Patents

Literature

84results about How to "Reduce friction work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

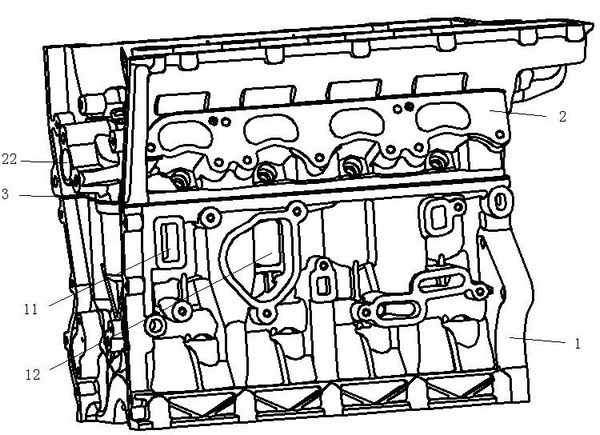

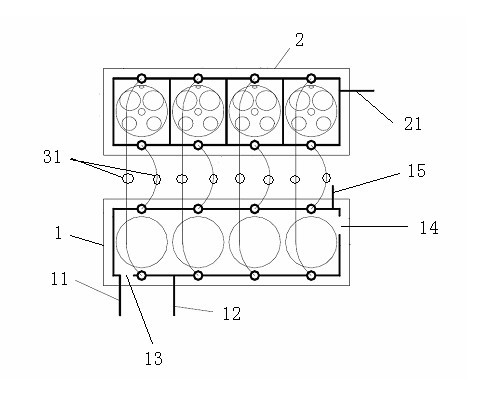

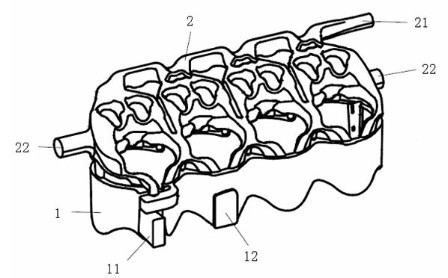

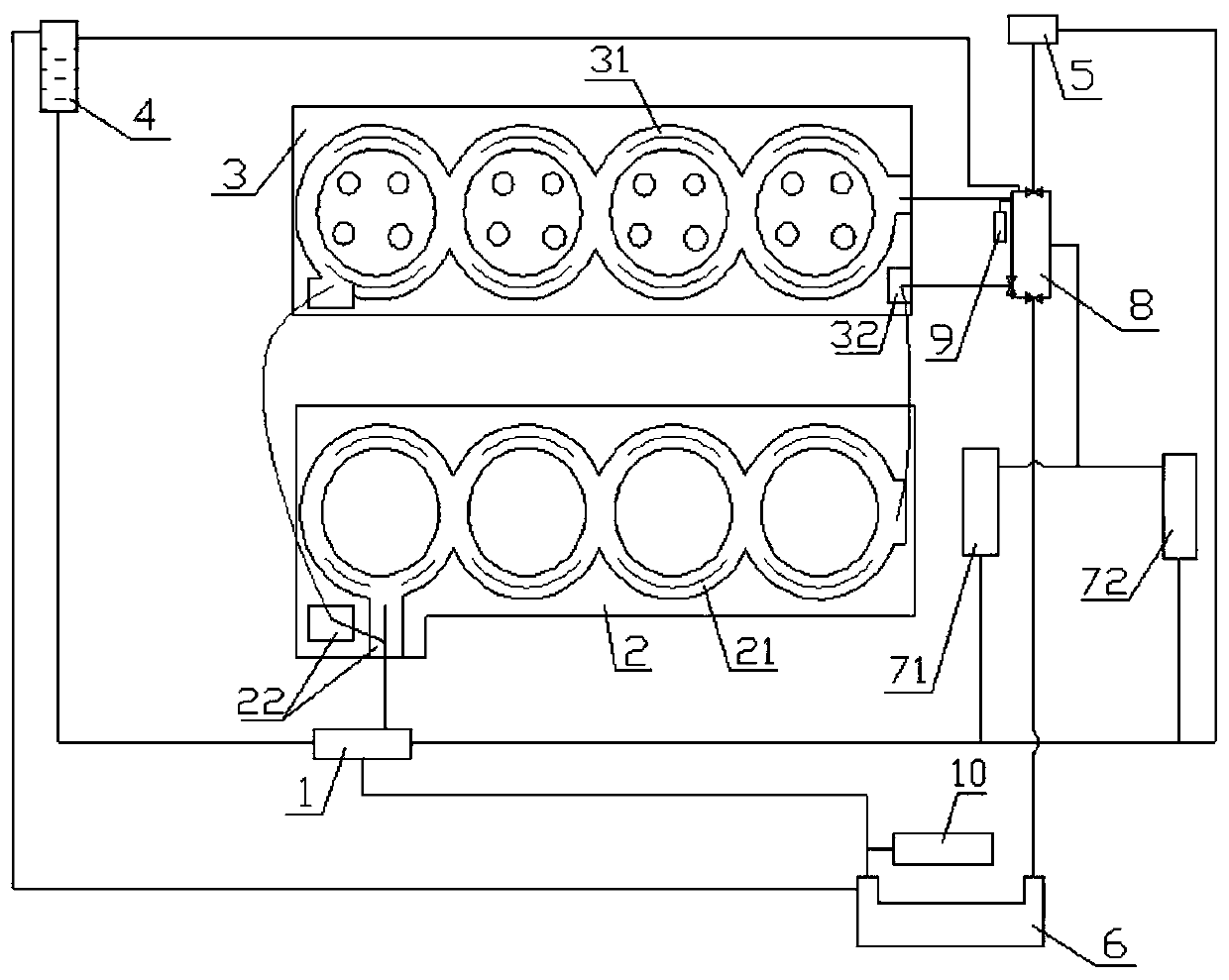

Engine cooling water jacket

InactiveCN102042116AImprove powerImprove performanceLiquid coolingCylinder headsThermal stateEngineering

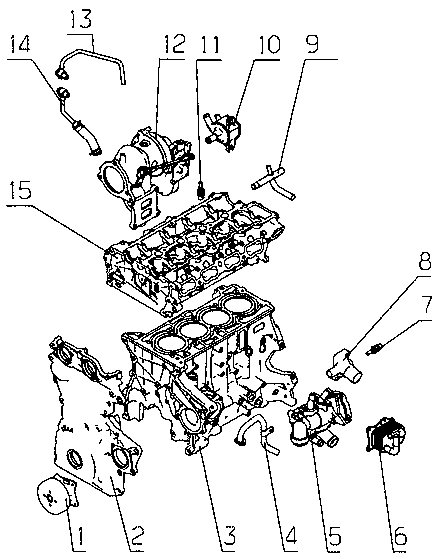

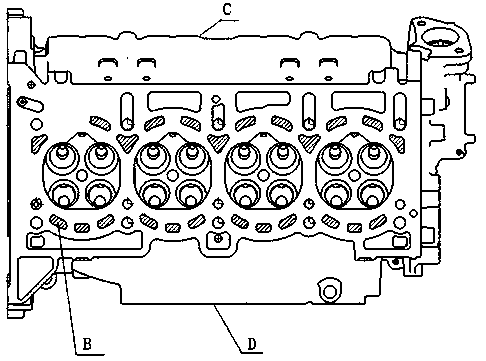

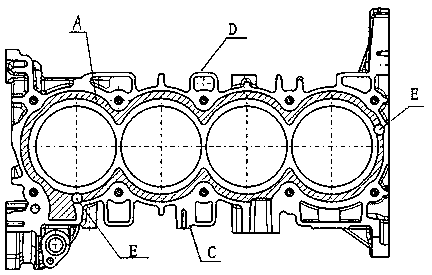

The invention provides an engine cooling water jacket which has the advantages of simple structure, small volume, uniform flow rate and low pressure loss. The engine cooling water jacket comprises a cylinder body water jacket and a cylinder cover water jacket, wherein the cylinder body water jacket is separated by two baffle plates to form a first flow channel and a second flow channel, and the first flow channel and the second flow channel are communicated with the cylinder cover water jacket through water holes in a cylinder gasket; and coolant mainly flows into the first flow channel from a water inlet and flows through an air exhaust side, then flows into the cylinder cover water jacket through the water holes at one side of the cylinder gasket, subsequently flows into the second flow channel through the water holes at the other side of the cylinder gasket and flows through an air admission side, and finally flows out from a water outlet. Thus, the invention enables the flow rate of the coolant in the whole engine cooling water jacket to be more uniform, reduces the thermal-state deformation of the cylinder holes and improves the dynamic performance of the engine; and the water holes in the cylinder gasket can be arranged as required without being influenced by the design of traditional water jacket cylinder holes, thereby integrally increasing the flow areas of the water holes in the cylinder gasket, reducing the pressure loss of the whole water jacket and lowering the performance requirements for water pumps.

Owner:CHERY AUTOMOBILE CO LTD

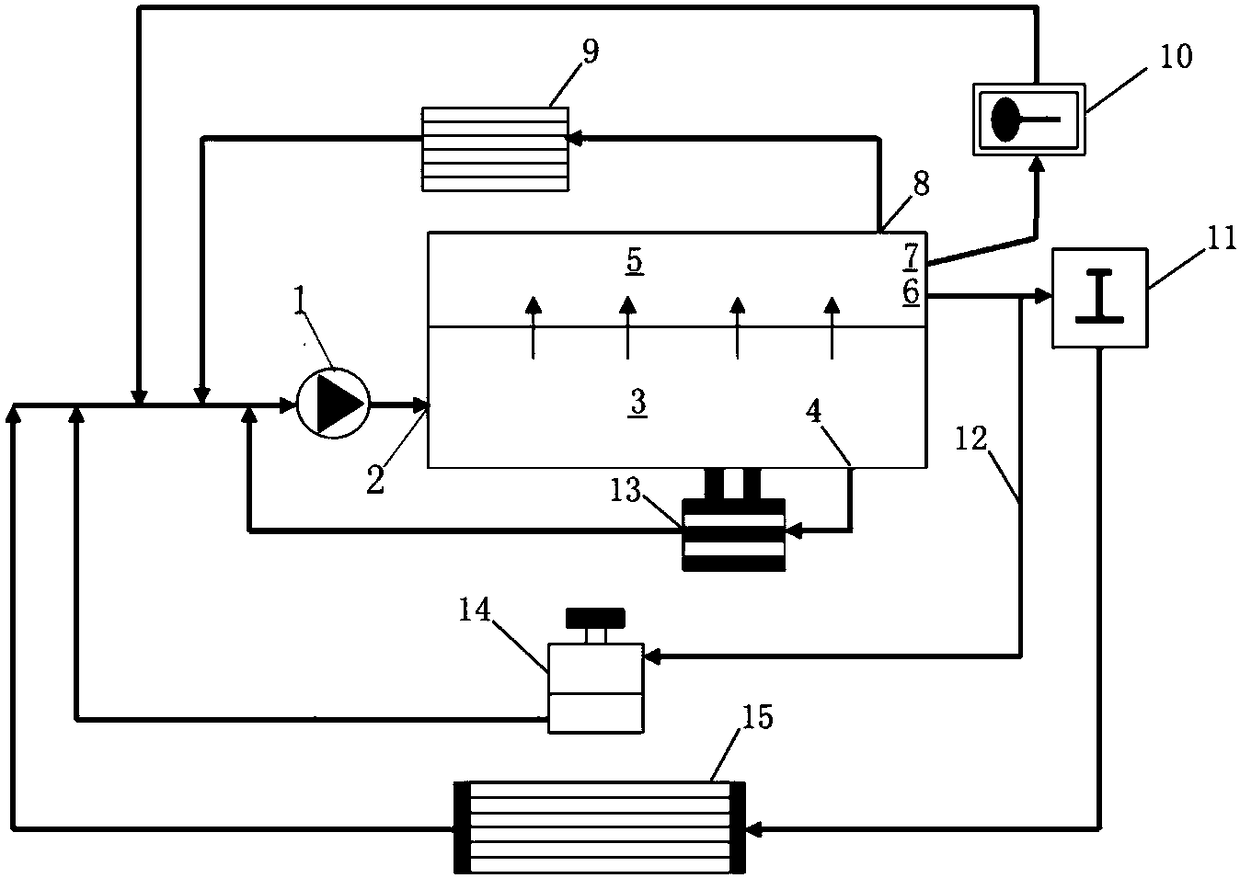

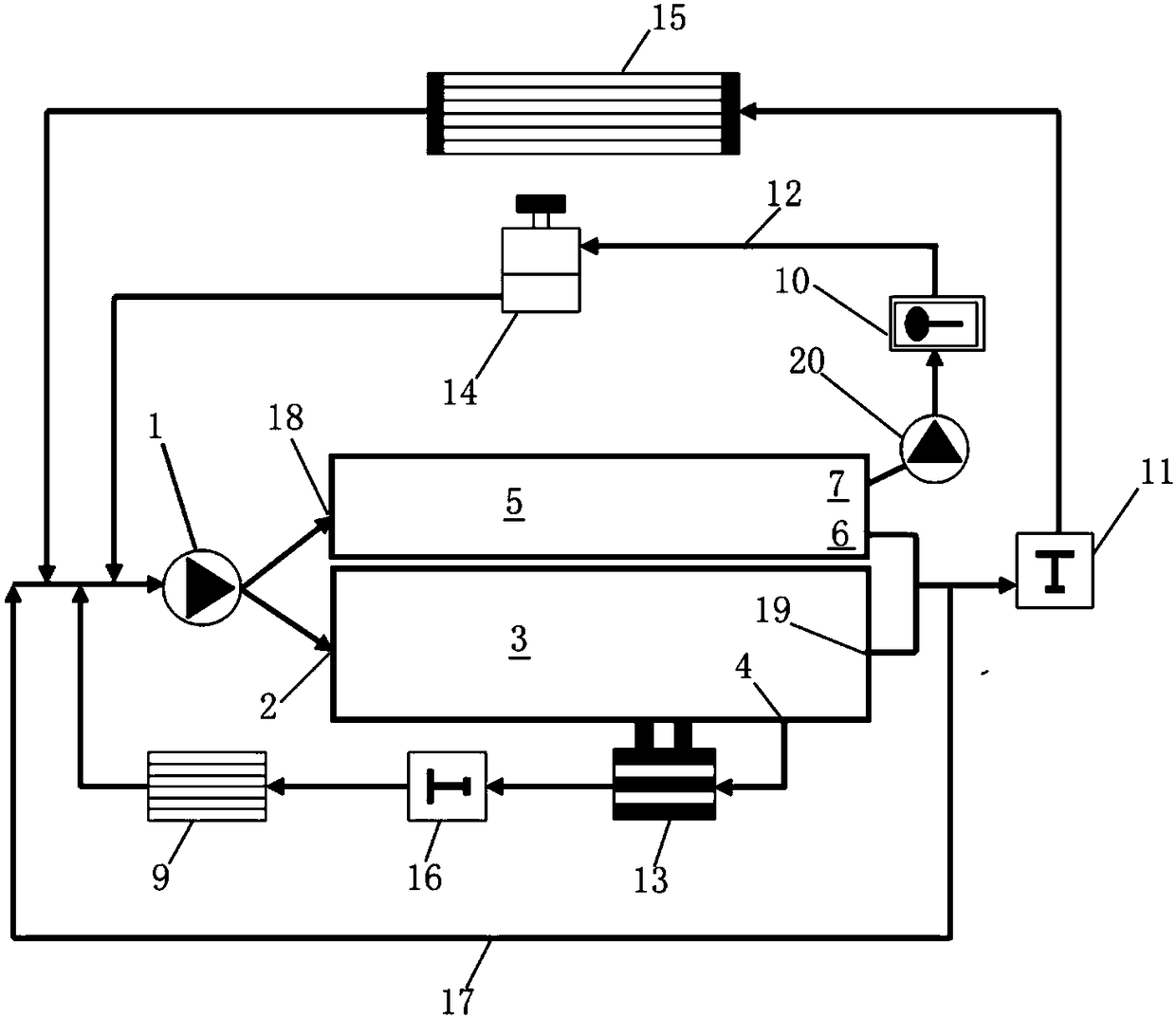

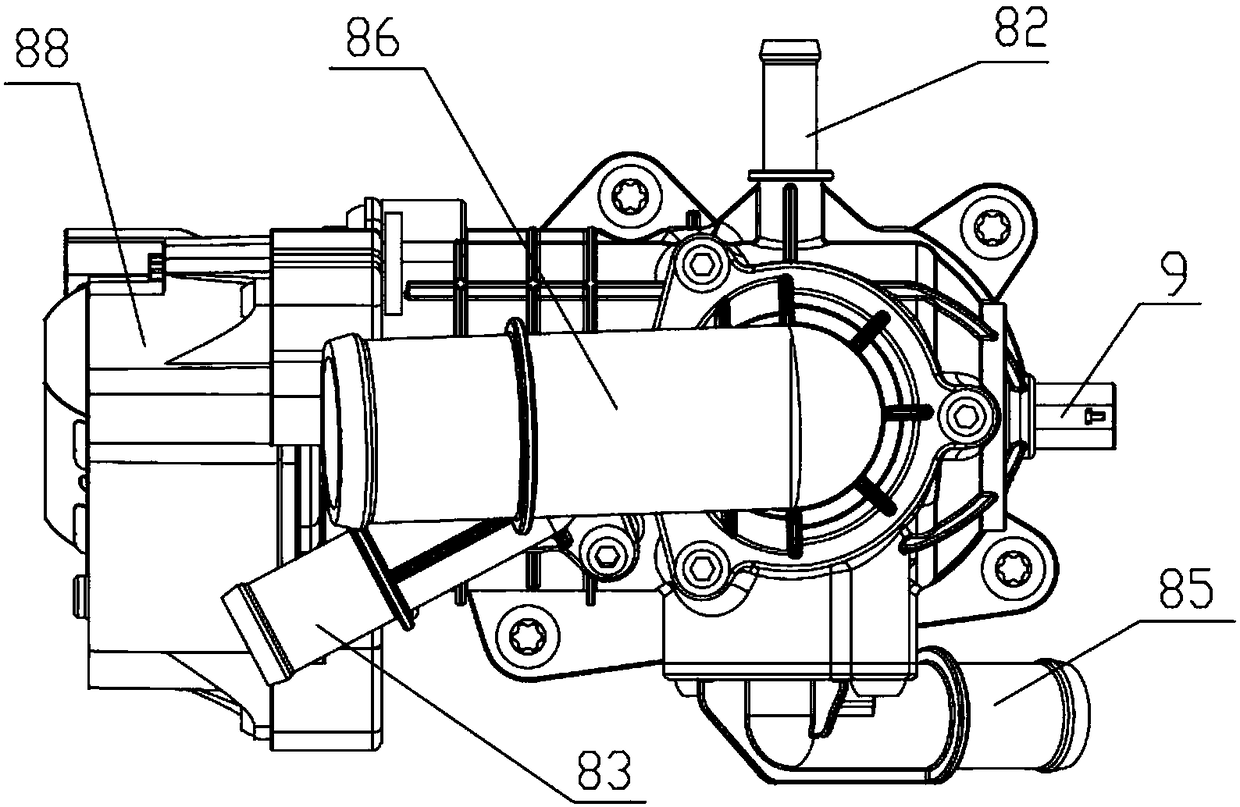

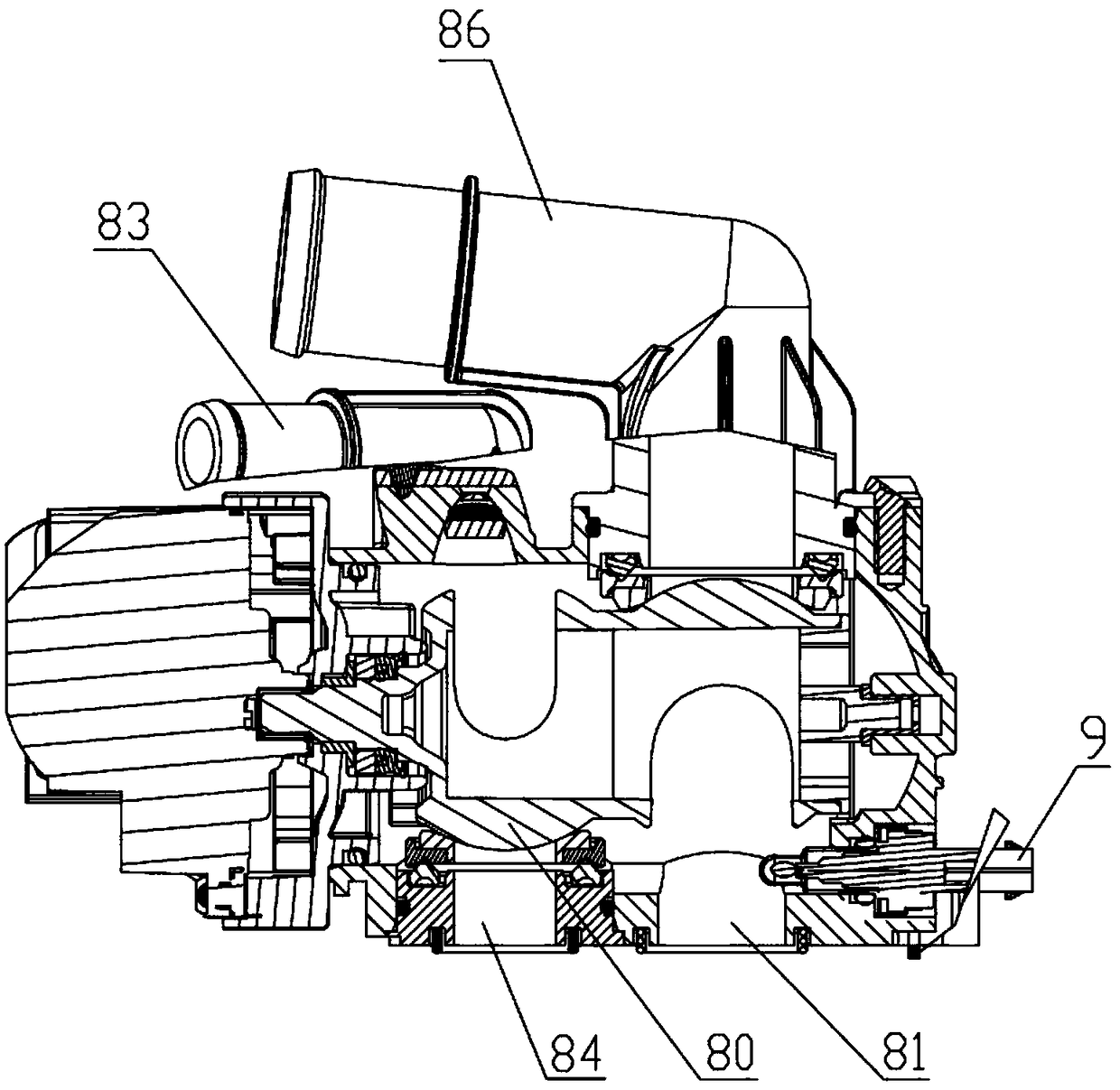

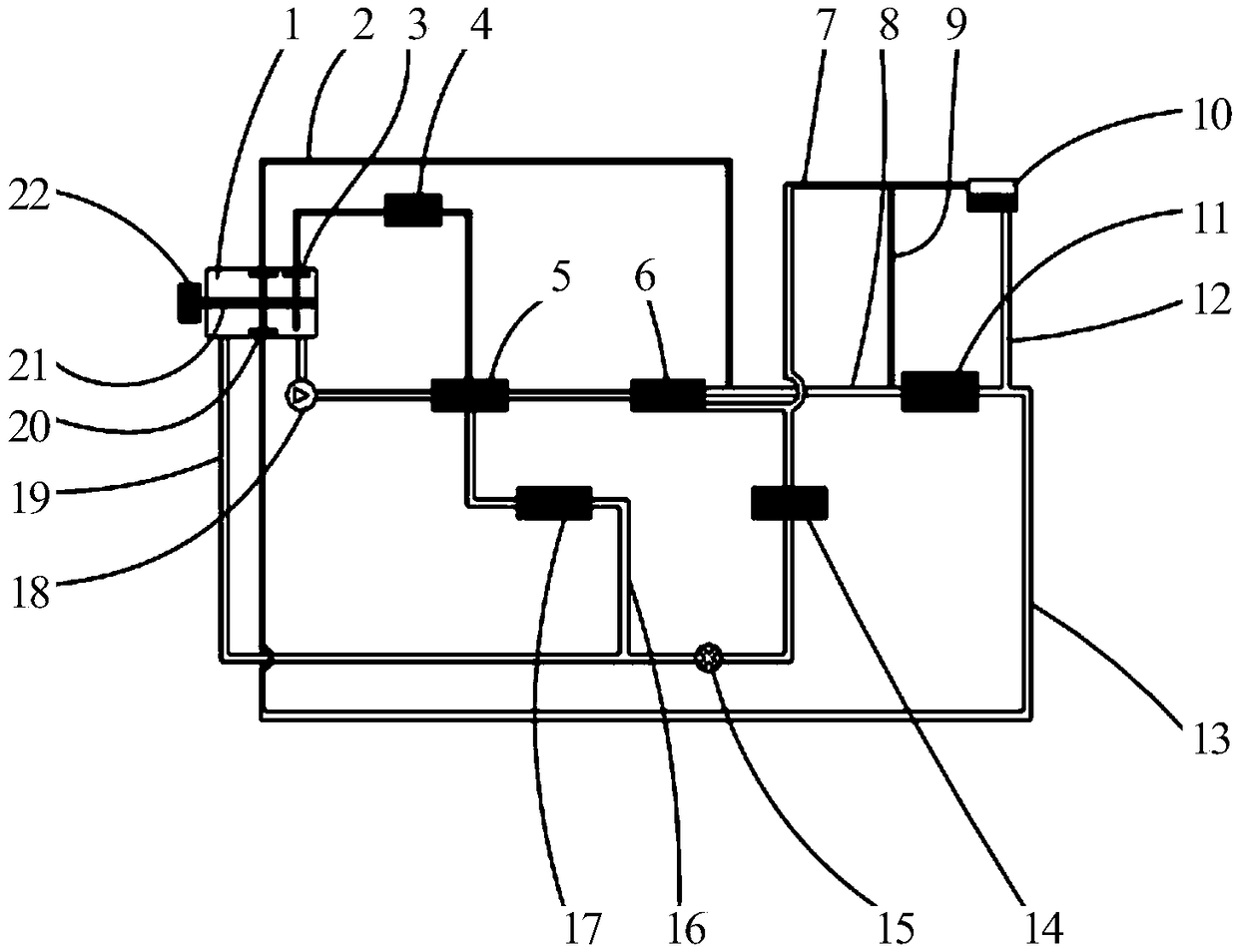

Automobile engine cooling system

ActiveCN108343500AReduce trafficTraffic restrictionsCoolant flow controlMachines/enginesExpansion tankCombustion

The invention provides an automobile engine cooling system which comprises a water pump, a cylinder cover water jacket, a cylinder body water jacket, a first thermostat, a heat radiator, an electronicwater pump, a supercharger, an expansion tank, an engine oil cooler, a second thermostat, a fan heater and an engine degassing pipeline, wherein the opening and closing of corresponding pipelines ofthe engine oil cooler and the fan heater are controlled by the second thermostat; after the supercharger is shut down, the electronic water pump carries out delay cooling; and the flow rate of each loop is about 30 L / min, so that the requirements of the engine oil cooler and the fan heater are met at the same time. With the adoption of the engine cooling system, the friction is reduced, oil consumption is reduced, the requirement on water pump performance is lowered, the combustion efficiency is improved, and the reliability of the supercharger is ensured.

