Rail gnawing preventing device for hanging beam crown block, hanging beam crown block and traveling method thereof

A technology of crane beam cranes and rail-gnawing crane cranes, which is applied in safety devices, traveling mechanisms, transportation and packaging, and can solve problems such as difficult maintenance, good safety guarantees, and poor stability, and achieve installation and operation Convenience, good security, strong self-adaptive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

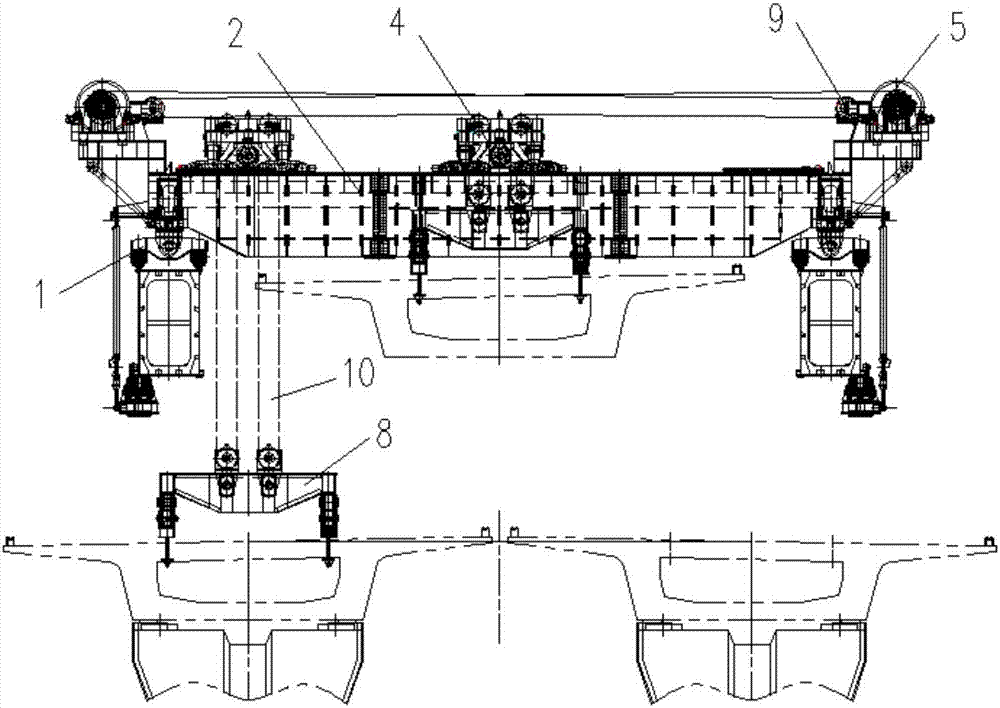

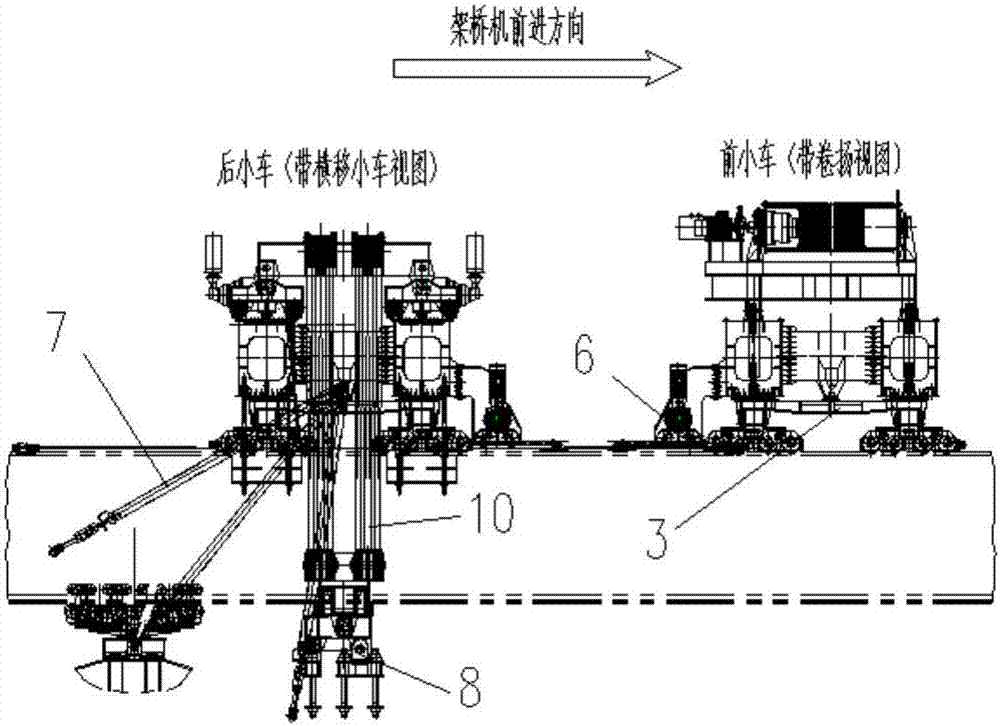

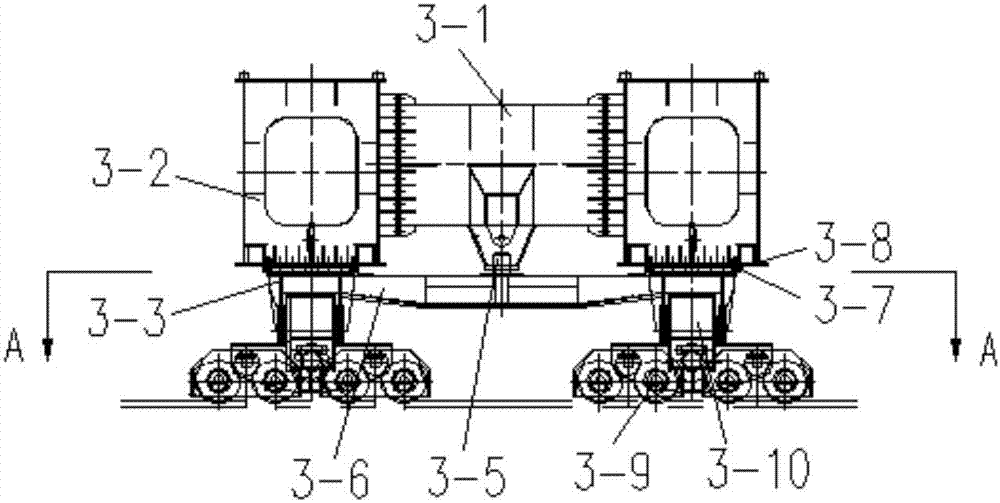

[0038] like Figure 1 to Figure 2 As shown, a single girder crane consists of two frame girders spanning the left and right bridge erecting machine arms and the left and right frame end beams to form a longitudinal moving frame 2 . The longitudinal movement driving mechanism 6 is flange-connected with the ends of the two main beams on the longitudinal movement frame 2. Steel rails are installed on the upper part of the main beam of the longitudinal movement frame 2 to provide support for the traverse trolley 4, and the lower part of the end beam is supported on the longitudinal movement. The trolley 1 can run longitudinally, and the hoist assembly 5 and the guide pulley block 9 on the traversing trolley 4 are provided on the outside of the end beam to provide vertical movement. The outer side of the beam works together with the longitudinal movement drive mechanism 6 to drive the arm of the bridge erecting machine to move longitudinally through the hole.

[0039] like Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com