Pitching and azimuth calibration method for remote optical rotary table based on ground remote sensing image map

A remote sensing image and calibration method technology, which is applied to satellite radio beacon positioning systems, measuring devices, instruments, etc., can solve the problems of judging the actual location of the observation site, inconvenient use, and cumbersome operation by industry users, so as to improve operational efficiency and Ease of use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] A method for calibrating the pitch and azimuth of a remote optical turntable based on a ground remote sensing image map, comprising the following steps:

[0026] Step a, configure the high-definition satellite ground image map of the monitored area;

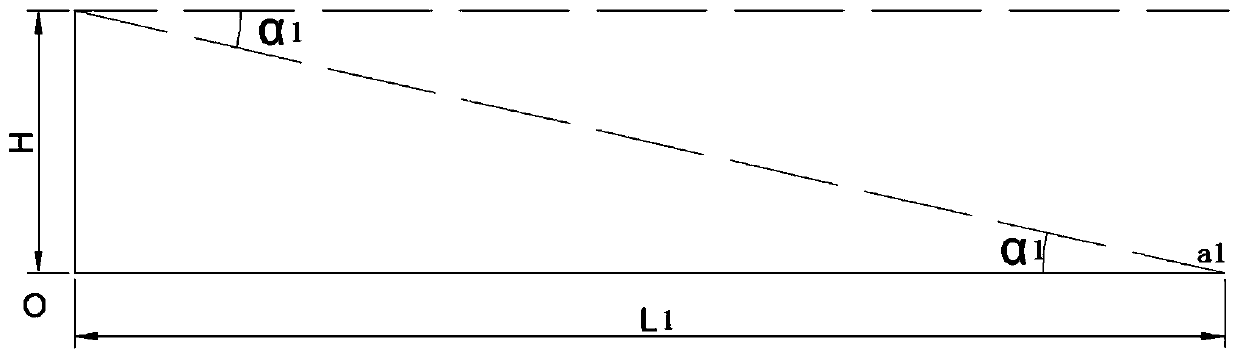

[0027] Step b, adding the installation position and installation height of the servo turntable optical monitoring equipment to the high-definition satellite ground image map;