Owner:HAIMA AUTOMOBILE CO LTD +1

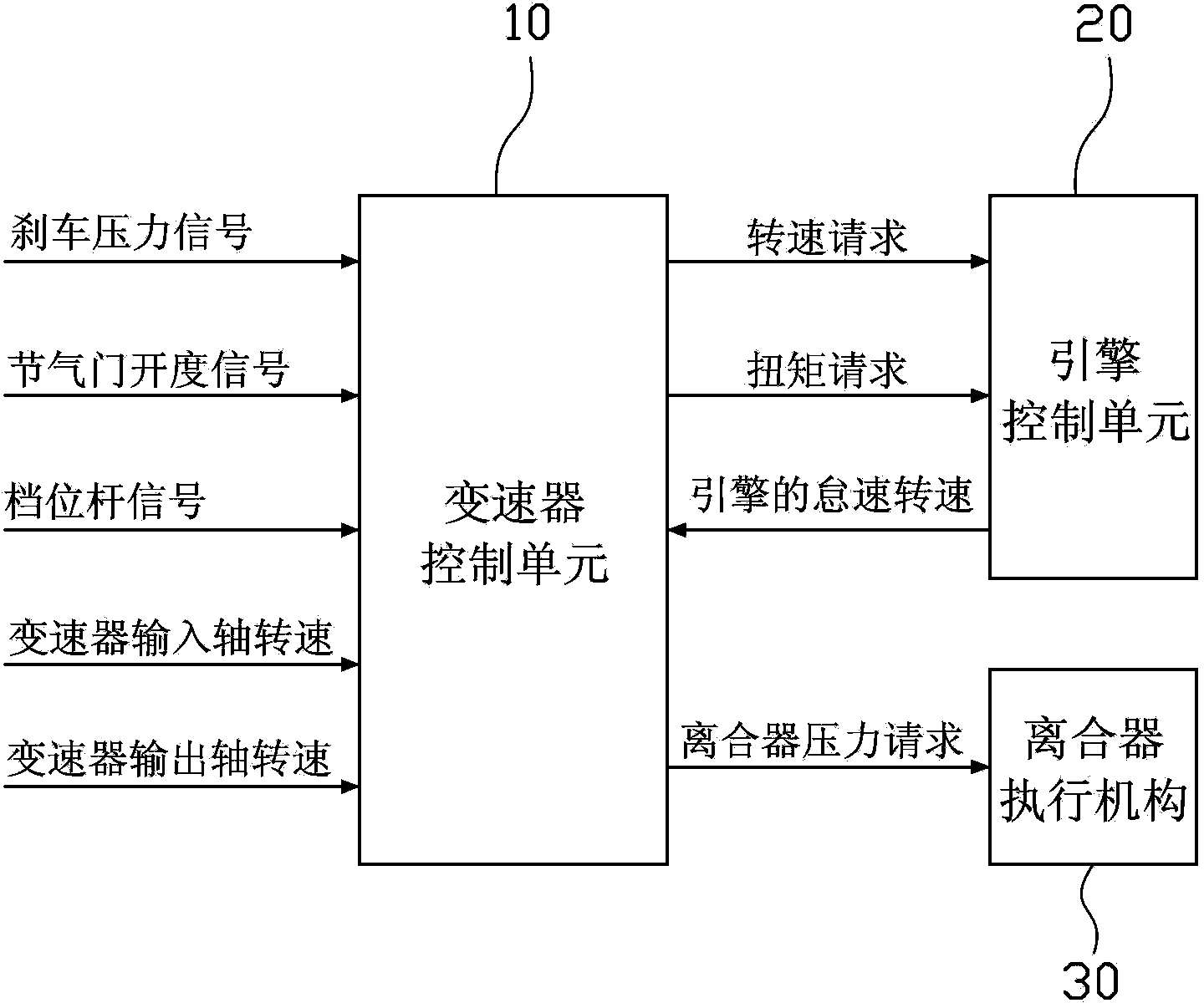

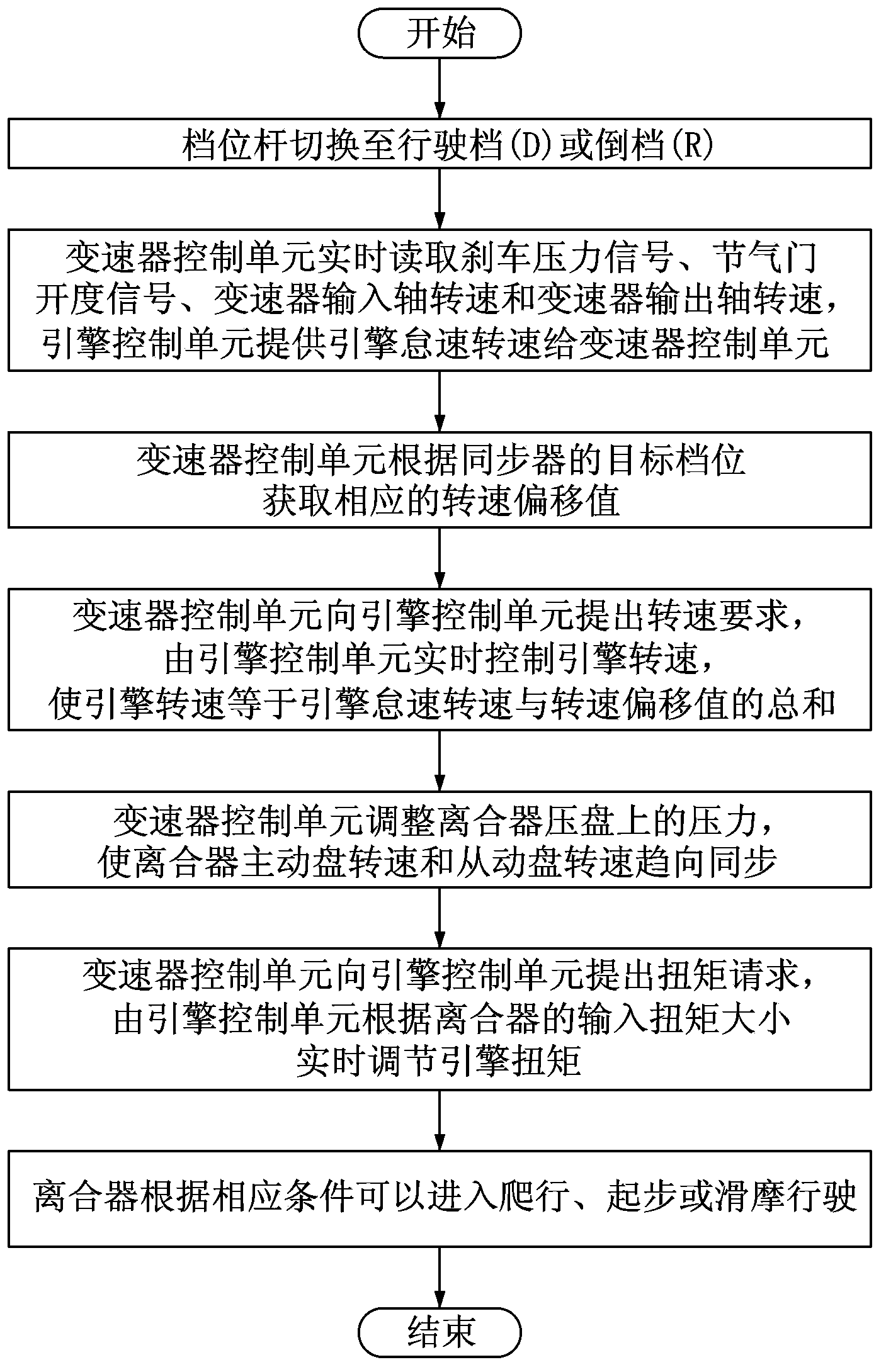

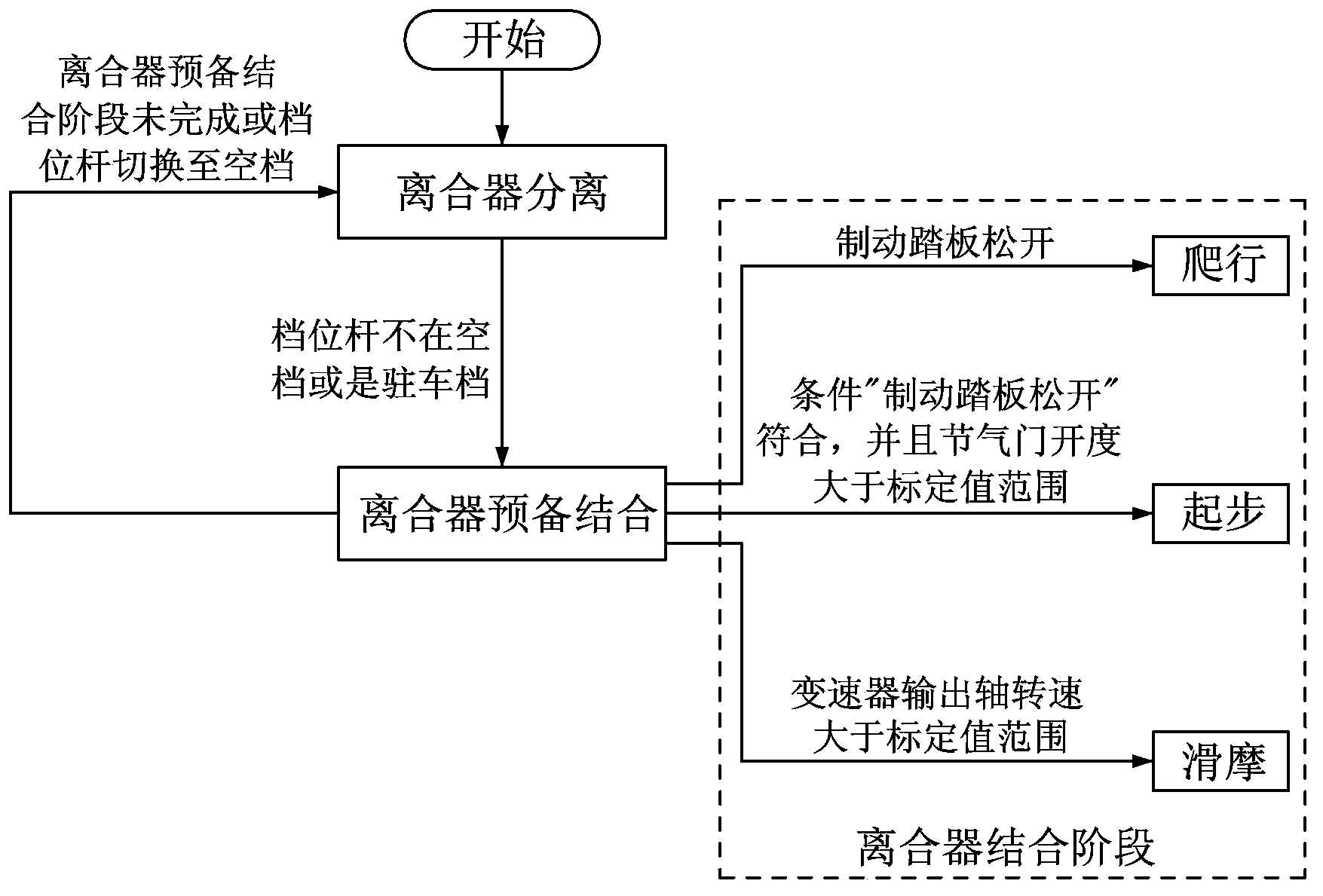

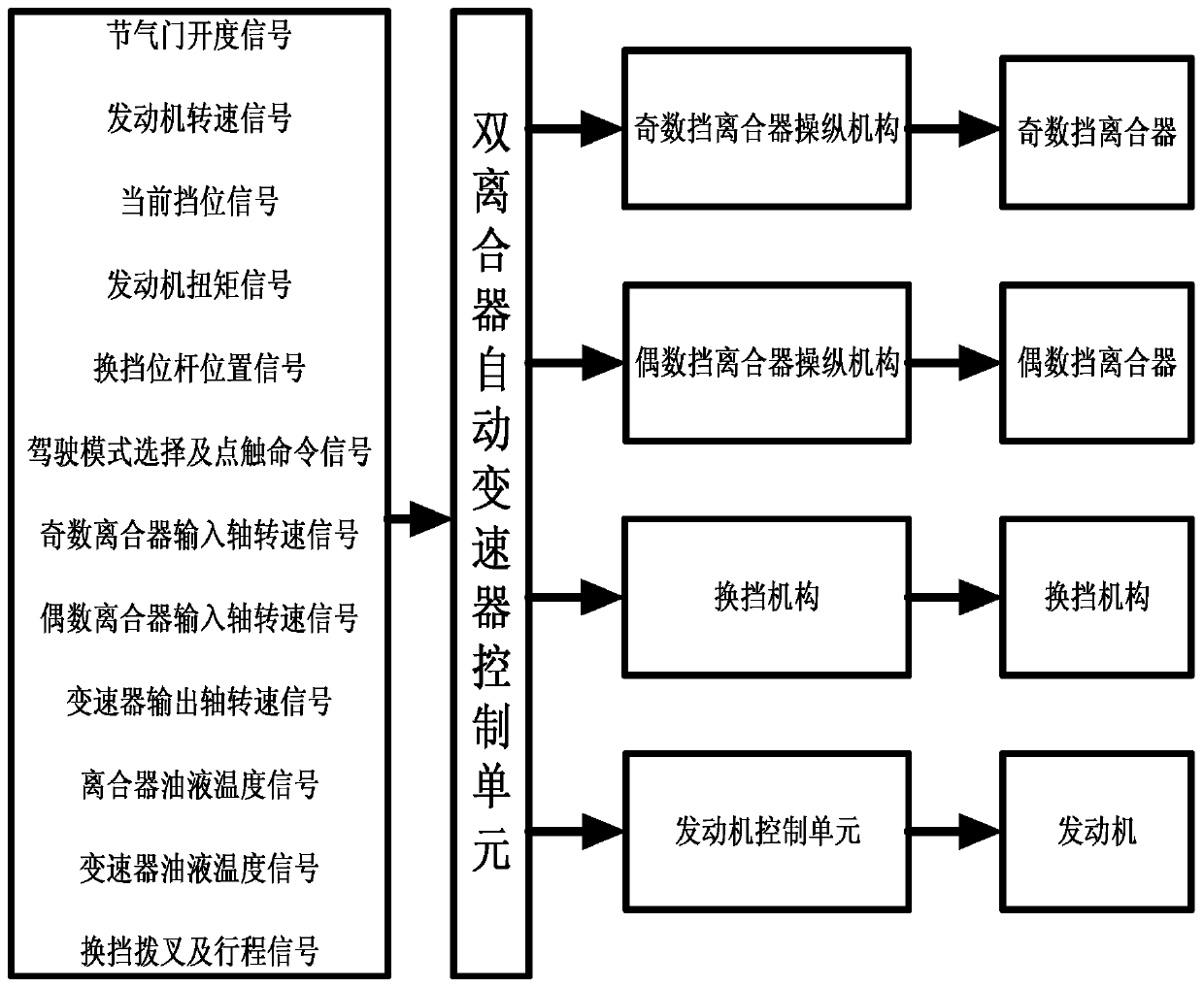

Clutch pre-engagement control system and method of automatic transmission

ActiveCN103363095APrevent abnormal flameoutReduce shockClutchesGearing controlAutomatic transmissionControl system

The invention discloses a clutch pre-engagement control system of an automatic transmission. The clutch pre-engagement control system comprises a transmission control unit and an engine control unit, wherein the transmission control unit obtains a rotation speed offset to be compensated to the revolution speed of an engine under a target gear according to the target gear of a synchronizer before a clutch is engaged, and transmits a revolution speed request signal to the engine control unit; and the engine control unit regulates the target revolution speed of the engine under the target gear according to the revolution speed request signal in real time, so that the target revolution speed of the engine under the target gear is passively increased to be equal to the sum of the idle speed of the engine and the revolution speed offset. According to the clutch pre-engagement control system of the automatic transmission, which is disclosed by the invention, the transmission control unit transmits a torque request signal to the engine control unit when the clutch is engaged, the engine control unit regulates the torque of the engine according to the size of the input torque of the clutch in real time, so that the torque of the engine is subjected to real-time compensation and the abnormal flameout of the engine is prevented.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

