Compressing and regulating device of coating machine

A technology of compression adjustment and coating machine, which is applied to the device and coating of surface coating liquid, which can solve the problems of reducing production efficiency, failing to meet production requirements well, and prone to bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

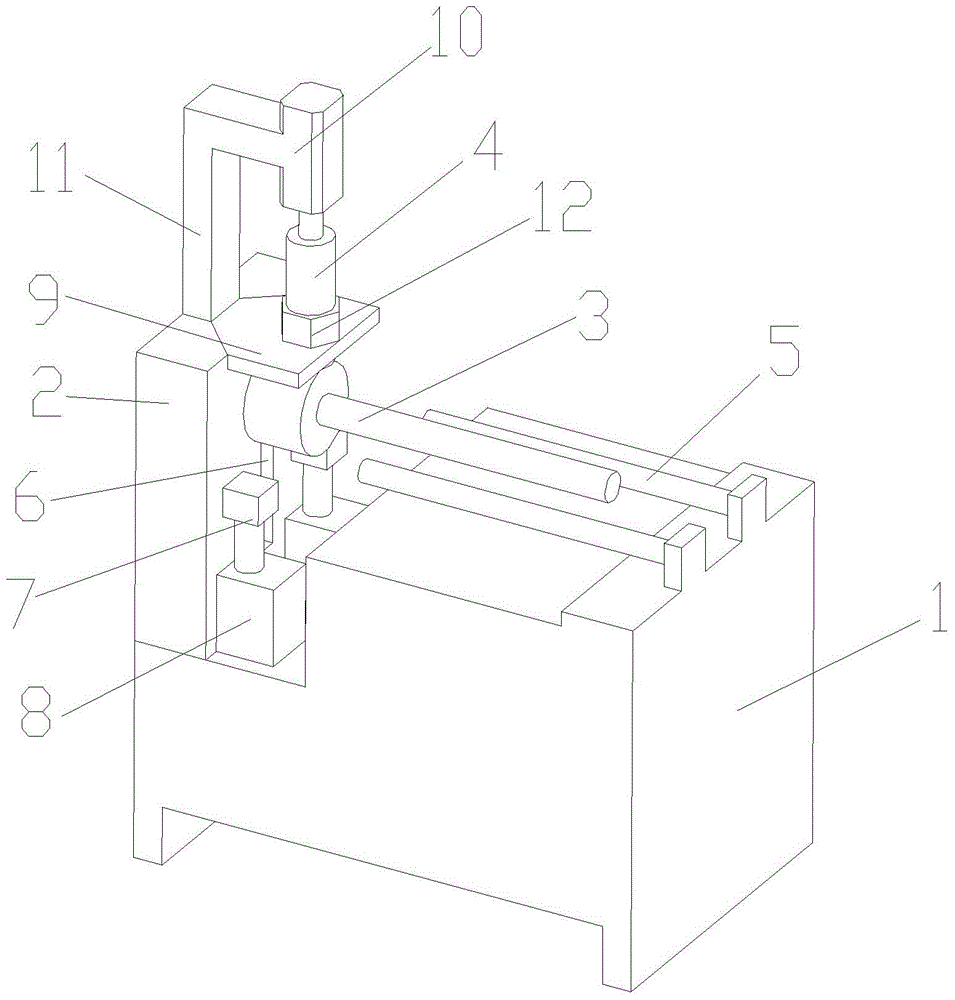

[0012] as attached figure 1 Shown is a coating machine compression adjustment device according to the present invention, including a workbench 1, a deck 2, a pressure roller 3 and an adjustment rod 4; the deck 2 is fixedly installed on one side of the workbench 1; the Two winding rolls 5 are installed on the workbench 1; the deck 2 is provided with a chute 6 for installing the pressure roller 3; the two sides of the chute 6 are provided with fixed inserting rods 7; the fixed inserting rods 7 is installed in the fixed block 8 on the workbench 1; the pressure roller 3 can move up and down in the chute 6; the upper part of the deck 2 is provided with a mounting plate 9; the mounting plate 9 is provided with an adjusting rod 4; The adjusting rod 4 vertically passes through the mounting plate 9 and the upper part is provided with a cylinder 10; the cylinder 10 is fixed on the deck 2 by a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com