Guide roller, steel belt guide mechanism and material receiving system

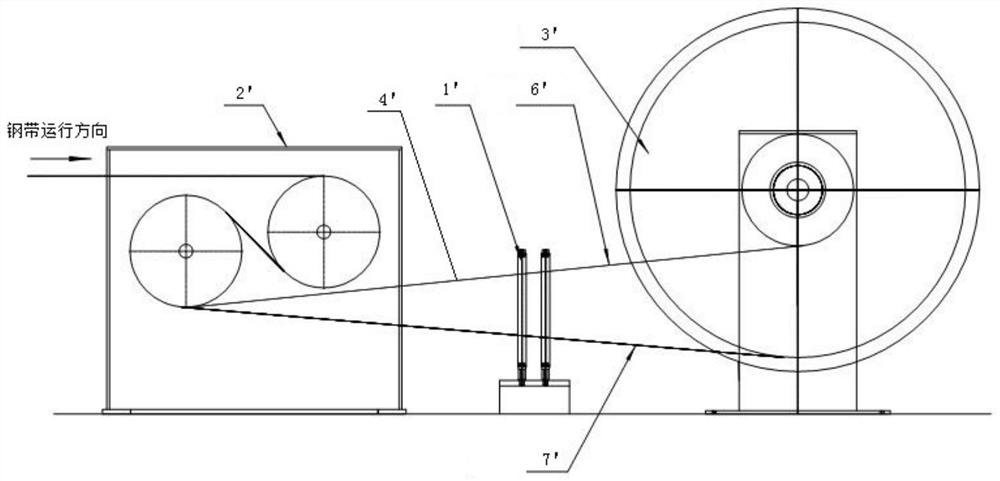

A technology of guiding rollers and guiding mechanisms, applied in thin material handling, coiling strips, transportation and packaging, etc., can solve the problems of uneven collection of steel belts, easy collapse of narrow belts, etc. Untidy, solve the effect of uneven trimming and receiving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

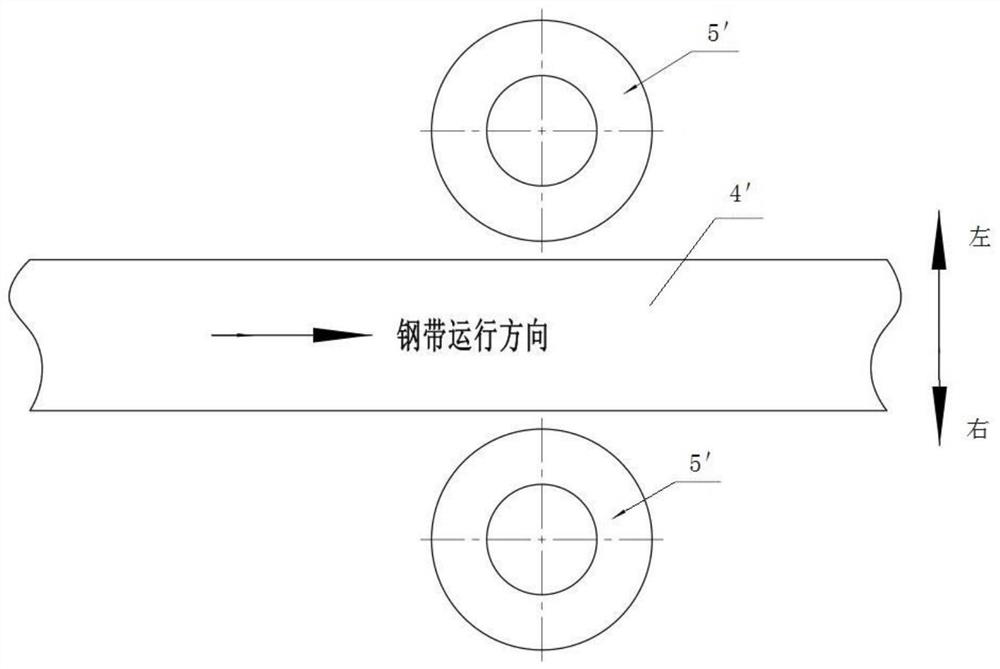

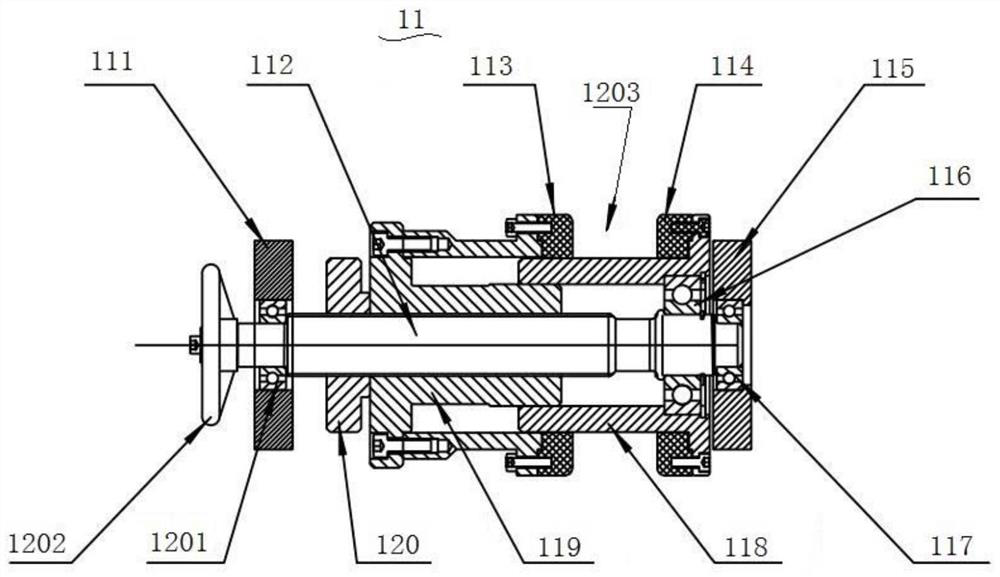

[0042] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

[0043] Such as image 3 As shown, a guide roller 11 provided in this embodiment includes a first bearing support 111, a screw 112, a first retaining ring 113, a second retaining ring 114, a second bearing support 115, a third bearing 116, a second Bearing 117, positioning sleeve 118, adjustable sleeve 119, lock nut 120, first bearing 1201 and hand wheel 1202.

[0044]Both ends of the screw 112 are respectively provided with a first bearing support 111 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com