Polishing method of aluminum trim workpiece and its shelving table

A technology for decorative strips and workpieces, which is applied to the polishing method of aluminum decorative strip workpieces and the field of shelving platen, which can solve the problems of not mentioning the polishing efficiency and effect of the outer surface of the end cover (2), the poor consistency of the polishing effect, and the low operating efficiency, etc. problems, to achieve high-quality and efficient polishing operations, good polishing effects, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

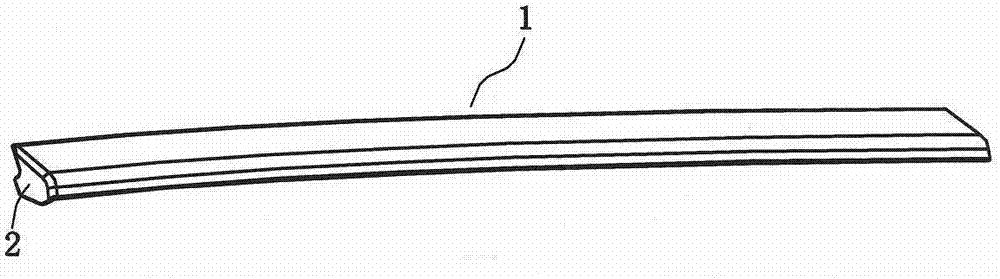

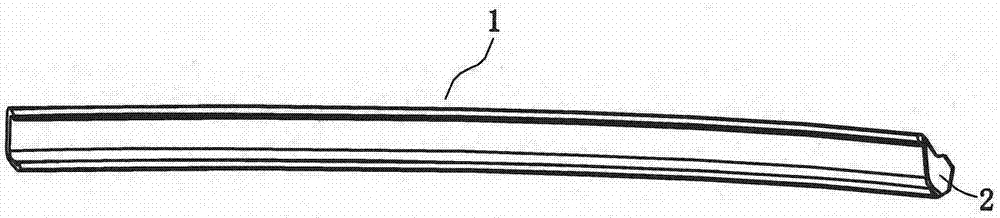

[0034] Below to figure 1 , figure 2 Shown is an aluminum trim workpiece 1 for a car, using the shelving platform of the present invention as an example to describe the specific implementation of the present invention in detail.

[0035] Such as figure 1 , figure 2 As shown, it is an aluminum trim workpiece 1 of a car, figure 1 To show a perspective view of its front, figure 2 In order to show the three-dimensional schematic diagram of the back side, the front side is a surface to be polished, and the end cap 2 is provided at one end, and the end cap 2 is provided at both ends, and the outer surface of the end cap 2 also needs to be polished.

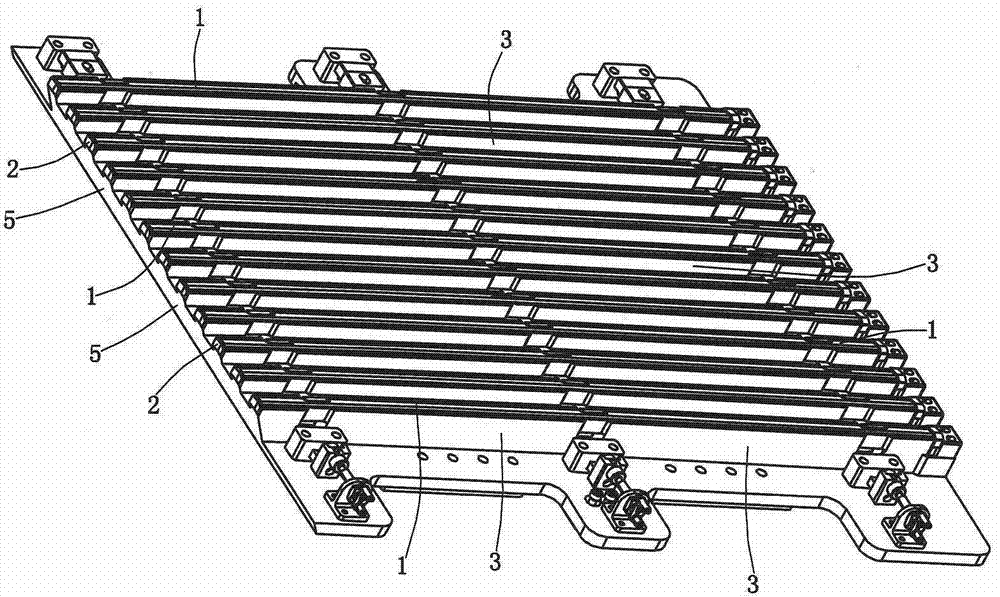

[0036] Such as image 3 , Figure 4 As shown, a plurality of convex strips 3 whose surface shape and size match the shape and size of the back of the aluminum trim workpiece 1 are arranged on the resting platen. The clamping mechanism of the decorative strip workpiece 1, the side end of each convex strip 3 has an end cover fitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com