An Axial Flow Check Valve with Online Maintenance

A check valve, axial flow technology, applied in the valve's device for absorbing fluid energy, lift valve, control valve, etc., can solve the problems of valve leakage, lack of precise guidance, safety hazards, etc., to avoid bending loads, ensure Sealing requirements, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

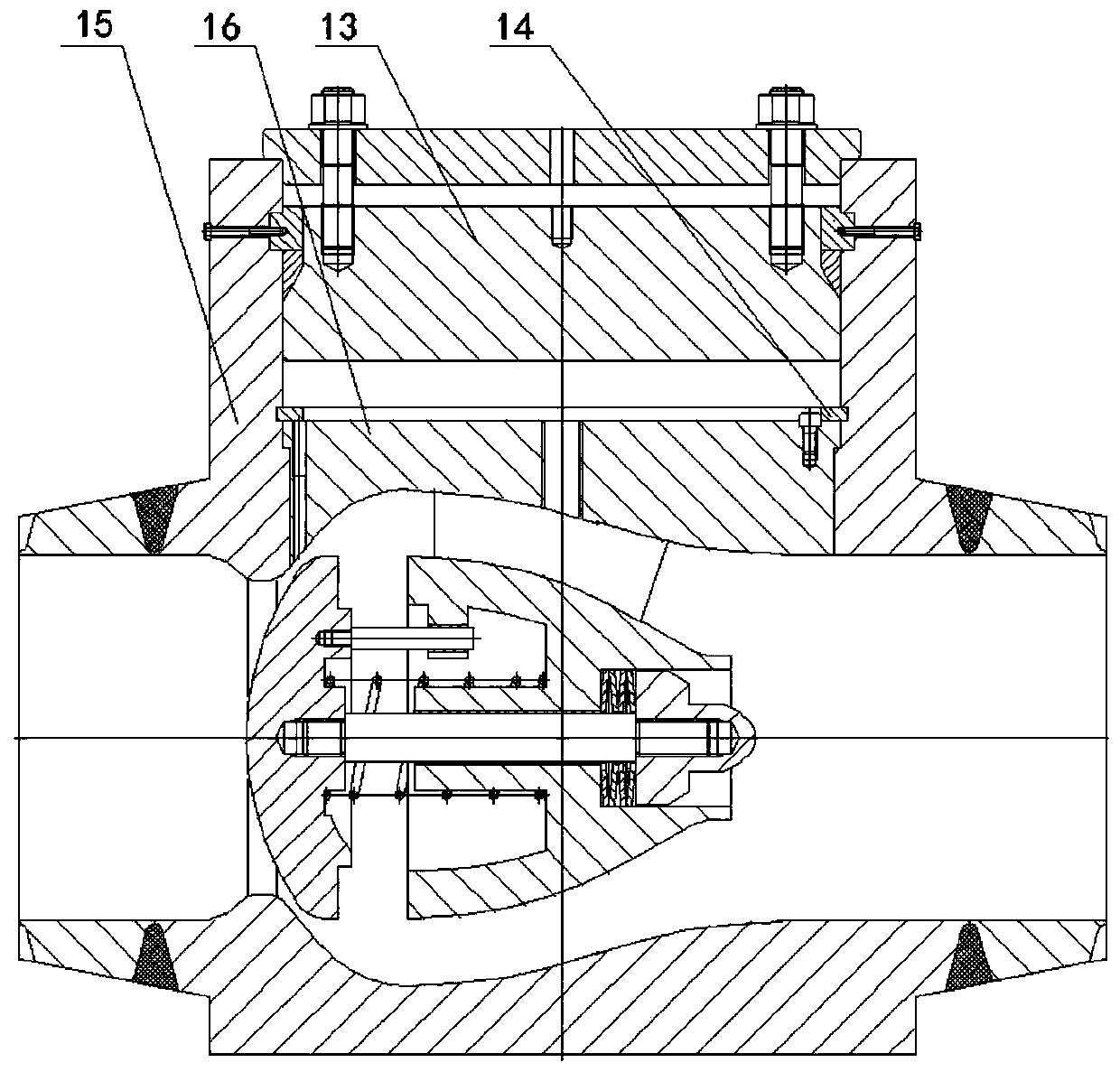

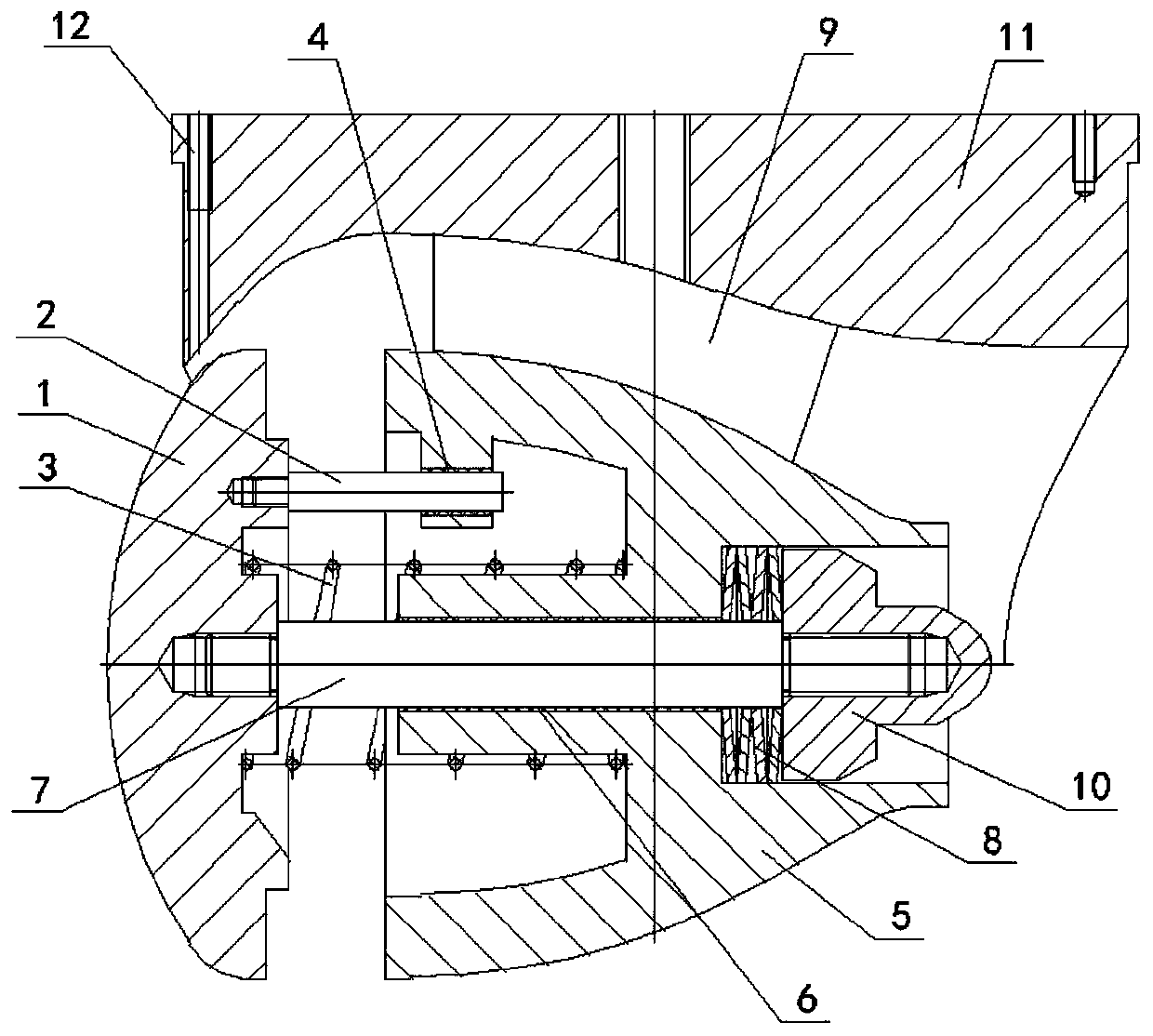

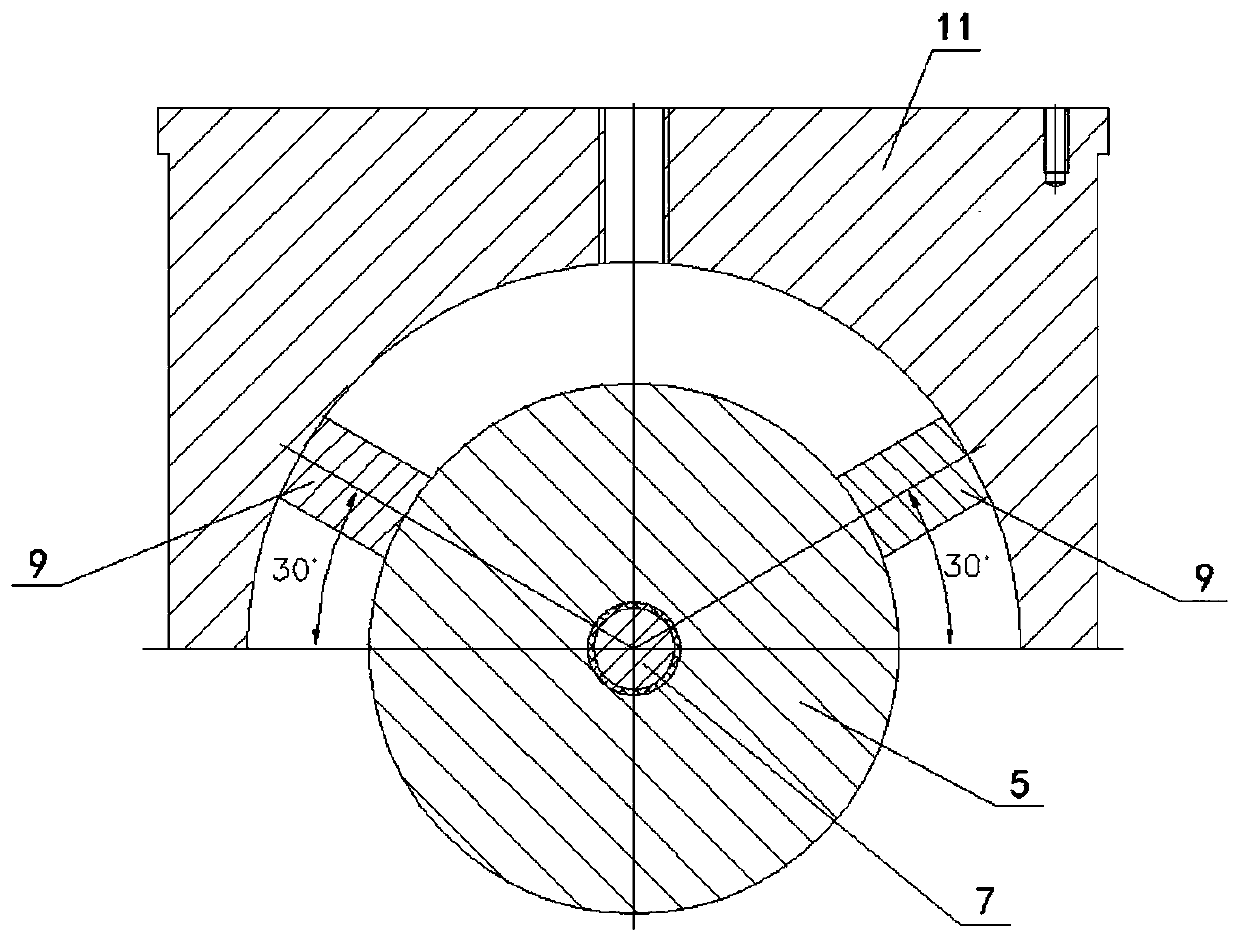

[0023] see figure 1 , figure 2 and image 3 , the structural form of the axial flow check valve that can be maintained online in this embodiment is: a top opening is set on the top of the valve body 15, and the valve core assembly 16 is placed in the valve body 15 at the position of the top opening, and in the valve body A bonnet 13 is set on the top opening of 15 so that the valve body 15 can be closed; the spool assembly 16 is to hang the spool 5 on the spool support 11 by using the support rib 9, and the spool support 11 is fixed by the spool fixing snap ring 14 At the top opening position of the valve body 15.

[0024] In specific implementation, the corresponding structural forms also include:

[0025] The valve core assembly 16 includes a valve disc 1 supported by a valve stem 7 and a coil spring 3 sleeved on the outer periphery of the valve stem 7 at the front end of the valve core 5, and a guide shaft 2 is arranged parallel to the valve stem 7, and the valve stem 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com