A kind of running mechanism of double-track trolley group of super-large gantry crane

A technology of super-large doors and running mechanisms, which is applied in the direction of walking mechanism, track system, transportation and packaging, etc., which can solve the problems of high manufacturing cost, weakened horizontal rigidity, and increased working blind area, so as to facilitate maintenance and reduce construction costs , Reduce the effect of working blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

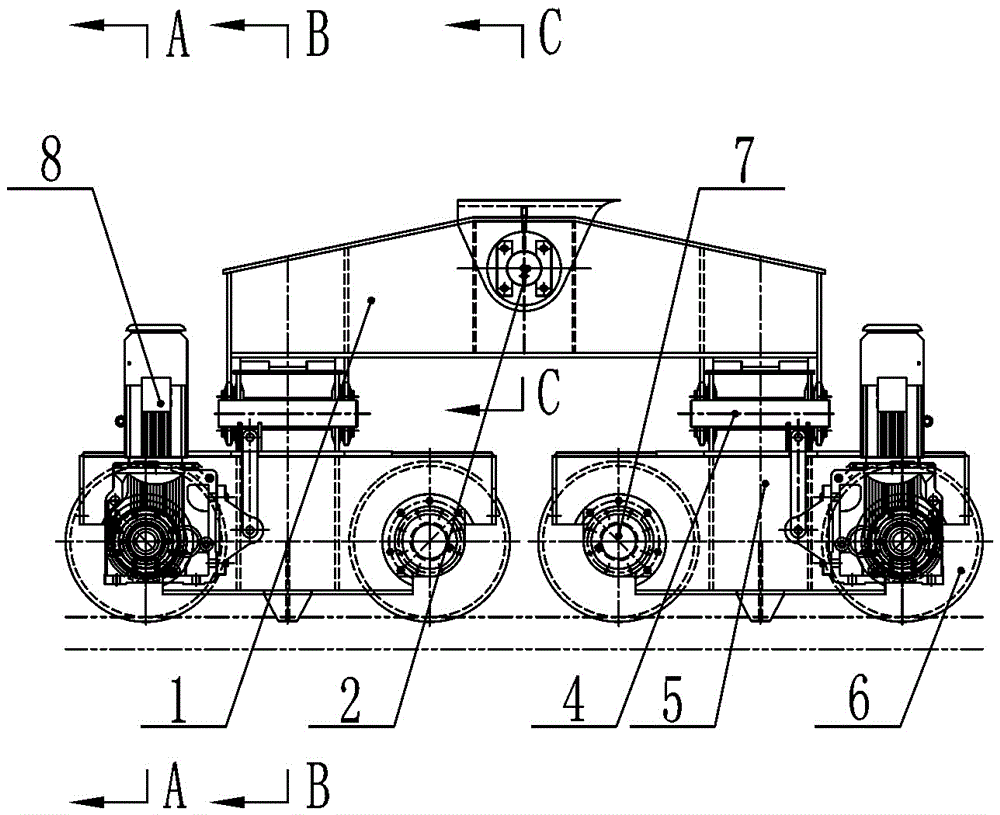

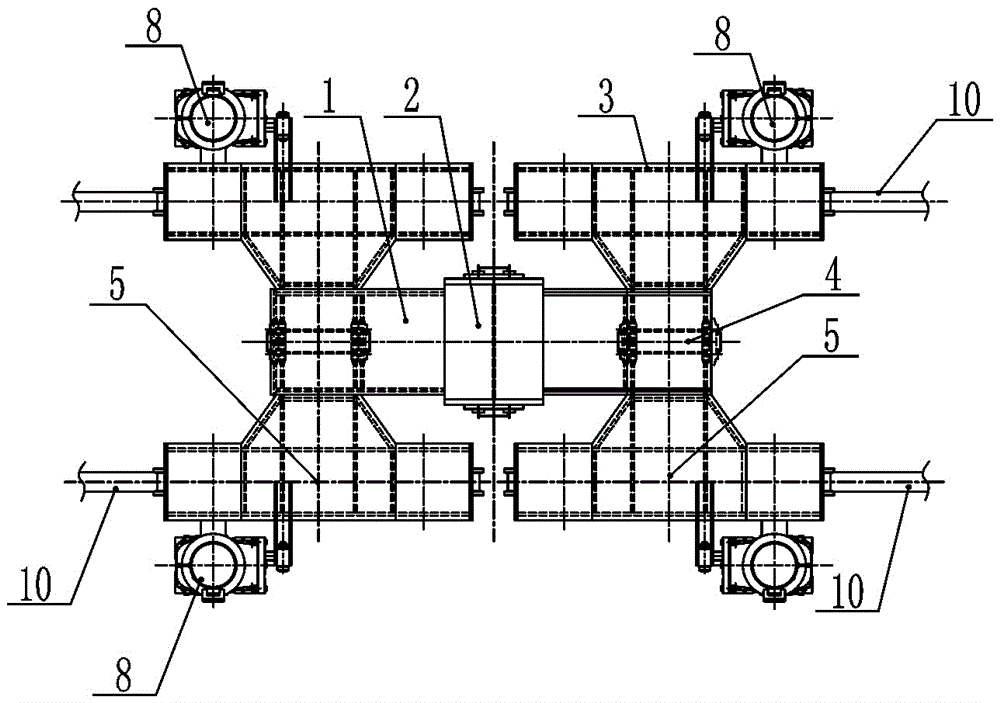

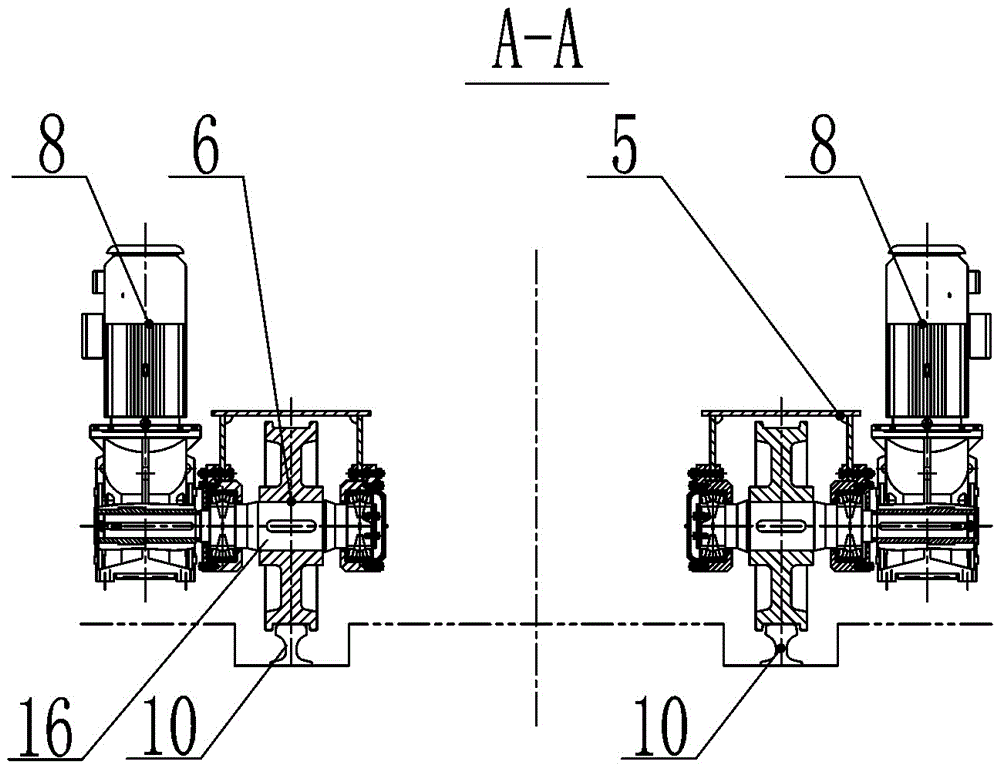

[0019] See attached figure 1 ~attached figure 2 The present invention is composed of a balance beam 1 and a double-track trolley 3. The double-track trolley 3 is a four-wheel dual-drive mechanism composed of running wheels 6 and driven wheels 7 symmetrically arranged on both sides of the frame 5. The double-track trolley 3 is fixed on both ends of the balance beam 1 by hinge shafts 4 , and the double-track trolley 3 and the balance beam 1 are hingedly connected. The frame 5 is an "I"-shaped box structure. The driven wheel 7 is fixed on the frame 5 by the axle. The traveling wheel 6 is a driving wheel provided with a driving mechanism 8 , and the driving mechanism 8 enables the traveling wheel 6 to push the driven wheel 7 to drive the trolley group consisting of two double-track trolleys 3 to run on the track 10 . The drive mechanism 8 is a three-in-one device of an electric motor, a reducer and a brake. The driven wheel 7 may be provided with a drive mechanism 8 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com