Patents

Literature

83results about How to "Achieve flame retardant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fireproof and flame retardant mineral compound filling material and cable containing the same

ActiveCN103102134ANo harmImprove fire performanceInsulated cablesInsulated conductorsPolymer scienceFirming agent

The invention relates to a fireproof and flame retardant mineral compound filling material for cables. The filling material comprises a silicon-containing binder; an inorganic flame retardant compound; and a mineral compound. The filling material also can include a silicate modifier, a silicate curing agent and a pigment. Being free of any flammable substance, the fireproof and flame-retardant mineral compound filling material provided in the invention has an excellent fireproof effect, can lose moisture and absorb a lot of heat so as to achieve the flame retardant effect. With good flexibility, the fireproof and flame retardant mineral compound filling material has no hazard to the nature after it is abandoned.

Owner:上海宏胜电线电缆有限公司 +1

High-temperature resistant flame-retardant epoxy glue and preparation method thereof

ActiveCN104726045AReduce usageHigh heat distortion temperatureNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyFire retardant

The invention relates to high-temperature resistant flame-retardant epoxy glue and a preparation method of the high-temperature resistant flame-retardant epoxy glue. The epoxy glue is a double-component epoxy glue; when the epoxy glue is used, a first component and a second component are mixed in a weight ratio of 4:(2-3); the first component is prepared from the following raw materials in parts by weight: 30-50 parts of polyfunctional epoxy resin, 5-15 parts of low-viscosity epoxy resin, 3-10 parts of an active toughening agent, 10-30 parts of temperature-resistant reinforcing fillers, 10-15 parts of flame retardant and 0.3-3 parts of antioxidant; the second component is prepared from the following raw materials in parts by weight: 70-95 parts of a temperature-resistant curing agent, 10-30 parts of temperature-resistant reinforcing fillers and 0.3-1 part of a coupling agent. Compared with the prior art, the high-temperature resistant flame-retardant epoxy glue has the advantages of high high-temperature toughness, high adhesion strength, high flame retardant performance and the like.

Owner:上海海鹰粘接科技有限公司

Environment-friendly and flame-retardant polypropylene material and preparation method thereof

The invention relates to the field of preparation of polypropylene composite materials, in particular to an environment-friendly and flame-retardant polypropylene composite material. The environment-friendly and flame-retardant polypropylene composite material is prepared from 100 parts of polypropylene, 0.1-2 parts of modified graphene, 0.5-3 parts of modified carbon nano tubes, 10-20 parts of an inorganic flame retardant, 5-10 parts of a compatilizer, 3-10 parts of a toughening agent, 0.1-0.3 parts of an antioxidant and 0.1-0.3 parts of a heat stabilizer. Graphene, the carbon nano tubes and the inorganic flame retardant are added to polypropylene resin, and a brand-new flame retardant system is formed; dispersing performance of graphene in a polymer system is improved through modification of graphene; migration of combustible matter in a polymer matrix can be effectively inhibited; a compact protective carbon layer is formed on the surface of the polymer matrix by graphene in the burning process of the composite material, and finally, the flame-retardant effect is achieved.

Owner:JIANGSU CHANGHAI COMPOSITE MATERIALS CO LTD

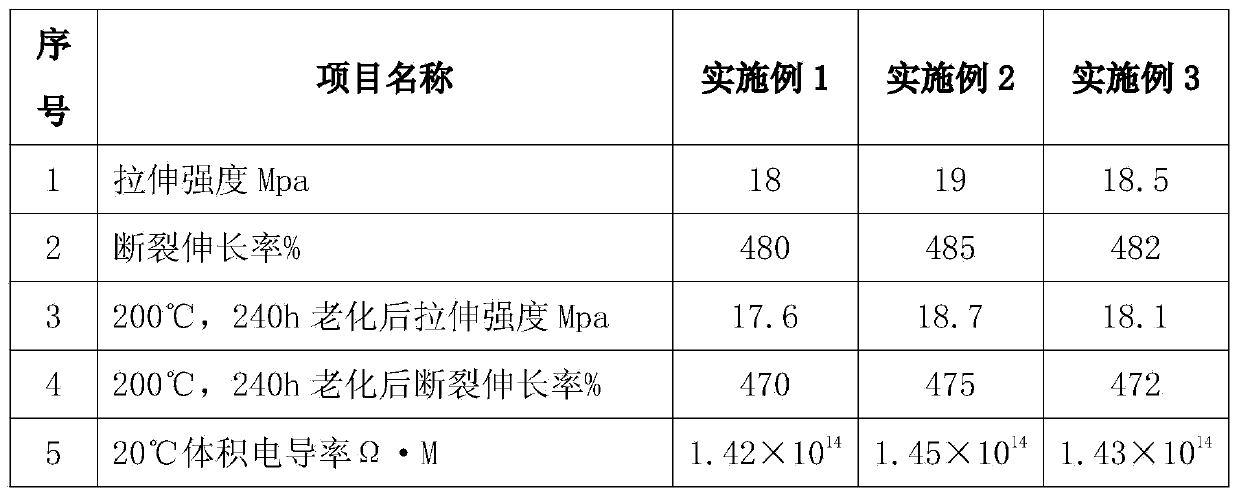

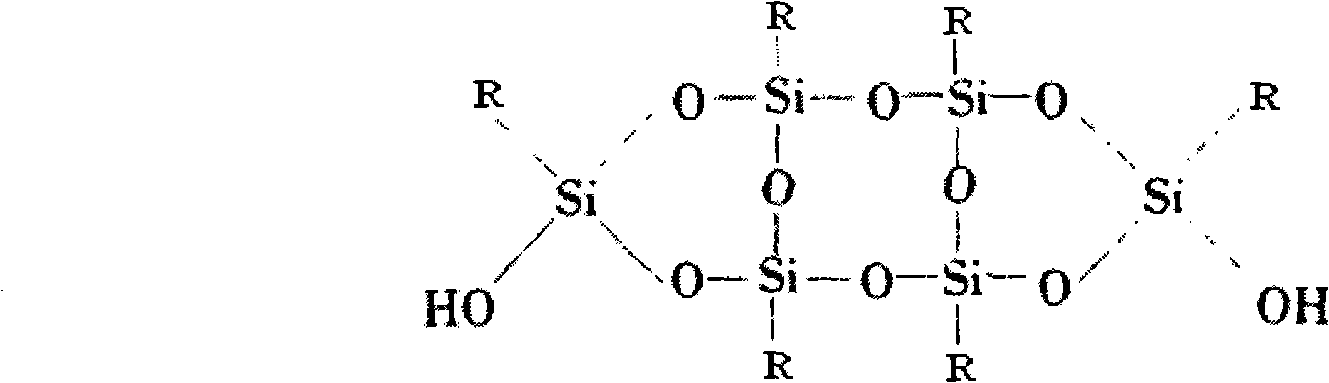

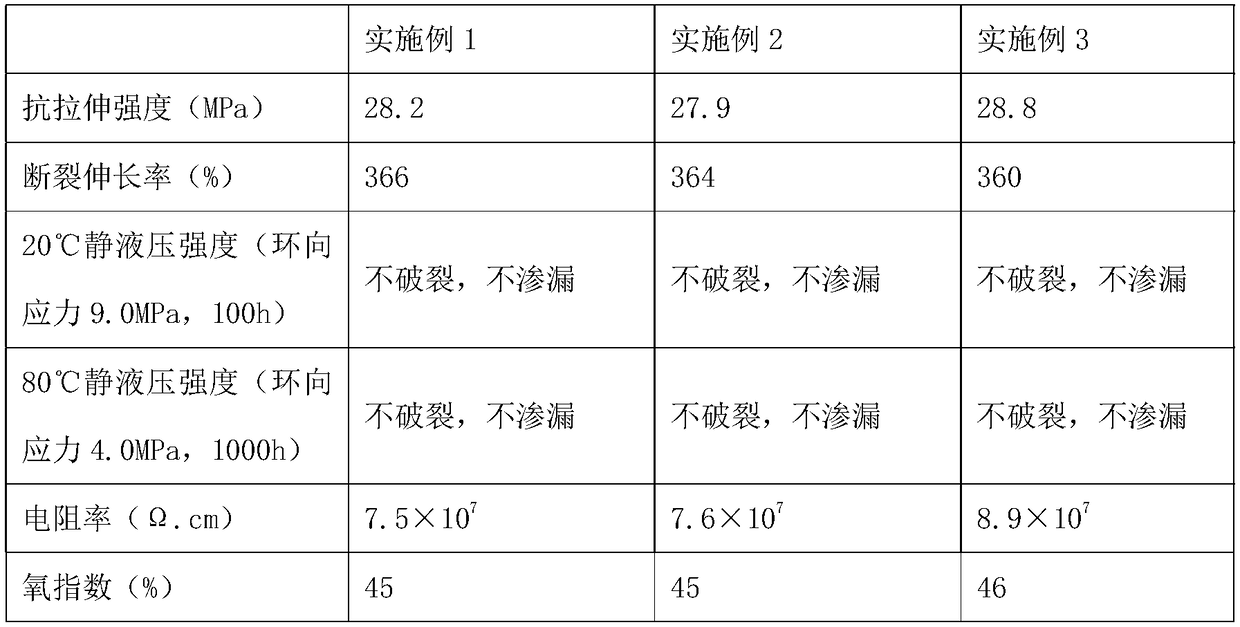

Fluorosilicone rubber cable material for coal mine cable and preparation method of cable material

The invention relates to a fluorosilicone rubber cable material for a coal mine cable and a preparation method of the cable material. The cable material comprises the following raw materials: fluorosilicone rubber, methyl vinyl silicone rubber, precipitation-method white carbon black, light calcium carbonate, zinc oxide, magnesium oxide, stearic acid, an accelerator N, N-tetramethylthiuram disulfide, an antiager-2-mercapto benzimidazole, a vulcanizer-2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, a flame retardant-ammonium polyphosphate, diphenyl silanediol, talcum powder and vaseline. According to the cable material, the advantages of the fluorosilicone rubber and the methyl vinyl silicone rubber as raw materials are combined, the performance of a conventional fluorosilicone rubber cable material is improved, the cable material has excellent performances such as friction and collision resistance, high and low temperature resistance, medium resistance, ageing resistance, flame retardance, waterproof and moistureproof properties, long service life and the like, the requirement of safety use in a coal mine in a special environment is met, and the preparation method of the cable material is simple in process and free of environmental pollution and three-waste emission.

