Vacuum glass sealing method

A technology of vacuum glass and glass powder, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc. It can solve problems such as high temperature and rising, and achieve the effects of eliminating air bubbles, increasing welding strength, and shortening heating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

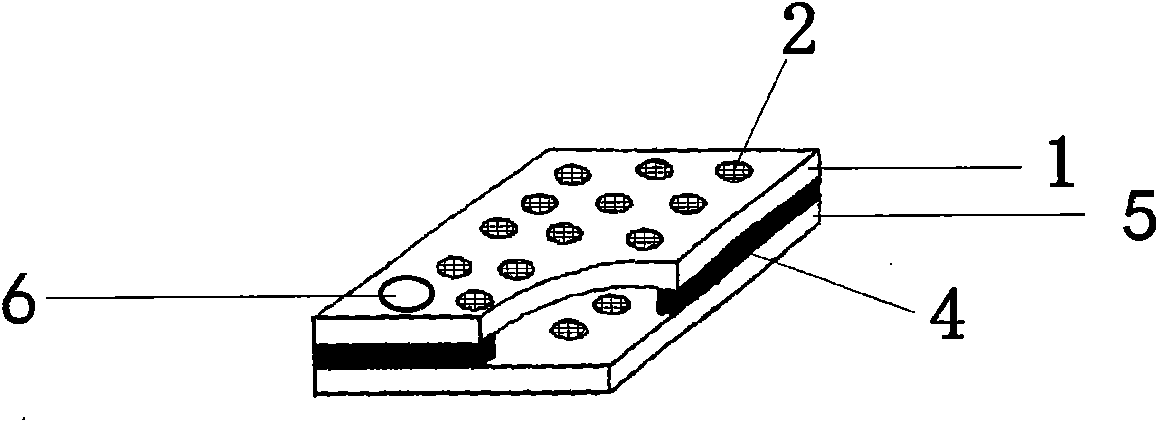

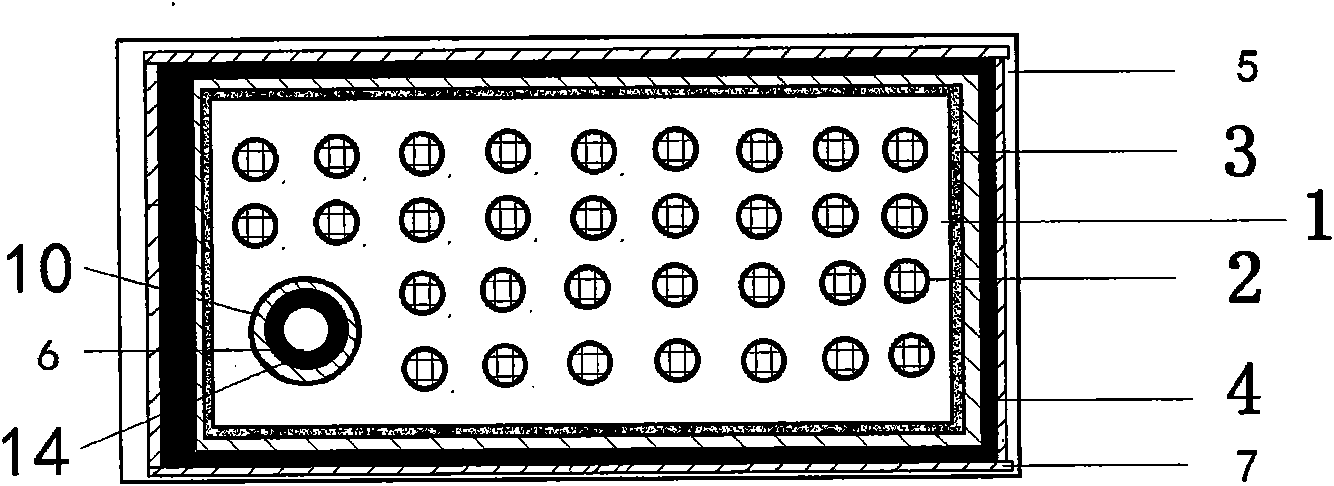

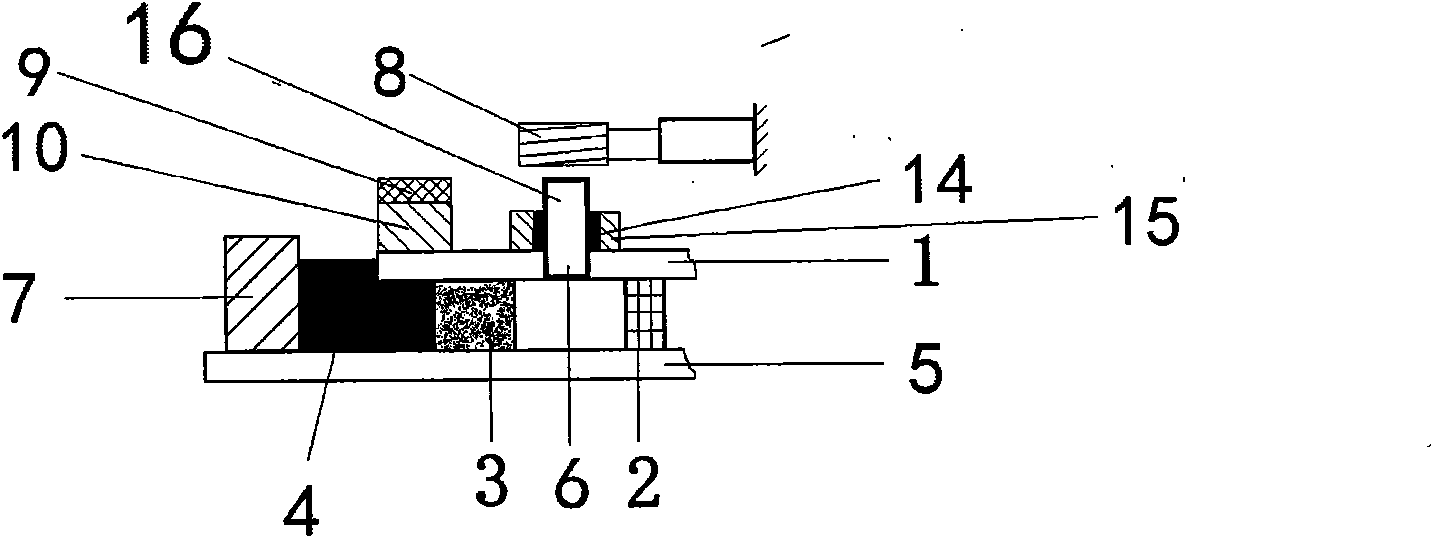

[0017] Embodiment 1: as figure 2 As shown, this is a vacuum glass original plate with air extraction holes, a support body 2 is placed in the middle, and welding glass powder 4 is placed around the periphery. The melting temperature of the welding glass powder is 410°C to 430°C. Arrest bar 7 is arranged on welding glass powder 4 outside, and the effect of arresting bar 7 is to prevent that welding glass powder molten liquid flows out lower floor glass plate 5. The effect of the spacer 10 is to prevent the fusing liquid of the welding glass frit from flowing arbitrarily at the upper glass plate 1 . First put the vacuum glass original plate into the vacuum heating furnace, and extract the air in the vacuum heating furnace to make the vacuum degree in the vacuum heating furnace reach 0.05 atmosphere. The purpose of extracting the air in the vacuum heating furnace is to eliminate the adverse effect of air convection on the heating process. Quickly raise the temperature in the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com