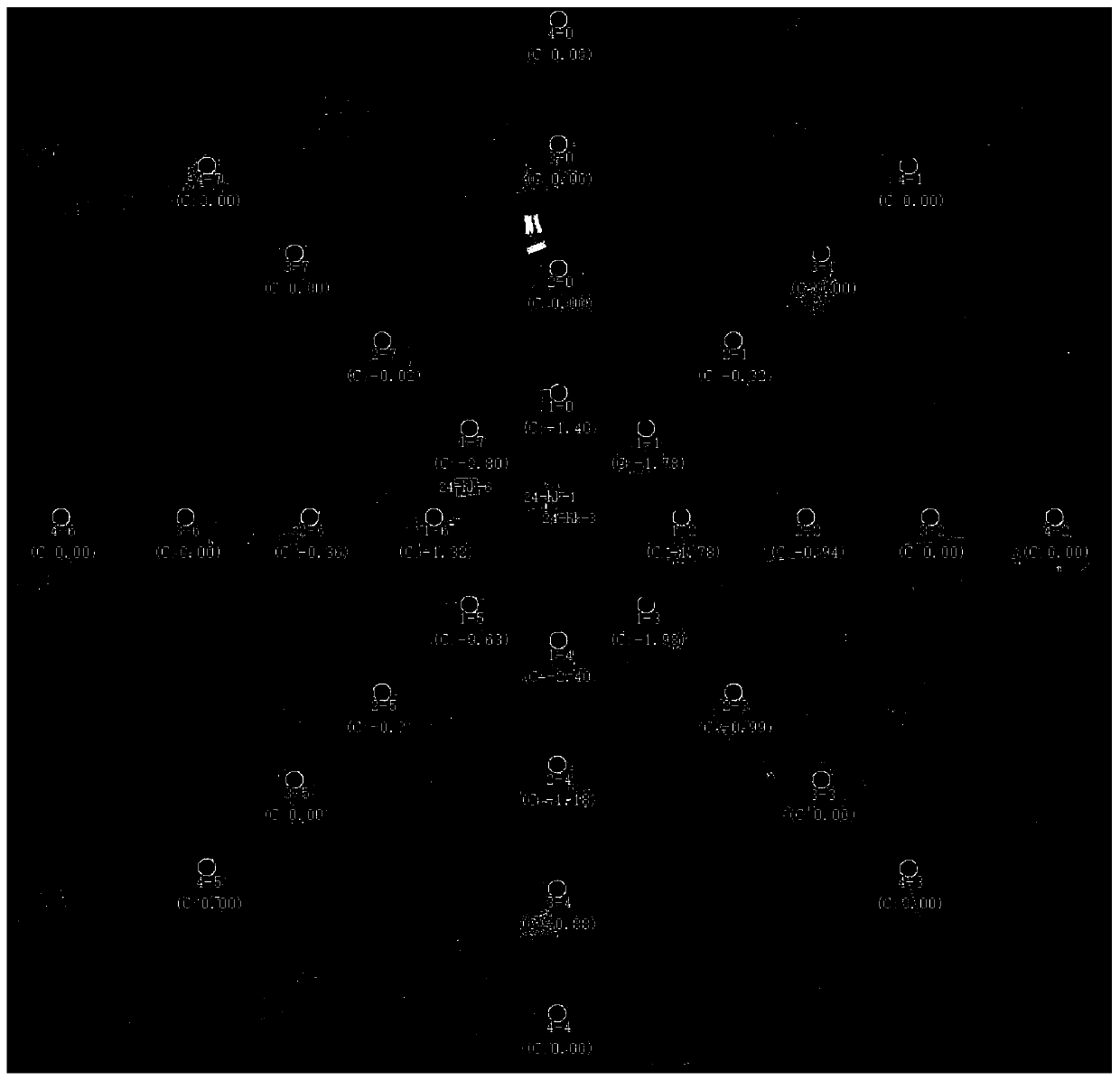

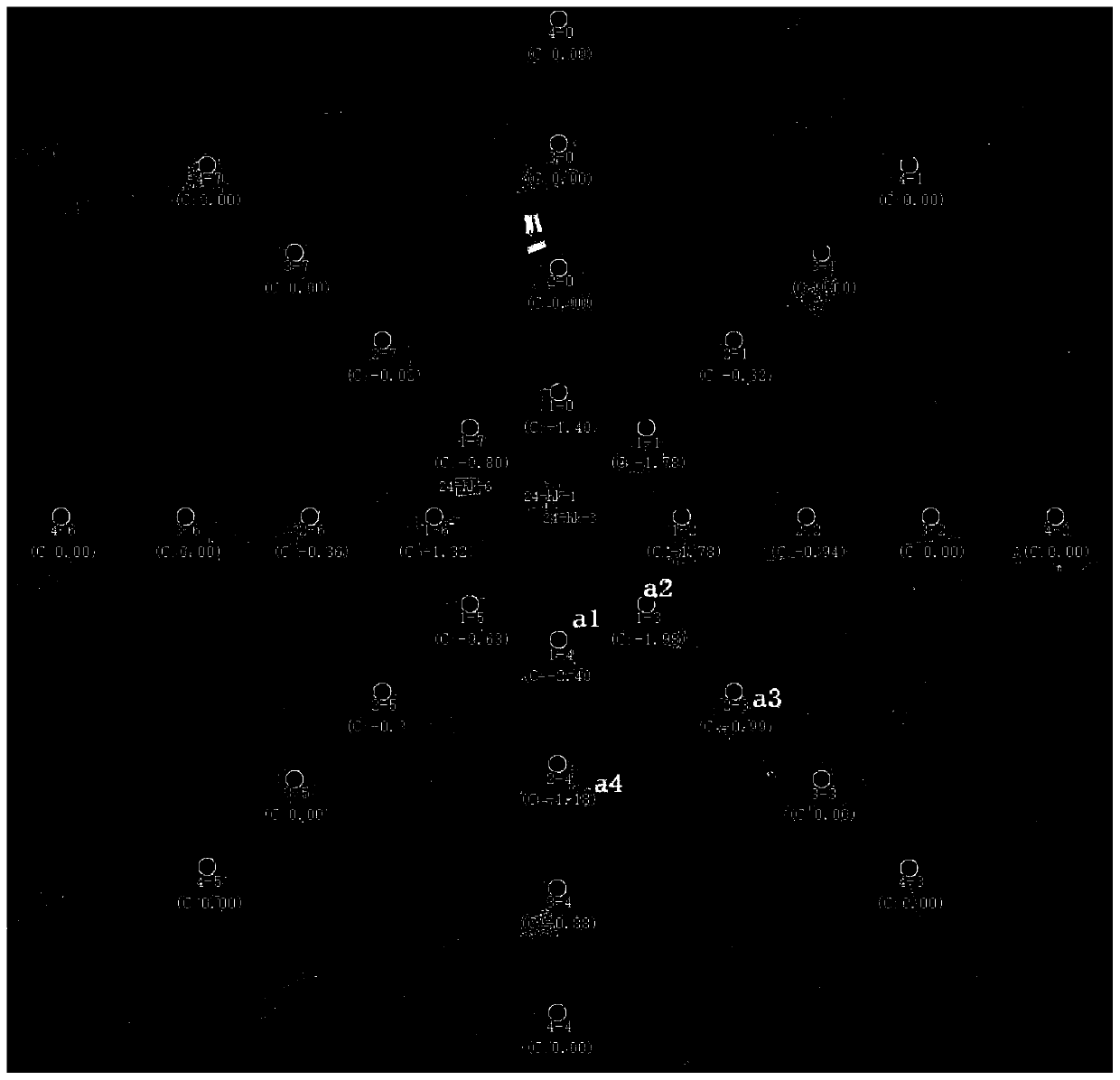

[0028] Step c, establishing a 360-degree azimuth-distance data matrix based on the installation position of the servo turntable optical monitoring equipment;

[0029] Step d, calibrate the pitch data of the servo turntable optical monitoring equipment for each unit of the azimuth distance data matrix, and complete the calibration;

[0030] Step e, click any position according to the map, calculate the azimuth, pitch and distance parameters of the guiding servo turntable optical monitoring equipment through the matrix difference of the position poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com