Owner:WUXI HUAMEI CABLE

Low-smoke flame-retardant rubber cable material and preparation method thereof

InactiveCN104961929ALow smoke productionImprove flame retardant performanceRubber insulatorsElastomerPolymer science

The invention relates to cable materials and a preparation method thereof, in particular to a low-smoke flame-retardant rubber cable material and the preparation method thereof. The low-smoke flame-retardant rubber cable material is composed of the following raw materials including, by weight, 40-100 parts of natural rubber, 40-80 parts of chloroprene rubber, 30-40 parts of nitrile rubber, 4-5 parts of stearic acid, 4-5 parts of a coupling agent, 5-6 parts of zinc oxide, 5-6 parts of antioxidant BHT, 3-5 parts of accelerator, 100-120 parts of a fire retardant and 60-100 parts of a filling agent. The main component of the natural rubber is polyisoprene which is one of the air-dried rubber piece and crepe; the accelerator is rubber accelerator TMTD; the chloroprene rubber is an elastic body generated through alpha-polymerization with chloroprene as a main raw material. The low-smoke flame-retardant rubber cable material and the preparation method thereof have the advantages that low-smoke, fire-retardant and weather-resistance effects of the cable material are achieved, environmental-protection and safety are achieved, the physical and mechanical properties and the machining processing property of the prepared cable material are good, the machining is easy, the raw materials are more environmental, the toxicity is low, and the popularization strength is large.

Owner:梁忠顺

Ethylene-propylene-diene monomer material used for electric wire and preparation method of ethylene-propylene-diene monomer material

ActiveCN104448664AHigh strengthGood anti-aging performanceRubber insulatorsSodium stearateEthylene-propylene-diene-monomer

The invention relates to an ethylene-propylene-diene monomer material used for an electric wire and a preparation method of the ethylene-propylene-diene monomer material. The ethylene-propylene-diene monomer material comprises the following components in parts by weight: 85-115 parts of an ethylene-propylene-diene monomer, 2.5-10 parts of acrylic acid, 1.5-7 parts of sodium stearate, 1.5-6 parts of an initiator, 2.5-8 parts of an antiager, 0.5-1.5 parts of an inorganic filler and 1-2 parts of a fire retardant. According to the preparation method, a mixture is added to a double-screw extruder to carry out extrusion pelleting. The ethylene-propylene-diene monomer material used for the electric wire is high in strength, good in anti-aging, good in flame retardant property, stable in power supply property and convenient to process.

Owner:JIANGSU LONG E CABLE

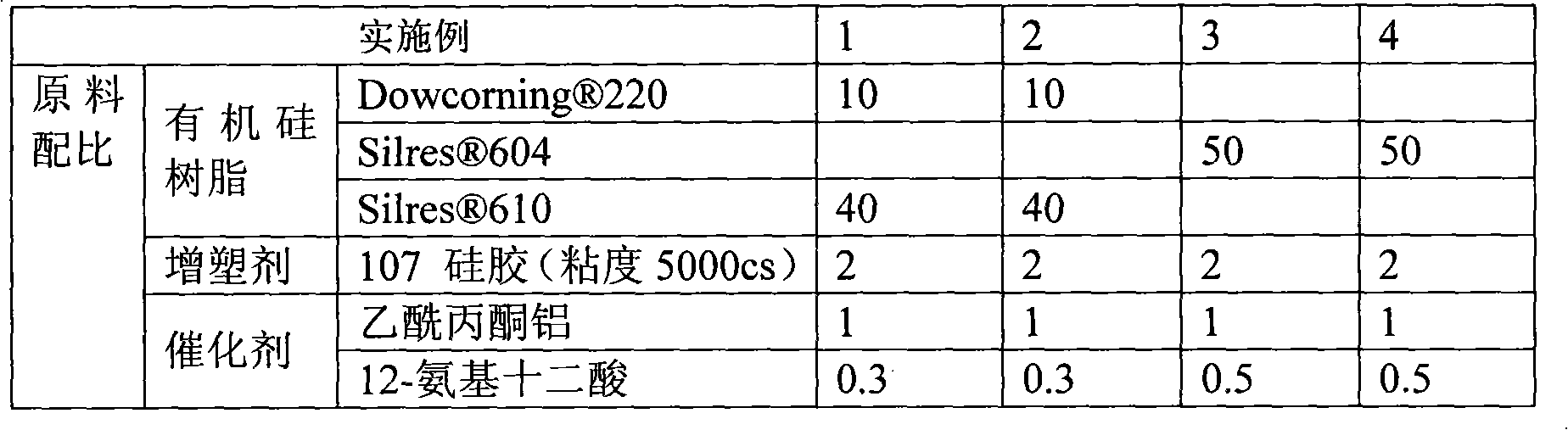

Flame-retardant organosilicon powder encapsulating material for electronic component

InactiveCN101302343AAchieve flame retardant effectLow curing temperatureOther chemical processesElectrical resistance and conductancePlasticizer

The invention relates to a flame-retardant organic silicon powder encapsulation material used for an electronic component. The compositions by weight percentage of the flame-retardant organic silicon powder encapsulation material are: 15 to 60 percent of organic silicon resin, 20 to 80 percent of padding, 1 to 20 percent of plasticizer, 0.5 to 1.5 percent of catalyst, and 0.5 to 5 percent of addition agent. The flame-retardant organic silicon powder encapsulation material has the characteristics of environmental protection, innocuousness, high temperature resistance, good flame redartance, low solidification temperature, self-levelling, good electrical insulation property and so on, and is applicable to encapsulations of voltage dependent resistor, thermistance, porcelain capacitor and other electronic components.

Owner:天津凯华绝缘材料股份有限公司

Flame retarding polyurethane foam and preparation method thereof

The invention discloses a flame retarding polyurethane foam and a preparation method thereof. The flame retarding polyurethane foam comprises the following raw materials of premixed polyether polyol, diisocyanate and a composite flame retardant, wherein the weight ratio of the premixed polyether polyol to the diisocyanate is 1: (1-1.5), the usage amount of the composite flame retardant is 10%-20% of that of the premixed polyether polyol, the composite flame retardant comprises graphite and dimethyl phosphate, and the weight ratio of the graphite to the dimethyl phosphonate is (0.8-3):1. According to the flame retarding polyurethane foam and the preparation method thereof, the used graphite and the dimethyl methyl phosphonate are synergetic with each other, the graphite can be rapidly expanded into an efficient heat insulation oxygen barrier which is capable of preventing polyurethane from flaming, and the dimethyl methyl phosphonate is used for catalyzing dehydration and char formation of polyol to achieve the effect of retarding flame. To improve flame retarding performance of rigid polyurethane foams, compared with rigid polyurethane foam oxygen index generated during the usage of the graphite or the dimethyl methyl phosphonate, the rigid polyurethane foam oxygen index generated during the simultaneous usage of the graphite and the dimethyl methyl phosphonate can be increased by 5.

Owner:JIANGSU KETAI NEW HEAT INSULATION MATERIAL

Zinc phosphomolybdate flame retarding and smoke suppressing PVC sheet material

InactiveCN107286494APromote cross-linking into charReduce generationPhosphorus compoundsPlasticizerPhosphate

The invention discloses a zinc phosphomolybdate flame retarding and smoke suppressing PVC sheet material which is prepared from the following components in parts by weight: 100 parts of PVC resin, 4 to 5 parts of a heat stabilizer, 5 to 20 parts of a plasticizer, 3 to 7 parts of a flame retarding and smoke suppressing agent, 0.5 to 3 parts of a phosphate coupling agent and 0.4 to 0.6 part of PE wax. According to the PVC sheet material, by the flame retarding action of phosphorus and the smoke suppressing action of molybdenum and zinc, the synergistic effect of phosphorus, molybdenum and zinc can effectively improve the flame retarding and smoke suppressing performance of the PVC sheet material.

Flame-retardant coating fabric high in moisture-penetrability

The invention discloses a flame-retardant coating fabric high in moisture-penetrability. The flame-retardant coating fabric high in moisture-penetrability comprises a first base coating and a second base coating, wherein the first base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of a bridging agent, 1.6-2 parts of an accelerant, 1.4-1.6 parts of a washable agent and 9-11 parts of phosphate ester flame-retardant oil. The second base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of the bridging agent, 1.6-2 parts of the accelerant, 1.4-1.6 parts of the washable agent and 9-11 parts of phosphate ester flame-retardant oil. The flame-retardant coating fabric high in moisture-penetrability is small in smoke generation quantity, free of molten drop, high in flame-retardant effect and highly washable; the flame-retardant substance has a small possibility of hydrolyzing.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Modified and enhanced flame retardant treating agent for wood floor wood

ActiveCN104057506ADoes not affect textureDoes not affect colorWood impregnation detailsUltimate tensile strengthEucalyptol

The invention relates to the field of modified treatment of wood floor wood, and particularly relates to a modified and enhanced flame retardant treating agent for the wood floor wood. The modified agent is prepared from the following raw materials in parts by weight: 1 to 2 parts of eucalyptol, 1 to 3 parts of nekal, 3 to 5 parts of natrium salicylicum, 0.1 to 0.2 part of capsaicine, 2 to 4 parts of iso-tridecanol polyoxyethylene ether, 1 to 2 parts of sodium alginate, 20 to 25 parts of sodium chloride, 28 to 30 parts of water glass, 10 to 12 parts of sodium sulfamate, 380 to 400 parts of water and 6 to 8 parts of auxiliaries. According to the modified agent disclosed by the invention, the effects of corrosion prevention, desinsectization and aroma enhancement of the raw materials including the eucalyptol and the capsaicine are combined, and the raw materials including the water glass and the sodium alginate are added, so as to enhance the wood intensity, improve the heat resistant capability and achieve the flame retardant effect. The modified agent has the advantages of being easy in raw material obtaining, simple in preparation method, good in penetrability, difficult in running off after permeating through the wood, long in modified effect and free from influence on wood textures or color, the modified wood is good in size stability, and manufactured wood floor has the advantage of durability, high safety and high market competitiveness.

Owner:定远县林能木业有限责任公司

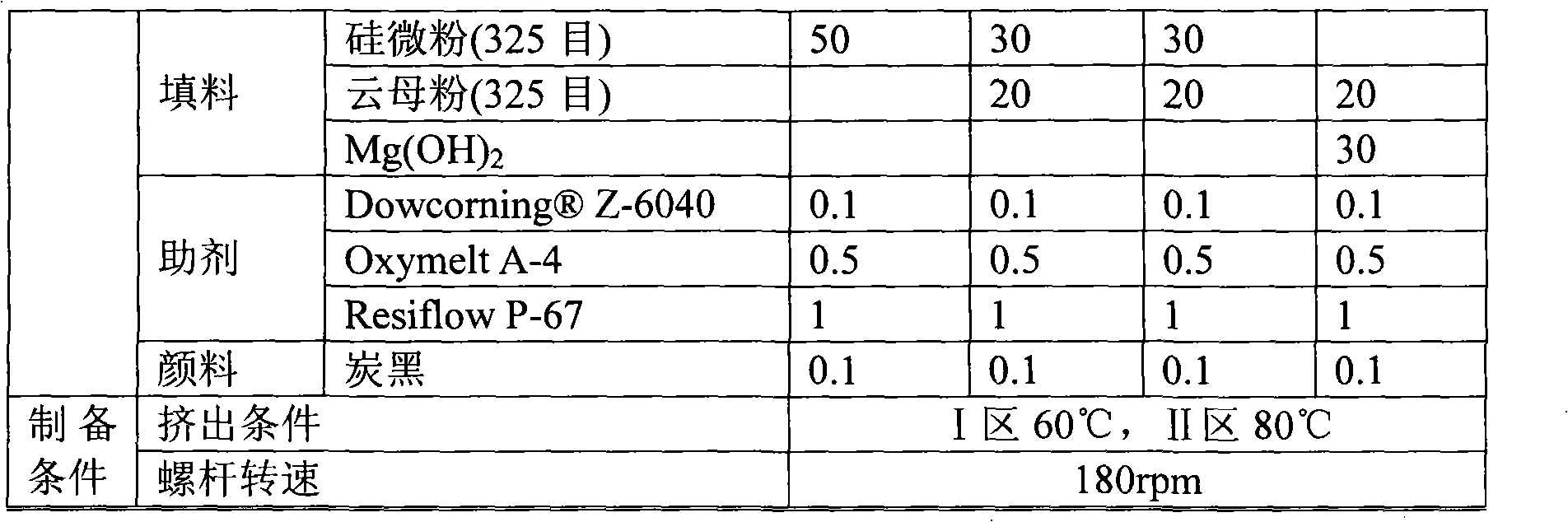

Rapidly extinguished battery tank

PendingCN107579180AShort strokeShorten the timeSecondary cellsFire rescueElectrical batteryEngineering

