Wort boiling device based on circulation pump

A circulating pump and wort technology, applied in the field of beer brewing, can solve the problems of poor boiling effect, uneven heating, increased cost, etc., and achieve the effects of good heating effect, reduced work, and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

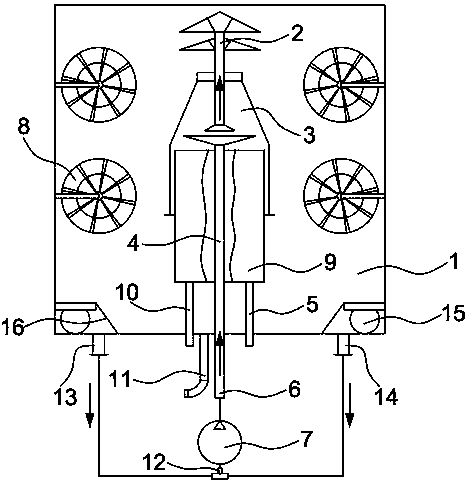

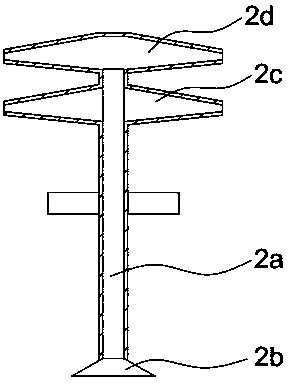

[0023] Such as figure 1 As shown, the wort boiling device based on a circulating pump includes a housing 1 and a heat exchanger 9, the heat exchanger 9 is arranged in the center of the housing 1, the inner wall of the housing 1 is connected to a waterwheel 8, and the upper end of the heat exchanger 9 is The return cylinder 3 is connected, the upper end of the return cylinder 3 is connected with the uniform distributor 2, the lower end of the housing 1 is connected with the wort inlet 6, the upper end of the wort inlet 6 is connected with the heating pipe 4, and the heating pipe 4 passes through the heat exchanger 9 and is connected with a jet One side of the wort inlet 6 is provided with a wort outlet pipe 11 connected to the bottom of the housing 1, and the bottom of the housing 1 is connected to a circulation outlet I13 and a circulation outlet II14. Heat exchanger 9 is used for providing heat energy for wort boiling, and its work is stable, and energy exchange efficiency is...

Embodiment 2

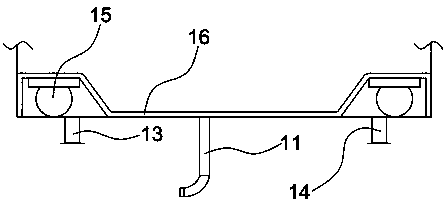

[0026] Such as Figure 1~5 As shown, this embodiment is further optimized on the basis of Embodiment 1: the circulation outlet I13 and the circulation outlet II14 are respectively connected to the two openings of the three-way pipe 12 through conduits, and the other opening of the three-way pipe 12 is connected to the water pump 7 , the water pump 7 is connected to the wort inlet 6. The three-way pipe 12 connects the circulation outlet with the wort inlet to realize the circulation heating of the wort and improve the wort boiling effect.

[0027]Two openings of the three-way pipe 12 connected to the circulation outlet I13 and the circulation outlet II14 are provided with a plurality of sub-ports 12a. The multiple split ports 12a provided make the wort entering the three-way pipe 12 divided into multiple water columns, and different water columns with smaller volumes are mixed in the three-way pipe 12, which reduces the impact force of the water column mixing and reduces the w...

Embodiment 3

[0035] Such as Figure 1~5 As shown, the working principle of the wort boiling device based on the circulation pump is as follows: add the wort to be boiled from the initial wort inlet to the inside of the housing 1, turn on the power, and the electric roller 15 rolls to the upper end of the wort outlet pipe 11, Make the circulation outlet I13 and the circulation outlet II14 in the "conduction" state, the heat exchanger 9 and the water pump 7 start to work, the wort flows out from the circulation outlet I13 and the circulation outlet II14, and flows into the tee pipe 12, and the water pump 7 transfers the wort from the wheat The juice inlet 6 is pumped into the heating pipe 4, and the heat exchanger 9 heats the wort inside the heating pipe 4. After the wort with a certain temperature flows out of the heating pipe 4, it is injected into the uniform distributor 2 through the ejector, and part of the wort enters the reflux cylinder 3, the wort entering the uniform distributor 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com