Oil thermal management control method and device in engine lubrication system

A technology of lubricating system and control method, which is applied in the direction of engine lubrication, lubricant temperature control, engine components, etc., can solve the problems of increased emissions and increased fuel consumption, and can reduce oil viscosity, increase oil temperature, and reduce fuel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

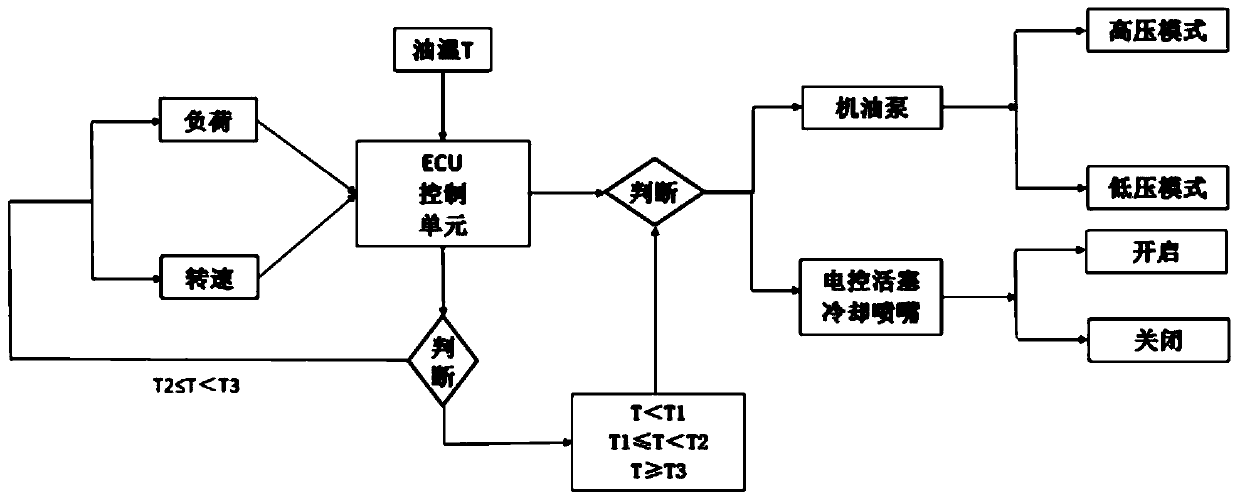

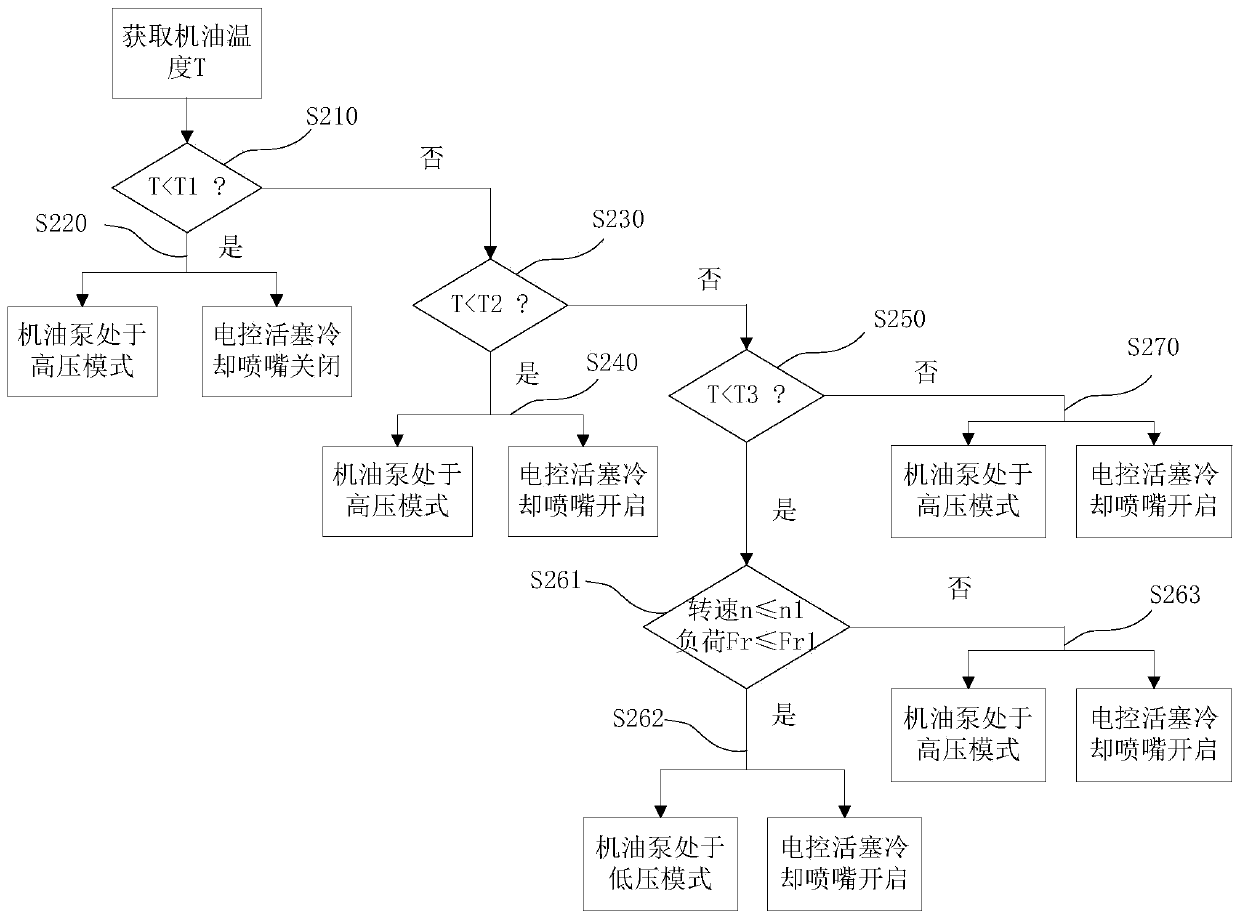

[0044] Such as Figure 1-Figure 2 As shown, the present invention discloses a method for controlling engine oil thermal management in an engine lubrication system, comprising:

[0045] S100: Obtain the temperature of the engine oil in the main oil passage of the engine;

[0046] S200: According to the oil temperature, control the variable displacement oil pump to work in high pressure mode or low pressure mode, and at the same time control the opening or closing of the electronically controlled piston cooling nozzle.

[0047] Wherein, after the engine oil temperature T in the main oil passage of the engine is obtained in step S100, the first temperature threshold T is set 1 , the second temperature threshold T 2 , the third temperature threshold T 3 , preferably, T 1 is 15 degrees, T 2 at 60 degrees, T 3 is 125 degrees.

[0048] to combine figure 2 As shown, in step S200, according to the oil temperature, the variable displacement oil pump is controlled to work in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com