The invention discloses battery tank fire extinguishing technique and discloses a rapidly extinguished battery tank which comprises channels, wherein the channels are formed in a tank wall; an external interface for connecting the channel with a fire extinguishing agent pipeline is formed in the battery tank; internal ejection holes corresponding to battery packs are formed inside the battery tank; the internal ejection holes are communicated with the channels; one or more channels are formed in the tank wall; a plurality of the channels are uniformly formed in the tank wall at intervals. Thechannels are formed in the tank wall of the battery tank, and a fire extinguishing agent can be directly ejected to the battery packs through the channels, so that the distance and the time that the fire extinguishing agent reaches the battery packs are shortened, the temperature can be rapidly reduced, the battery packs can be prevented from contact with the air, a flame retardancy effect is achieved, a rapid fire extinguishing speed is achieved, and a good effect is achieved.

Owner:SICHUAN CAMY NEW ENERGY CO LTD

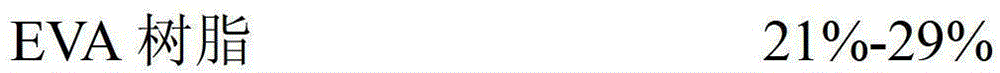

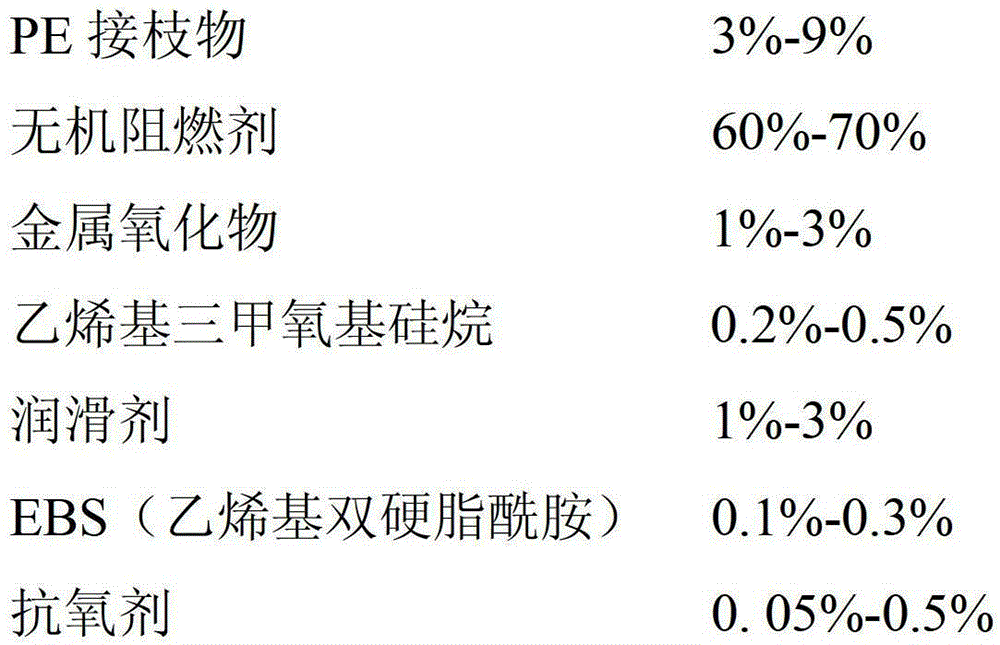

A low-smoke halogen-free flame-retardant cable material

ActiveCN103087394BImprove performanceExtended service lifePlastic/resin/waxes insulatorsInsulated cablesLow smoke zero halogenSilanes

The invention discloses an LSOH (Low Smoke Zero Halogen) flame-retardant cable material which comprises the following components by weight percent: 21%-29% of EVA (Ethylene-vinyl acetate copolymer) resin, 3%-9% of PE (Poly Ethylene) grafts, 60%-70% of an inorganic flame retardant, 1%-3% of metallic oxide, 0.2%-0.5% of vinyl trimethoxy silane, 1%-3% of a lubricant, 0.1%-0.3% of EBS (Ethylene Bis Stearamide) and 0.05%-0.5% of an antioxidant. The LSOH flame-retardant cable material which is obtained by adopting the components and the ratio thereof has a good effect of low smoke flame retardancy, meets the requirement of vertical burning tests, can be used for replacing the traditional PVC (polyvinyl chloride) cable materials, and is secure.

Owner:和昌电业(肇庆)有限公司

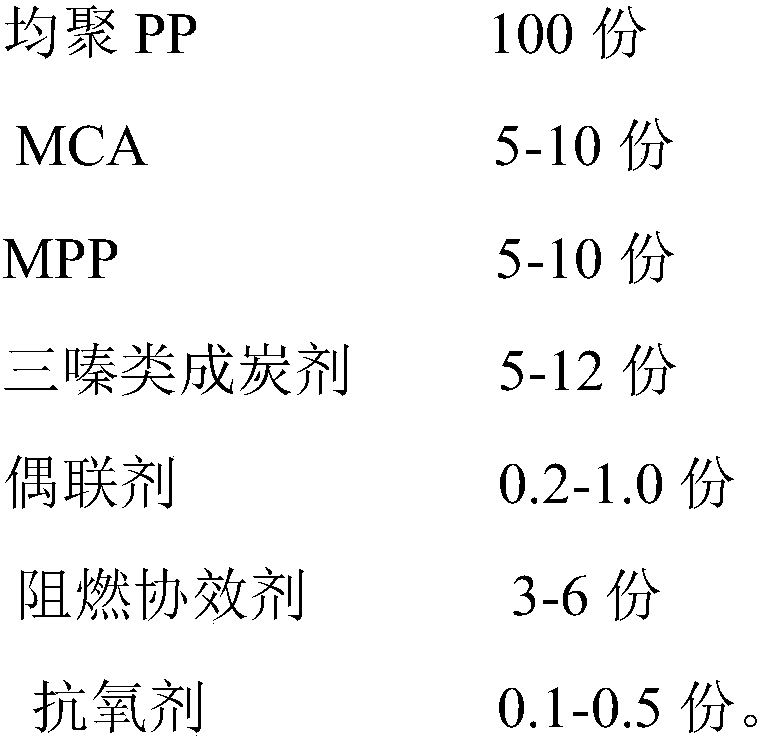

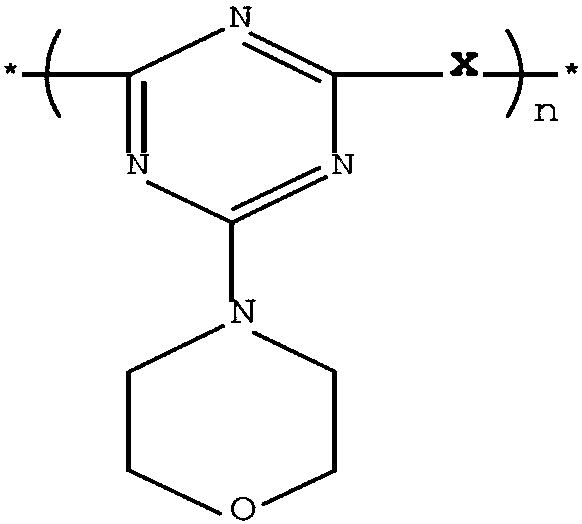

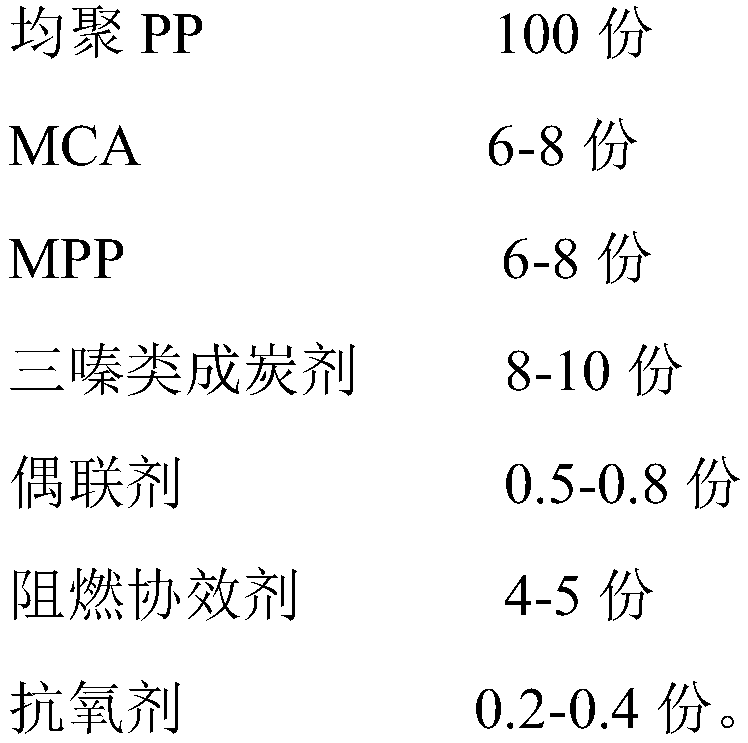

High-limit oxygen index halogen-free flame-retardant PP material and preparation method thereof

The invention discloses a high-limit oxygen index halogen-free flame-retardant PP material. The high-limit oxygen index halogen-free flame-retardant PP material is prepared from 100 parts by weight ofhomopolymerized PP, 5-10 parts by weight of MCA (melamine cyanurate), 5 to 10 parts by weight of MPP (melamine polyphosphate), 5 to 12 parts by weight of a triazine charring agent, 0.2 to 1.0 part byweight of a coupling agent, 3 to 6 parts by weight of a flame retardant synergist and 0.1 to 0.5 parts by weight of an antioxidant. The invention also discloses a preparation method of the high-limitoxygen index halogen-free flame-retardant PP material. The preparation method comprises selecting a specific matrix homopolymerized PP, and adding a flame retardant which is composed of an acid source, a carbon source, a gas source and a flame retardant synergist and is subjected to coupling agent surface treatment into the homopolymerized PP. The high-limit oxygen index halogen-free flame-retardant PP material improves the compatibility between the flame retardant and the PP matrix, solves the problems of surface frosting and precipitation of the flame-retardant PP material, has a high limitoxygen index under less use of the flame retardant, has the advantages of simple processes, good processing performances, no dripping and environmental friendliness and is suitable for large-scale industrial production.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

