A kind of preparation method of nanocrystalline polycrystalline magnesium material

A nanocrystalline and magnesium technology, applied in the field of high-performance magnesium alloys or magnesium-based composite materials, can solve the problems of limited range of strength and toughness improvement, unstable material structure, and small size of the external phase, achieving simple equipment and easy industrialization. Promotion and popularization, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment one: The cryogenic and low heat cycle treatment of the "nano-matrix crystalline structure" of AZ91 deformed magnesium alloy:

[0029] The AZ91D magnesium alloy obtained by semi-continuous casting is made into a 10*10*20 block after homogenization treatment, extrusion deformation, and solution aging treatment.

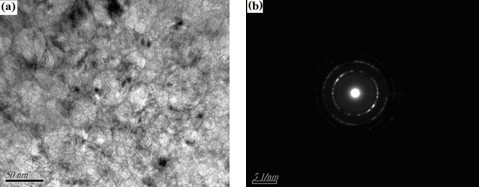

[0030] One cryogenic treatment: put the sample into the cryogenic treatment box, control the cooling rate at 80°C / s, until the liquid nitrogen temperature is -196°C, the cold treatment time is 30min, take it out and put it in graphite powder to prevent oxidation during low heat treatment, Put it into a heat treatment furnace, the low thermal aging temperature is 195°C, which is 5°C lower than the conventional aging temperature of 200°C, and the aging time is 4h. After the end, the tissue test is carried out, and the results are as follows figure 1 As shown, the grain size is 40-50nm.

Embodiment 2

[0031] Embodiment two: the cryogenic and low heat cycle treatment of the "nano-matrix crystalline structure" of AZ31 cast magnesium alloy:

[0032] The smelted AZ31 cast magnesium alloy is formed by gravity casting and prepared into a 20*20*40 block.

[0033] The first cryogenic and low-heat treatment: put the sample into the cryogenic treatment box, control the cooling rate at 60°C / s, until the liquid nitrogen temperature is -196°C, and the cold treatment time is 80 minutes. After taking it out, put it in the air for 80 minutes;

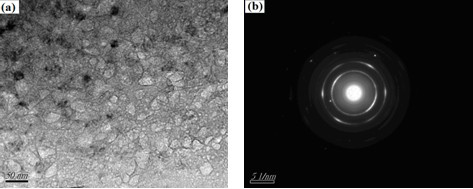

[0034] The first cryogenic low-heat cycle treatment: put it into the cryogenic treatment box again, and control the cooling rate at 60°C / s until the liquid nitrogen temperature is -196°C, and the cold treatment time is 80 minutes. After taking it out, put it in the air for 80 minutes. Tissue tests were performed with results such as figure 2 As shown, the grain size is 30-40nm.

Embodiment 3

[0035] Embodiment three: Mg 2 Cryogenic and low heat cycle treatment of "nano-matrix crystal structure" of Si-strengthened AZ91 wrought magnesium matrix composites:

[0036] Adding Si during the smelting process of AZ91 to prepare Mg 2 Si particle reinforced AZ91 magnesium-based composite material, the AZ91D magnesium-based composite material obtained by semi-continuous casting is made into a 30*30*60 block after homogenization treatment, extrusion deformation, and solution aging treatment.

[0037] The first cryogenic and low heat treatment: put the sample into the cryogenic treatment box, control the cooling rate at 40°C / s until the liquid nitrogen temperature is -196°C, and the cold treatment time is 120min; take it out and put it into graphite powder (to prevent low heat treatment time oxidation) placed in a heat treatment furnace, the low heat aging temperature is 195°C, and the aging time is 4h.

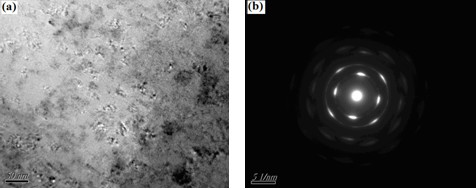

[0038] The first cryogenic and low heat cycle treatment: put the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com