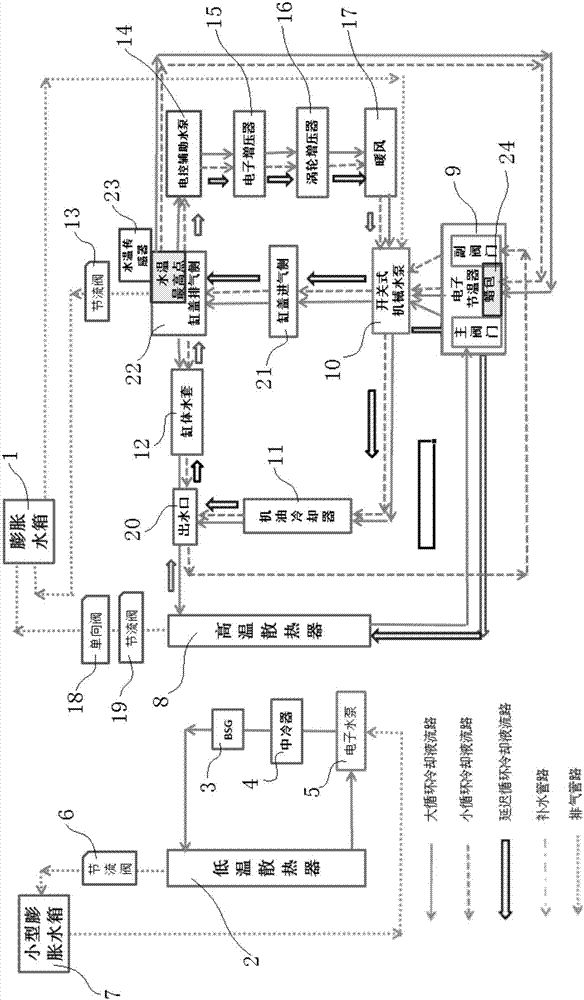

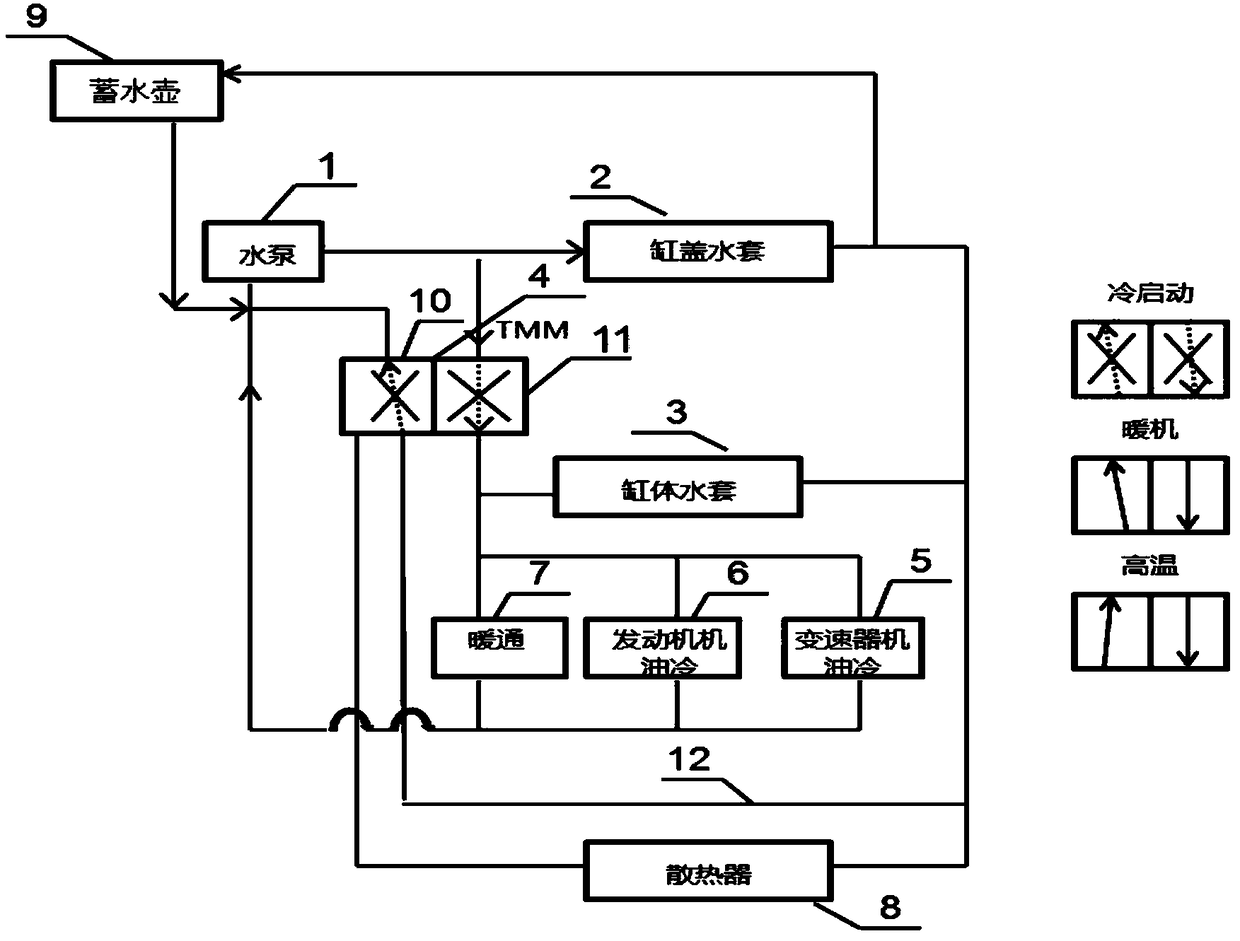

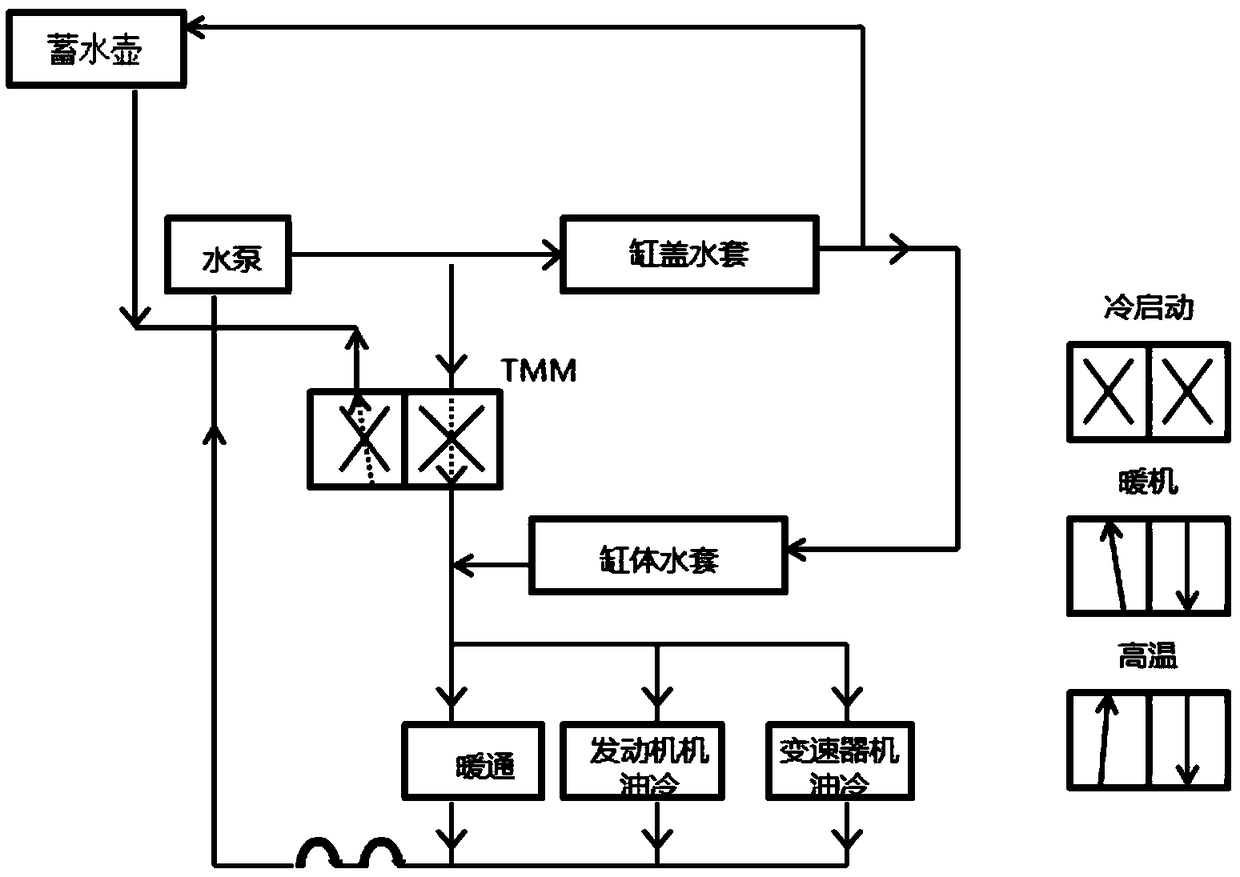

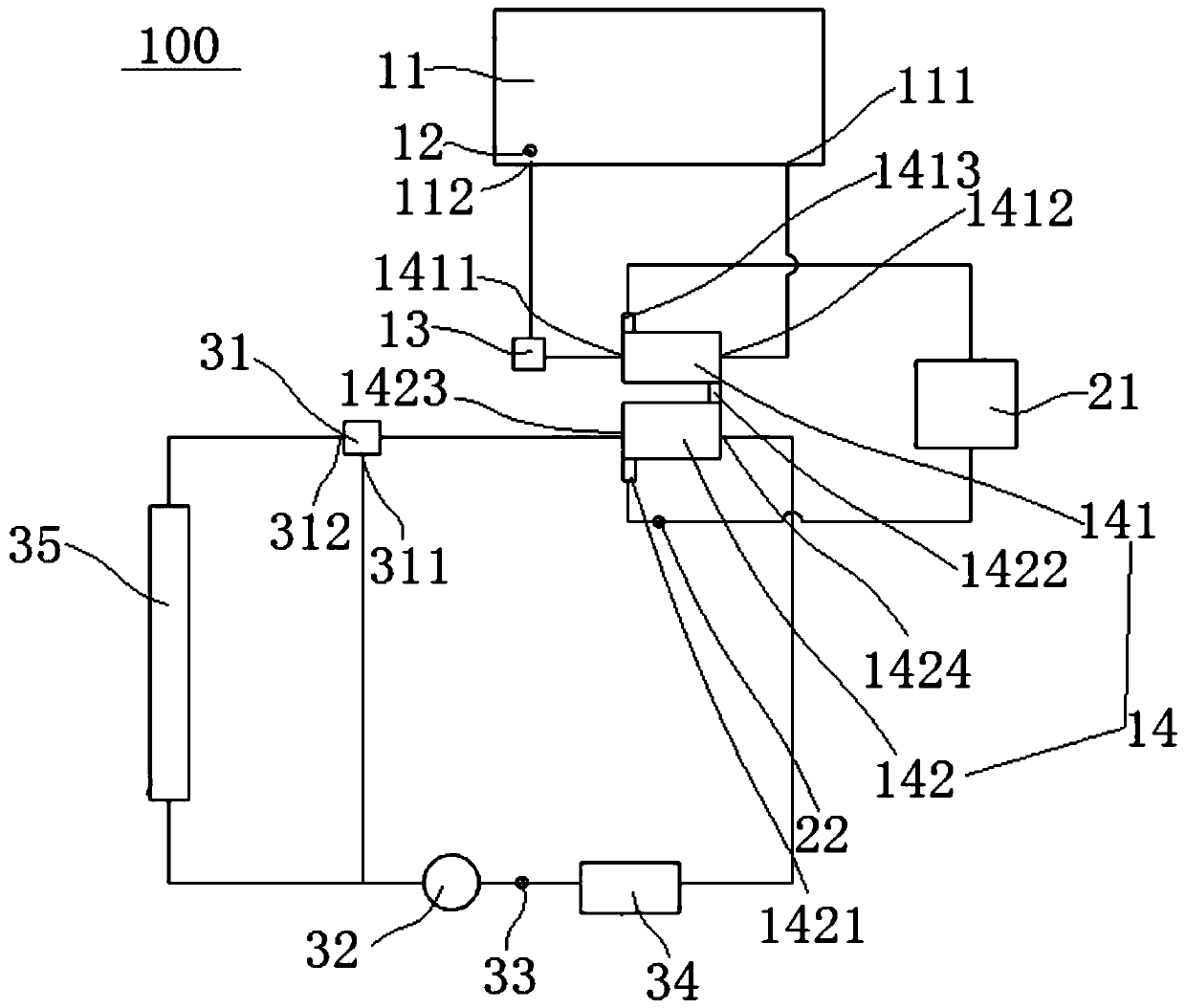

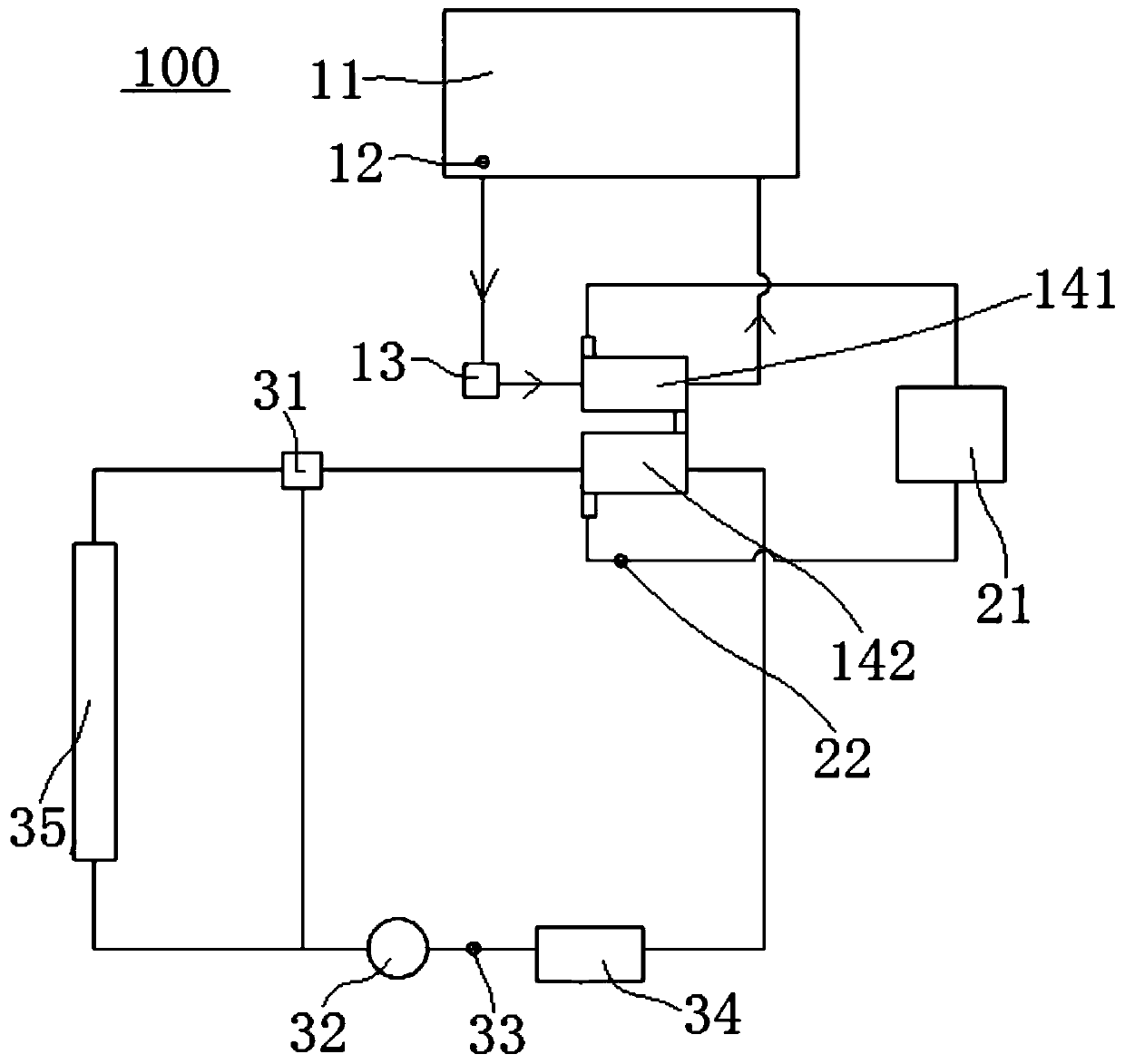

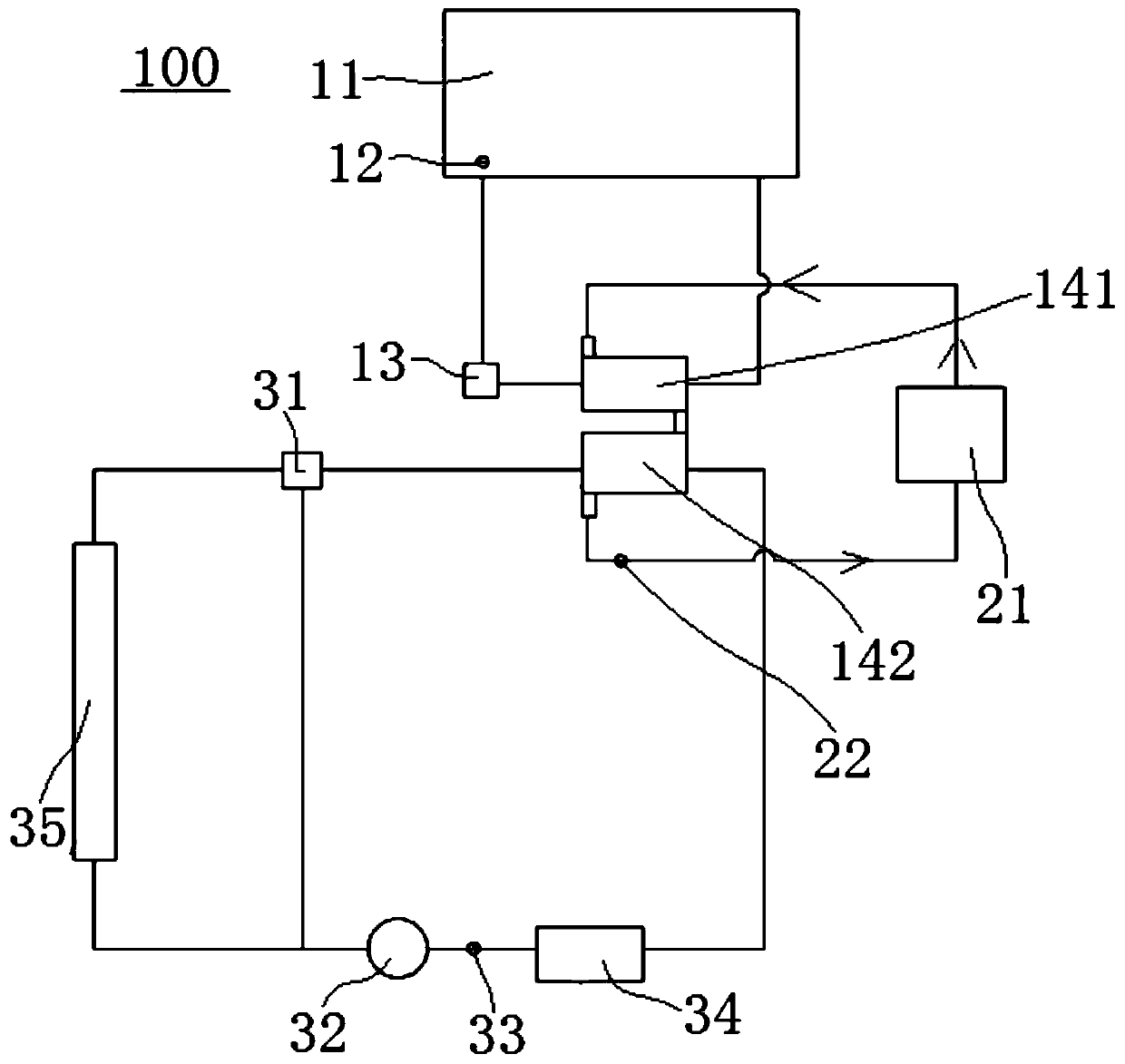

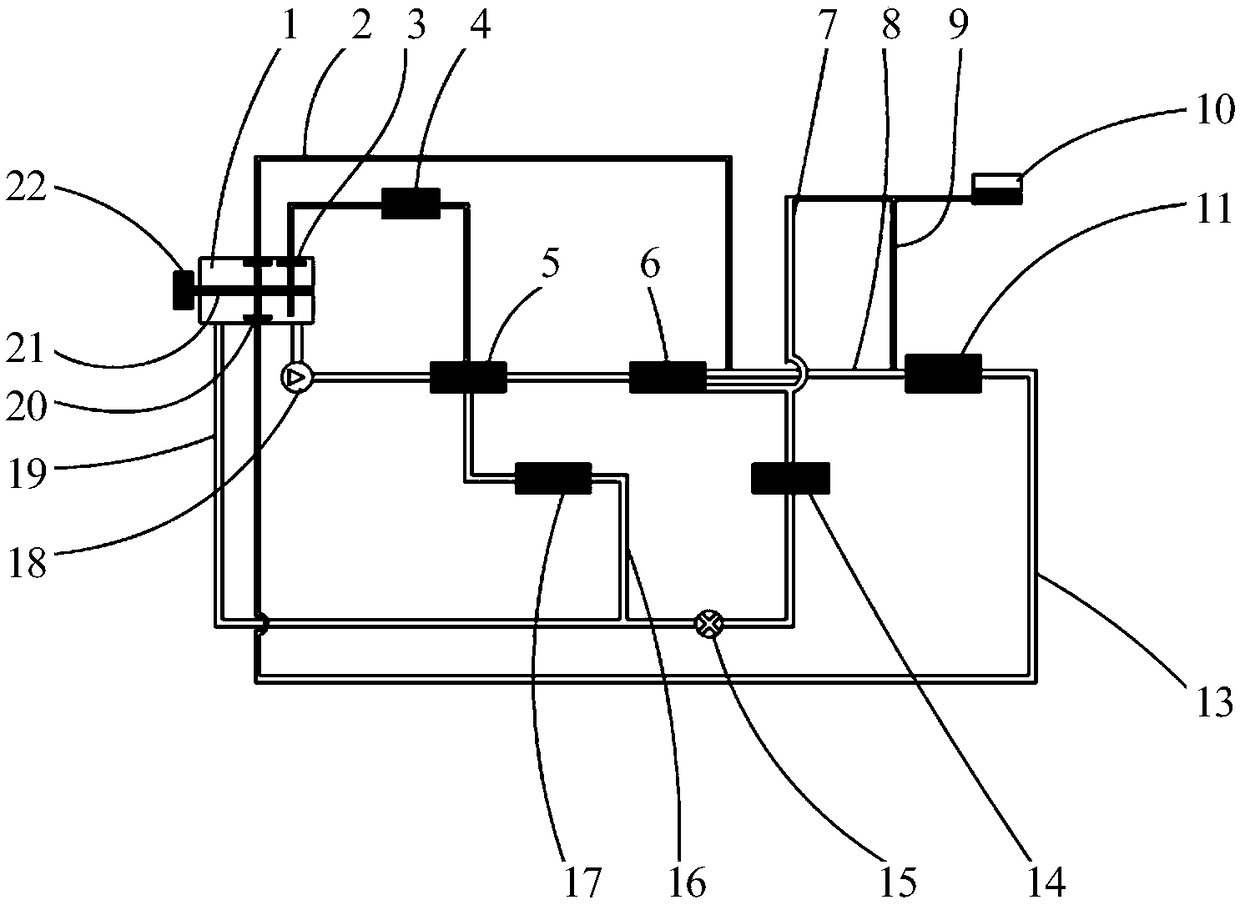

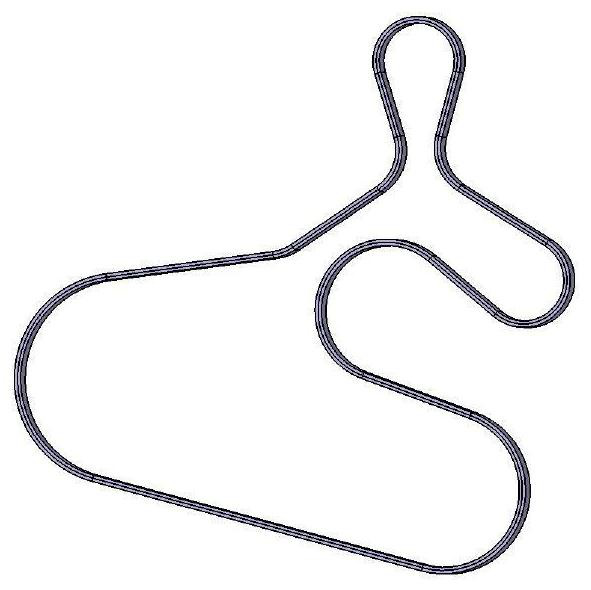

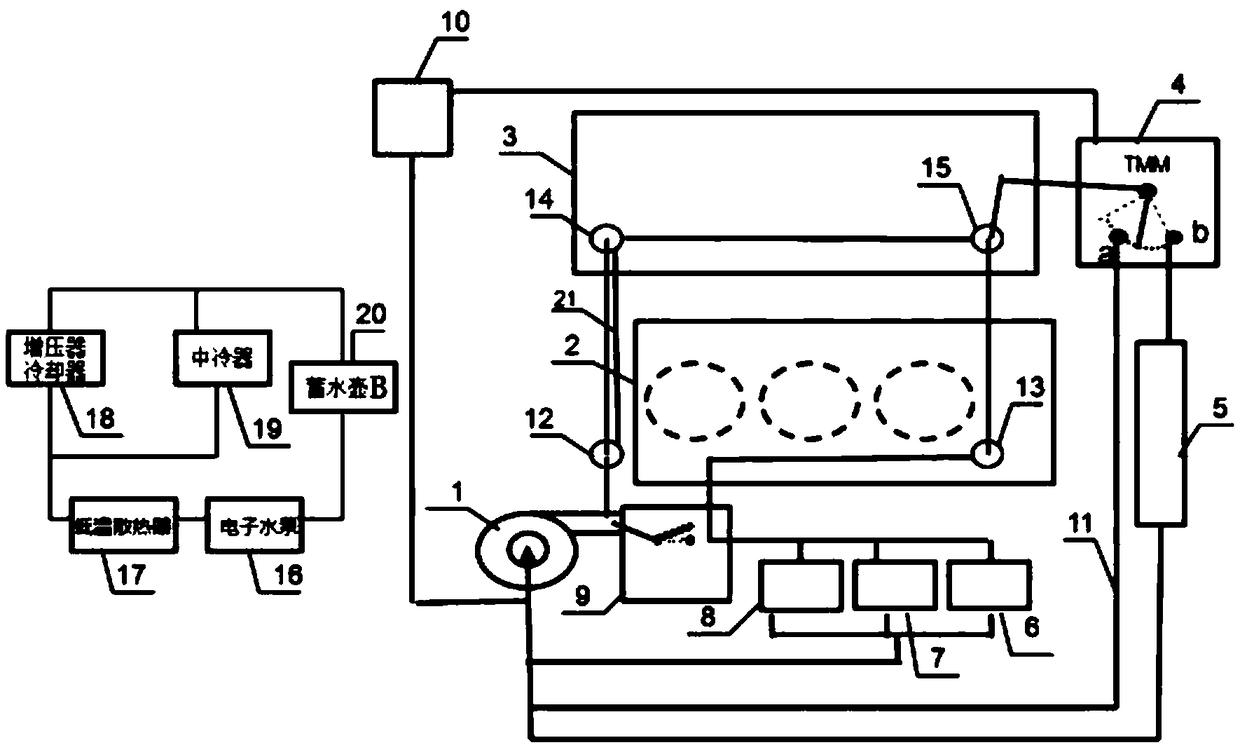

Cooling system and cooling method for automobile engine

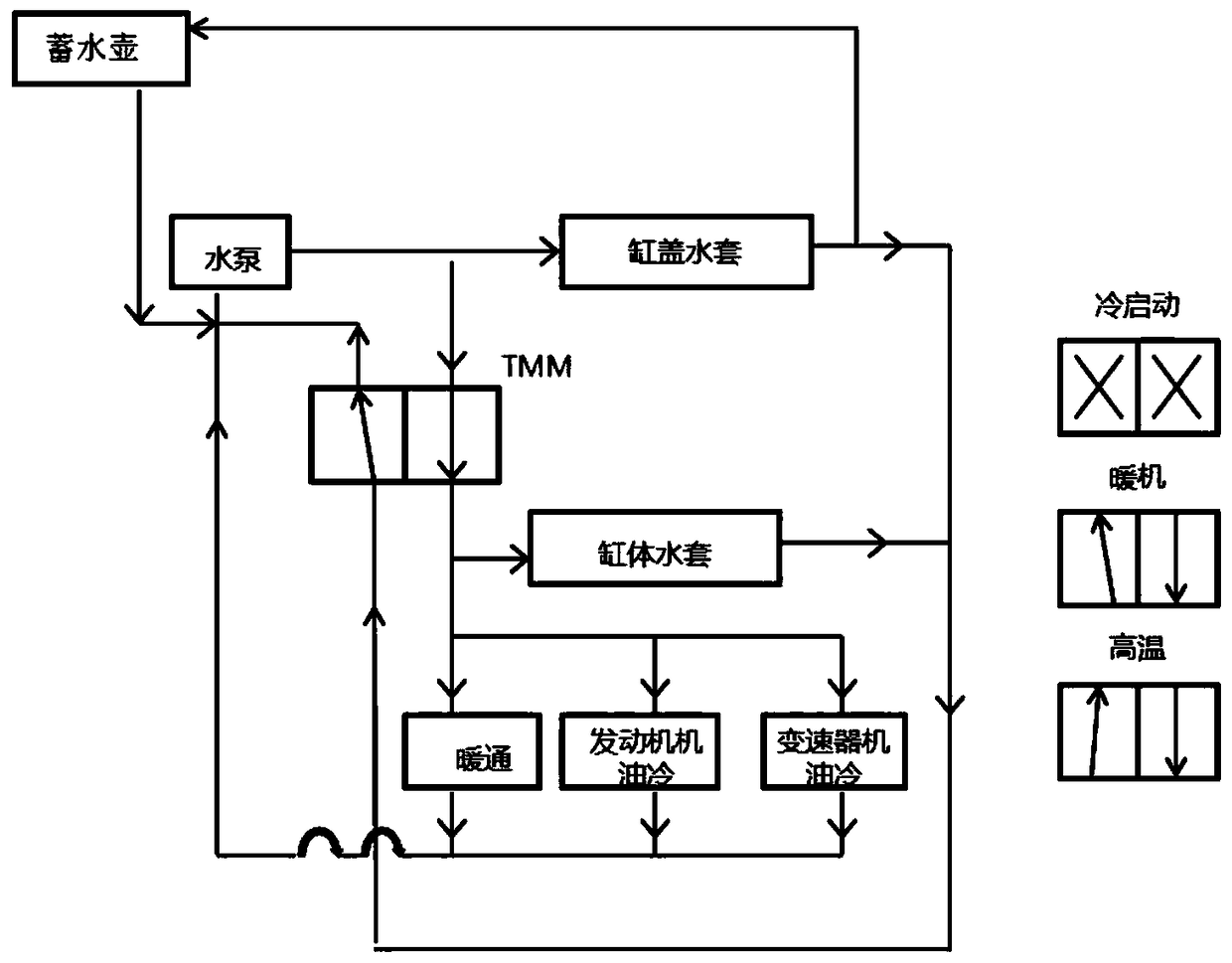

ActiveCN108278172AControl allocationHeating up fastLiquid coolingCoolant flow controlHeat managementControl valves

The invention discloses a cooling system and a cooling method for an automobile engine. The automobile engine cooling system comprises a cylinder body, a cylinder cover, a water storage pot, a heat exchanging part, a radiator, engine oil coolers and a heat management module, wherein the heat management module is provided with a control valve, a normally-communicated cylinder cover water jacket connector, a water storage pot connector, an engine oil cooler connector, a cylinder cover water passing channel connector capable of adjusting a connecting area through the control valve, a heat exchanging part connector and a radiator connector. During a cold start, a connecting area of the cylinder cover water passing channel connector, the heat exchanging part connector and the radiator connectoris enabled to be zero; when the engine is heated, the connecting area of the cylinder cover water passing channel connector and the radiator connector is enabled to be zero, and the connecting area of the heat exchanging part connector is enabled to be 100 percent; and when temperature of the engine is in a high working state, the connecting area of the cylinder cover water passing channel connector, the heat exchanging part connector and the radiator connector is enabled to be 100 percent. According to the cooling system and the cooling method for the automobile engine, the heating speed ofthe engine and the engine oil heating speed can be increased, and the oil consumption can be reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

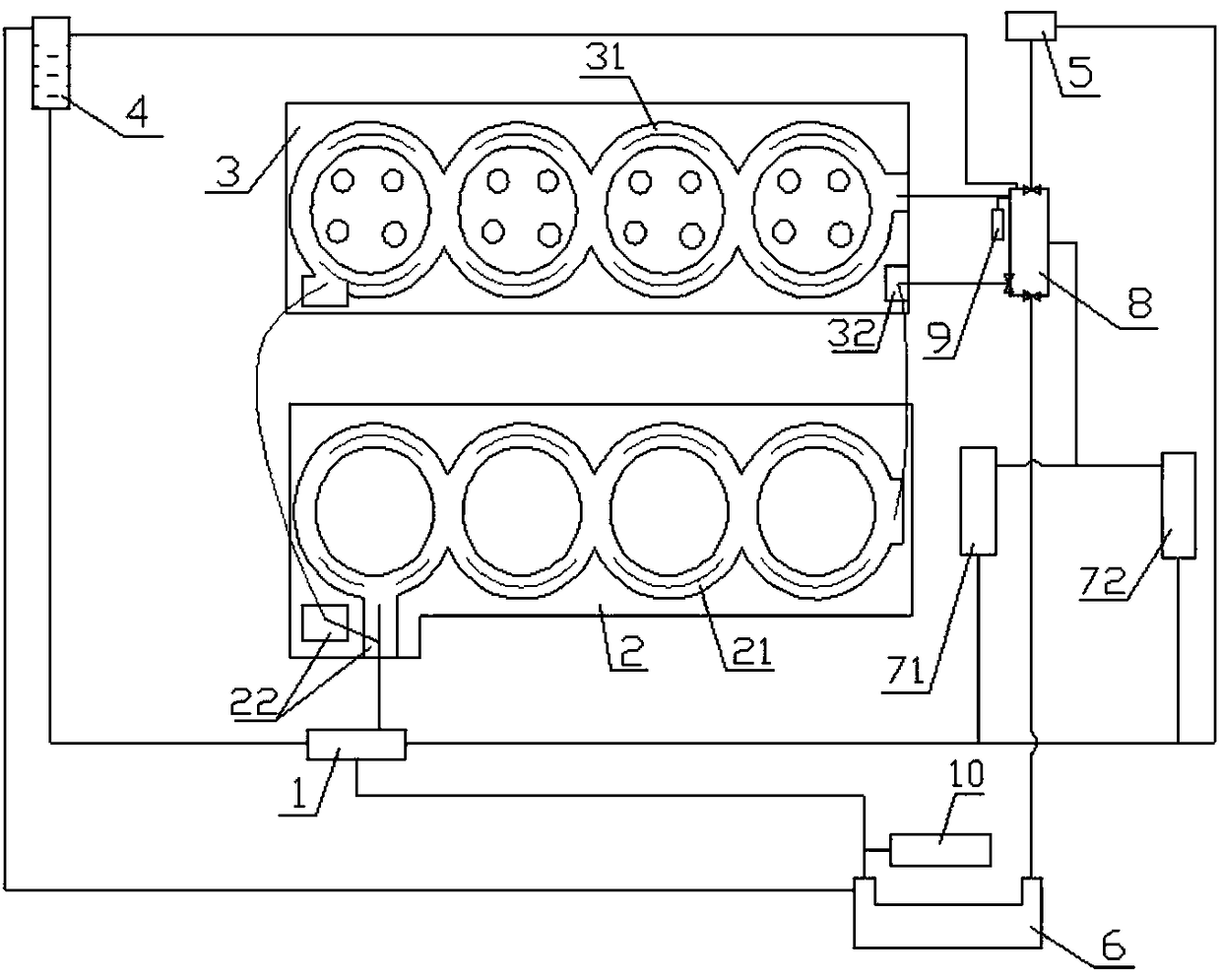

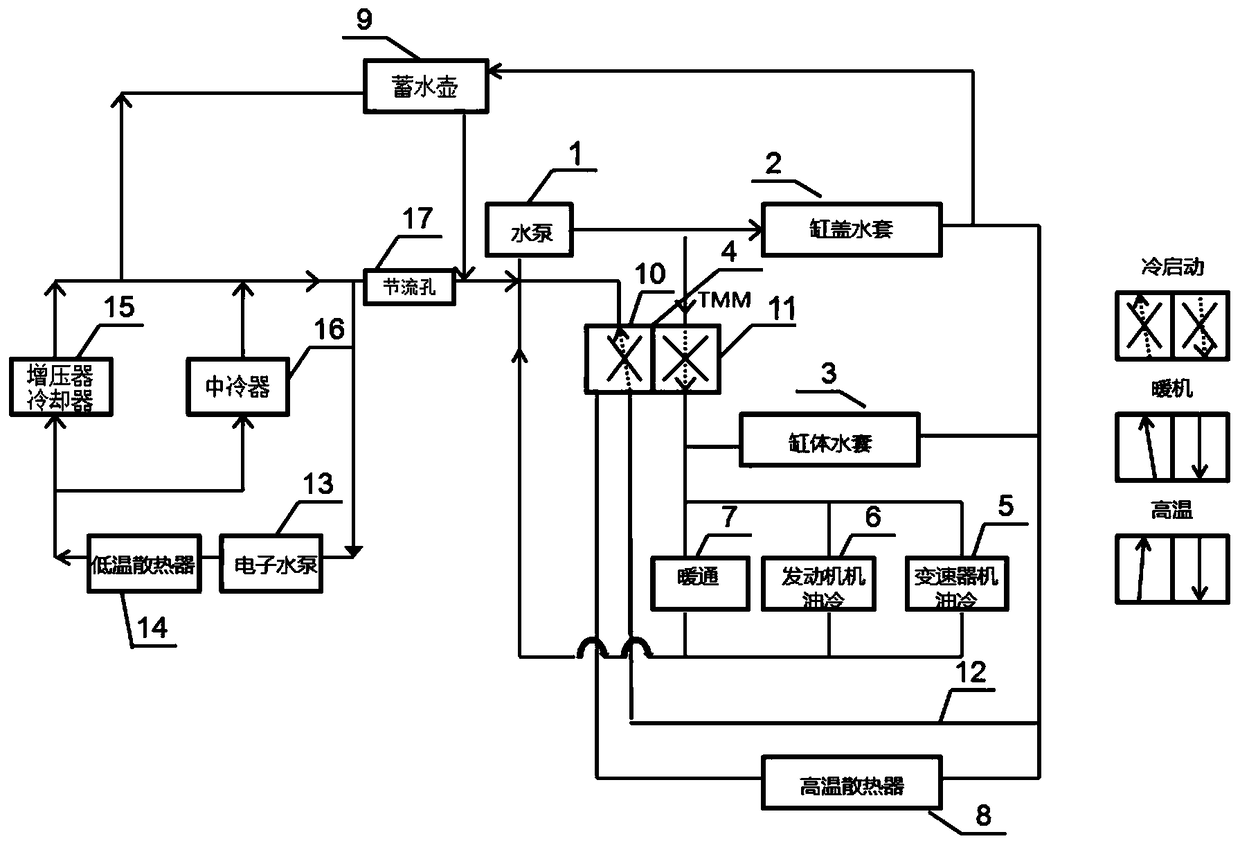

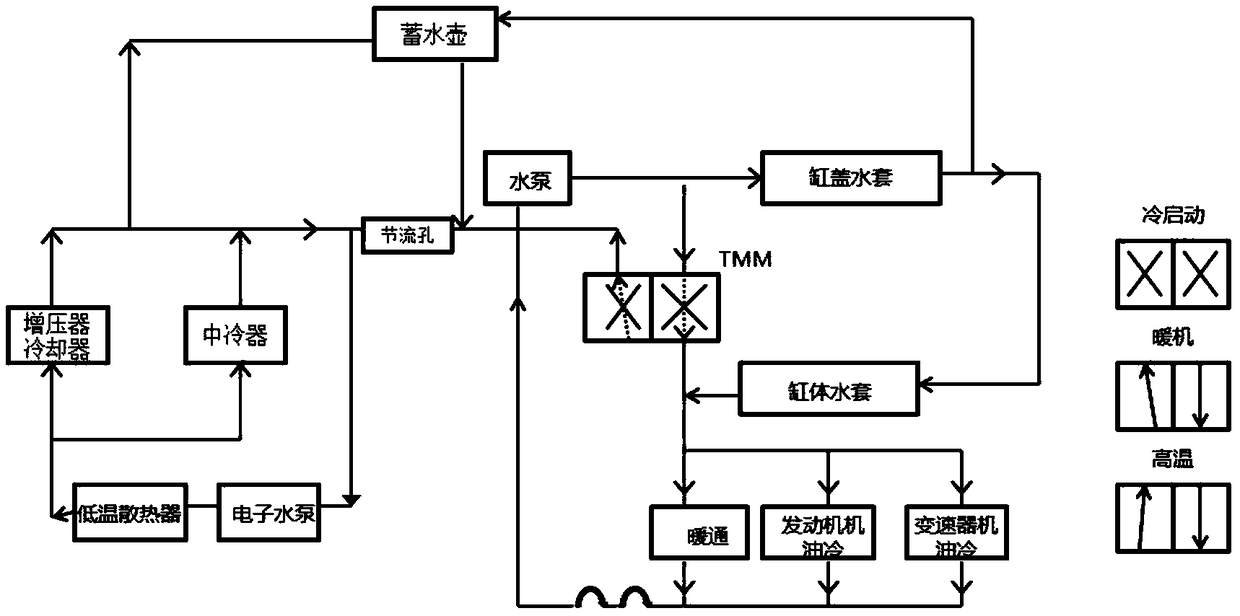

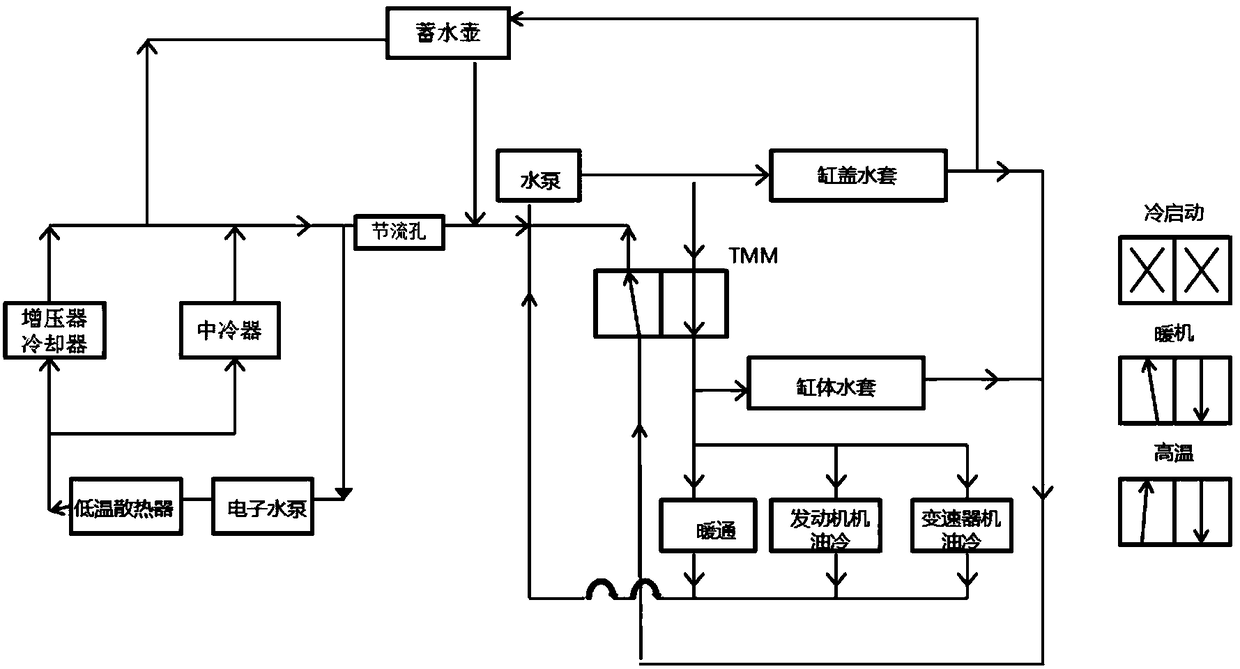

Engine cooling system

ActiveCN106948915AReduce fuel consumptionIncrease temperatureLiquid coolingCoolant flow controlExpansion tankThermodynamics