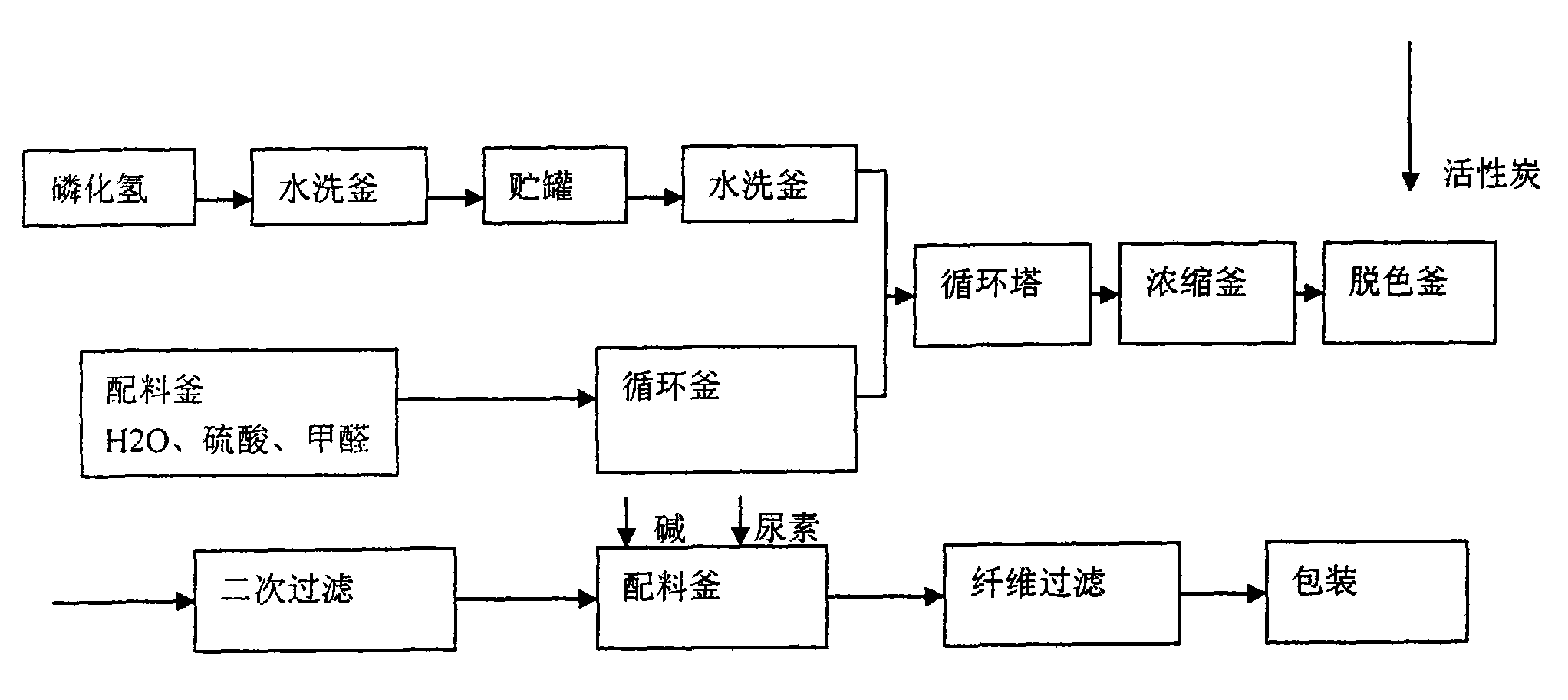

Preparation method of tetrakis hydroxymetyl phosphonium sulfuric-urea polymer

InactiveCN101560225AGuaranteed main contentFeel goodGroup 5/15 element organic compoundsFibre treatmentFiberPhosphonium

The invention relates to a preparation method of tetrakis hydroxymetyl phosphonium sulfuric-urea polymer. The technique process comprises the following steps: phosphine gas is collected and stored after being bathed in an intake washing kettle; deionized water is added into a dosage kettle, then sulphuric acid and formaldehyde is pumped into the dosage kettle to be stirred according to the mol ratio of 1:8.5-8.7; the above mixed liquid is driven into a recycling kettle in which phosphine gas is absorbed by a recycling tower; the feed liquor is pumped into a decoloring kettle, then 2 per mill of active carbon power is added; the feed liquor and urea is pumped into the dosage kettle to be stirred according to the mol ratio of 1.25:1, sodium hudroxide is used for adjusting PH value; tetrakis hydroxymetyl phosphonium sulfuric-urea polymer is obtained through fiber filter bag with aperture being 2um. The method has the advantages that sulphuric acid and formaldehyde is mixed according to the ratio so that sulphuric acid and formaldehyde can fully react while absorbing phosphine gas, and the feed liquor and the urea is mixed according to the mol ratio of 1.25:1 so as to ensure the primary content of tetrakis hydroxymetyl phosphonium sulfuric. The product is enhanced in tenacity and is unlikely to be torn. The fabric has good fire resistance and washing resistance without affecting various initial excellent performances of the fabric. The method has no environmental pollution and can realize zero emission of toxic gas.

Owner:JIANGSU DANAI CHEM

Preparation method of flame-retardant super-fine wool fabric

InactiveCN109467615AReduce the temperaturePromote charcoalHeat resistant fibresAnimal fibresFiberWater vapor

The invention discloses a preparation method of flame-retardant super-fine wool fabric. The preparation method comprises the following three steps: oxidizing sodium alginate, finishing fabric with oxidized sodium alginate and performing ion exchange. In the preparation method of the flame-retardant super-fine wool fabric, multi-aldehyde sodium alginate is adopted as a finishing agent for film formation on the surfaces of fibers, and the sodium alginate covered on the surfaces of the fibers are used for isolating air and heat, so that char formation is promoted, water vapor is vaporized by absorption of heat, and the thermal decomposition temperature is lowered accordingly; in addition, the step that the sodium alginate is heated is earlier than the step of decomposition of wool, so that the temperature on the surface of the fabric is lowered while heat is absorbed and the flame retardant effect is achieved finally.

Owner:JIANGSU EAST CHINA TEXTILE PROD TESTING CO LTD

Thermal radiation prevention and flame retardance knitted fabric and manufacturing method

The invention discloses a manufacturing method of a thermal radiation prevention and flame retardance knitted fabric. The method includes the steps of knitting a double-faced knitted gray fabric through silver-plated fiber filaments and Lenzing thermal protection fiber filaments so that one face of the gray fabric can be a silver-plated fiber face and the other face of the gray fabric can be a flame retardance fiber face, and then conducting dyeing and finishing on the gray fabric, wherein chinlon filaments serve as carriers for the silver-plated fiber face, silver is arranged on the surface layer of the silver-plated fiber face through an electrolytic method or a permeating and fixing method, the Lenzing thermal protection fiber filaments serve as carriers for the flame retardance fiber face, and a flame retardance medium is arranged on the surface of the flame retardance fiber face through a soaking method. The silver-plate fiber is reasonably combined and matched with the Lenzing thermal protection fiber, and therefore a fabric with a thermal radiation prevention function and a flame retardance function is produced.

Owner:JIHUA 3543 KNITTING CLOTHING

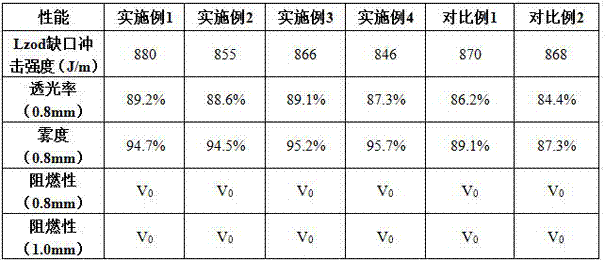

Photodiffusion PC material with high flame-retardant performance and preparation method thereof

The invention discloses a photodiffusion PC material with high flame-retardant performance and a preparation method thereof. The PC material is prepared from PC granules, PC powder, a photodiffusion agent, a brominated flame retardant, an organic-silicon flame retardant, a main antioxidant, an auxiliary antioxidant, an ultraviolet light absorber and a lubricant. The preparation method comprises the steps as follows: 1) drying the PC granules and the PC powder; 2) preparing photodiffusion agent master batch; 3) fully and uniformly mixing the PC granules, the photodiffusion agent master batch, the brominated flame retardant, the organic-silicon flame retardant, the main antioxidant, the auxiliary antioxidant, the ultraviolet light absorber and the lubricant; 4) adding the material in step 3) to a twin-screw extruder for extrusion granulation to obtain the photodiffusion PC material with high flame-retardant performance. The photodiffusion PC material with high flame-retardant performance has the advantages of high light transparency, high haze, high flame-retardant performance and the like, has excellent comprehensive performance and can be widely applied to electrical lighting and other fields. The preparation method is simple, the process operation is easy to realize, the production cost is low, and industrial production is facilitated.

