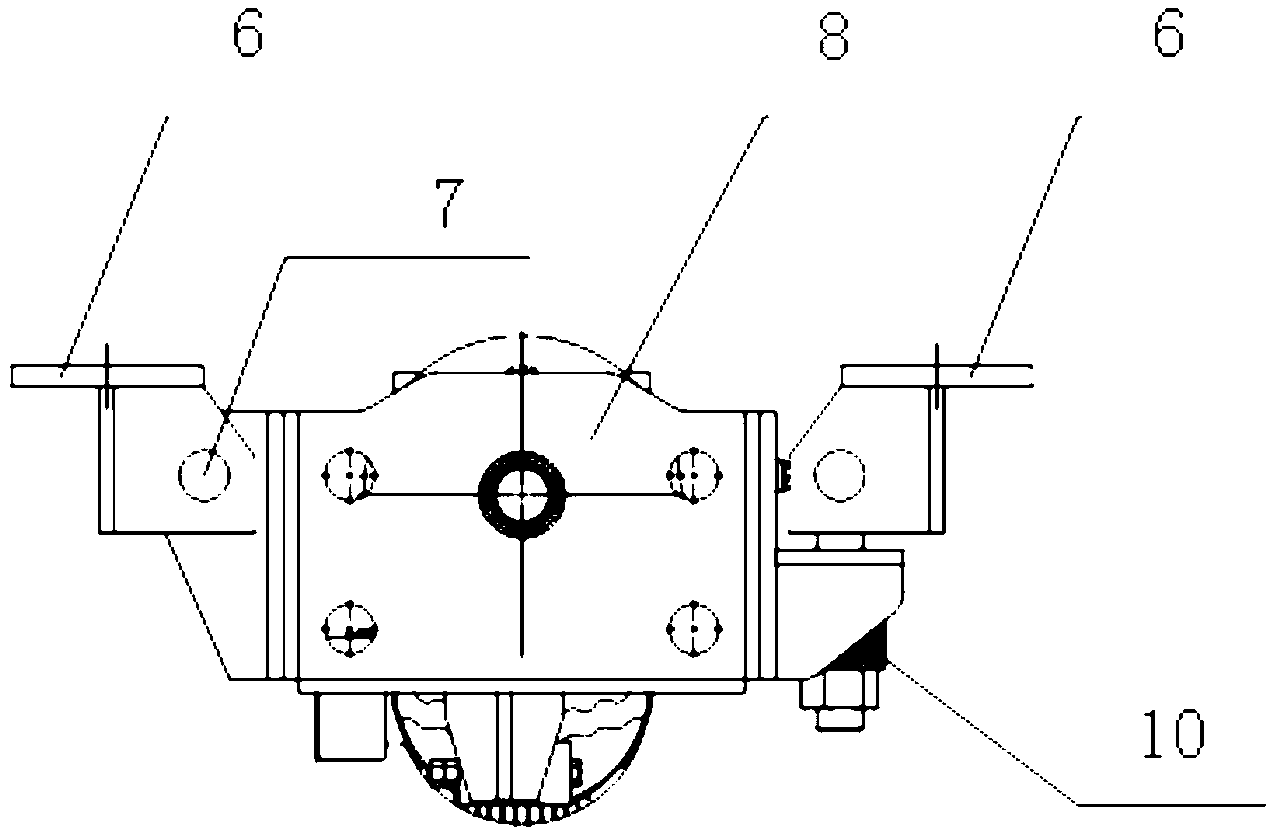

[0025] Such as figure 2 , 3 , shown in 4, a kind of constant-pressure friction-driven running trolley of suspended lifting equipment, comprising: suspended trolley load-bearing device and suspended trolley driving device, the suspended trolley load-bearing device and suspension on the described suspension running track 14 The driving device of the trolley is fixedly connected; the load-bearing device of the suspended trolley is composed of end beams stuck on both sides of the running track 14 and guide wheel devices and load-bearing wheel devices arranged on the end beams. The guide wheels 2 of the wheel device are opposite and contact with the center beam of the running track 14; the load-bearing wheels 3 of the load-bearing wheel device of the end beams on both sides are parallel and contact with the upper end faces of the lower beams on both sides of the center beam of the running track 14; the suspension The two ends of the driving mechanism housing 8 are provided with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com