The invention relates to an engine cooling system. The engine cooling system comprises a high-temperature circulation cooling system and a low-temperature circulation cooling system. The high-temperature circulation cooling system is provided with a large cycle cooling liquid flow path, a small cycle cooling liquid flow path and a delay cycle cooling liquid flow path. In the large cycle and the small cycle, cooling liquid passes through a cylinder cover water jacket and then is diverted, one part of cooling liquid enters a cylinder water jacket, and the other part of cooling liquid enters warm air. Independent expansion water tanks are adopted in the high-temperature circulation cooling system and the low-temperature circulation cooling system. An electric control auxiliary water pump is additionally arranged for the high-temperature circulation cooling system, the delayed cycle is achieved, the cooling liquid is diverted into the cylinder water jacket and the warm air after passing through the cylinder cover water jacket, and the engine cooling system can better meet the heat supply requirement of various components after engine shutdown. The problem about the flowing direction of cooling circulation between different components is solved, and the engine knock probability can be reduced by arranging the independent expansion water tanks.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

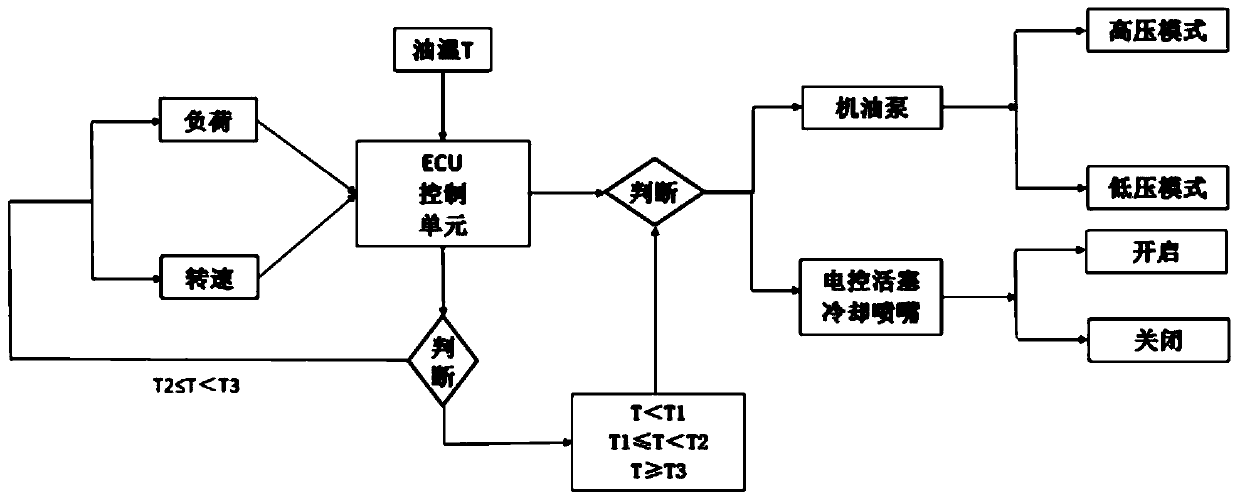

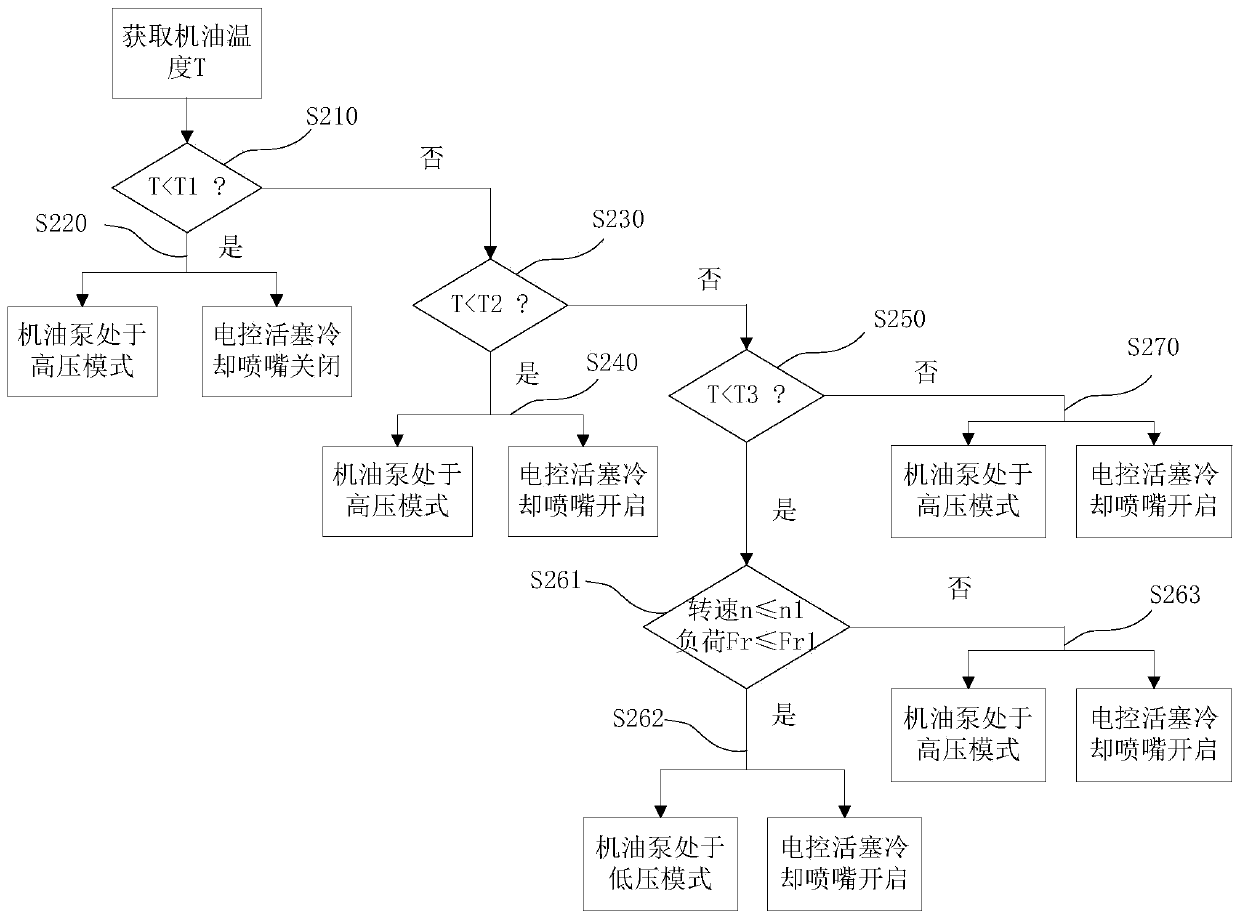

Oil thermal management control method and device in engine lubrication system

ActiveCN110359980AIncrease temperatureLow viscosityLiquid coolingCoolant flow controlEngineeringOil viscosity

The invention discloses an oil thermal management control method in an engine lubrication system. The control method comprises the steps of acquiring the oil temperature in a main oil duct of an engine; judging whether the oil temperature is lower than a first temperature threshold or not; controlling a variable displacement oil pump to work according to the high pressure mode if yes, and closingan electric control piston cooling nozzle; judging whether the oil temperature is lower than a second temperature threshold or not if not; controlling the variable displacement oil pump to work according to the high pressure mode if the oil temperature is no lower than the first temperature threshold and is lower than the second temperature threshold; and opening the electric control piston cooling nozzle. According to the oil thermal management control method, the variable displacement oil pump is combined with the electric control piston cooling nozzle effectively, and segmental control is performed according to the oil temperature; meanwhile, the high and low pressure modes of the variable displacement oil pump and the opening and closing of the electric control piston cooling nozzle are controlled; quick oil temperature rise is achieved, and the oil viscosity is reduced so that the oil consumption is reduced; and meanwhile, the situation that the piston temperature is too low and consequently the displacement is increased is avoided. The invention further discloses a device.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Engine cooling system

InactiveCN109139219ALarge water flowQuick warm upLiquid coolingCoolant flow controlTemperature conditioningWater flow

The invention provides an engine cooling system. The engine cooling system comprises an engine cylinder body, a cylinder body water sleeve, a cylinder cover water sleeve, a temperature conditioning device, a heating and ventilating device, an engine oil cooler and a water storing kettle. According to the engine cooling system, a switch is controlled based on the selection of the temperature conditioner, and the flowing direction of cooling water can be switched based on the load of an engine, so that rapid machine heating and oil consumption reducing can be realized; the cylinder cover water sleeve and the cylinder body water sleeve are connected in series in the engine cold starting stage, and the cooling water can be heated twice in one circulation, so that the temperature increasing speed of the cooling water is maximized; in addition, the oil cooler performs heat exchanging, so that the temperature of engine oil can be rapidly increased, the frictional power of the engine is reduced, and the oil consumption and emission can be reduced; the cylinder cover water sleeve and the cylinder body water sleeve are connected in parallel in the high-temperature engine heating and high-temperature stages, the water flow rate of the engine is increased to the maximum, and the water flow rate of the cylinder body and the cylinder cover can be controlled, so that the cylinder body and thecylinder cover can reach the optimal temperature, and as a result, engine knocking can be reduced, and the oil consumption can be decreased.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Split type cooling system and method for engine

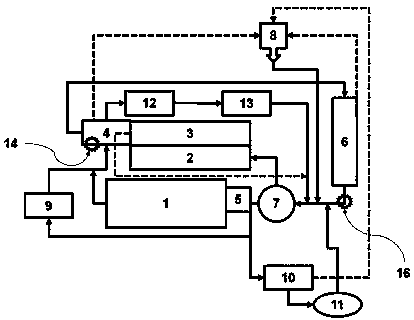

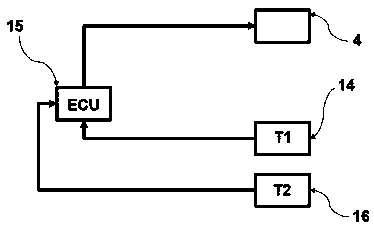

ActiveCN111396186AExtend the scope of controlPrecise temperature controlLiquid coolingCoolant flow controlThermostatCylinder block

The invention provides a split type cooling system and method for an engine. The system comprises a cylinder body water jacket, a cylinder cover lower water jacket and a cylinder cover upper water jacket which are arranged around an engine cylinder body. The cylinder cover lower water jacket of the engine is connected with the cylinder cover upper water jacket in series. The cylinder body water jacket is connected with the cylinder cover lower water jacket and the cylinder cover upper water jacket in parallel after the cylinder cover lower water jacket and the cylinder cover upper water jacketare connected in series. Cooling liquid passes through a water pump, then flows into the cylinder cover upper water jacket through the cylinder cover lower water jacket and is mixed with cooling liquid of the cylinder body water jacket and cooling liquid of an engine oil cooler in an electronic thermostat installation cavity, and then the mixture is redistributed. A first temperature sensor is arranged on an electronic thermostat. A radiator is connected with the water pump. A second temperature sensor is arranged at a radiator cooling liquid outlet. According to the split type cooling systemand method for the engine, the consumed power of an electronic fan is effectively reduced, so that power consumption of the engine is reduced, and the fuel economy is improved.

Owner:KUNMING YUNNEI POWER +1

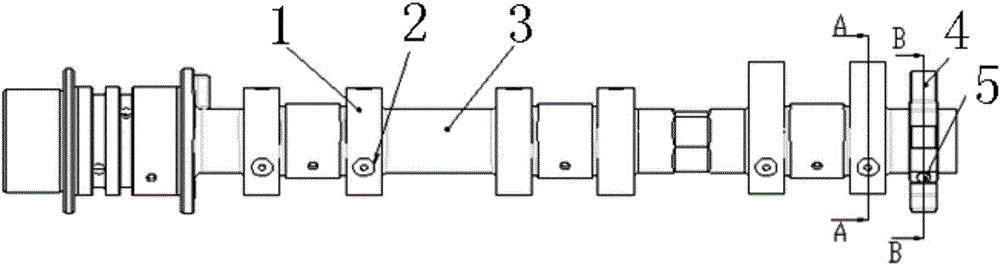

Combined type hollow camshaft and machining process thereof

ActiveCN106837453AReasonable designReduce design and development costsCamsValve arrangementsEngineeringCam

The invention discloses a combined type hollow camshaft. The combined type hollow camshaft comprises a camshaft body, a combined type cam and a signal wheel, wherein the combined type cam and the signal wheel are arranged on the camshaft body. The combined type cam and the signal wheel are provided with assembly holes used for being formed in the camshaft body. The camshaft body is fixedly connected with a cam base circle part of the combined type cam and a tooth missing part of the signal wheel through pin structures. A machining process comprises the following steps that the hollow camshaft body is cast; a blind hole is machined in a corresponding shaft neck of a fastening cam on the camshaft body, a step hole corresponding to the blind hole in the camshaft body is machined in the combined type cam, and a cam rivet is pressed into the corresponding holes in the combined type cam and the camshaft body; a fixed hole is machined in the tooth missing part of the signal wheel, and a blind hole corresponding to the fixed hole is machined in the camshaft body; and a conical pin is pressed into the fixed hole of the signal wheel and the blind hole corresponding to the fixed hole. The machining process difficulty and cost are reduced.