Owner:GUANGDONG JUSHI CHEM CO LTD

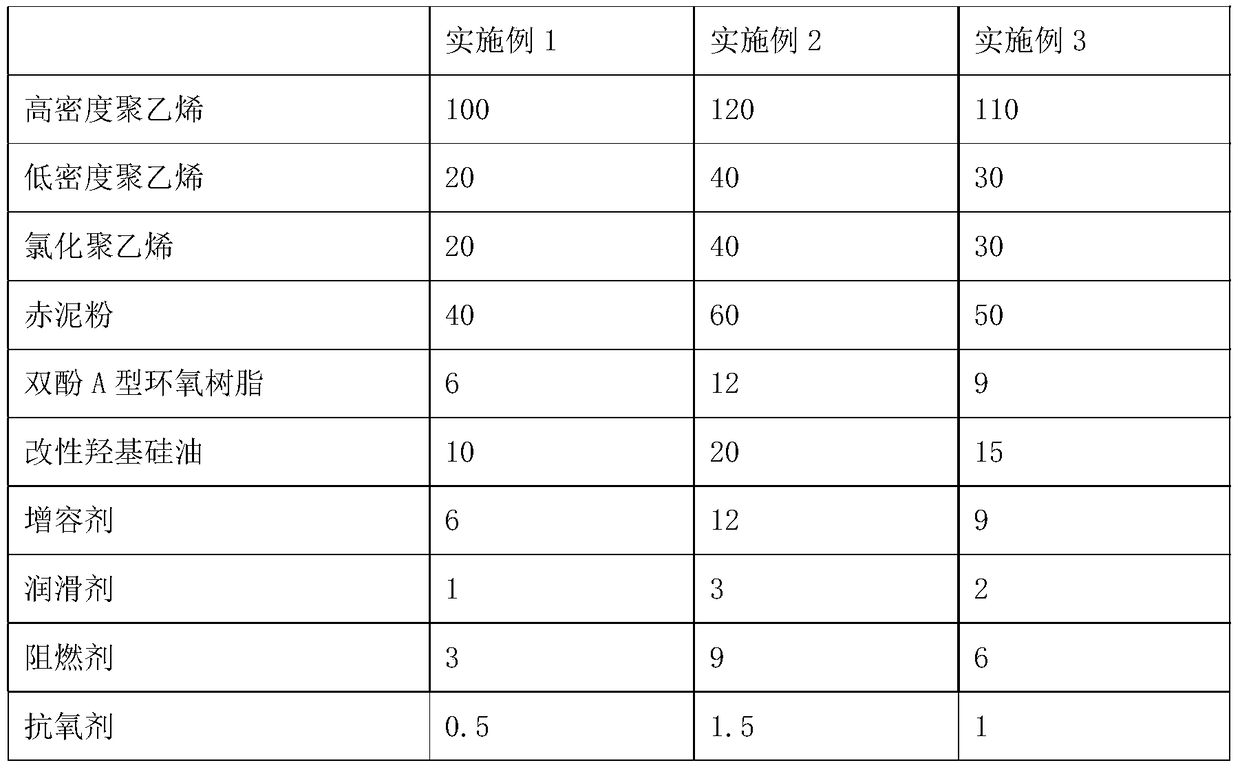

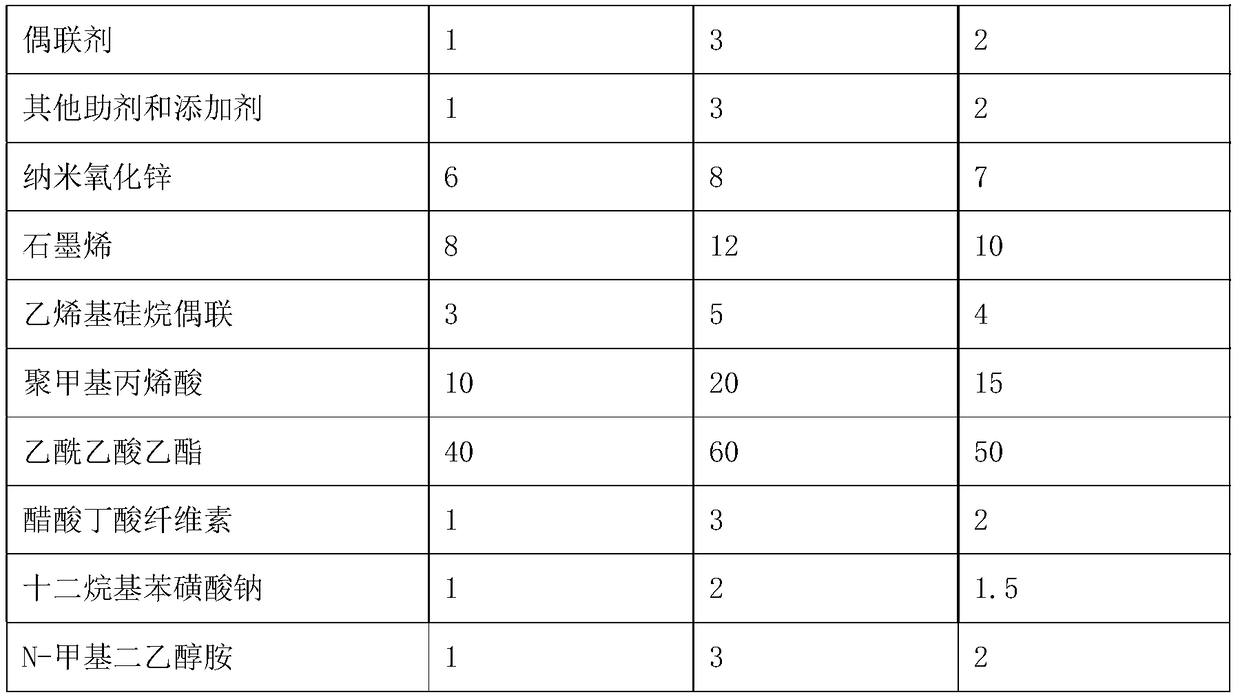

Preparation method of high toughness PE hollow wall twined pipe based on red mud modification

InactiveCN109021358AGood compatibilityIncrease the amount of carbonTubular articlesRed mudVolumetric Mass Density

The invention relates to a preparation process of a high toughness PE hollow wall twined pipe based on red mud modification. The process utilizes nano-zinc oxide and graphene for modification to improve the mechanical properties, toughness and rigidity of the pipe; nano-zinc oxide and graphene cooperate to form a continuous conductive path between systems, thus greatly improving the pipe conductivity; red mud is utilized for blending modification of a PE composite material, while the rigidity is improved, the PE pipe also has strong toughness, waste is turned into wealth, and the cost is greatly saved. Hydroxyl silicone oil can migrate on the PE surface and form a flame retardant layer to achieve flame retardant effect. Moreover, addition reaction can be carried out on the hydroxyl in themodified hydroxyl silicone oil and the epoxy group in a bisphenol A epoxy resin structure to enhance the crosslinking density and mechanical strength of the pipe. At the same time, hydroxyl silicone oil has low surface energy and endows the PE pipe with excellent waterproof performance. The preparation method is simple and scientific, the cost is low, the preparation process is environment-friendly, and has no pollution to the environment.

