Uncoiling and blanking die and multi-station machining device

An uncoiling blanking and mold technology, which is used in positioning devices, storage devices, feeding devices, etc., can solve the problems of high development and production cost, low production efficiency, and difficulty in picking up parts, achieve precise guidance, protect molds, and improve falling. The effect of material accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

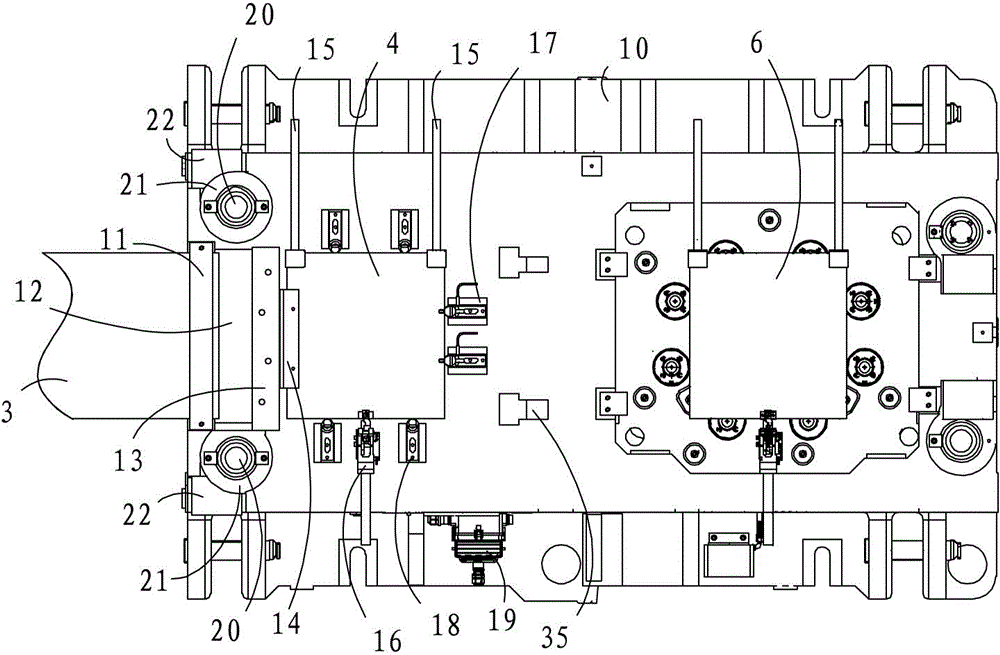

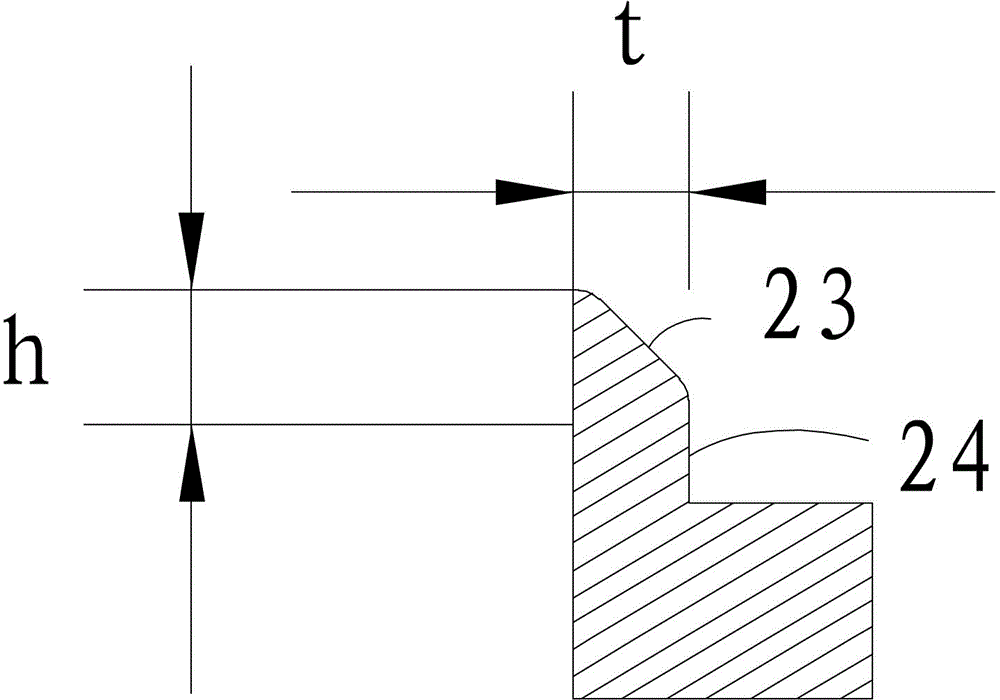

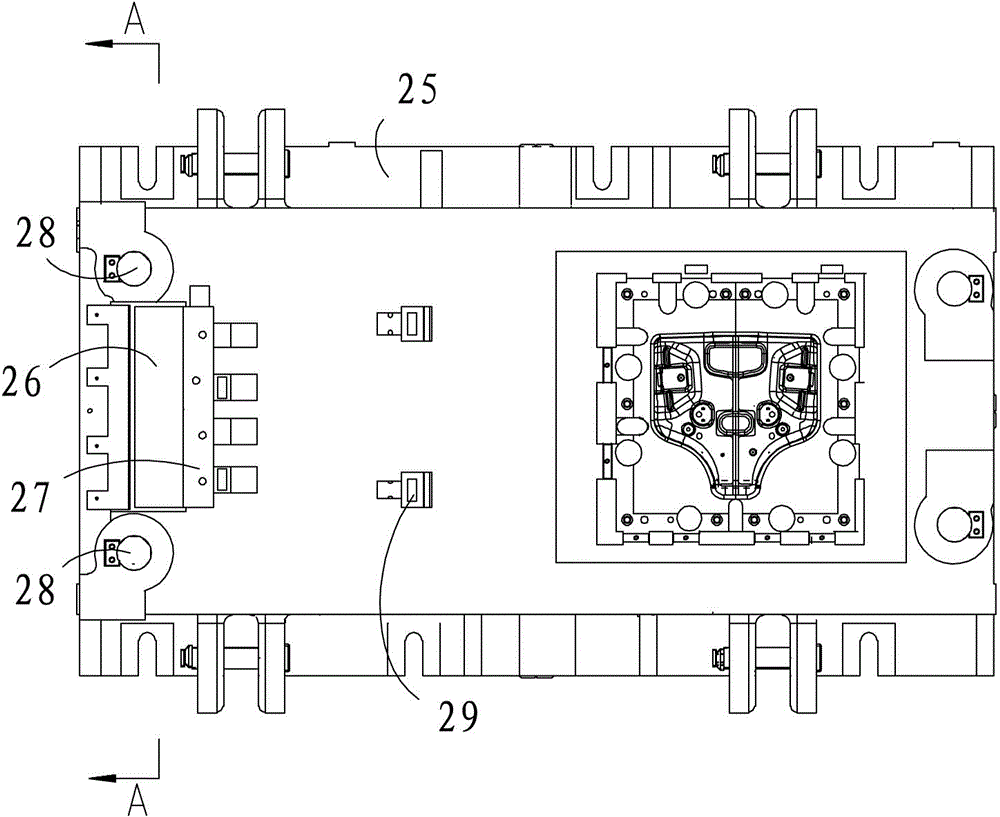

[0039] This embodiment relates to an uncoiling blanking die, which includes a lower mold base 10 and an upper mold base 25 located above the lower mold base 10 and cooperating with the lower mold base 10 for stamping. The structure of the lower mold base 10 is as figure 1 As shown in , an unshown decoiler is set on one side of the lower mold base 10 , and the sheet 3 output by the uncoiler enters the lower mold base 10 from one side of the lower mold base 10 . A supporting plate 4 is arranged on the lower mold base 10, and the supporting plate 4 is used for carrying the material sheet 3 after blanking. A lower mold trimming insert 13 is arranged on the side of the supporting plate 4 close to the direction of entry of the sheet 3, and a front supporting plate 12 is also arranged upstream of the lower mold trimming insert 13, and the front supporting plate 12 is a material. The sheet 3 provides support, so that the material sheet 3 smoothly enters the trimming insert 13 of the ...

Embodiment 2

[0049] This embodiment relates to a multi-station processing device, such as Figure 5 As shown in , it includes a frame 1, and one side of the frame 1 is provided with an uncoiler 2, and the uncoiler 2 transports the material sheet 3 to be processed on the frame 1, and on the frame 1, an end close to the uncoiler 2 The uncoiling blanking mold as described in Embodiment 1 is installed, and the second station 6, the third station 7, the fourth station 8 and the second station are successively arranged on one side of the uncoiling blanking mold on the frame 1. Five-station 9 and other stamping processing stations. Each processing station can be arranged on the lower mold base 10 as described in the first embodiment, or be arranged on the frame 1 adjacent to the lower mold base 10 . On the frame 1, beams 5 are installed on both sides of the uncoiling blanking mold and each processing station, and on the beams 5 on both sides, corresponding to the uncoiling blanking mold and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com