Owner:CHERY AUTOMOBILE CO LTD

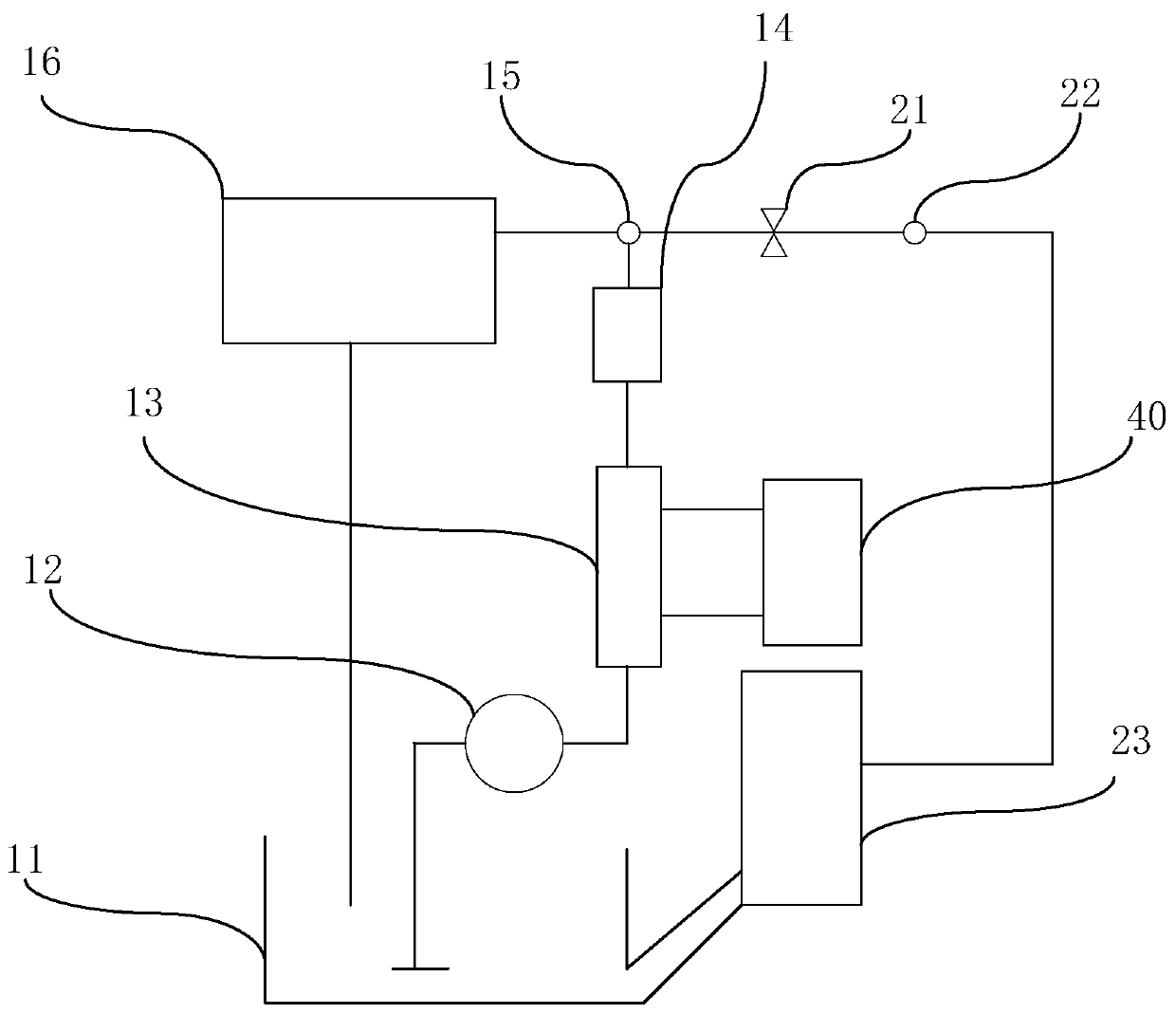

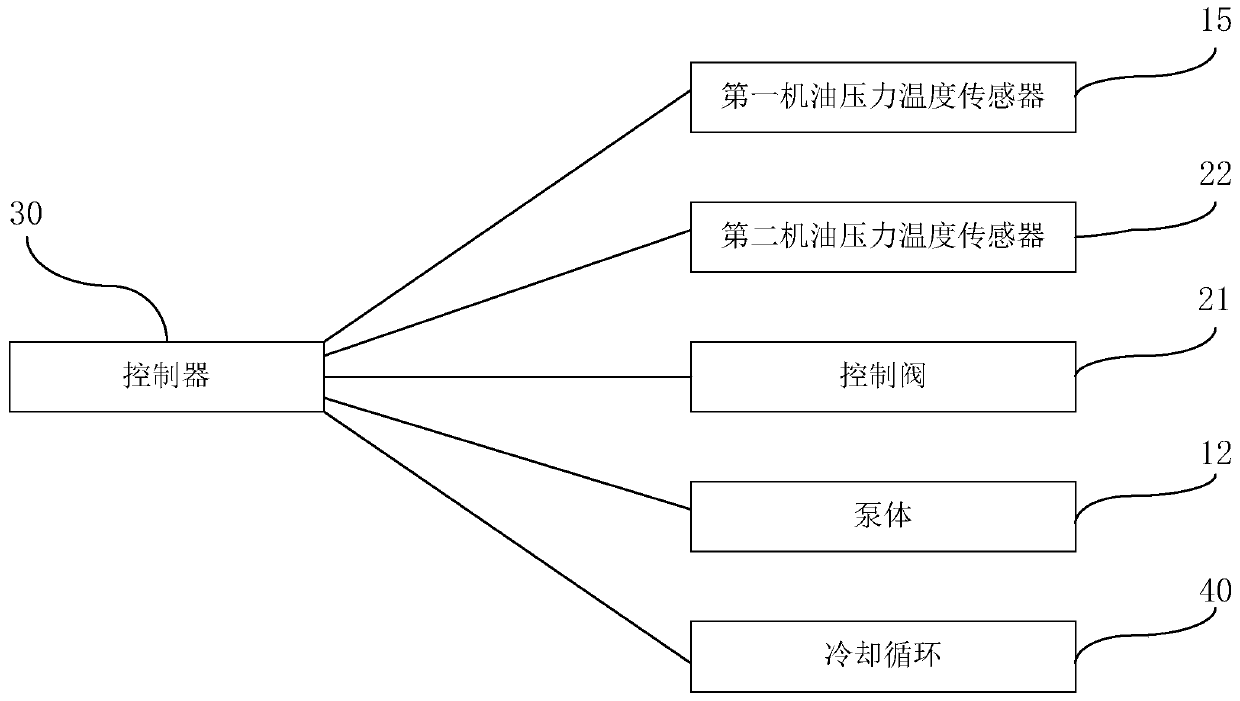

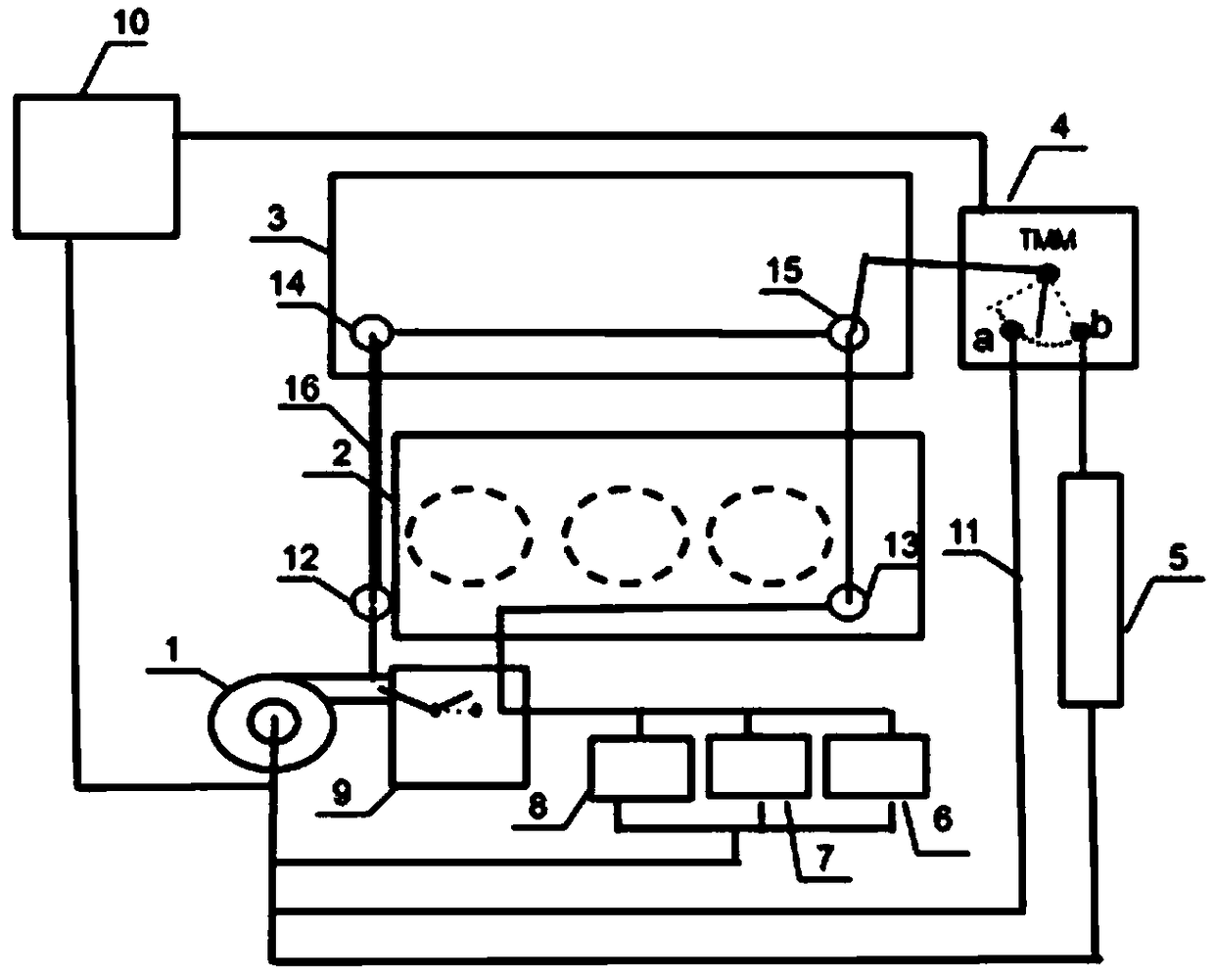

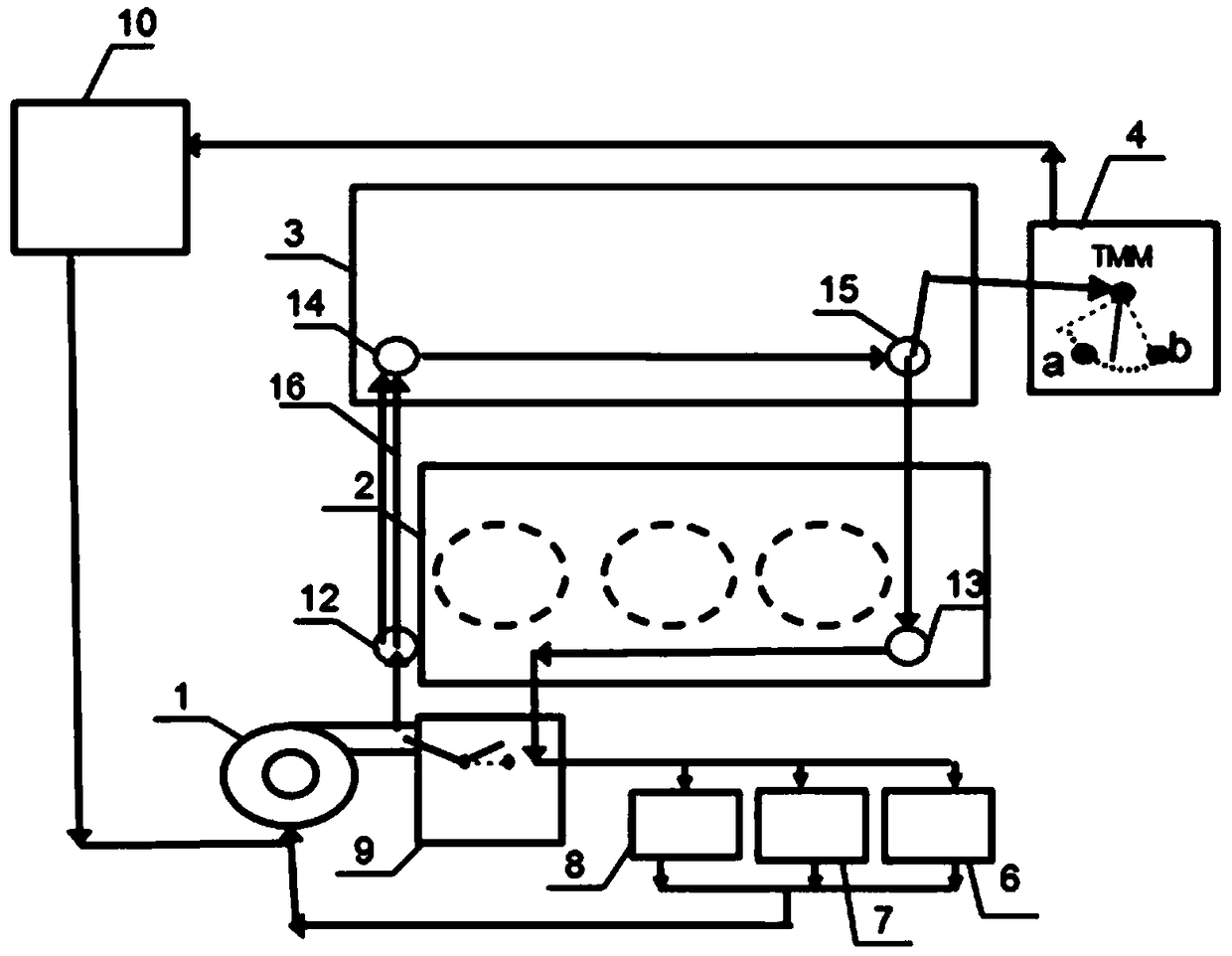

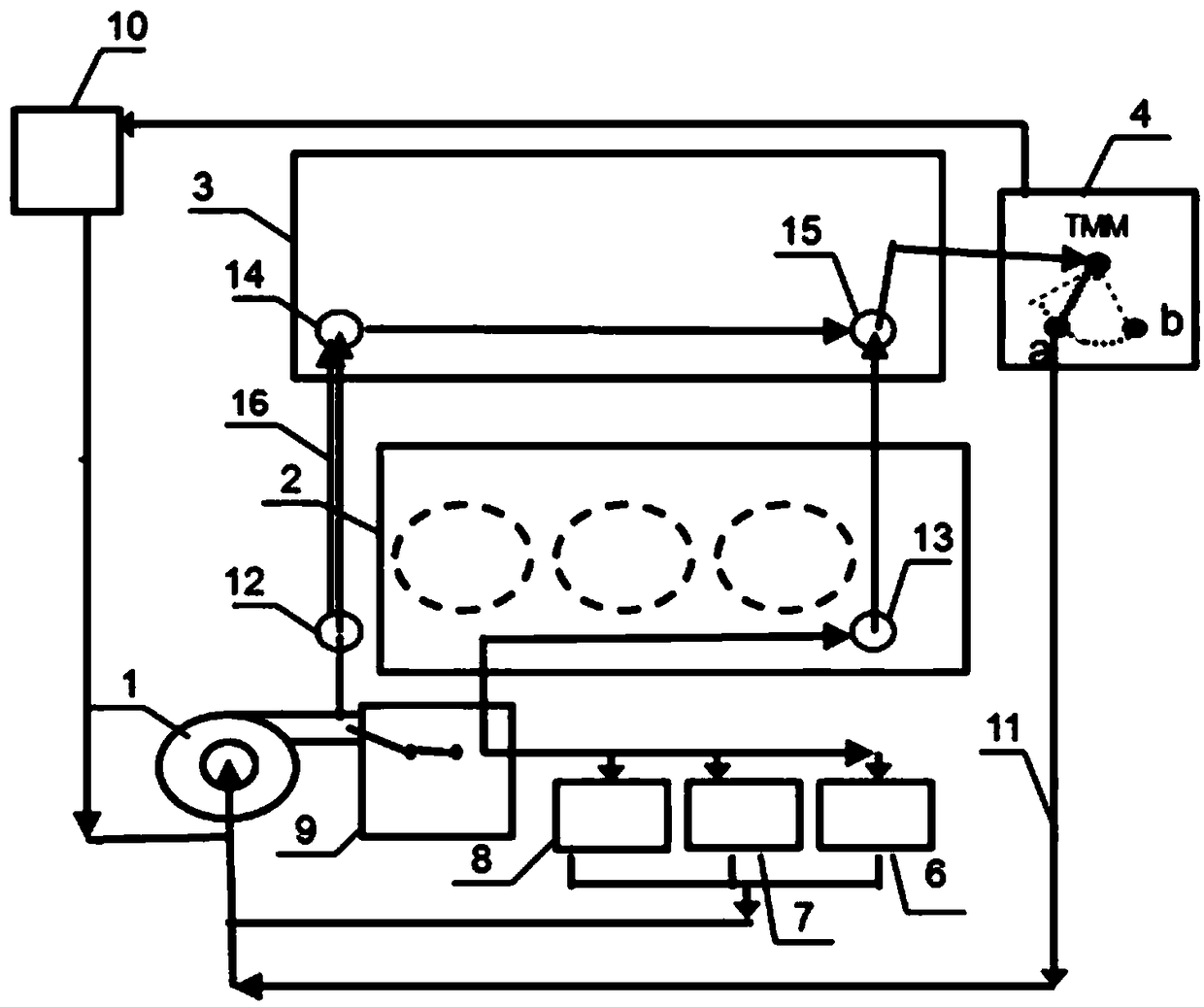

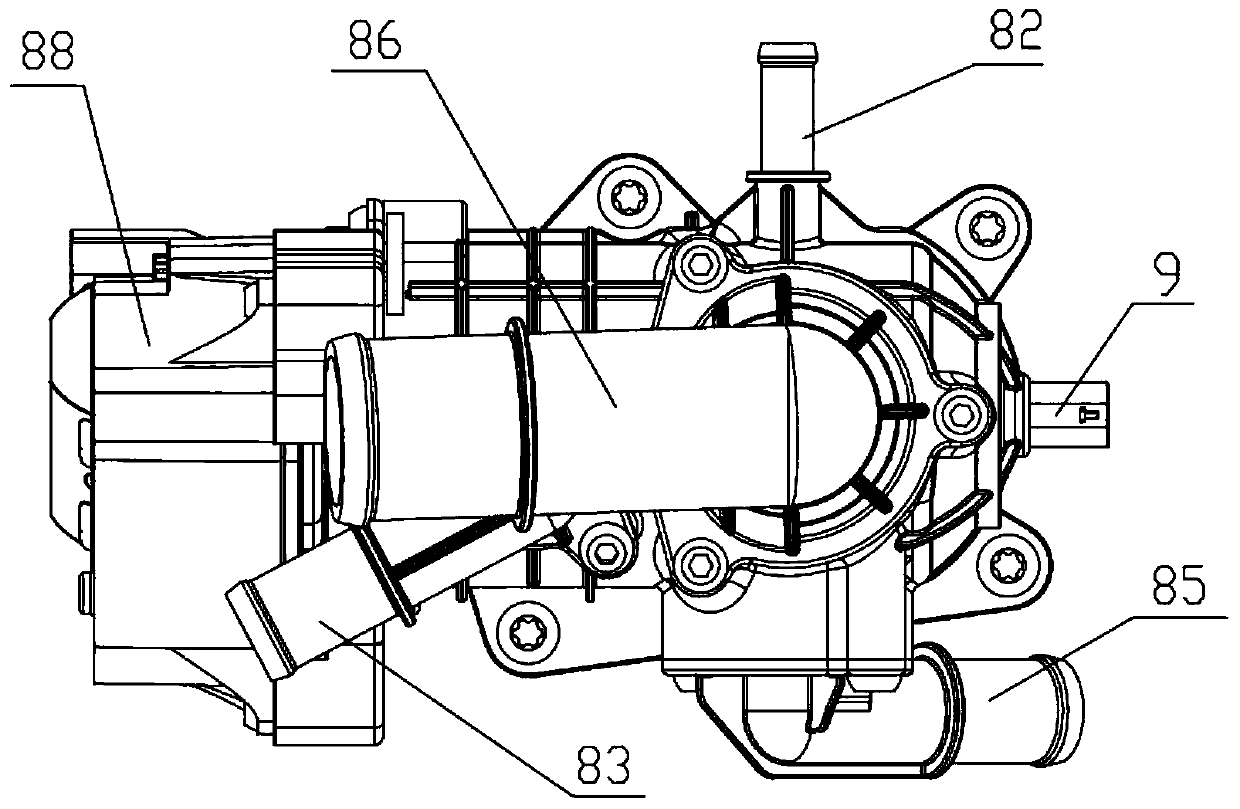

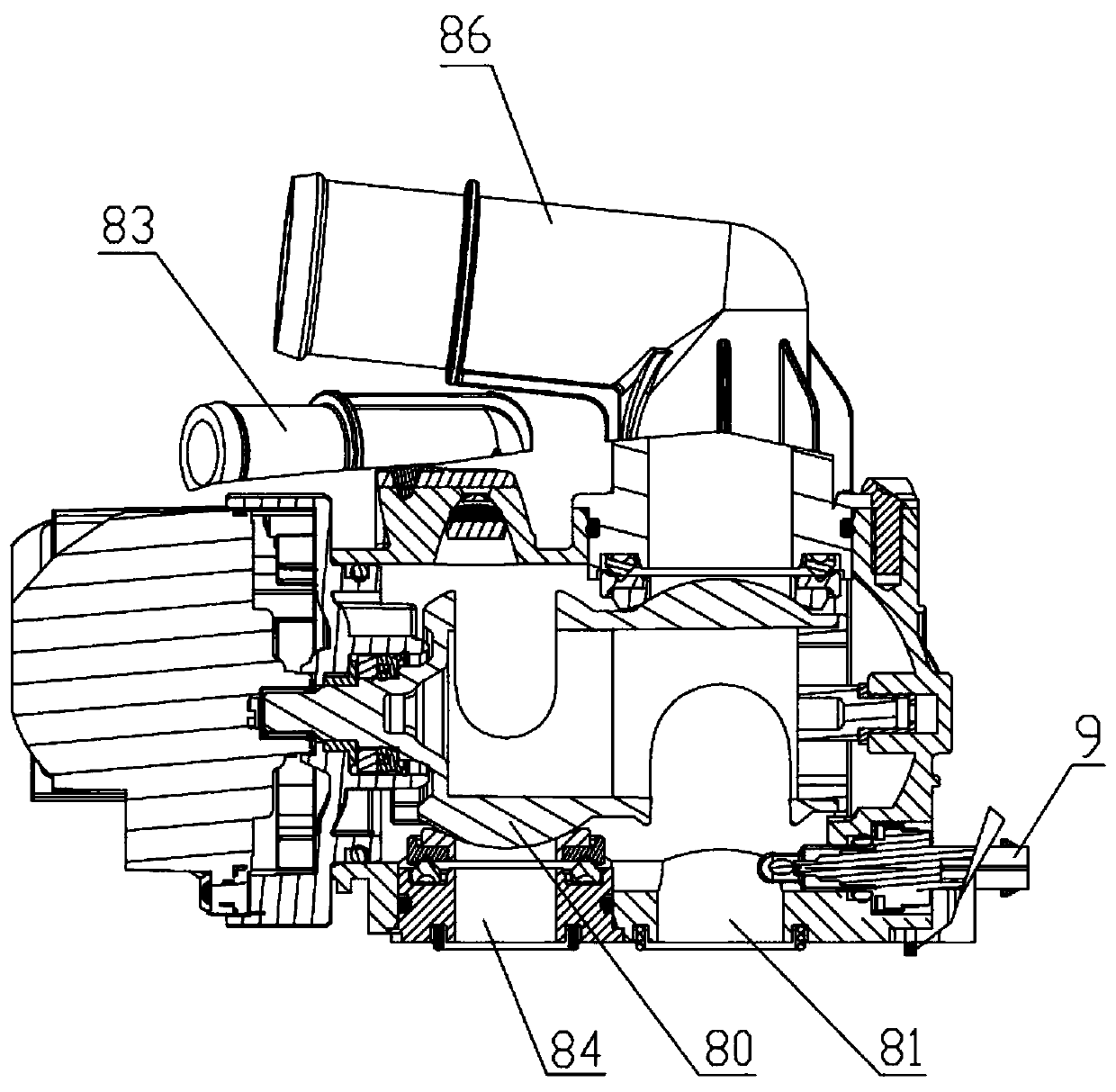

Extended-range lubrication management system, lubrication management method and vehicle

ActiveCN111042891ALow costReduce friction workMachines/enginesPressure lubrication with lubrication pumpElectric machineryAutomotive engineering

The invention discloses an extended-range lubrication management system, a lubrication management method and a vehicle. The extended-range lubrication management system comprises an engine lubricationsystem, an oil-cooled motor module and a controller, and the engine lubricating system and the motor module share an oil pan, a pump body, an engine oil cooler and an engine oil filter element. A control valve is further arranged in the oil-cooled motor module, the controller is electrically connected with the control valve, and the controller controls the opening degree of the control valve, sothat oil selectively and only enters the engine lubricating system or enters the engine lubricating system and the oil cooling motor module at the same time. Compared with the prior art, the extended-range lubrication management system has the advantages that the frictional work of the oil-cooled motor module can be reduced, the number of parts is reduced, the integration level is improved, and the cost is reduced.

Owner:NINGBO GEELY ROYAL ENGINE COMPONENTS +1

Cooling system capable of improving engine warming-up speed and lowering oil consumption

ActiveCN109057942AHeating up fastLarge water flowCoolant flow controlMachines/enginesThermostatEngineering

The invention providing a cooling system capable of improving the engine warming-up speed and lowering the oil consumption. The cooling system comprises an engine water pump, an engine cylinder body,a cylinder body water jacket, a cylinder cover water jacket, a thermostat, HVAC, a radiator, an engine oil cooler, a water storage pot and an electromagnetic valve. The cooling system can be controlled to start and stop through the choices of the electromagnetic valve and the thermostat, the flow directions of cooling water can be switched according to the load of an engine, the rapid engine warming-up process can be achieved, and the oil consumption can be lowered; in the engine cold-start stage, the cylinder cover water jacket and the cylinder body water jacket can be kept in a series connection structure, the cooling water can be heated twice during one cycle, the temperature rise of the cooling water can be accelerated to the greatest extent, the heat exchange process can be performedthrough the engine oil cooler, the rapid temperature rise of engine oil can be achieved, the friction work of the engine can be reduced, and the oil consumption and emissions can be lowered; and in the relatively-high-temperature engine warming-up stage and the high-temperature stage, the cylinder cover water jacket and the cylinder body water jacket can be kept in a series connection structure, the water flow rate of the engine can be increased to the greatest extent, the water flow rate of a cylinder body and that of a cylinder cover can be controlled respectively, both the optimum temperature of the cylinder body and that of the cylinder cover can be reached, the knocking phenomenon can be reduced, and the oil consumption can be lowered.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

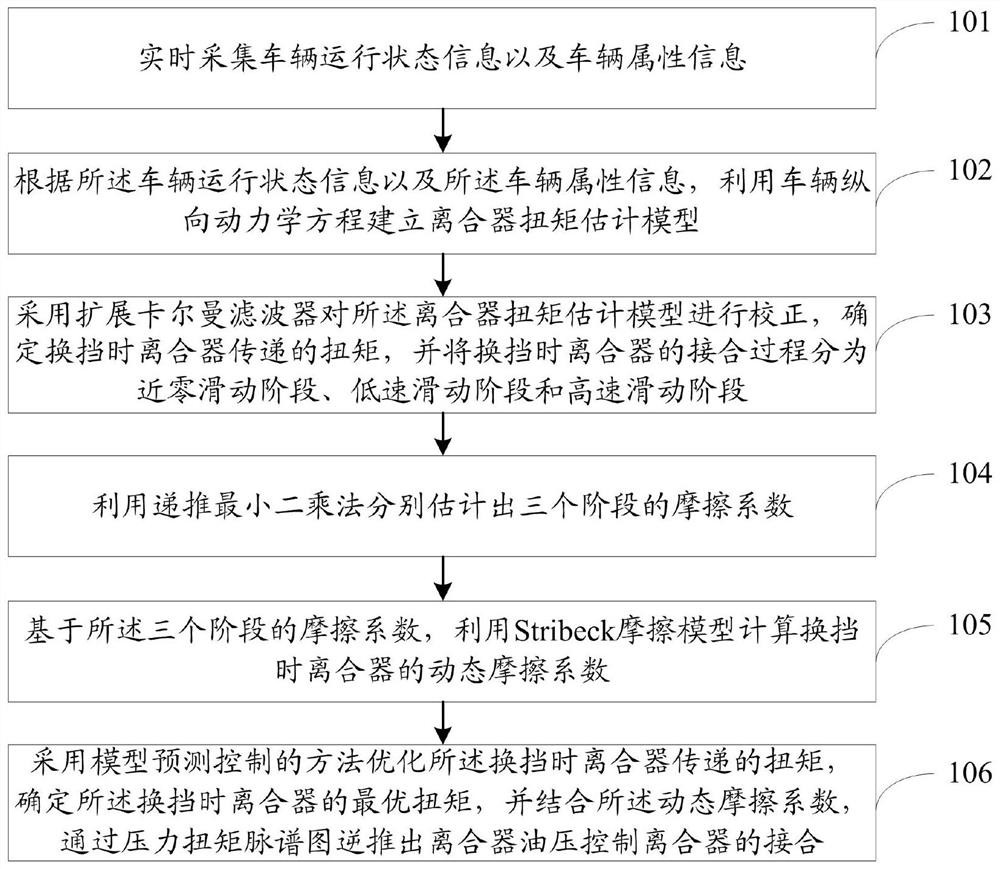

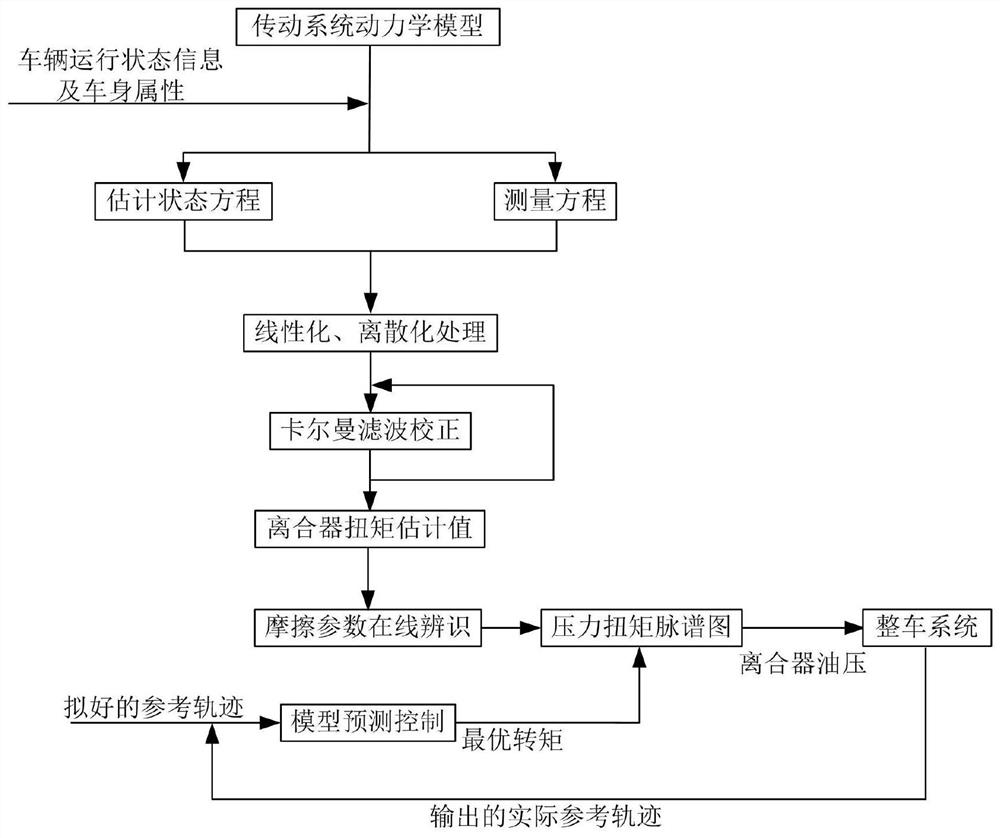

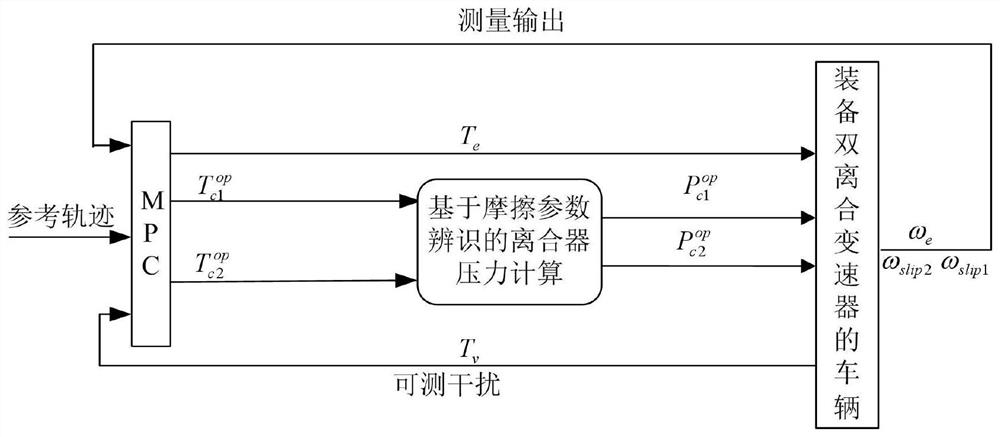

Wet-type double-clutch gear shifting control method and system

ActiveCN112417592AExtended service lifeImproved shift qualityGeometric CADSustainable transportationLeast squaresOil pressure

The invention relates to a wet-type double-clutch gear shifting control method and system. The control method comprises the steps of collecting vehicle running state information and vehicle attributeinformation in real time; establishing a clutch torque estimation model by using a vehicle longitudinal kinetic equation; correcting the clutch torque estimation model by adopting an extended Kalman filter, determining the torque transmitted by the clutch during gear shifting, and dividing the engagement process of the clutch during gear shifting into three stages; respectively estimating frictioncoefficients of the three stages by using a recursive least square method; calculating the dynamic friction coefficient of the clutch during gear shifting by using a Seebeck friction model; optimizing the torque transmitted by the clutch during gear shifting by adopting a model prediction control method, determining the optimal torque of the clutch during gear shifting, and controlling the engagement of the clutch by reversely deducing the clutch oil pressure through a pressure torque pulse spectrogram in combination with the dynamic friction coefficient. The gear shifting quality of the clutch can be rapidly improved through the control method without changing the structure of the transmission.

Owner:NINGXIA UNIVERSITY

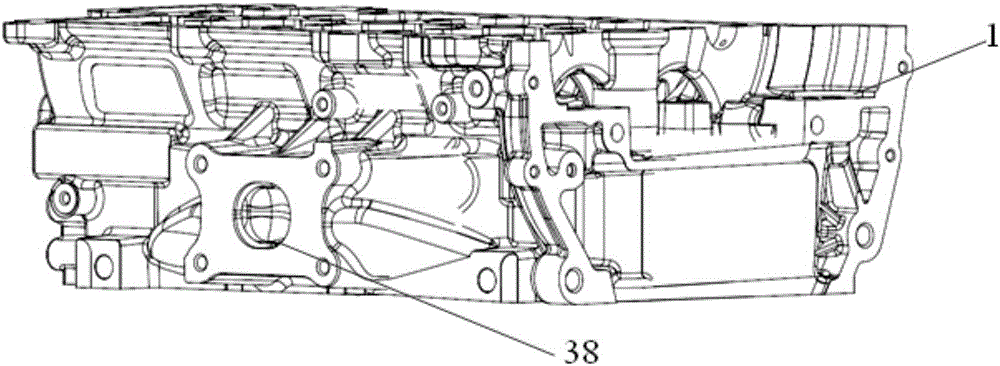

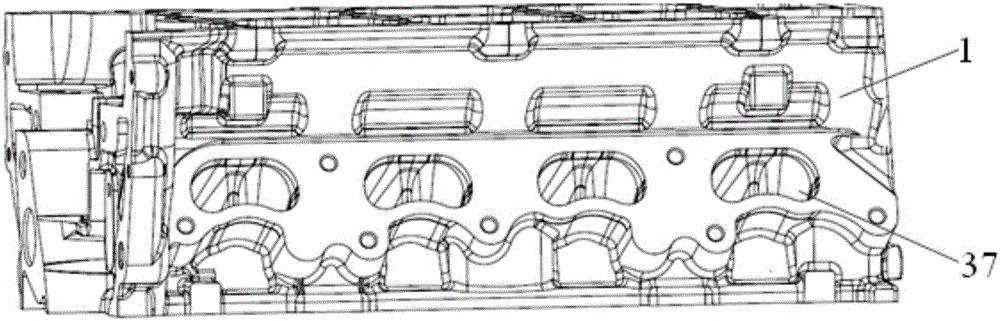

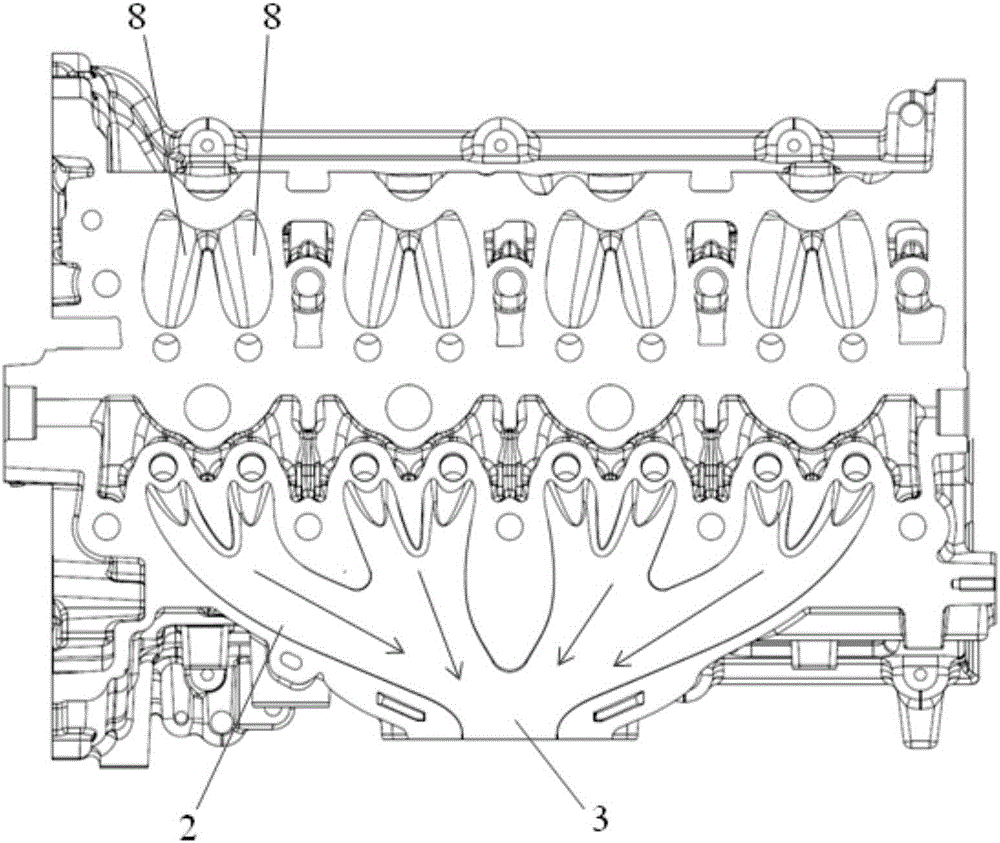

Air cylinder cover of automobile engine

InactiveCN106224079AIncrease temperaturePromote combustionCylinder headsCombustion enginesParticulatesCombustion chamber

The invention discloses an air cylinder cover of an automobile engine. The air cylinder cover comprises air inlet channels, exhaust channels, an exhaust manifold, a water jacket and a combustion chamber. The air inlet channels and the exhaust channels are connected with the combustion chamber. A combustion chamber step structure is arranged in the combustion chamber, and combustion chamber steps are arranged at the positions, facing the upper portion of the combustion chamber, of seat ring holes. According to the technical scheme, the air inlet channels and the combustion chamber are optimized, and therefore the low-speed tumble ratio is increased, in-cylinder combustion is improved, and the wall wetting condition is reduced to the largest degree; oil consumption is reduced, and particle emissions are reduced; branches of the exhaust channels of all cylinders are slightly lengthened and are finally gathered to a general branch, and an assembly type exhaust manifold is omitted; the exhaust manifold is integrated on a cylinder cover body, exhaust heat is fully utilized, the temperature of the engine is increased fast, and driving and taking comfort is improved; the complete engine frictional work is reduced, and therefore oil consumption of the complete engine is reduced; and by means of the water jacket structure, the water flow manner is adjusted, the temperature field of the cylinder cover body and the part integrated with the exhaust manifold is improved, and the cylinder cover body and the exhaust integration structure are fully cooled.

Owner:CHERY AUTOMOBILE CO LTD

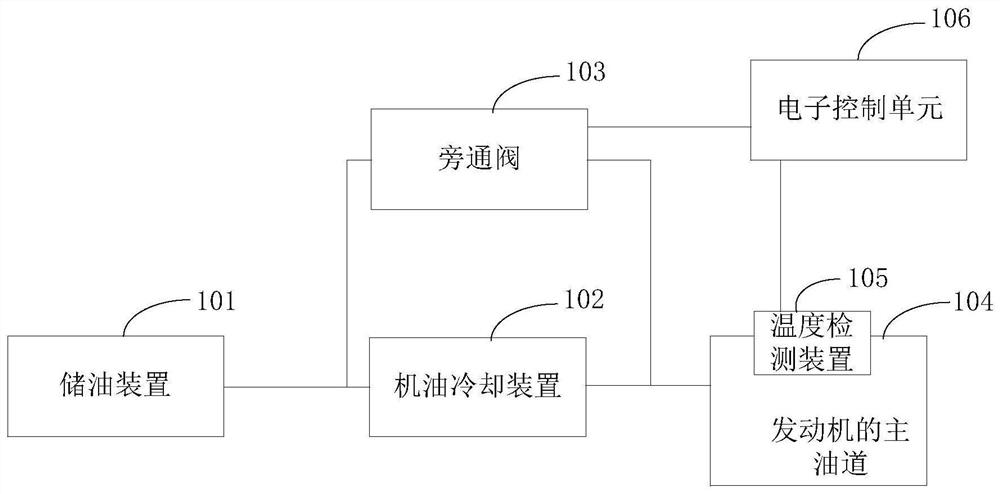

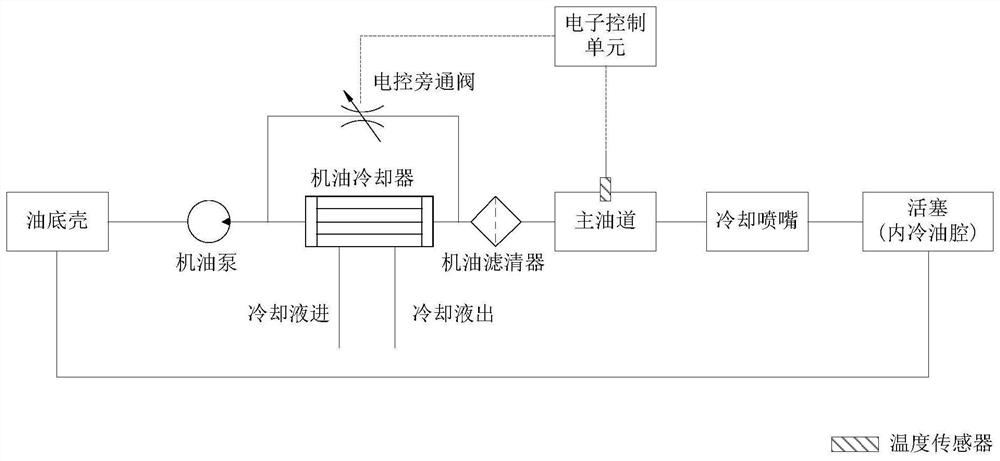

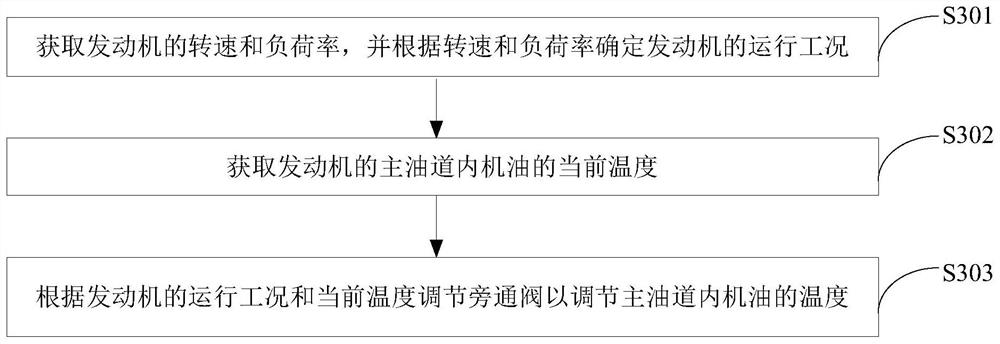

Temperature adjusting method, device and system and electronic control unit

ActiveCN112031890AImprove reliabilityReduce friction workMachines/enginesLubrication temperature controlControl theoryOil temperature

Embodiments of the invention provide a temperature adjusting method, device and system and an electronic control unit. The method comprises the steps that the rotating speed and load rate of an engineare obtained, and the operation condition of the engine is determined according to the rotating speed and load rate; a current temperature of engine oil in a main oil duct of the engine is obtained;a bypass valve is adjusted according to the operation condition of the engine and the current temperature to adjust the temperature of engine oil in the main oil duct, adjustment of the temperature ofthe engine oil in the main oil duct is achieved, the temperature of the engine oil in the main oil duct is matched with the operation condition, that is, the temperature of the engine oil in the mainoil duct is proper and not too high or too low, and accurate adjustment of the temperature of the engine oil in the main oil duct is achieved, so that the reliability of the engine is improved, the friction work of the engine is reduced, and the fuel economy is improved.