Owner:徐州辛辛那提新型材料有限公司

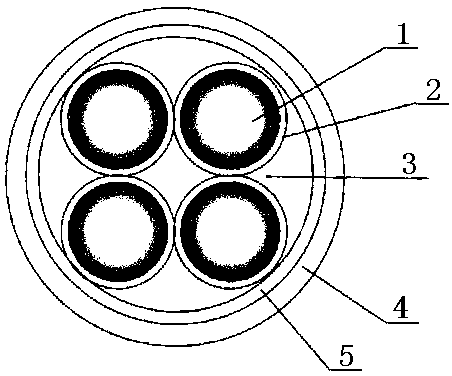

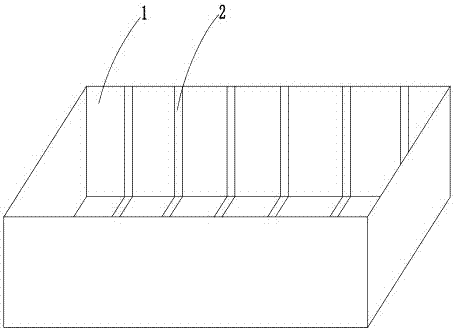

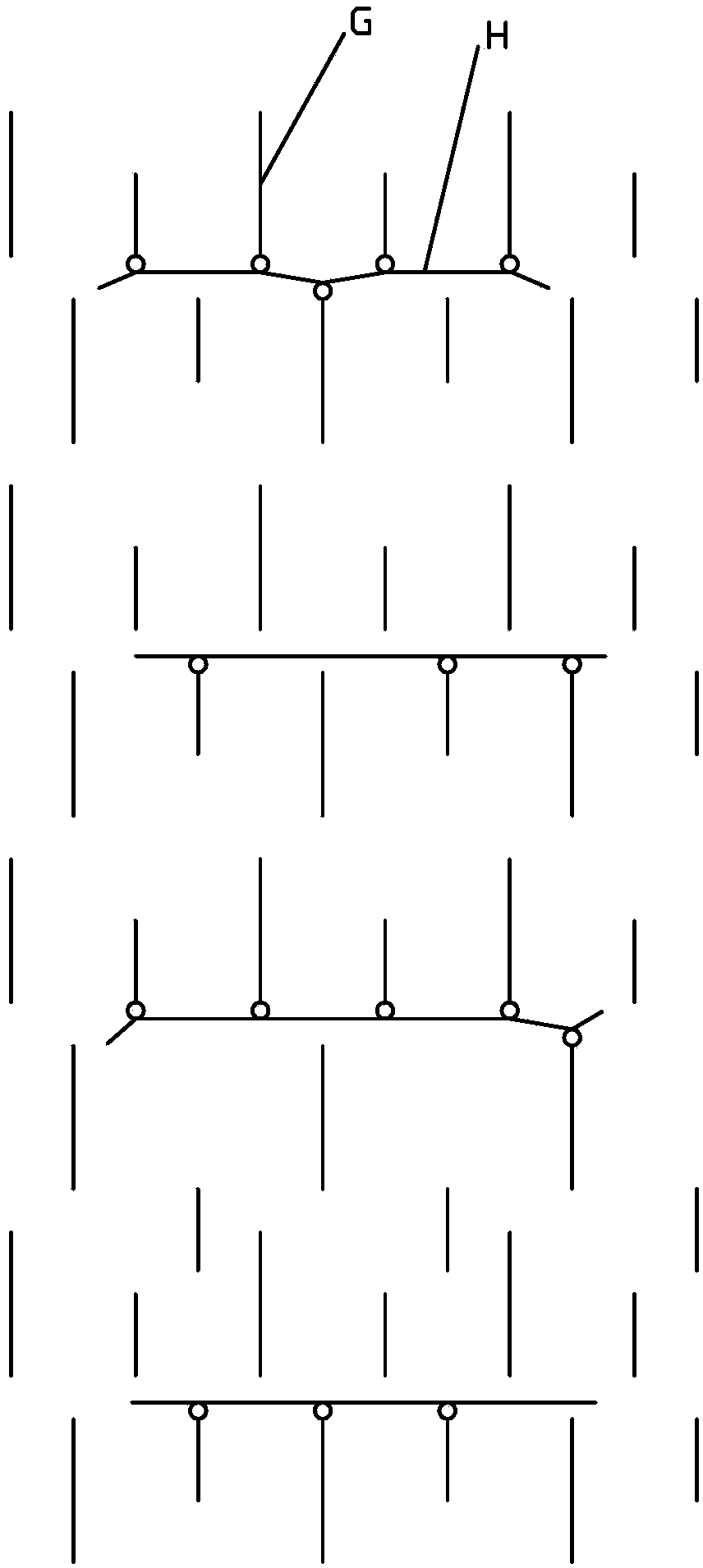

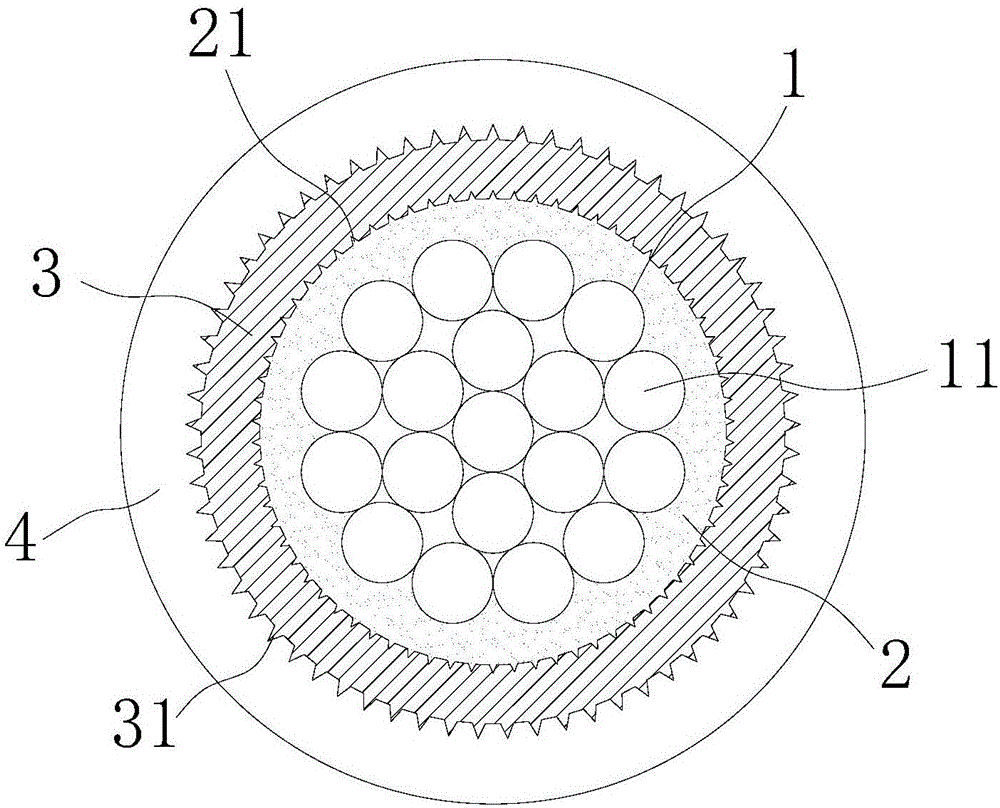

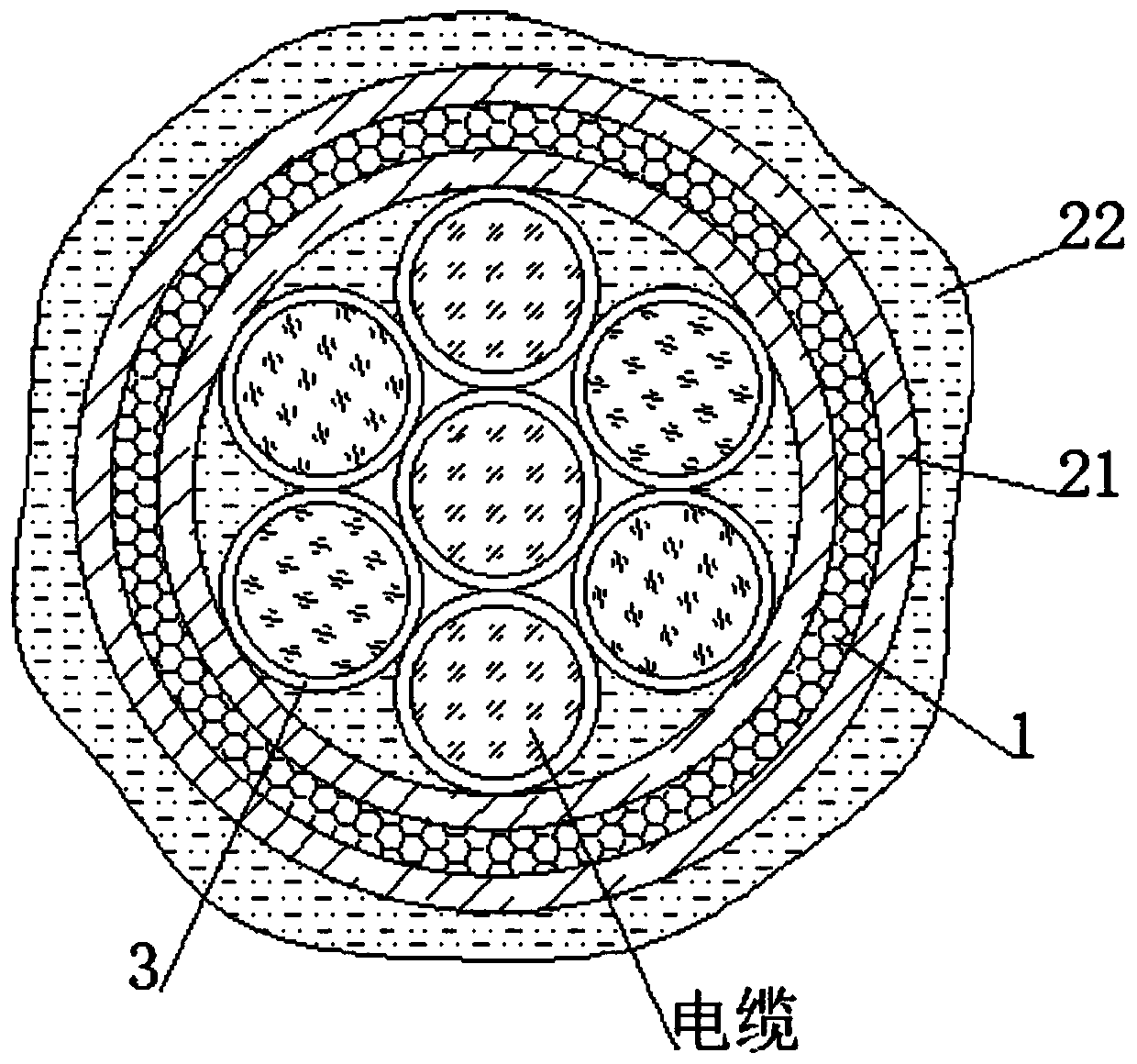

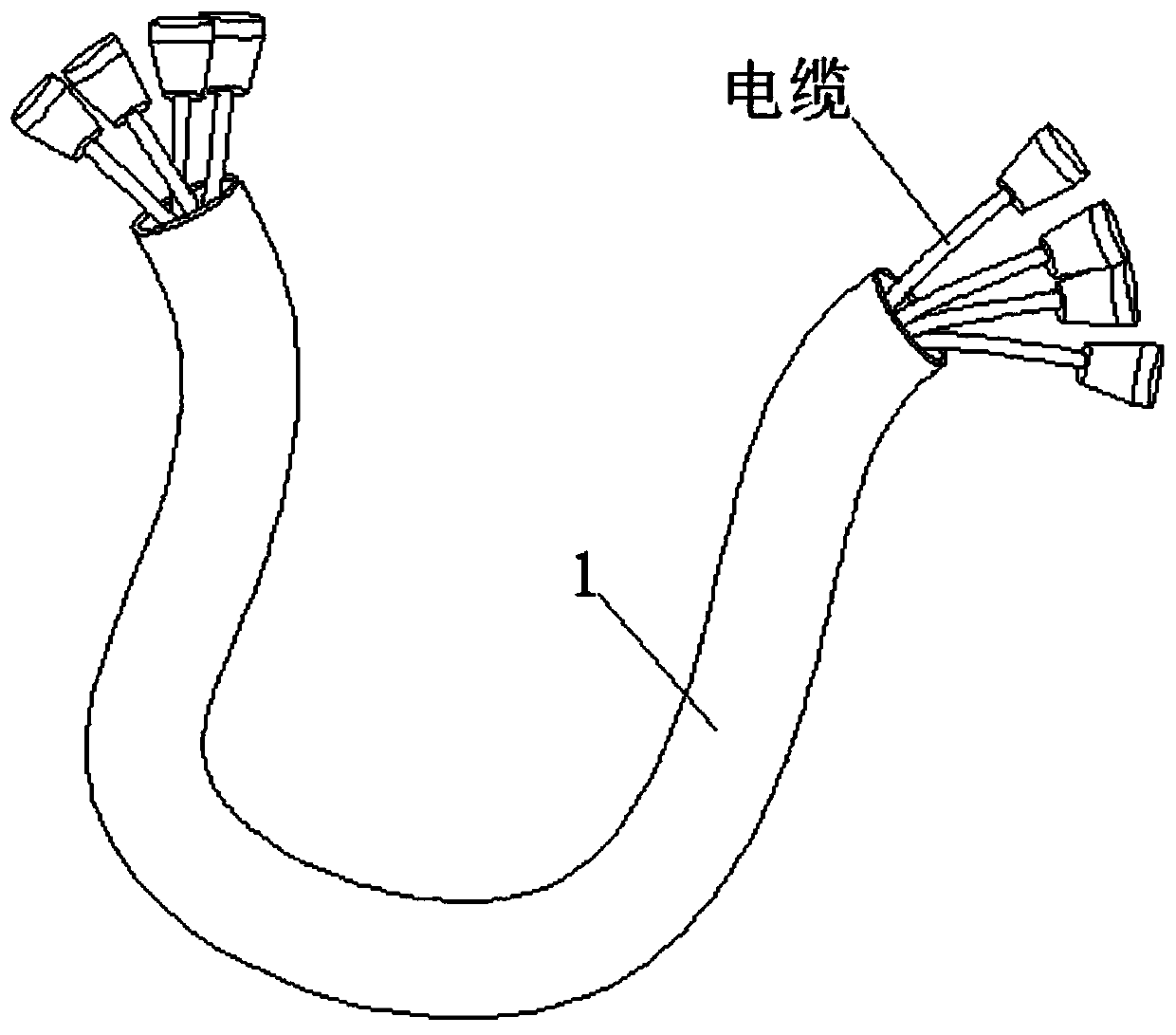

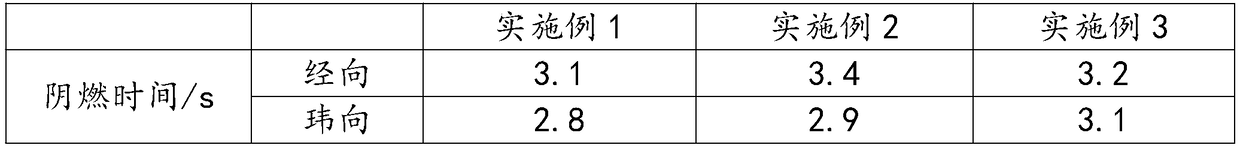

High-insulation cable with high flexibility and easy to bend and fabrication method thereof

ActiveCN106205809AEasy to bendAchieve flame retardant effectFlexible cablesCable/conductor manufactureLow smoke zero halogenElectrical conductor

The invention is applicable for the technical field of a cable, and discloses a high-insulation cable with high flexibility and easy to bend. The high-insulation cable with high flexibility and easy to bend comprises a conductor, a high-insulation layer and a sheath, wherein the sheath comprises a low smoke zero halogen flame-retardant inner layer and a low smoke zero halogen flame-retardant outer layer, second protruding thorns are densely arranged on an external circumferential surface of the low smoke zero halogen flame-retardant inner layer and are internally embedded onto an internal circumferential surface of the low smoke zero halogen flame-retardant outer layer, the conductor is formed by twisting a single conductor line or a plurality of conductor lines and is coated in the high-insulation layer, and first protruding thorns are densely arranged on an external circumferential surface of the high-insulation layer and are internally embedded onto an internal circumferential surface of the low smoke zero halogen flame-retardant inner layer coated at the periphery of the high-insulation layer. The high-insulation cable with high flexibility and easy to bend is reasonable in structure, adjacent layers are highly engaged, the high-insulation cable with high flexibility and easy to bend still has relatively high bending and flexible performance in a low-temperature environment, is long in service life, and has a high insulation effect, and the risk of electric leakage is reduced.

