A Slit Iris Diaphragm Based on Air Float Guide

An air-flotation-guided, slit-type technology, applied in optics, optical components, instruments, etc., can solve the problems of multiple motion links, poor rotational stiffness, and bulky volume, so as to improve motion and positioning accuracy, avoid collisions and damage, The effect of increasing speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

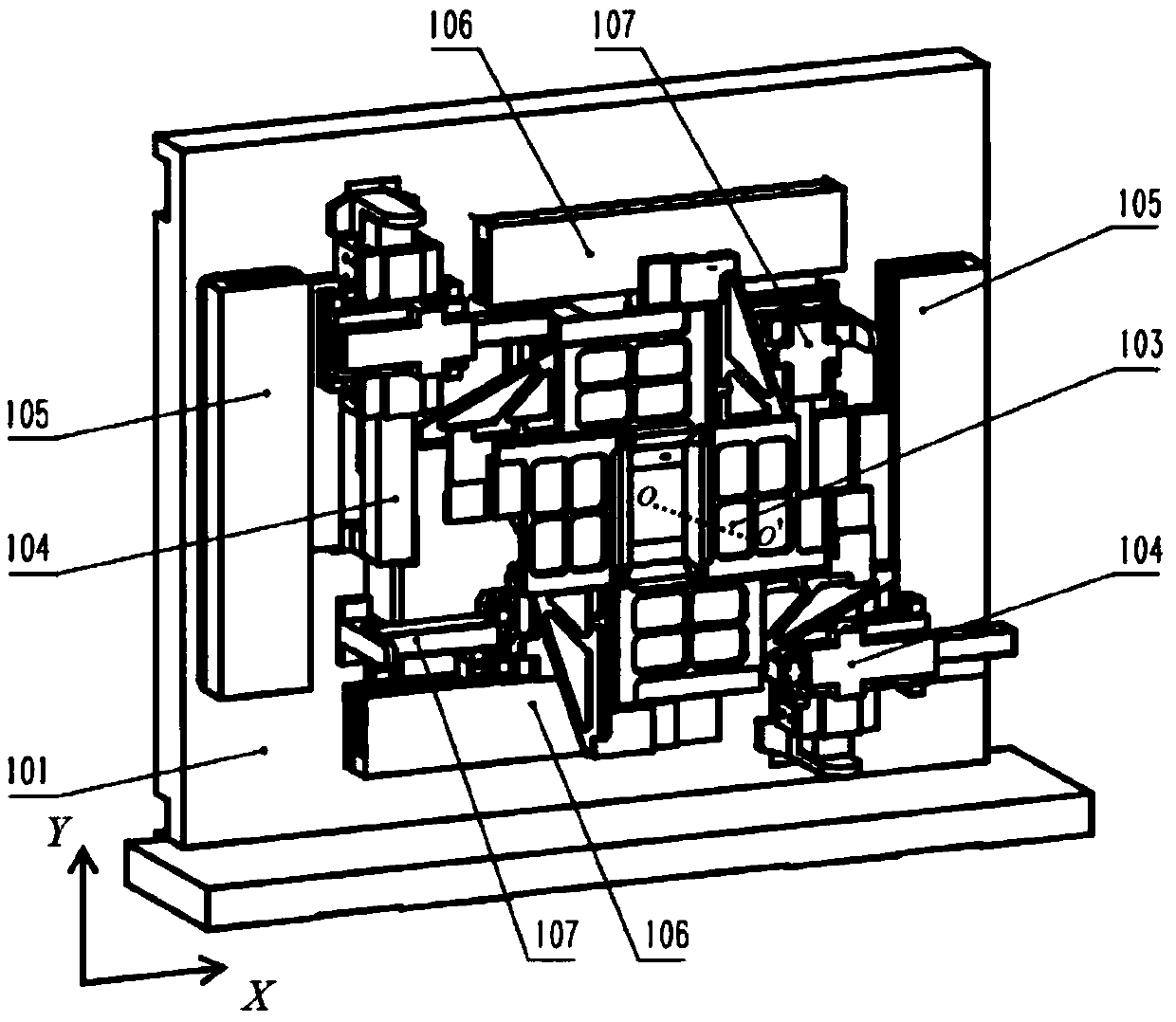

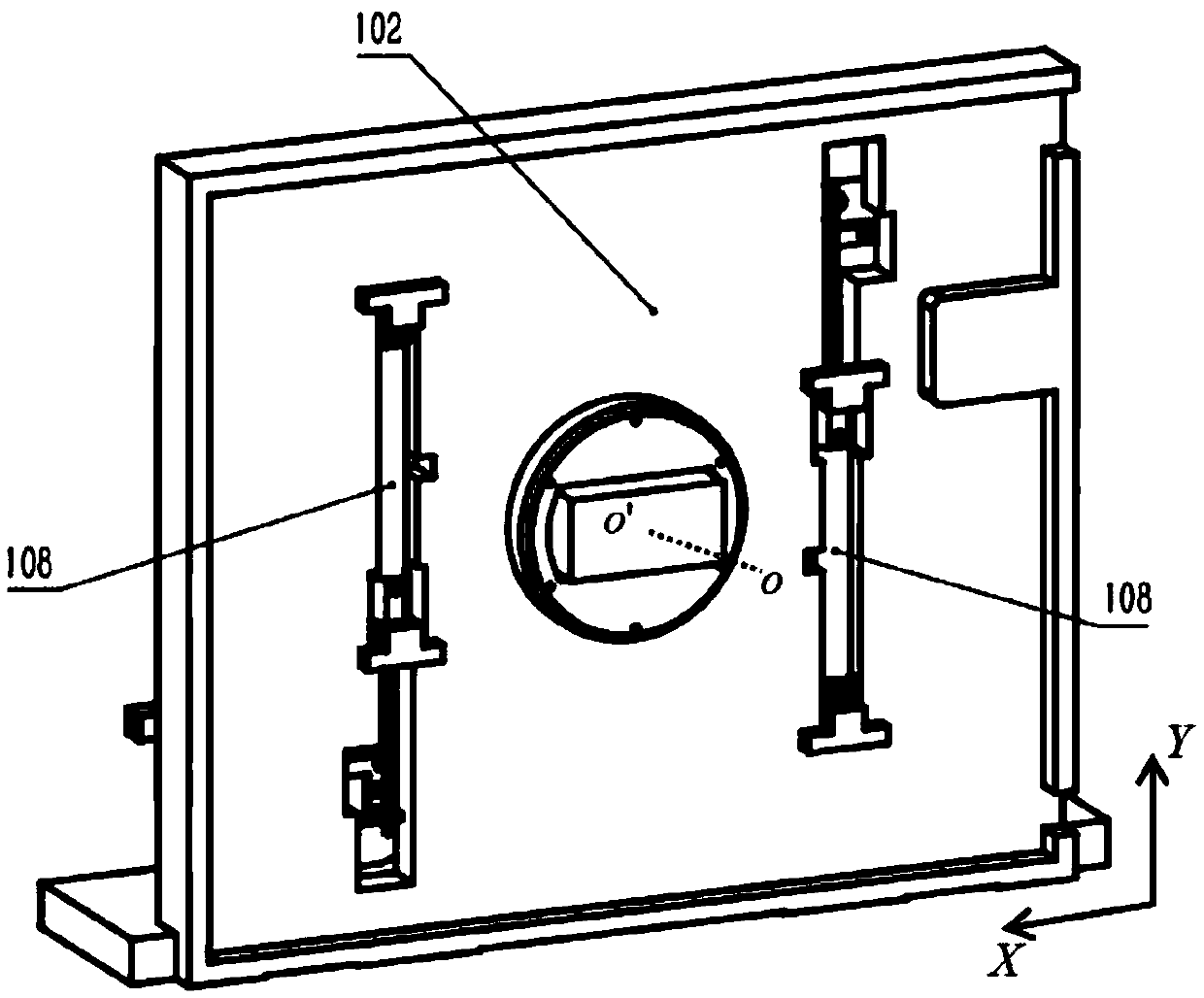