Owner:WEICHAI POWER CO LTD

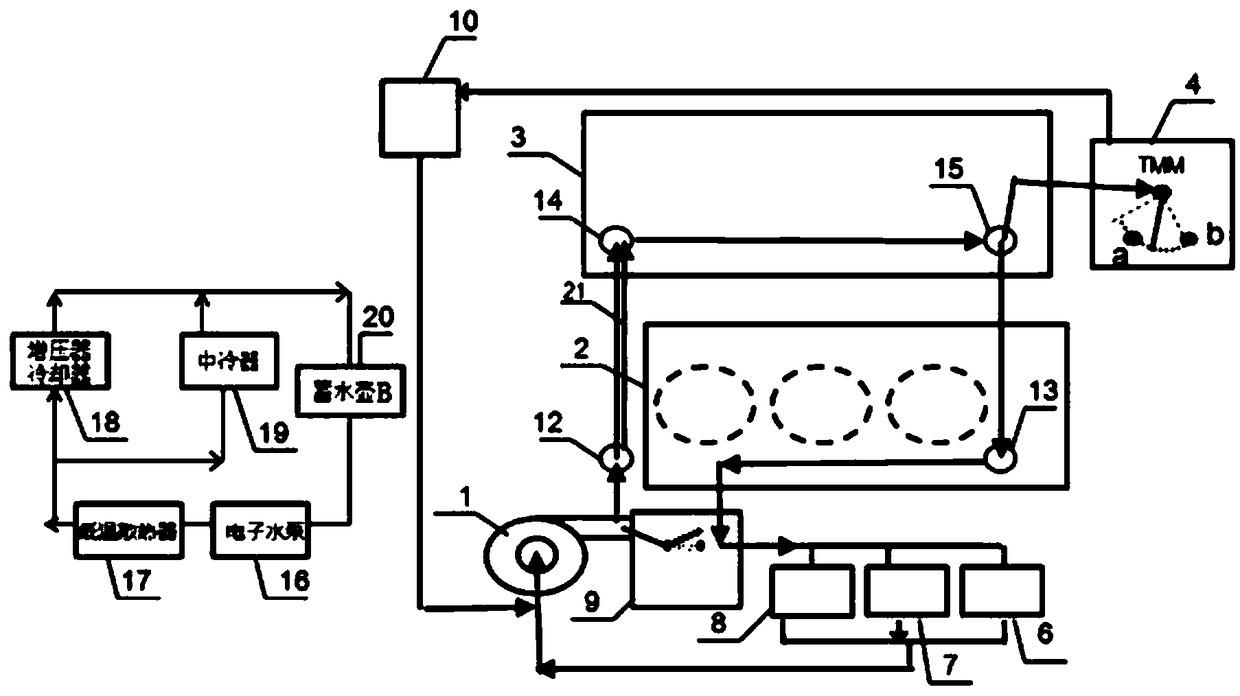

Engine dual-cycle cooling system

InactiveCN109139224ALarge water flowIncrease water flowCoolant flow controlMachines/enginesWater storageCooling effect

The invention discloses an engine dual-cycle cooling system. The engine dual-cycle cooling system comprises high-temperature and low-temperature water circulating cooling systems. The high-temperaturesystem is controlled to open or close through selection of a temperature adjuster to switch the flowing direction of cooling water according to engine loads so as to realize quick machine warming andreduction of the oil consumption. A cylinder cover and a cylinder block water jacket are maintained in serial connection in the cold starting phase of an engine, so that twice heating is performed inone cycle of the cooling water to accelerate heating of the cooling water to the greatest extent. In the machine warming and high-temperature phase with higher engine temperature, the cylinder coverand the cylinder block water jacket are maintained in parallel connection to increase the water flow of the engine to the greatest extent; and respective water flows of a cylinder block and the cylinder cover can be controlled to achieve optimal temperature so as to reduce the knocking and the oil consumption. The low-temperature system adopts an electronic water pump and a common water storage kettle; and a throttling hole is formed between the water storage kettle and the low-temperature system, so that the arrangement space and cost are reduced, the influence on the low-temperature system by the high-temperature system is reduced, the cooling effect is guaranteed, the intake temperature and the intake efficiency of the engine are effectively guaranteed, the dynamic property of the engine is exerted, and the knocking is prevented.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Heat management system of hybrid vehicle and hybrid vehicle

ActiveCN110281763AReduce viscosityReduce friction workElectric propulsion mountingPropulsion coolingHeat managementWater circulation

The invention provides a heat management system of a hybrid vehicle and the hybrid vehicle. The heat management system of the hybrid vehicle comprises an engine water circulation system, a motor transmission module oil cooling circulation system and a motor cooling circulation system, wherein the engine water circulation system is used for absorbing heat generated by an engine of the vehicle; the motor transmission module oil cooling circulation system communicates with the engine water circulation system to heat an oil liquid in the motor transmission module oil cooling circulation system by using the engine water circulation system; the motor cooling circulation system communicates with the motor transmission module oil cooling circulation system; and the motor cooling circulation system is used for controlling the value of the temperature of the oil liquid in the motor transmission module oil cooling circulation system. According to the heat management system of the hybrid vehicle, by using the engine water circulation system to heat the oil liquid in the motor transmission module oil cooling circulation system, the temperature of the oil liquid is increased, the viscosity of the oil liquid is reduced, and the friction power of the motor transmission module oil cooling circulation system is reduced, and therefore, the oil consumption of the whole vehicle is reduced.

Owner:NINGBO GEELY ROYAL ENGINE COMPONENTS +1

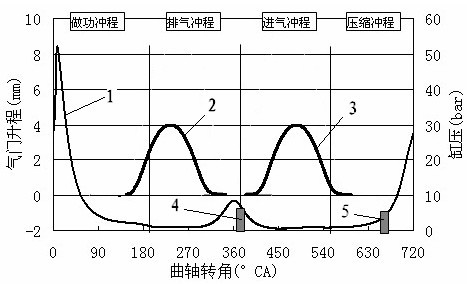

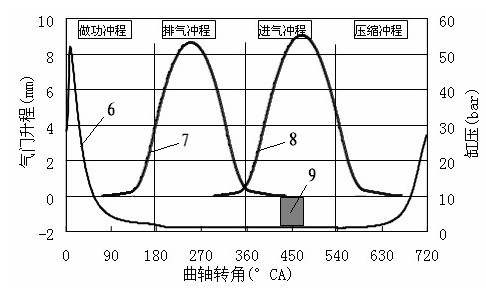

In-cylinder direction injection gasoline engine and control method thereof

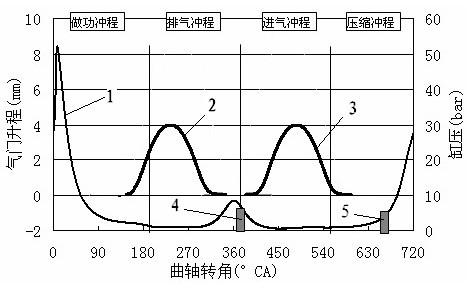

ActiveCN102322360AIncrease pressureAvoid Wet Wall PhenomenonElectrical controlInternal combustion piston enginesTop dead centerInjector

The invention provides an in-cylinder direction injection gasoline engine and a control method thereof so as to reduce the throttling loss, increase the combustion stability and reduce the oil consumption. As the in-cylinder direction injection gasoline engine of the invention is provided with two-stage type variable valve lift and variable valve timing, under a low load working condition, an electronic control unit controls an exhaust valve to be closed before a top dead center of an exhaust stroke and an intake valve to be closed in the first half of a suction stroke, therefore, a section of negative valve overlapping interval is formed nearby the top dead center of a compression stroke, a part of exhaust gas is remained in an air cylinder; the electronic control unit respectively controls a fuel injector to carry out the first injection in the minus 30-30 degree CA range of the top dead center of the air suction and the second injection in the compression stroke, therefore, the high remained waste gas in the cylinder can be used, the thermal efficiency is increased, and meanwhile the combustion stability is ensured; and under a high load working condition, the electronic control unit controls the intake valve and the exhaust valve to work under the big lift to carry out the normal fuel injection and phase control.

Owner:CHERY AUTOMOBILE CO LTD

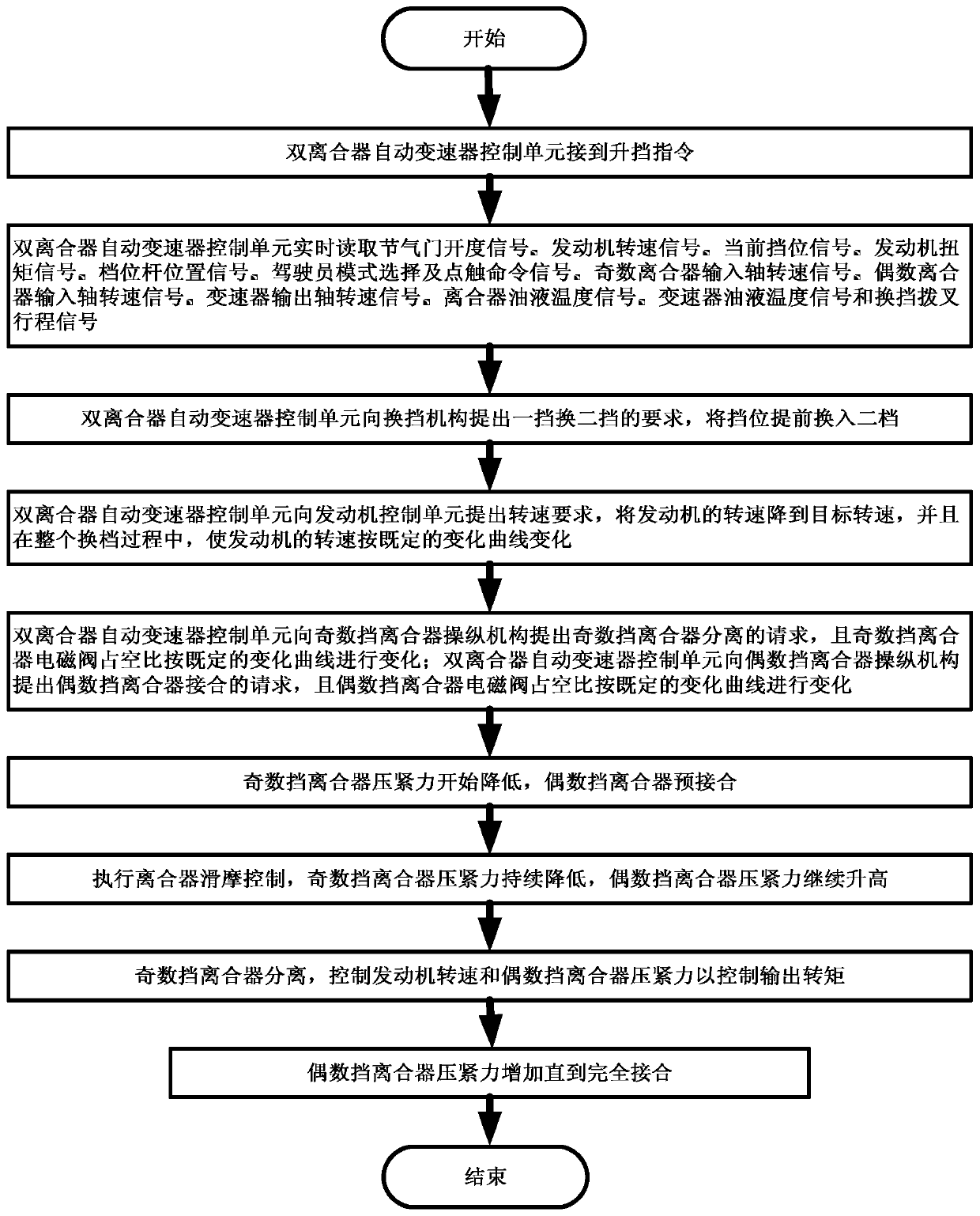

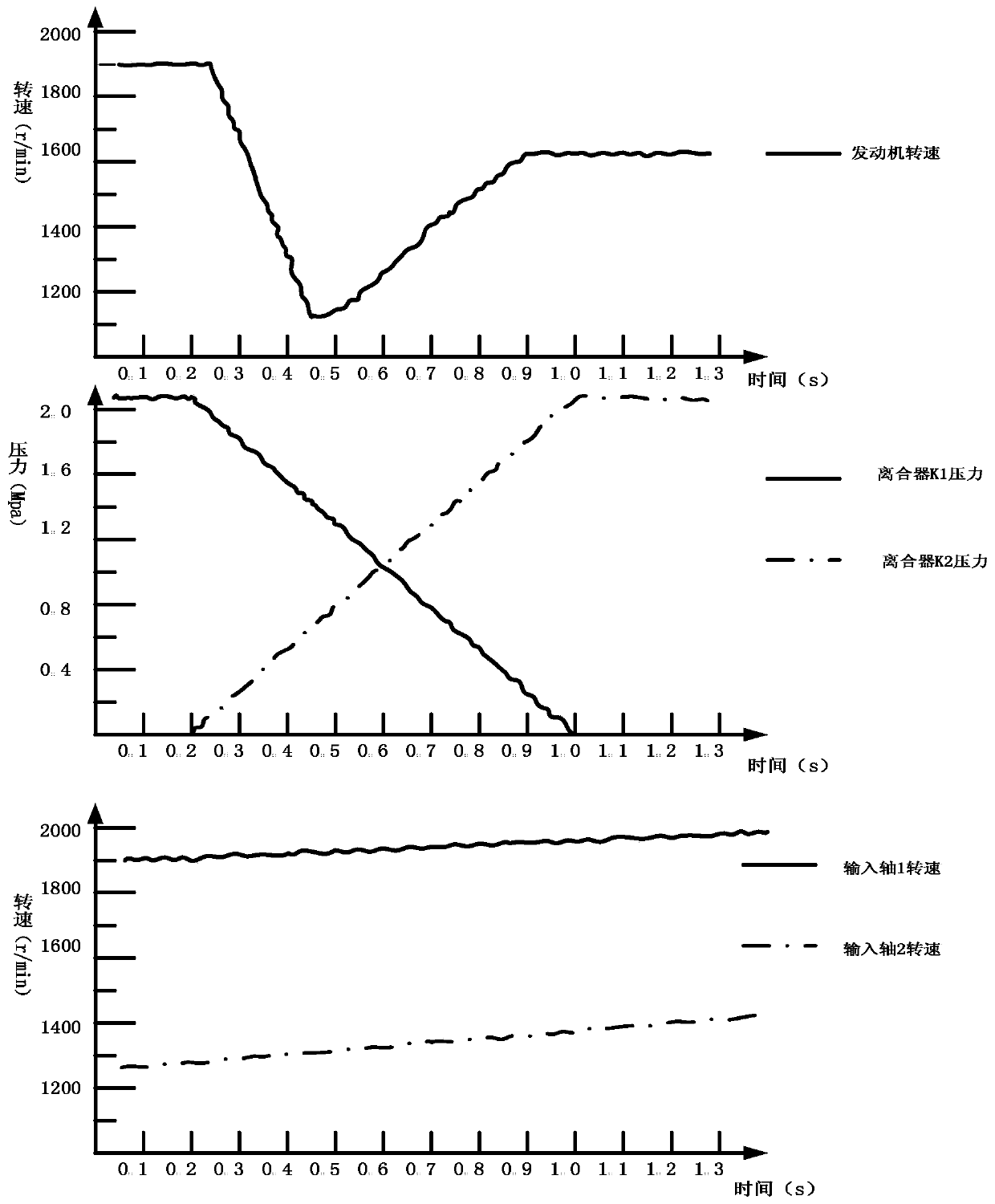

Double-clutch switching control method for vehicle double-clutch automatic transmission

InactiveCN110195779AReduce shockReduce friction workElectrical controlGearing controlClutch controlAutomatic transmission

The invention relates to the field of clutch control, in particular to a double-clutch switching control method for a vehicle double-clutch automatic transmission. A double-clutch automatic transmission gear shifting experiment platform is used, analysis and calculation are carried out according to theories, a gear shifting process of the double-clutch automatic transmission under various workingconditions with the optimal gear shifting quality is found, and changing curves on the rotating speed of an engine, the rotating speed of a first input shaft, the rotating speed of a second input shaft, the pressure of a first clutch and the pressure of a second clutch in the process are recorded; and by adjusting the duty ratio of electromagnetic valve engaging and separating through the clutchesin the double-clutch automatic transmission, the sum of the transmission torque of the two clutches of the front-sequence clutch and the rear-sequence clutch in the gear-shifting process is matched with the torque of the engine, the impact degree and the friction work in combination of the double clutches can be effectively reduced, the rapid smooth and safe switching between the double clutchescan be realized, and stable and safe power transmission can be completed.

Owner:HANTENG AUTOMOBILE CO LTD

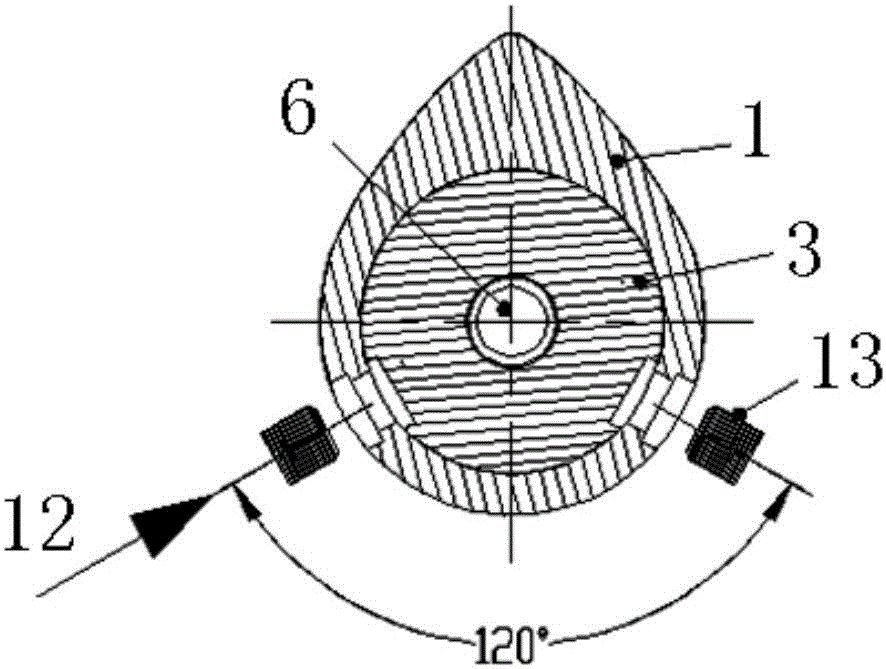

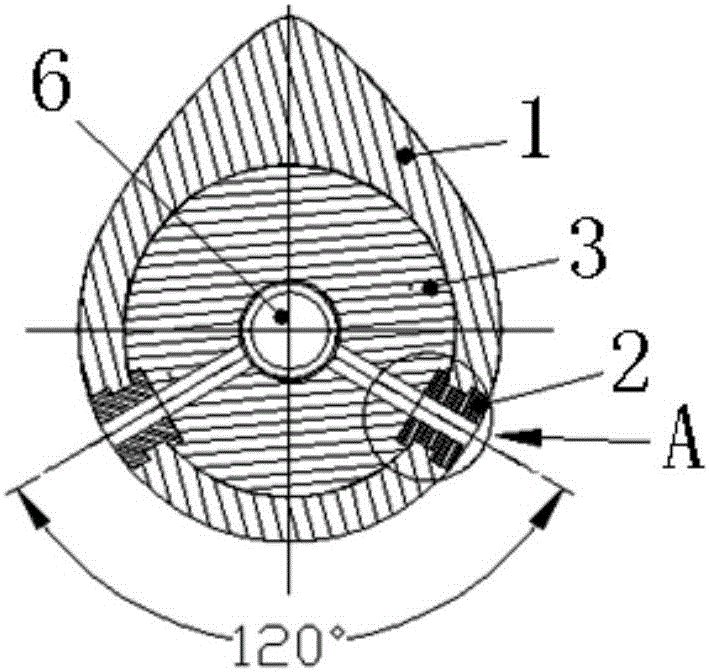

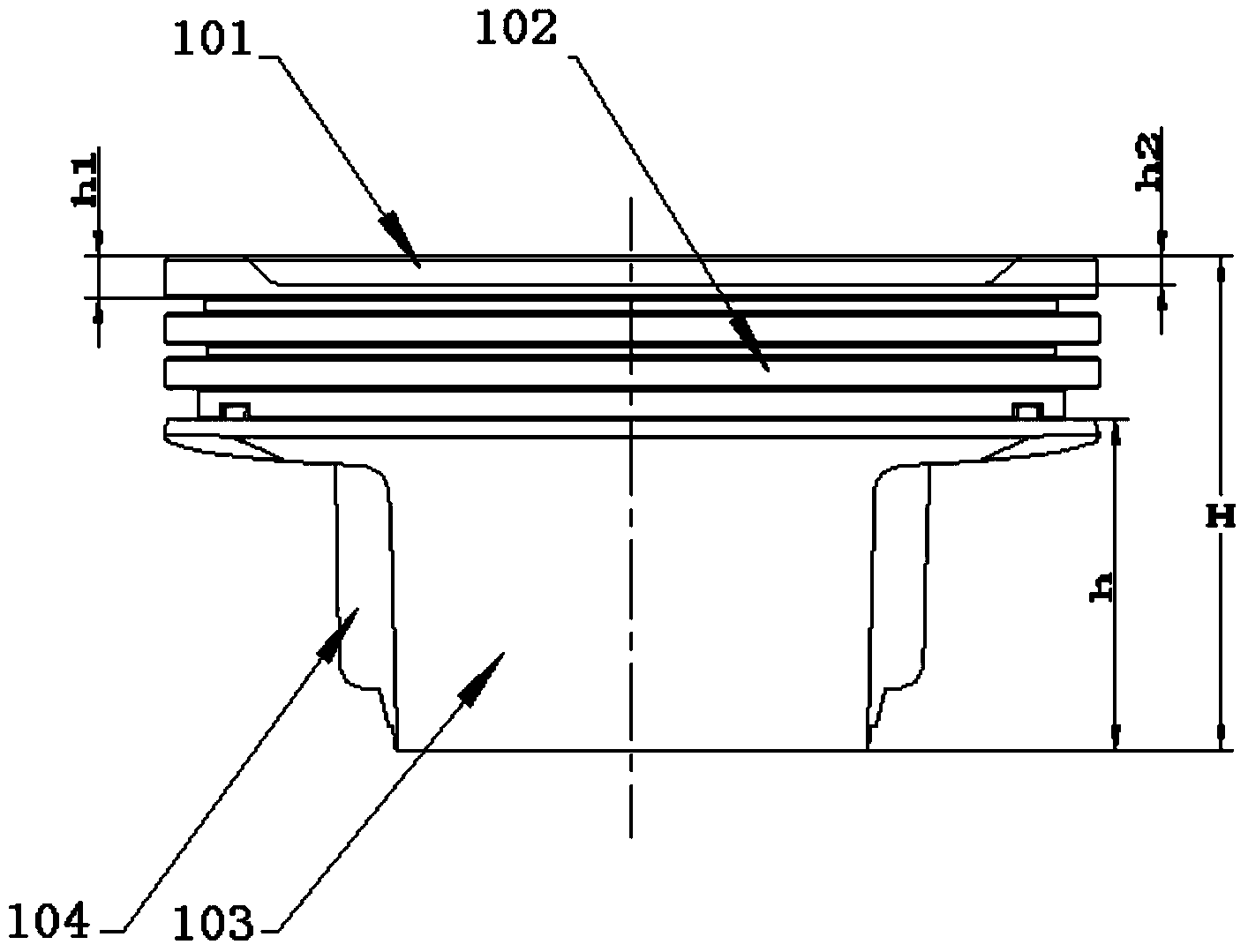

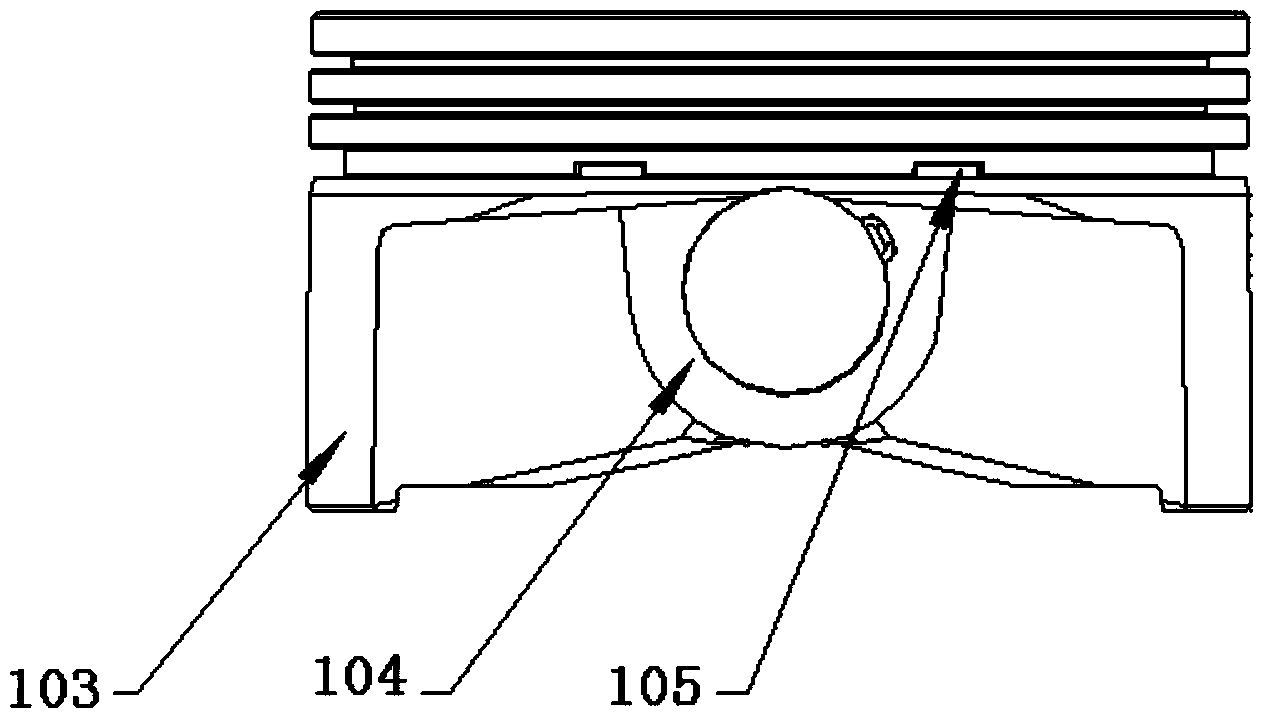

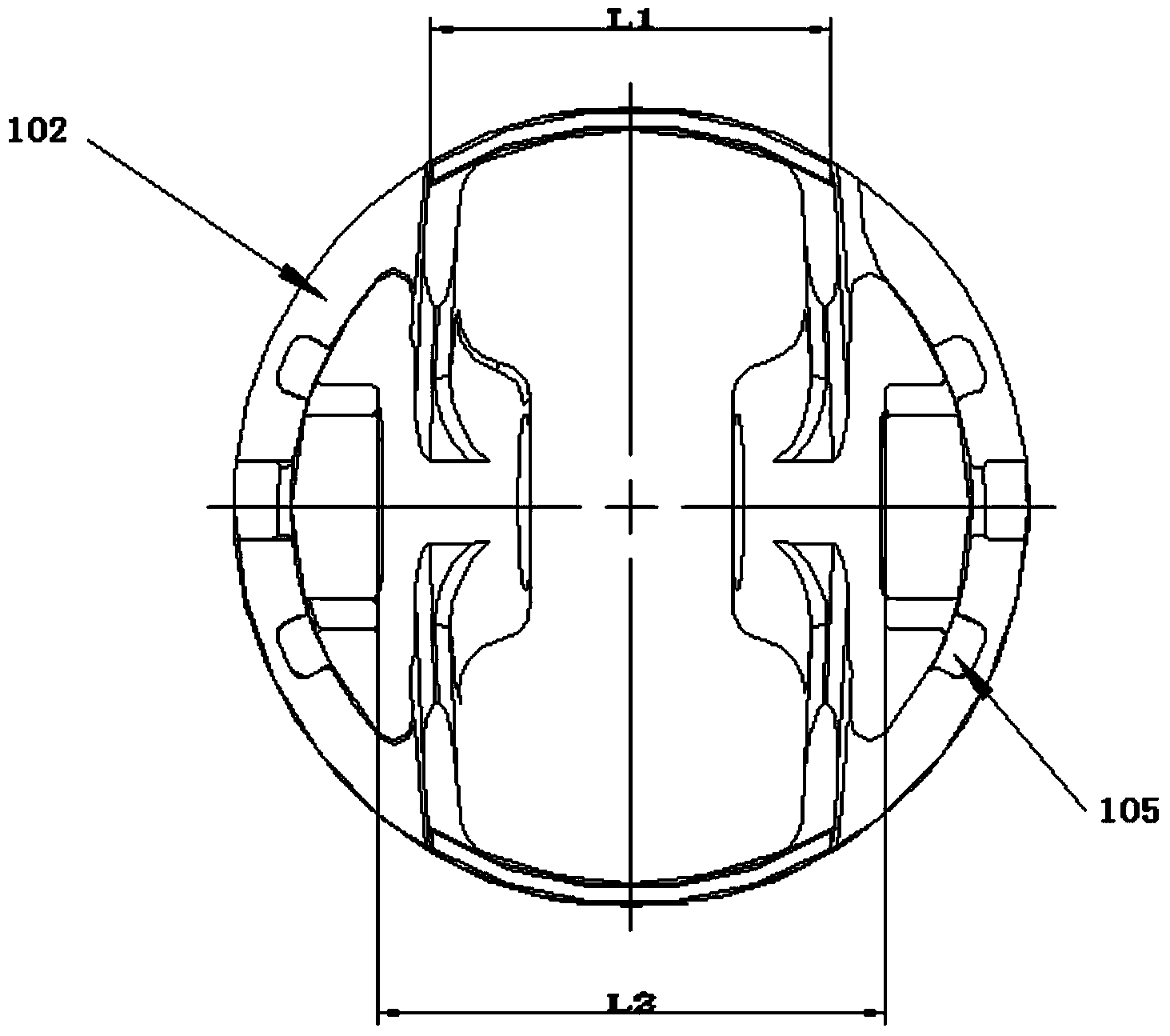

Gasoline engine

ActiveCN103867296AImprove mechanical efficiencyReduce friction workValve arrangementsInternal combustion piston enginesGasolineEngineering

The invention relates to a gasoline engine, which comprises a piston, a combustion chamber and a fuel-oil supplying system, wherein the piston is formed by a piston top, a head, a pin seat and a skirt, wherein the ratio of the height of the skirt to the total height formed by the head and the skirt is 0.6 to 0.7, and the ratio of the chord length of the projection of the molded line of the skirt on a plane on the piston top to the diameter of a cylinder is 0.5 to 0.6; the combustion chamber is hemispheric and is jointly formed by a cylinder head, the piston top, a cylinder-head gasket and one part of a box body, and the surface-to-volume ratio delta of the combustion chamber is 0.15 to 0.25; the fuel-oil supplying system comprises a gasoline pump, a ventilating pipe and a negative-pressure pipe, wherein a negative-pressure impulse-type gasoline pump is adopted as the gasoline pump, the ventilating pipe is arranged on a cylinder head cover, one end of the negative-pressure pipe is connected with the ventilating pipe of the cylinder head cover, and the other end of the negative-pressure pipe is connected with the negative-pressure impulse-type gasoline pump. Through the improvement on structures, such as the piston, a connecting rod, a rocker and the like, the frictional work is reduced, and therefore the mechanical efficiency of the gasoline engine is greatly enhanced.