Owner:JIANGSU DONGTENG CABLE TECH CO LTD

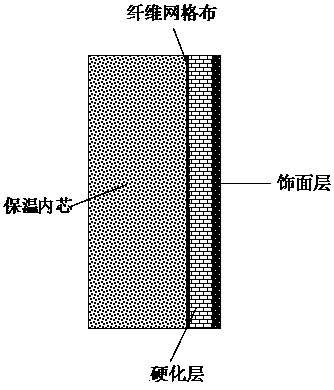

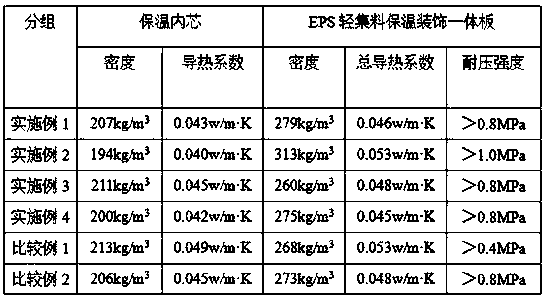

EPS lightweight aggregate thermal-insulation decorative all-in-one board, and preparation method thereof

The invention discloses an EPS lightweight aggregate thermal-insulation decorative all-in-one board, and a preparation method thereof. The EPS lightweight aggregate thermal-insulation decorative all-in-one board comprises a thermal insulation inner core, a fiber grid cloth, a hardened layer, and a stone-like coating decorative layer successively from inner to outer; by weight, the thermal insulation inner core comprises 30 to 50 parts of EPS foam particle, 40 to 80 parts of iron tailing sand, 200 to 300 parts of Portland cement, 10 to 20 parts of rubber powder, and 10 to 20 parts of hydroxymethyl cellulose. According to the preparation method, the flame-retardant EPS foam particle is taken as a lightweight aggregate to prepare the thermal insulation inner core, EPS foam is ultra low in heat conductive coefficient, so that the whole board is provided with excellent thermal insulation performance. The EPS lightweight aggregate thermal-insulation decorative all-in-one board is excellent in thermal insulation effect, and low in density, is simple in preparation technology, and is convenient for large scale production.

Owner:ZHEJIANG UNIV OF TECH

Flame-retardant master batch and preparation method thereof

InactiveCN111574773AEvenly dispersedAuxiliary effectMicroballoon preparationMicrocapsule preparationAntioxidantEngineering

The invention discloses a flame-retardant master batch and a preparation method thereof, and relates to a flame-retardant material. The flame-retardant master batch is characterized by comprising thefollowing components in parts by weight: 100-120 parts of a carrier, 60-130 parts of a halogen-based flame retardant, 150-300 parts of a microcapsule flame-retardant synergist, 0.1-3 parts of an antioxidant, and 3-5 parts of a lubricant. The microcapsule flame-retardant synergist comprises a core material and a wall material, wherein the weight part ratio of the core material to the wall materialis 1: (4-6). The core material is one or a mixture of more of antimony trioxide, antimony pentoxide and sodium antimonate and can improve the durability of the flame-retardant master batch, and the microcapsule flame-retardant synergist can be uniformly dispersed in the carrier in the production process, so that the flame-retardant effect of the flame-retardant master batch is improved.

Owner:厦门毅兴行塑胶原料有限公司

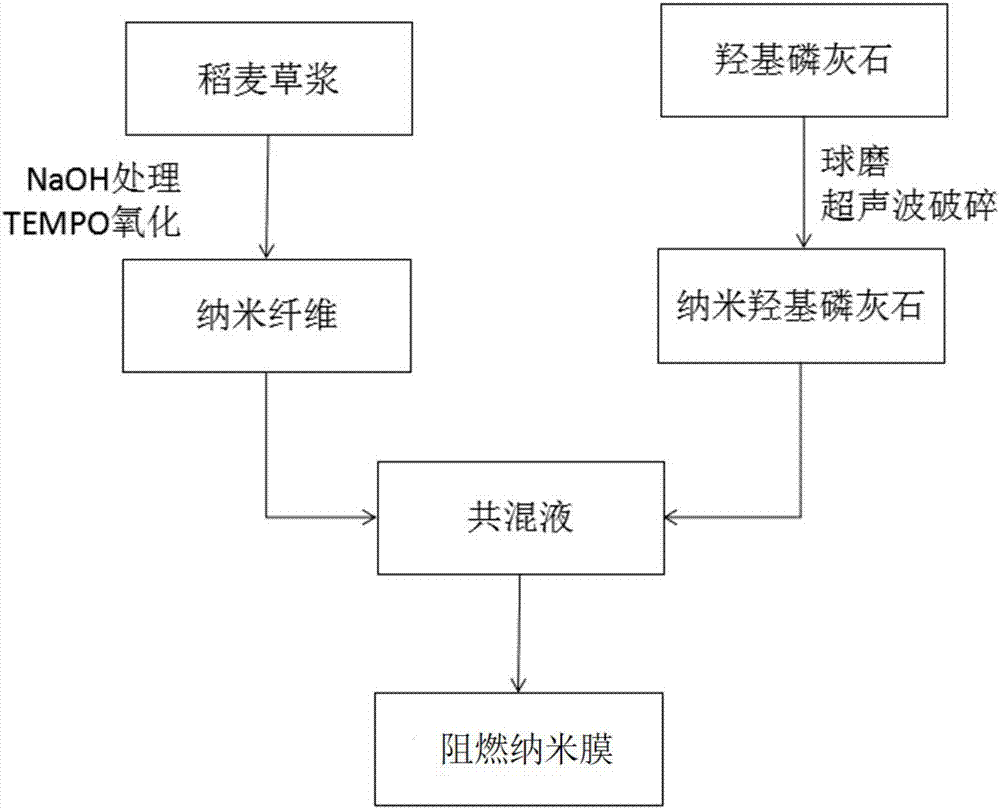

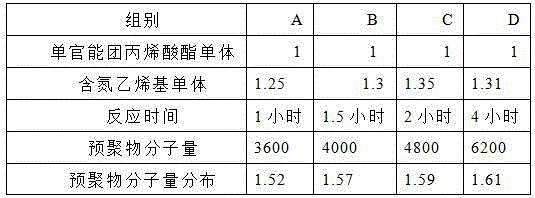

Flame-retardant nanometer film and preparation method and application thereof

ActiveCN107540857AIncrease the speed of formationIncrease char formationEmulsionBiocompatibility Testing

The invention belongs to the field of nanometer materials, and discloses a flame-retardant nanometer film and a preparation method and application thereof. The preparation method of the flame-retardant nanometer film comprises the steps that hydroxyapatite is dried and then subjected to ball milling, and after ultrasionic cell-break treatment is conducted for a period of time, nanometer hydroxyapatite emulsion is obtained; nanocellulose and nanometer hydroxyapatite are prepared into a blend solution according to certain proportion, film formation is conducted under the condition of constant temperature and humidity, and the flame-retardant nanometer film is obtained. The flame-retardant nanometer film has good flame retardance, the nanocellulose and the nanometer hydroxyapatite have the very good biocompatibility, and the flame-retardant nanometer film can be applied to the fields of flame-retardant materials, flexible electronic devices, biological and medical materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

Chip BGA packaging reinforcing method

ActiveCN105047570AEasy accessReduce the temperaturePolyureas/polyurethane adhesivesSemiconductor/solid-state device manufacturingElectrical and Electronics engineering

The invention discloses a chip BGA packaging reinforcing method. The method comprises the following steps that after a chip is mounted to a PCB via a BGA, a BGA packaging reinforcing glue is filled between the chip and the PCB; solidification under a normal temperature for 5-50 minutes is performed and then reinforcing to chip BGA packaging is completed. By using the BGA packaging reinforcing method of the invention, a curing condition is simple and curing can be realized through normal temperature placing so that chip damages brought by heating curing needed by reinforcing and a complex technology of ultraviolet curing in the prior art are avoided. During usage, curing is rapid and storage is stable before usage so that a problem of poor storage performance caused by acceleration curing is avoided. And the glue after curing is removed conveniently and can be completely removed under the normal temperature. A defect that the glue can be removed after being heated in the prior art is overcome. Quality of the BGA chip is protected and a product yield is effectively increased.

Owner:SUZHOU QITAI ELECTRONICS CO LTD

PP flame-retardant plastic

The PP flame-retardant plastic is prepared from the following raw materials in parts by weight: 80-100 parts of polypropylene, 2-5 parts of a flame retardant, 3-5 parts of a dispersing agent, 3-5 parts of a plasticizer and 3-5 parts of an anti-aging agent. A flame retardant is prepared and can generate phosphoric acid and polyphosphoric acid, the nitrogen element of the flame retardant can accelerate the phosphorylation reaction, the generation amount of the phosphorus-rich carbon residues is improved, and then a compact carbon layer is formed on the surface of a polymer, insulates oxygen andheat and acts in a condensed phase; various nitrogen-containing volatile matters such as nitrogen, oxynitride and water vapor can be generated after combustion and decomposition, so that the concentration of combustible gas is reduced, reaction heat absorption is performed to reduce the temperature of the material, a coke layer is quickly expanded, a flame-retardant effect is achieved, a crackingcarbon layer is formed on the surface of a polymer during combustion of an organic silicon carrier, and the oxidation resistance of the cracking carbon layer is improved; therefore, the flame-retardant effect is achieved.

Owner:卓开权

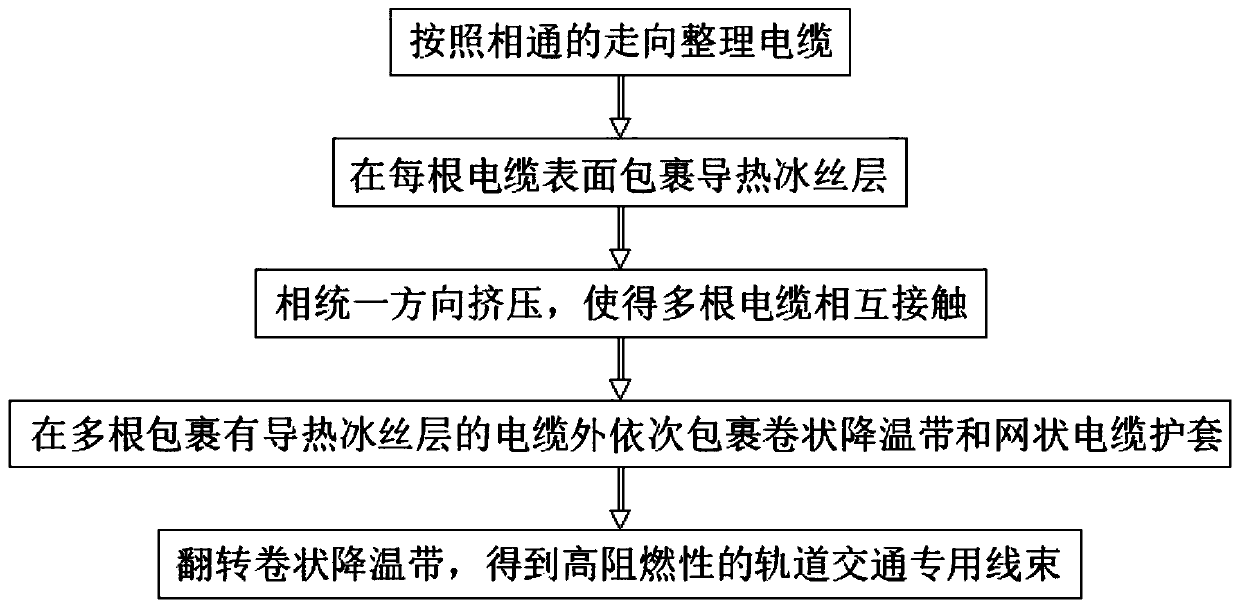

Production process of special highly-flame-retardant wire harness for rail transit