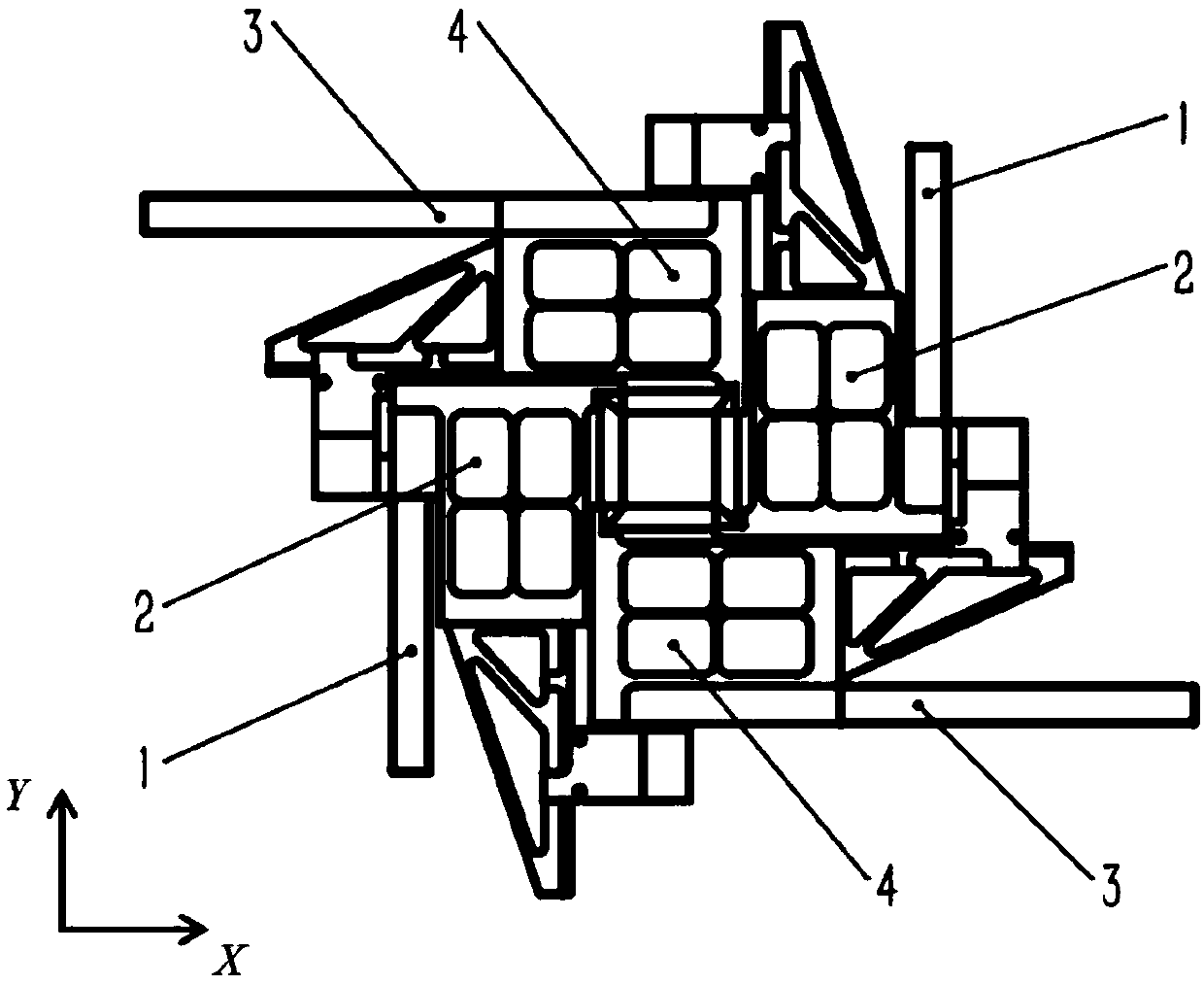

[0030] A slit-type iris diaphragm based on air-floating guidance. Two X-direction drive control units 106 arranged in parallel and two Y-direction drive control units arranged in parallel are respectively installed on the front panel 101 of the device. 105 , two X-direction support guide units 107 arranged parallel to each other, two Y-direction support guide units 104 and the aperture window 103 arranged parallel to each other. Two mutually parallel gravity compensation units 108 are installed on the back panel 102, and the aperture window 103 is composed of two correspondingly configured X-direction aperture plates 4, two correspondingly configured Y-direction aperture plates 2, and two correspondingly configured Y-direction aperture plates. The configured X-direction driven air-bearing guide rail 3 and two correspondingly configured Y-direction drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com