Owner:ZHEJIANG YAOFENG POWER TECH

Control method of cooling system and vehicle

ActiveCN108266260AControl Method AdvantagesAvoid passingLiquid coolingCoolant flow controlEngineeringWater temperature

The invention provides a control method of a cooling system and a vehicle. The control method of the cooling system comprises the steps that S1, the water temperature of an engine is determined; and S2, flow distribution of coolants in a bypass loop, a large circulation loop and an engine oil cooler loop is controlled according to the water temperature of the engine. According to the control method of the cooling system, oil consumption can be effectively reduced, emissions can be reduced, and taking comfort can be improved.

Owner:GREAT WALL MOTOR CO LTD

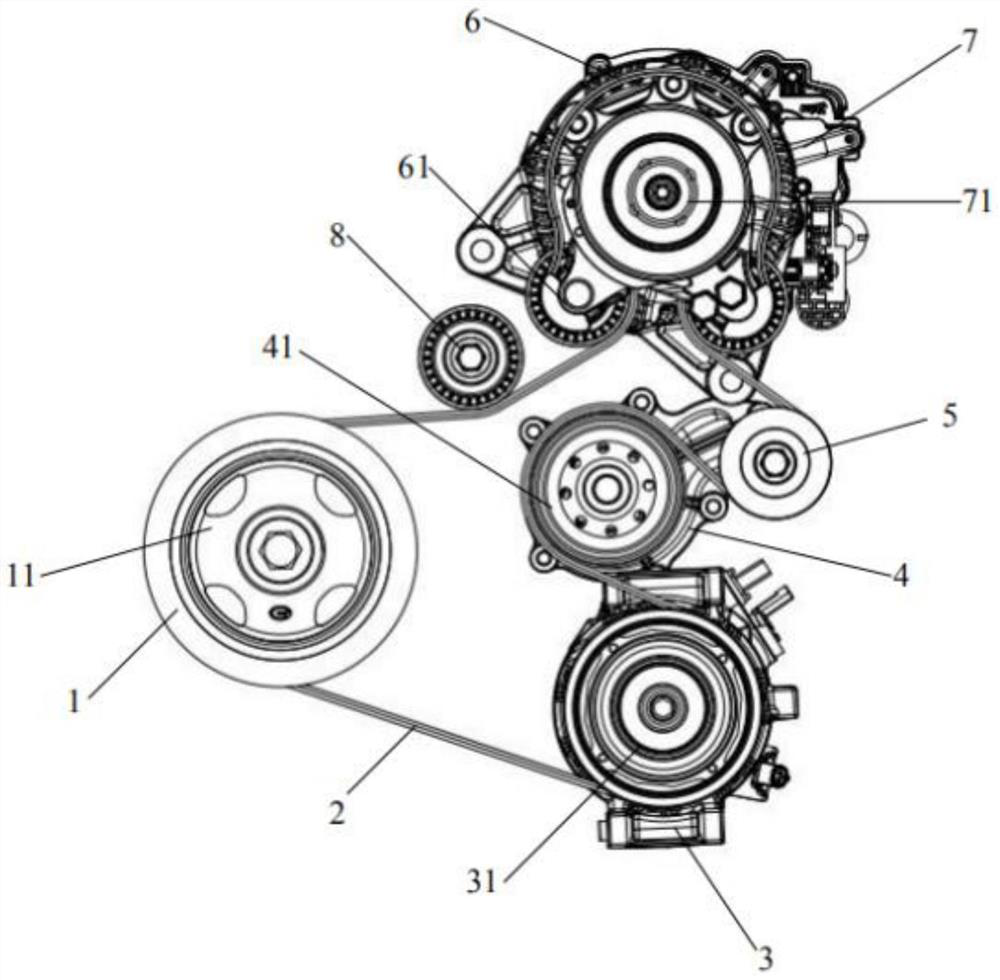

Accessory gear train of BSG hybrid power engine

InactiveCN112412623AReduce initial design tensionReduce friction workGearingMachines/enginesElectric machineryLeather belt

An accessory gear train of a BSG hybrid power engine comprises a V-ribbed belt, a BSG motor, a two-way tensioner, a first idle wheel, a water pump, an air conditioner compressor, a crankshaft and a second idle wheel, the two-way tensioner is arranged on the BSG motor, a motor belt wheel is arranged on the BSG motor, and a water pump belt wheel is arranged on the water pump; an air conditioner compressor belt wheel is arranged on the air conditioner compressor, a crankshaft belt wheel is arranged on the crankshaft, and the V-ribbed belt sequentially bypasses the motor belt wheel, the first idlewheel, the water pump belt wheel, the air conditioner compressor belt wheel, the crankshaft belt wheel and the second idle wheel to form a closed-loop belt; and the first idle wheel is arranged at the inner side of the V-ribbed belt. According to the accessory gear train, by increasing the wrap angle of tensioning wheels, the problem that because the compensation capacity of the tensioning wheelsfor the length change of the belt is not high, the initial design tension of the belt is too high is solved, and meanwhile the problem that abnormal sounds are generated during starting of the belt wheel due to insufficient wrap angle of the two-way tensioner is solved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

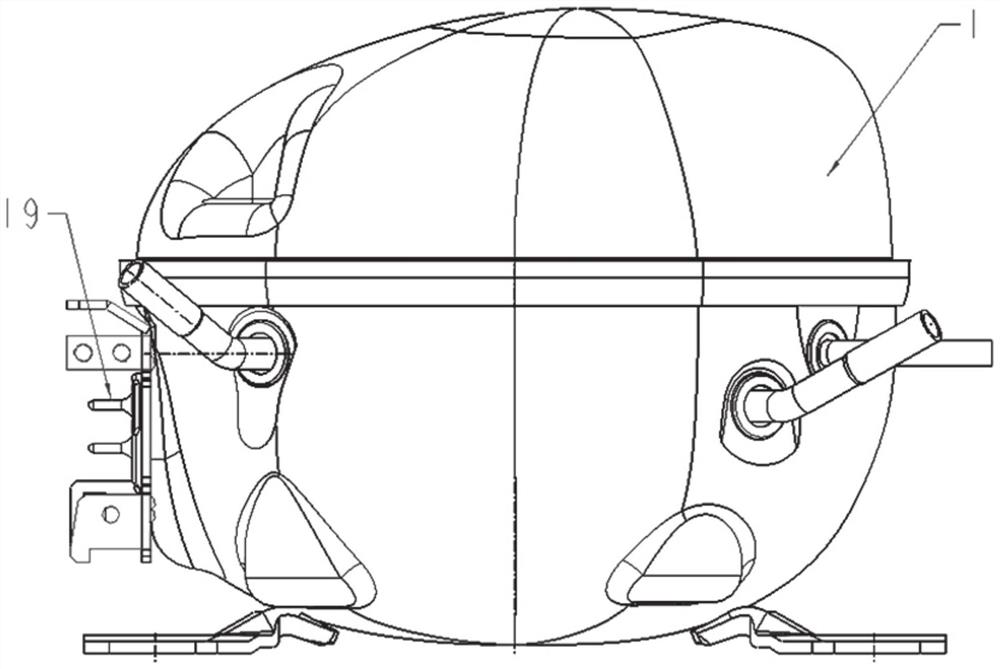

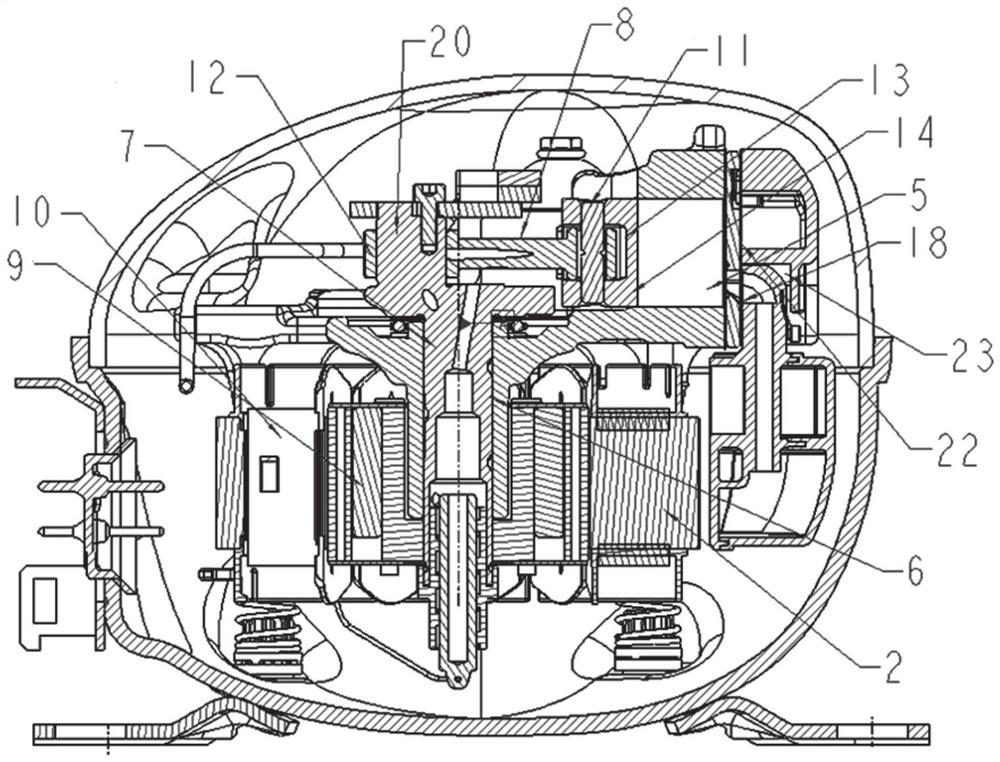

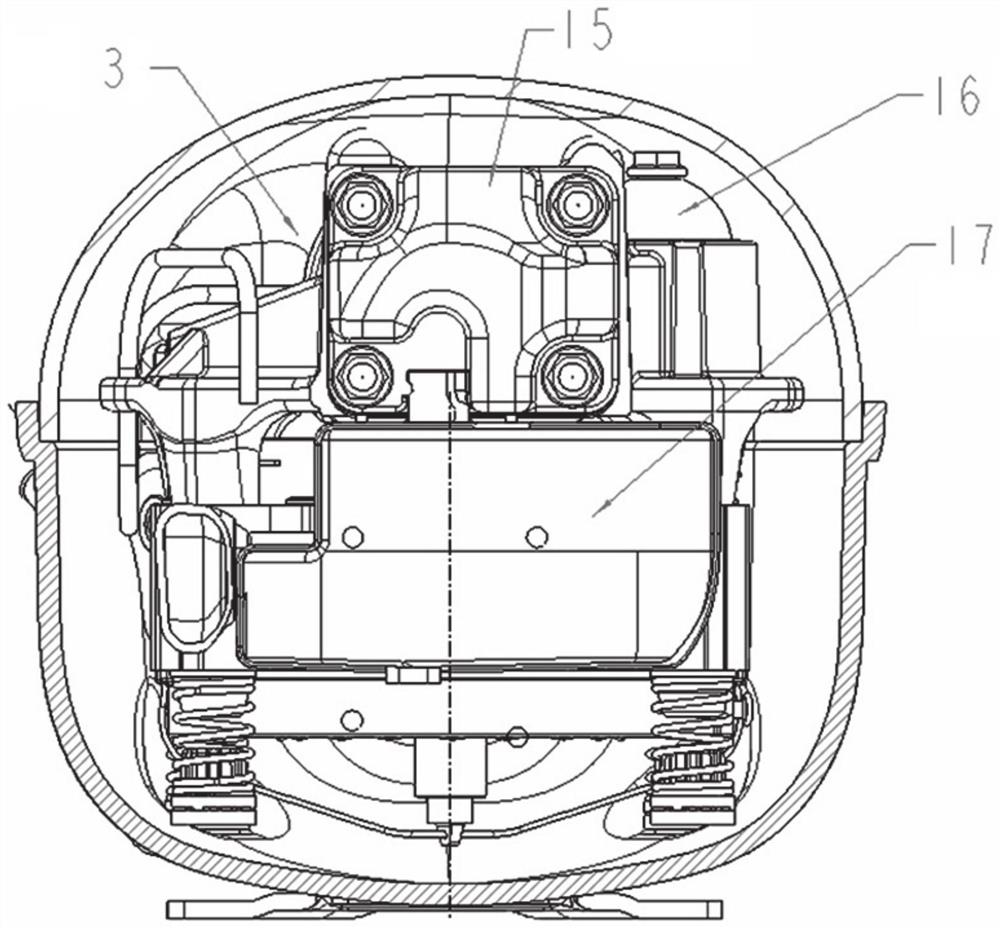

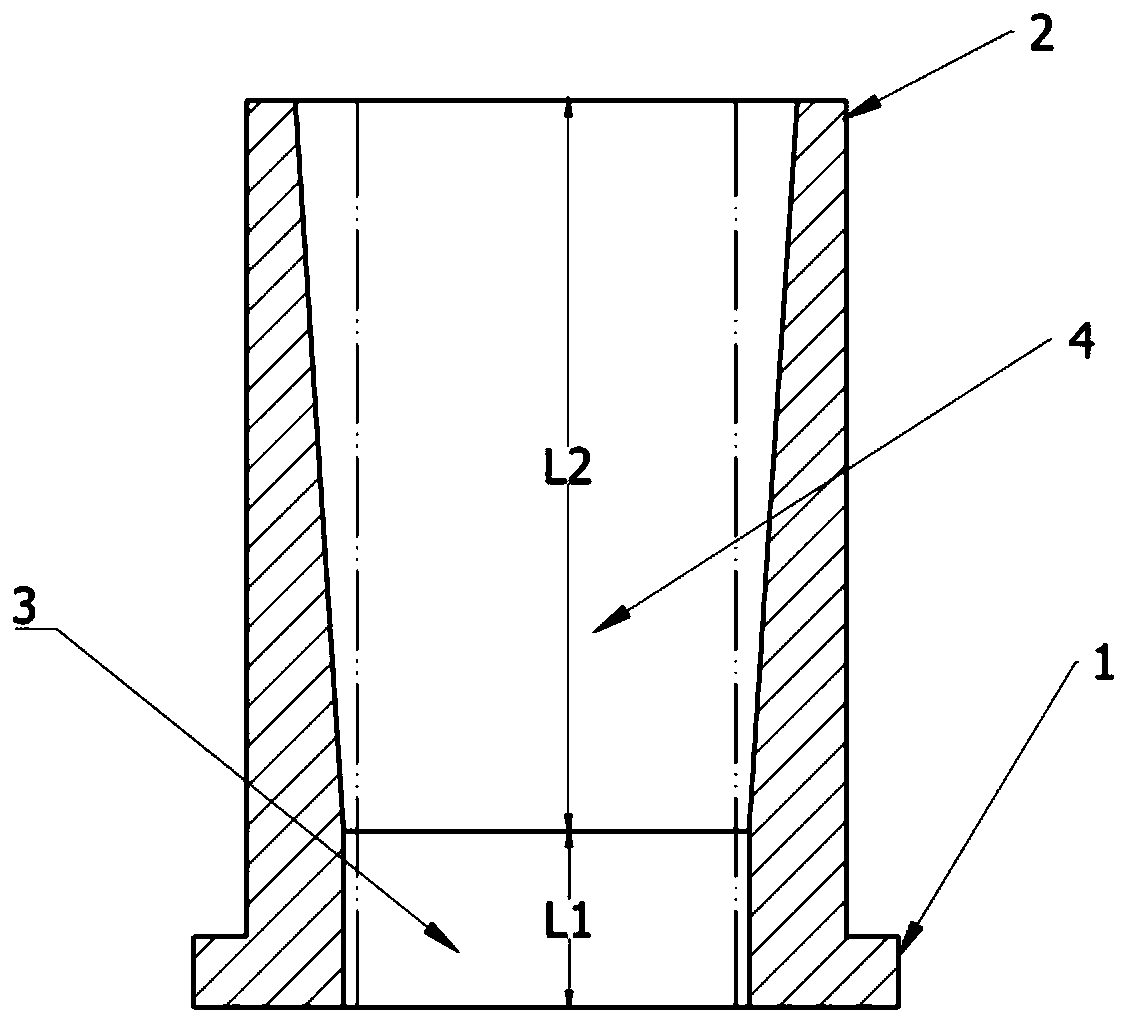

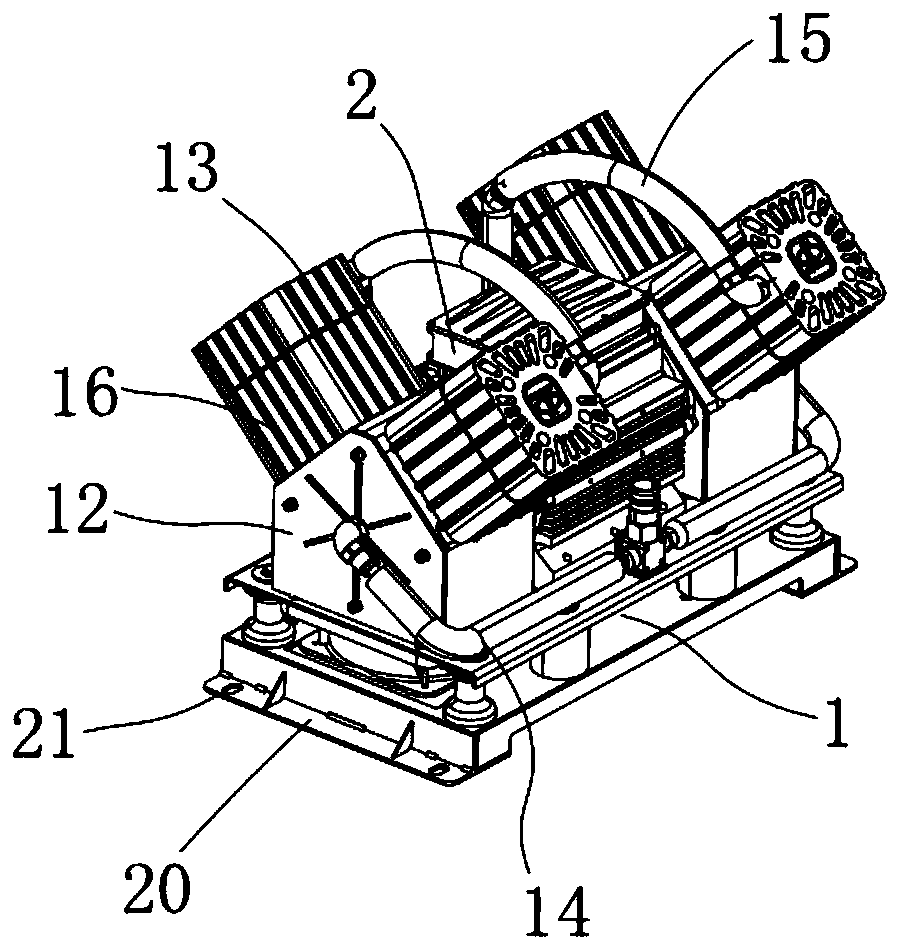

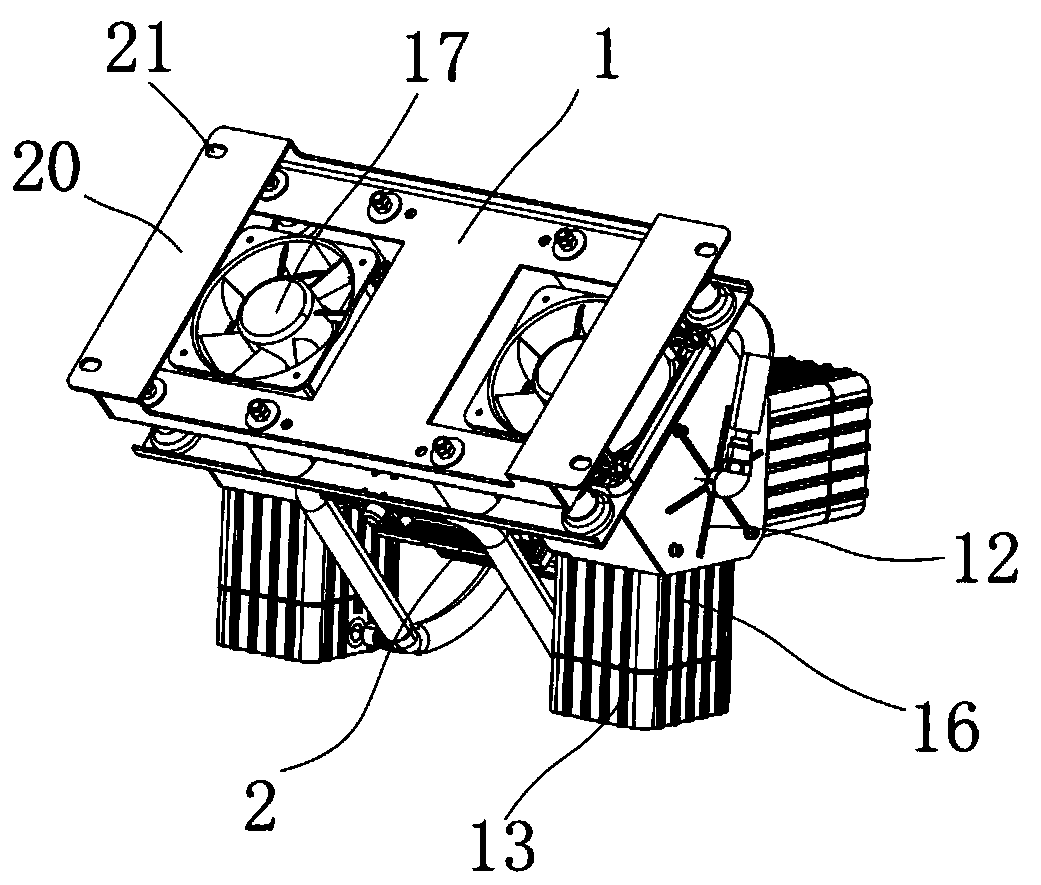

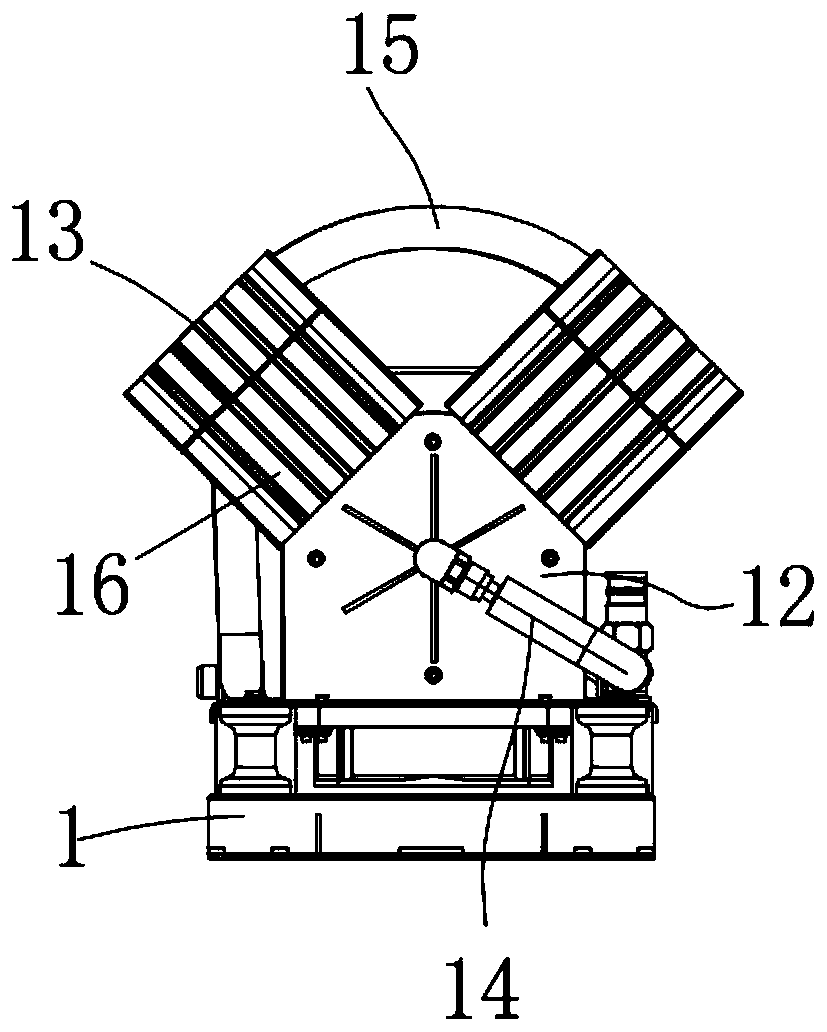

Single-stage reciprocating piston compressor for mixed refrigerant

InactiveCN111894830AEasy to adapt to compression needsAdapt to Compression NeedsPositive displacement pump componentsPump controlReciprocating motionElectric machinery

The invention discloses a single-stage reciprocating piston compressor for a mixed refrigerant, and belongs to the technical field of compressors. The efficiency and reliability of the compressor in the case of using the mixed refrigerant can be improved. The single-stage reciprocating piston compressor comprises a shell, a motor, a pump body and a variable-frequency controller; the shell, the motor and the pump body constitute a sealed machine body; the pump body comprises a cylinder; a piston is arranged in the cylinder, the motor drives the piston to move back and forth, and a valve plate is arranged at the top of the cylinder; the tail end of the cylinder is connected with a silencer through an air suction valve block arranged on the valve plate; when the piston moves back and forth, the valve plate can complete corresponding air suction and air exhausting; and the cylinder comprises two parts, and a coating is arranged at the junction of the two parts of the cylinder.

Owner:QINGDAO WANBAO COMPRESSOR

Special-shaped inner hole honing cylinder sleeve and manufacturing method thereof

InactiveCN111594336AReduce friction and wearReduce heat lossCylinder headsCylindersPhysicsExhaust gas

The invention relates to the technical field of cylinder sleeve inner hole machining, in particular to a special-shaped inner hole honing cylinder sleeve and a manufacturing method thereof. One end ofa special-shaped inner hole honing cylinder sleeve body is a large end, the other end of the special-shaped inner hole honing cylinder sleeve body is a small end, and the shape of an inner hole is machined into different sections according to different actual temperatures of different sections of the cylinder sleeve at the working temperature, the inner hole of the cylinder sleeve is wholly cylindrical under the working conditions, the section corresponding to the large end is in a straight cylinder shape, the other sections are in conical cylinder shapes or arc cylinder shapes, the sectionsare in smooth transition connection, the inner hole diameter of the large end is smaller than that of the small end, the inner hole diameter of the straight cylinder section is smaller than the minimum inner hole diameter of the other sections, and the inner hole diameters of the other sections are gradually increased from the large end to the small end of the cylinder sleeve. According to the special-shaped inner hole honing cylinder sleeve, the shape of the inner hole of the cylinder sleeve is changed by analyzing the temperature of the inner hole of the cylinder sleeve in the working state,the friction coefficient is reduced, the exhaust emission is reduced, the use performance of the air cylinder sleeve is improved, and the service life of the air cylinder sleeve is prolonged.

Owner:GKN ZHONGYUAN CYLINDER LINER CO LTD

Cooling waterway cycle structure of automobile engine

InactiveCN109595064AAvoid short circuitImprove cooling effectLiquid coolingAir-treating devicesCombustionCylinder head

The invention discloses a cooling waterway cycle structure of an automobile engine, and is applied to the technical field of automobile engines. A timing sprocket housing integrated water jacket and an engine main water pump are arranged on the front end face of a cylinder block; the timing sprocket housing integrated water jacket and the water inlet position of the cylinder block form an inner cavity of the engine main water pump; a timing sprocket housing integrated water jacket boss is embedded into a water outlet passage of the engine main water pump of the cylinder block; a water jacket Aof the cylinder block and a water jacket B of a cylinder head communicate; and a first one lock pin is arranged at the air inlet side of the water jacket A of the cylinder block, and thus, most of cooling liquid enters the exhaust side of the water jacket A of the cylinder block from the air inlet side of the water jacket A of the cylinder block, and enters the engine main water pump to form a major cycle of the engine. According to the cooling waterway cycle structure disclosed by the invention, uniform flow area is guaranteed; the water pump is enough in head, and the resistance of waterways is overcome to make the cooling liquid reach corresponding positions; and according to different working conditions under which the engine is, the warm-up time is shorted, the combustion performanceis improved, the friction work is reduced, and the cooling loss is reduced.

