Special-shaped inner hole honing cylinder sleeve and manufacturing method thereof

A cylinder liner and inner hole technology is applied in the field of special-shaped inner hole honing cylinder liner and its preparation, which can solve the problems of shortening the life of the cylinder liner, deformation of the inner hole of the cylinder liner, increasing oil consumption, etc. cylinder, the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

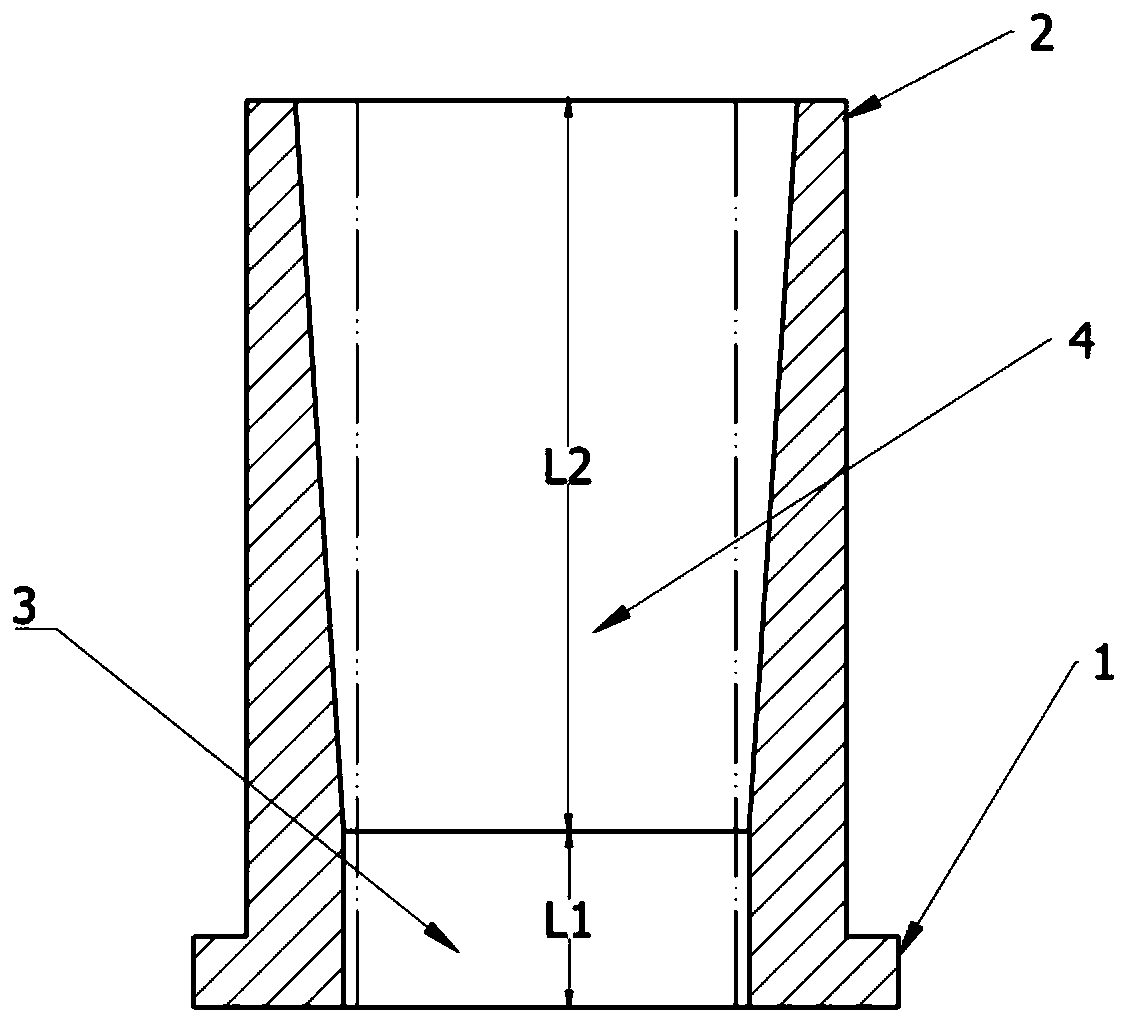

[0034] Such as figure 1 As shown, the present invention provides a special-shaped inner hole honing cylinder liner, including a cylinder liner body. The material of the cylinder liner body is pearlitic cast iron, and the cylinder liner body is provided with an inner hole. One end of the cylinder liner body is The big end 1 and the other end is the small end 2. The diameter of the outer circle of the big end 1 is larger than that of the small end 2. The shape of the inner hole depends on the actual temperature of the different sections of the cylinder liner at the working temperature. It is processed into two sections with different shapes, so that the inner hole of the cylinder liner is in the shape of a straight cylinder as a whole under working conditions. The actual temperature of the section corresponding to the big end 1 under working conditions is 180-240°C. Section 3, the diameter of the inner hole of the straight cylindrical section 3 is D=132±0.01mm, the length L1 is ...

Embodiment 2

[0037] Such as figure 1 As shown, the present invention also provides a kind of preparation method of special-shaped inner hole honing cylinder liner, comprising the following steps:

[0038] 61) Cylinder liner blank: the cylinder liner casting or formed steel pipe is prepared by wet coating centrifugal casting process, and the material is pearlitic cast iron;

[0039] 62) Machining: Cutting and preliminary honing of the cylinder liner blank, the specific process includes rough turning - rough boring inner hole - repairing - fine boring inner hole - semi-finishing outer circle - rough grinding inner hole - finishing turning Outer circle - semi-fine grinding;

[0040] 63) Fine grinding: firstly, according to the mesh parameters of the inner hole of the cylinder liner, sand bars are selected, and the honing parameters are input into the numerical control honing equipment, and the inner hole wall of the cylinder liner obtained in step 62) is finely honed by the numerical control h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com