Pressing adjusting mechanism for coating machine

A technology of compression adjustment and coating machine, which is applied in the direction of devices and coatings for coating liquid on the surface, which can solve the problems of reducing production efficiency, easily appearing air bubbles, and failing to meet production requirements well, and achieves elimination of air bubbles. Problems, good production, the effect of pressing and fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

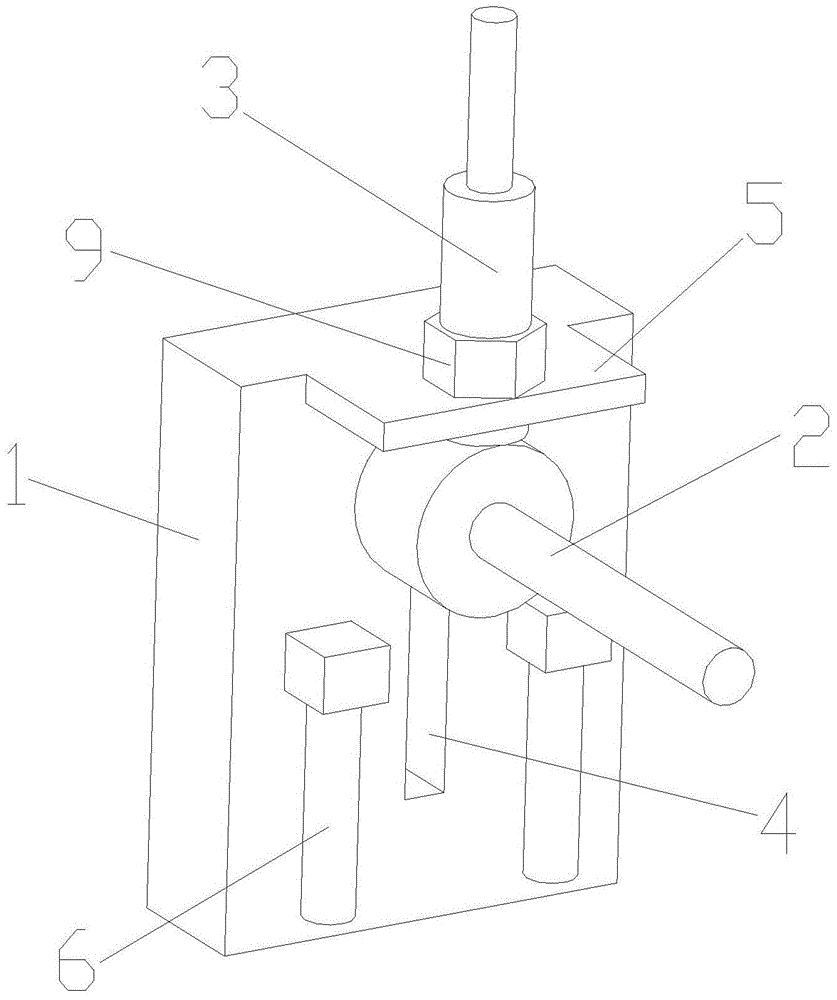

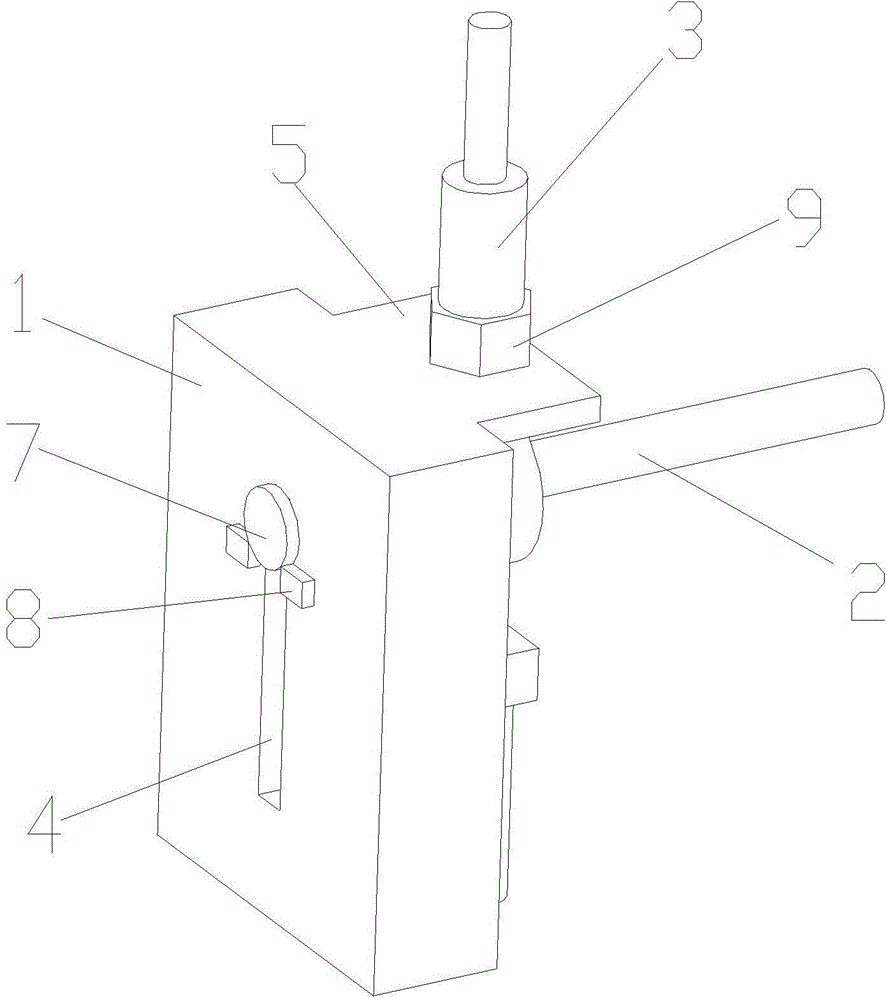

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] attached figure 1 , 2 It is a pressing adjustment mechanism for a coating machine according to the present invention, which includes a deck 1, a pressure roller 2 and an adjustment rod 3; the deck 1 is provided with a chute 4 for installing the pressure roller 2; the The pressure roller 2 can move up and down in the chute 4; the upper part of the deck 1 is provided with a mounting plate 5; the mounting plate 5 is provided with an adjusting rod 3; the both sides of the chute 4 are provided with fixed inserting rods 6; The tail of the pressure roller 2 is provided with a movable wheel 7; the movable wheel 7 is fixed by a block 8. The adjusting rod 3 is fixed by a nut 9 .

[0014] During use, a kind of coating machine of the present invention is installed on the pinch roller position of the coating machine with the compression adjustment mechanism, and the fixed inserting rod 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com