Owner:SHENYANG AEROSPACE MITSUBISHI AUTOMOBILE ENGINE MFG CO LTD

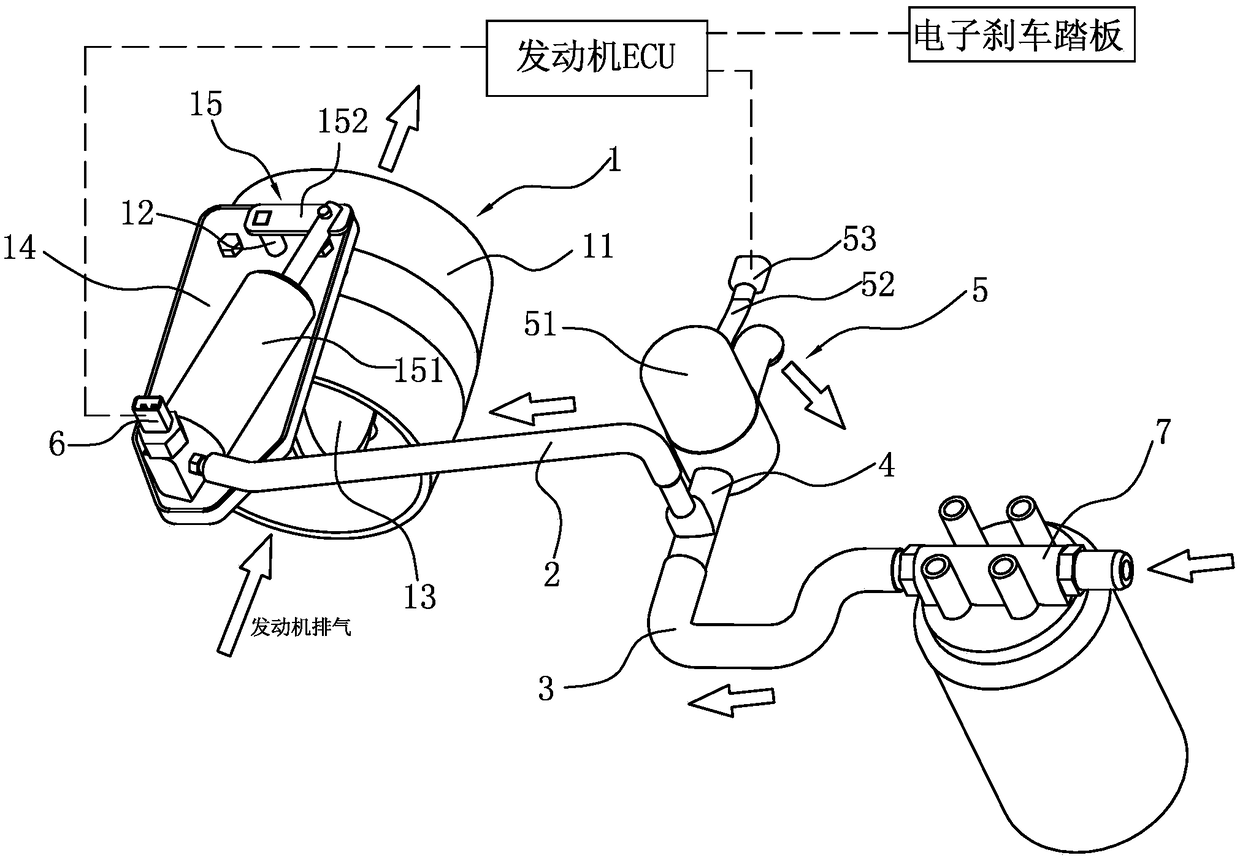

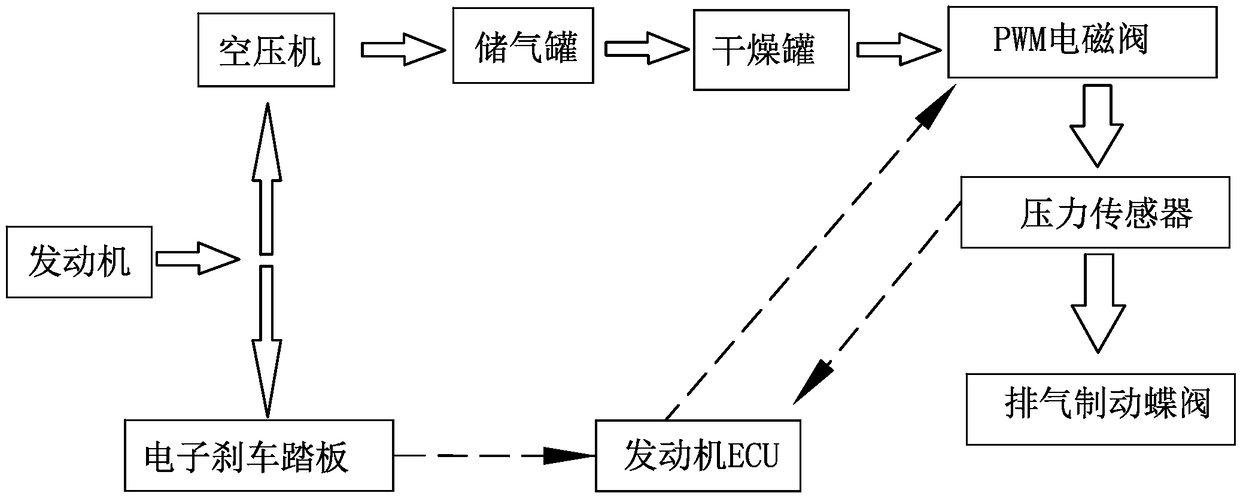

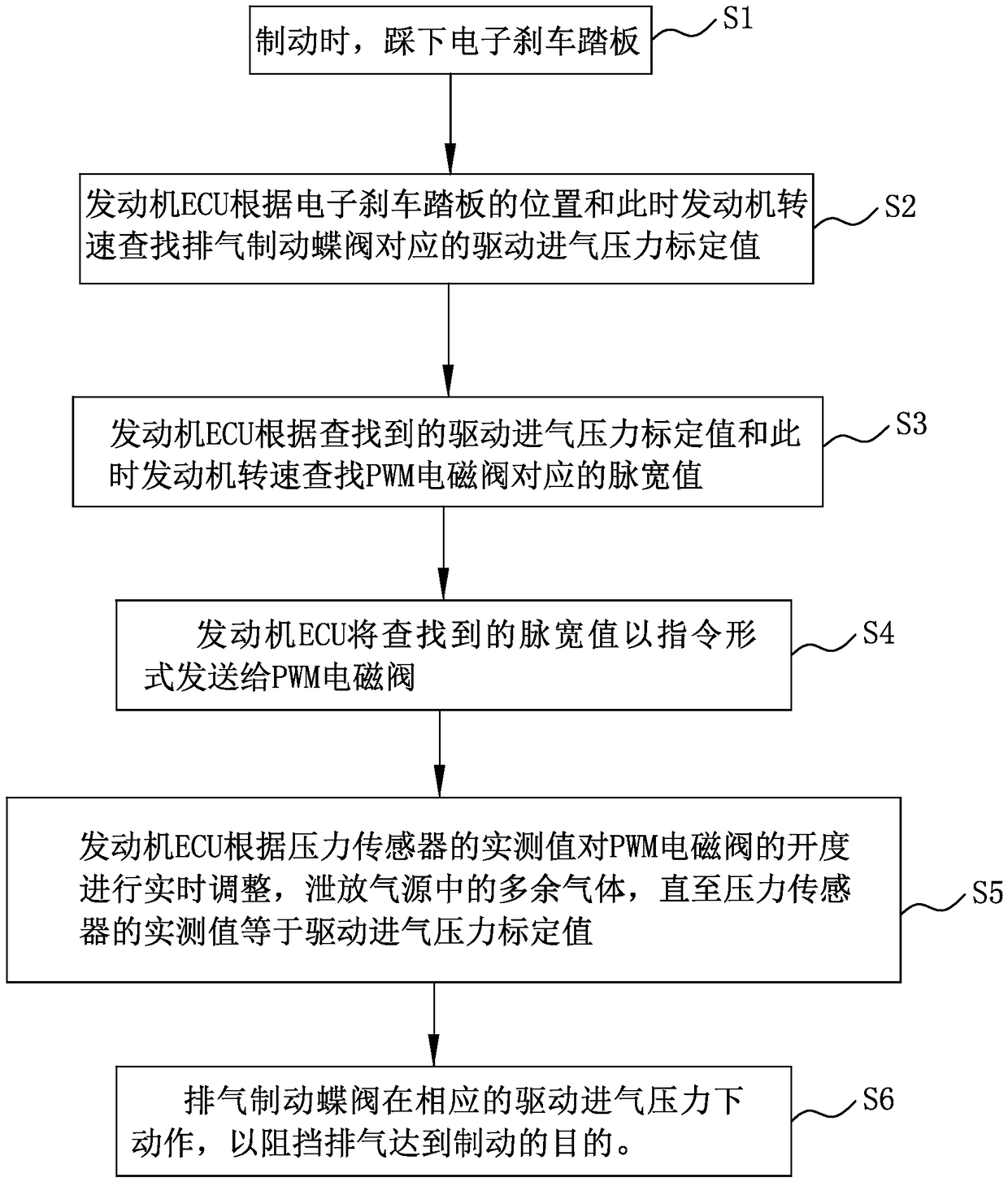

Air exhaust brake butterfly valve control system and control method

PendingCN109356729AConsistent pressureExhaust blockingEngine controllersMachines/enginesIntake pressurePower control

The invention discloses an air exhaust brake butterfly valve control system and control method. The control system comprises an air exhaust brake butterfly valve, a PWM electromagnetic valve on a pressure relief pipe segment and an electronic brake pedal, wherein a pneumatic actuator of the air exhaust brake butterfly valve communicates with a driving air inlet pipe segment, the driving air inletpipe segment communicates with both an air supplying pipe segment and the pressure relief pipe segment, the air supplying pipe segment communicates with an air source device, the pneumatic actuator orthe driving air inlet pipe segment is provided with a pressure sensor, and the pressure sensor, the PWM electromagnetic valve and the electronic brake pedal are all in electric connection with an engine ECU. According to the air exhaust brake butterfly valve control system and control method, on base of the position of the electronic brake pedal, the engine ECU finds out the driving air inlet pressure calibration value and the pulse width value in sequence, the opening of the PWM electromagnetic valve is adjusted in real time till a pressure actual measurement valve is equal to the driving air inlet pressure calibration value, the air exhaust brake butterfly valve blocks air exhaust to achieve the purpose of braking under driving of air inlet pressure, and by means of the air exhaust brake butterfly valve control system and control method, the opening of the air exhaust brake butterfly valve can be controlled on base of brake requirement power.

Owner:WEICHAI XIGANG NEW ENERGY POWER

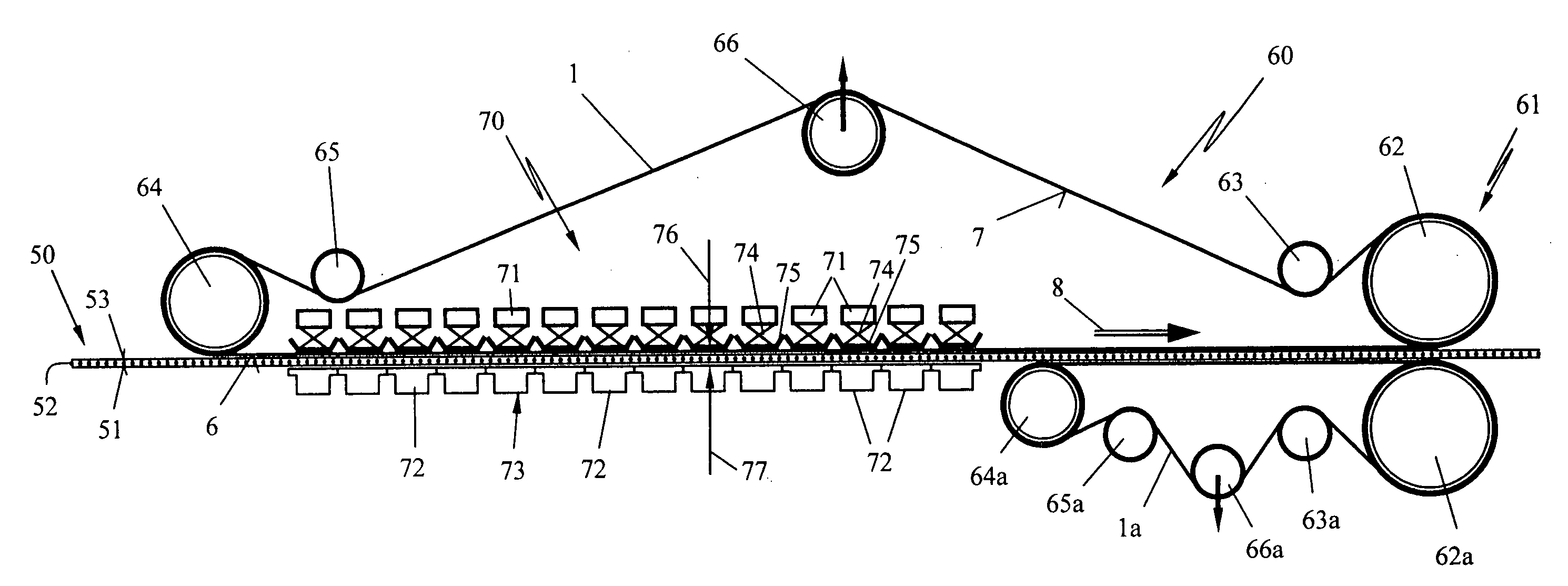

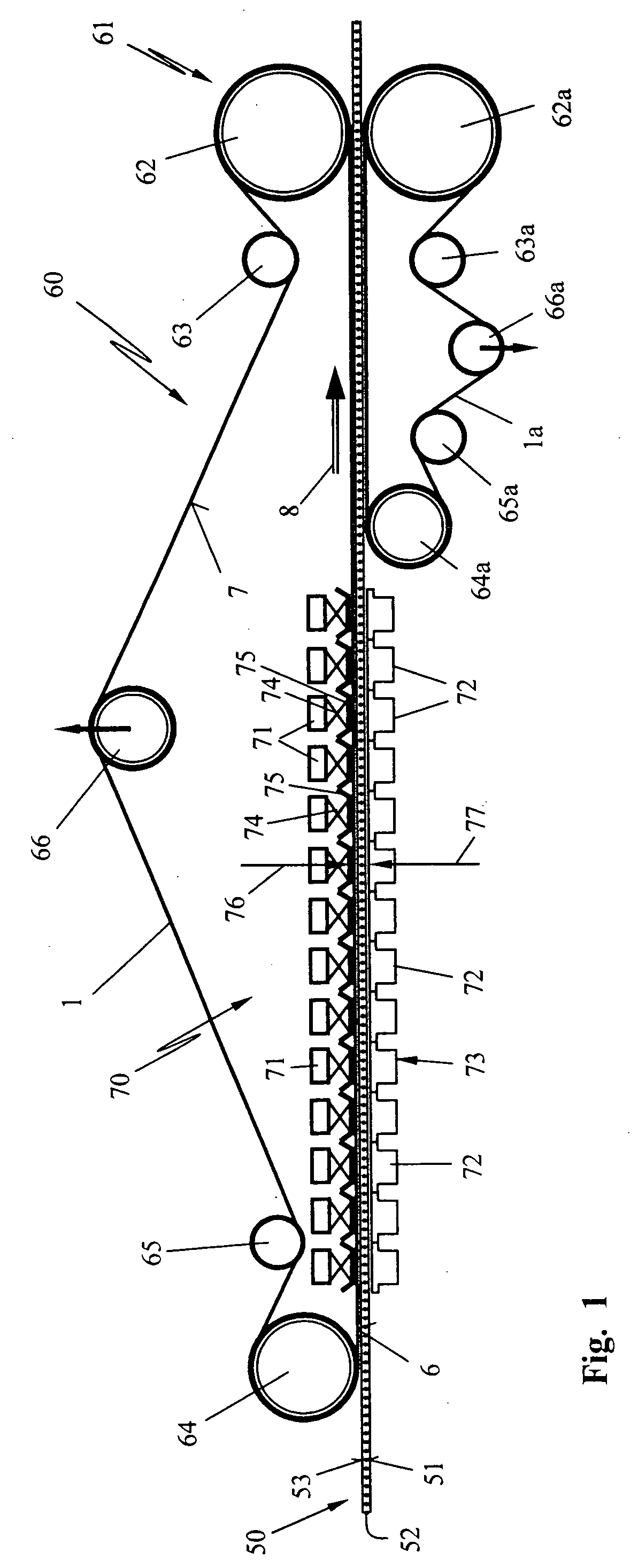

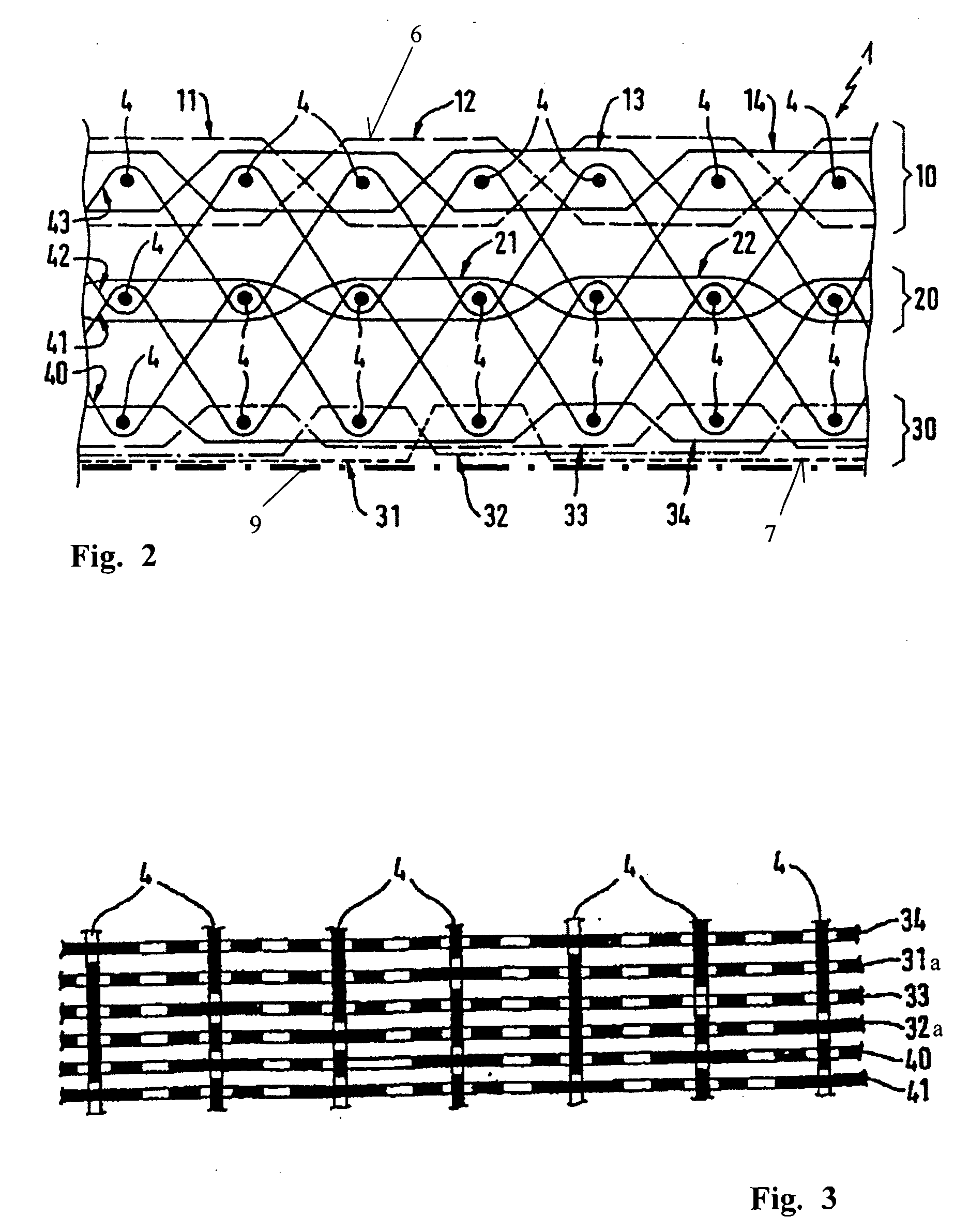

Belt for a corrugator machine having a friction coefficiet reduced driven side

ActiveUS20090107637A1Reduce friction workReduce coefficient of frictionMechanical working/deformationSynthetic resin layered productsFiberFriction loss

The invention relates to a belt for a corrugator machine for making corrugated board (50) wherein at least a middle layer (52) of corrugated material is joined under pressure to cover layers (51, 53) of smooth material to form the corrugated board (50). The belt (1) is made of a fabric of warp fibers and weft fibers (4) and has a paper side facing toward the corrugated board (50) to be manufactured. The paper side (6) lies against the corrugated board (50). A driven side (7) lies facing away from the corrugated board (50). The corrugator machine has a pressure zone (70) which includes a pressure element (71) and a countersupport (73). The corrugated board (50) together with the contact engaging fabric belt (1) pass between the pressure element (71) and the countersupport (73). A drive (61) is provided on the driven side (7) of the belt to generate the tension forces acting in the longitudinal direction of the belt. To reduce the friction loss in the pressure zone, a material is provided on the driven side (7) of the fabric belt (1) for reducing the coefficient of friction of the belt side defining the driven side (7).

Owner:MUHLEN SOHN

Novel flame-retarding magnesium alloy with high-temperature mechanical property and processing technology thereof

The invention discloses a novel flame-retarding magnesium alloy with high-temperature mechanical property and a processing technology thereof. The alloy is prepared from the following components in percentage by weight: 0.4 to 0.5 percent of Te, 0.6 to 0.8 percent of Li, 1.0 to 1.8 percent of In, 0.3 to 0.5 percent of Os, 1.0 to 1.2 percent of Pd, 0.5 to 0.8 percent of Ag, 2.0 to 3.0 percent of Sc, 10.0 to 12.0 percent of Al and the balance of magnesium. The material provides a flame-retarding scheme for magnesium alloy combustion caused by friction or external fire heating. Predicably, implementation and industrialization of the alloy can greatly push the commercial demand of China in the field of light weight for the novel flame-retarding magnesium alloy.

Owner:GUANGZHOU YUZHI TECH CO LTD

New-type electric oil-free air compressor

InactiveCN109944769ALow melting pointReduce temperature risePositive displacement pump componentsPiston pumpsWear resistantElectric machine

The invention discloses a new-type electric oil-free air compressor, which comprises a mounting base, wherein a servo motor is fixed at the upper end of the mounting base and provided with motor spindles; eccentric wheels are fixed on the motor spindles; driving cylinders are fixed on the eccentric wheels and rotationally connected with piston connecting rods; the piston connecting rods are rotationally connected with rotating shafts, which are rotationally connected with pistons; the upper ends of the pistons are clamped by sealing rings; the outer surfaces of the pistons are connected with piston cylinder blocks in a sliding manner; wear-resistant layers are arranged on the inner cylindrical surfaces of the piston cylinder blocks; the lower ends of the piston cylinder blocks are communicated with eccentric wheel boxes, which are fixed on the servo motor; piston cylinder covers are fixed at the upper ends of the piston cylinder blocks; one sides of the piston cylinder covers are communicated with air outlet pipes; and the middles of one sides of the eccentric wheel boxes are communicated with air inlet pipes. Through the above structure, the oil-free lubrication of the air compressor is achieved, so that the energy consumption is low and the environmental pollution is less.

Owner:江西捷控新能源科技有限公司

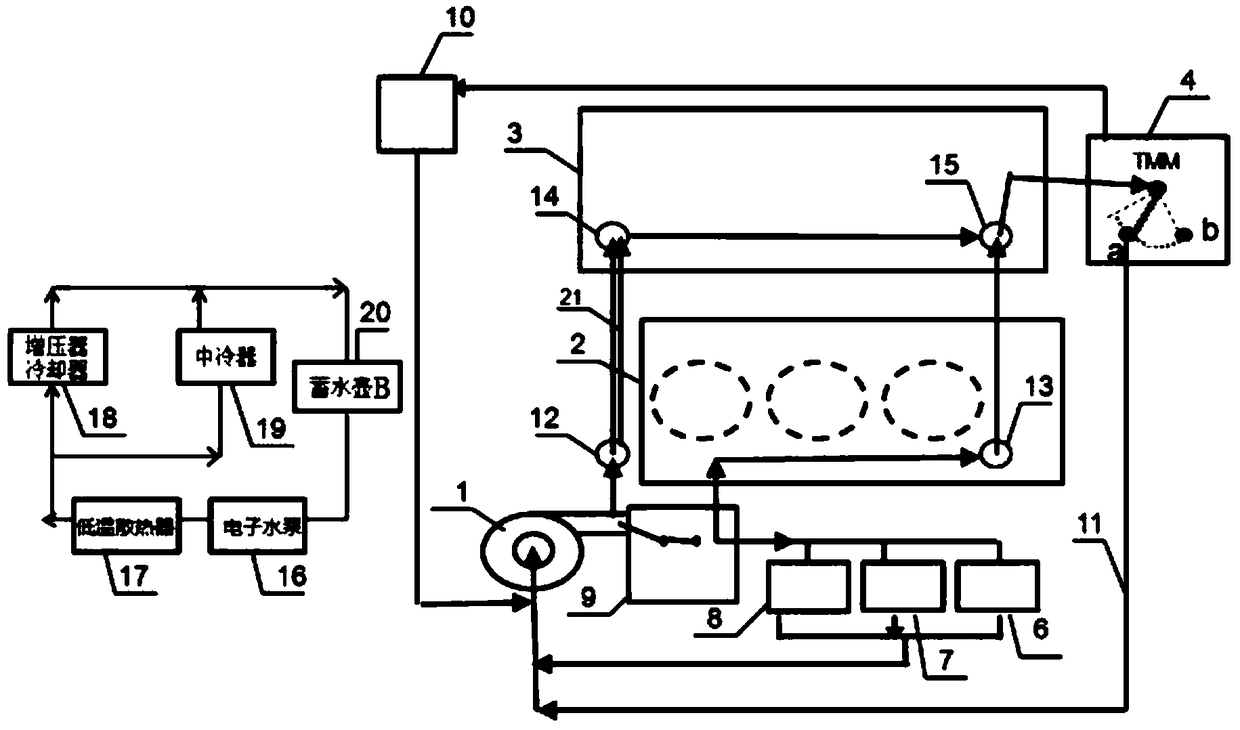

Independent double-circulation cooling system of engine

ActiveCN109057943ALarge water flowWater flow controllableCoolant flow controlMachines/enginesSolenoid valveEngineering

The invention provides an independent double-circulation cooling system of an engine. The double-circulation cooling system comprises a high temperature water circulation cooling system and low temperature water circulation cooling system. The high temperature system controls a switch through the selection of a thermostat and a solenoid valve, so that flow of cooling water is switched according toengine load to achieve rapid warm-up and reduce fuel consumption. In an engine cold start stage, a cylinder cover and a water jacket of cylinder body are connected in series, the cooling water is heated twice in one cycle, the temperature rise of the cooling water is increased to the maximum extent; and in warm-up and high-temperature stages where the engine temperature is high, the water jacketof the cylinder cover and the water jacket of the cylinder body are connected in a parallel, the water flow rate of the engine is increased to the maximum degree, the water flow rates of the cylinderbody and the cylinder cover can be controlled, the cylinder body and the cylinder cover can be controlled to reach optimal temperature, so that knock is reduced, and the oil consumption is reduced. The low-temperature water circulation system adopts an electronic water pump and a separate water storage pot, and is independent from the high-temperature water circulation, so that the cooling effectof the low-temperature system is ensured, the air inlet temperature and the air inlet efficiency of the engine are guaranteed effectively, the power performance of the engine is facilitated, and the knock is prevented.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

A kind of automobile engine cooling system and cooling method

ActiveCN108278172BControl allocationHeating up fastLiquid coolingCoolant flow controlHeat managementControl valves

The invention discloses a cooling system and a cooling method for an automobile engine. The automobile engine cooling system comprises a cylinder body, a cylinder cover, a water storage pot, a heat exchanging part, a radiator, engine oil coolers and a heat management module, wherein the heat management module is provided with a control valve, a normally-communicated cylinder cover water jacket connector, a water storage pot connector, an engine oil cooler connector, a cylinder cover water passing channel connector capable of adjusting a connecting area through the control valve, a heat exchanging part connector and a radiator connector. During a cold start, a connecting area of the cylinder cover water passing channel connector, the heat exchanging part connector and the radiator connectoris enabled to be zero; when the engine is heated, the connecting area of the cylinder cover water passing channel connector and the radiator connector is enabled to be zero, and the connecting area of the heat exchanging part connector is enabled to be 100 percent; and when temperature of the engine is in a high working state, the connecting area of the cylinder cover water passing channel connector, the heat exchanging part connector and the radiator connector is enabled to be 100 percent. According to the cooling system and the cooling method for the automobile engine, the heating speed ofthe engine and the engine oil heating speed can be increased, and the oil consumption can be reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com