ActiveCN110610786AImprove adsorption capacityFast conductionClimate change adaptationInsulated cablesEngineeringMechanical engineering

The invention relates to a production process of a special highly-flame-retardant wire harness for rail transit. Each cable in a wire harness is coated with a heat conduction ice wire layer, in orderto improve the heat conduction and heat dissipation capabilities of the wire harness. Through the arrangement of a coiled cooling belt and a net-shaped cable sheath, inner-outer double-layer heat conduction and heat dissipation effects can be achieved, the wire harness can be rapidly cooled, the temperature near the wire harness can be lower than the temperature of an electrical system of the whole rail transit, the situation in which a cable can be easily ignited due to excessive temperature is avoided, and the safety is improved. The coiled cooling belt located on the outer side after beingturned over can achieve a heat insulation effect and avoid the influence on normal use of the wire harness due to the too high or too low external environment temperature. Because of the use of a dual-state heat conductor in the coiled cooling belt, heat conduction and heat dissipation effects can be achieved, and the effects of reminding a worker of leakage of the dual-state heat conductor and guiding the worker to a leakage point can be achieved to a certain extent.

Owner:汇铂斯电子技术(苏州)有限公司

Fire-resistant and anti-bacterial cotton fabric and preparation method thereof

InactiveCN109098002AImprove antibacterial propertiesImprove comfortBiochemical fibre treatmentWoven fabricsSurface layerViscose

The invention discloses a fire-resistant and anti-bacterial cotton fabric. The fabric is set as a double-sided structure and comprises a fabric lining layer and a fabric surface layer, wherein the fabric lining layer is made by ramie, cotton and a Coolplus staple fiber via blending; the fabric is made by anti-flaming viscose, an anti-flaming acrylic fiber, ramie and cotton via blending; in the fabric lining layer, the specification of the ramie is 1.67 dtes * 38 mm, the specification of the cotton fiber is 1.85 dtex * 33 mm and the specification of the Coolplus staple fiber is 1.56 dtex * 38 mm; in the fabric surface layer, the specification of the anti-flaming viscose is 1.72 dtex * 36 mm and the specification of the anti-flaming acrylic fiber is 1.56 dtex * 28 mm. The invention furthermore discloses a preparation method of the fire-resistant and anti-bacterial cotton fabric. The cotton fabric is set as the double-sided structure and comprises the fabric lining layer and the fabric surface layer; the fabric lining layer undergoes antibacterial treatment in aloe extracting solution and organic germanium treatment solution; an anti-flaming thin film layer is sprayed on the surface of the fabric surface layer, so that the cotton fabric has more excellent anti-flaming and anti-bacterial properties.

Owner:SHENZHEN NANSHUO MINGTAI TECH CO LTD

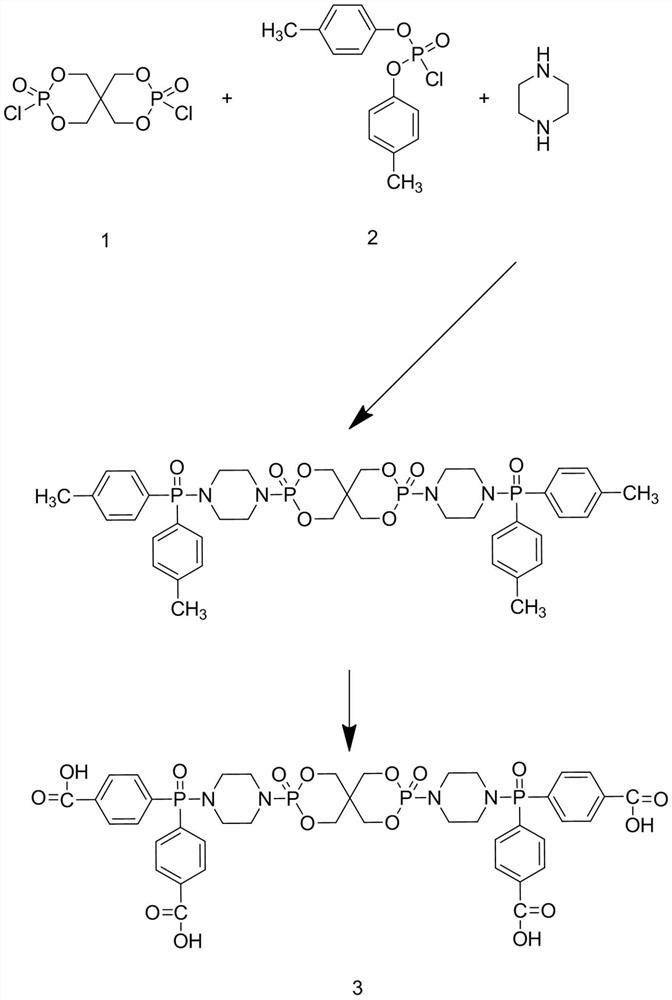

Nitrogen-phosphorus efficient flame retardant containing p-hydroxybenzaldehyde and tryptamine structures, preparation method and application

InactiveCN111303483AImprove flame retardant performanceHinder meltingGroup 5/15 element organic compoundsP-hydroxybenzaldehydeTryptamines

The invention discloses a nitrogen-phosphorus efficient flame retardant containing p-hydroxybenzaldehyde and tryptamine structures, a preparation method and an application. The preparation method comprises the following steps: S1, adding p-hydroxybenzaldehyde and tryptamine into a solvent for reaction under the protection of nitrogen to obtain a p-hydroxybenzyltryptamine Schiff base solution; S2,adding 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into the p-hydroxybenzyltryptamine Schiff base solution obtained in the step S1 for reaction to obtain a p-hydroxybenzyltryptamine phosphaphenanthrene solution; and S3, cooling the p-hydroxybenzyltryptamine phosphaphenanthrene solution obtained in the S2 to room temperature, adding deionized water to separate out a white solid, filtering,washing the white solid with deionized water for 2-3 times, and drying the white solid to obtain the nitrogen-phosphorus efficient flame retardant containing p-hydroxybenzaldehyde and tryptamine structures. The high polymer material prepared by the invention has good transparency.

Owner:WEST ANHUI UNIV

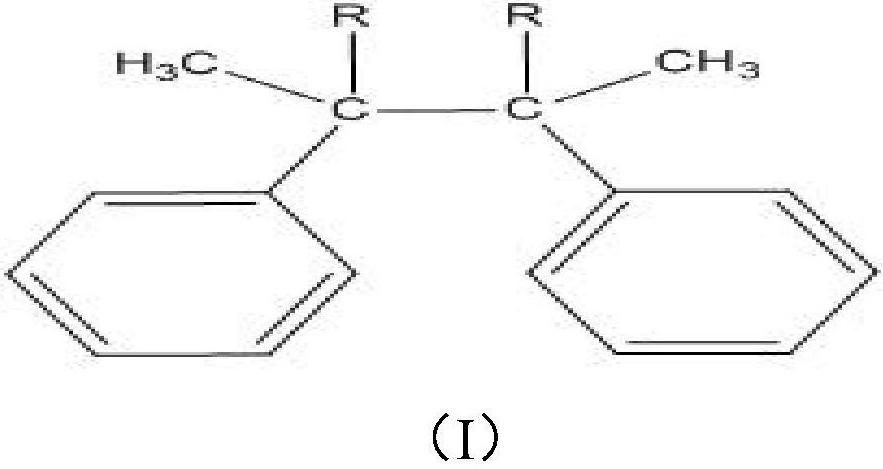

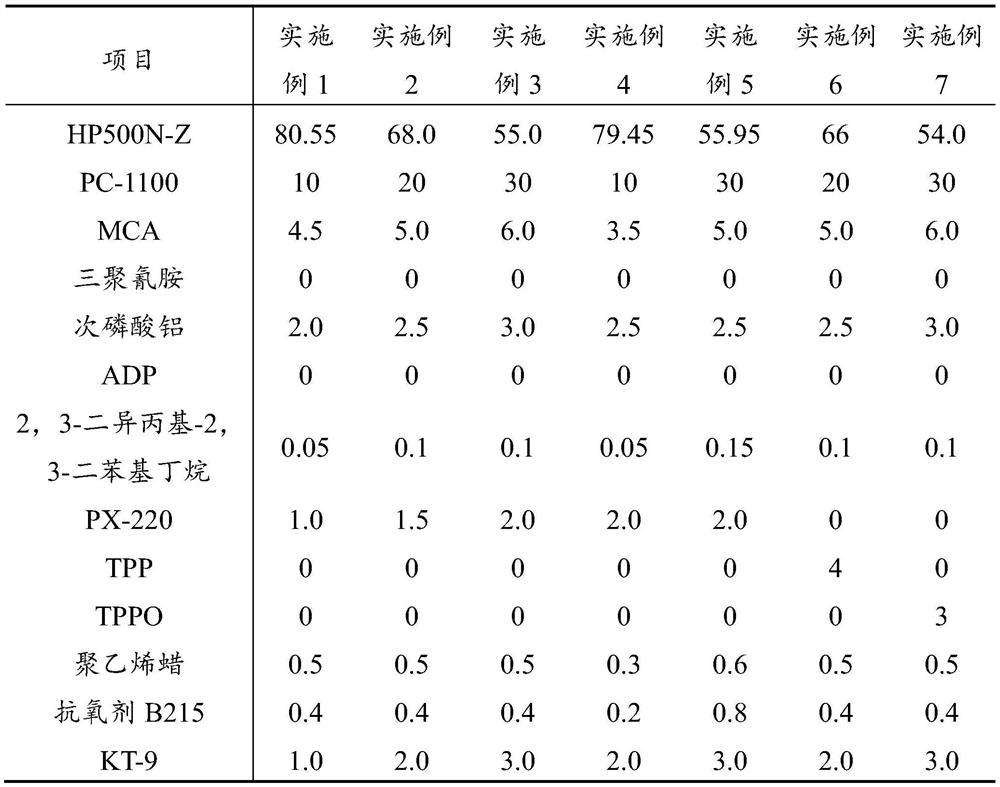

Low-gloss halogen-free flame-retardant alloy material and preparation method thereof

ActiveCN112321942AImprove flame retardant performanceGood mechanical propertiesCompound aPolycarbonate

The invention discloses a low-gloss halogen-free flame-retardant alloy material and a preparation method thereof, and belongs to the technical field of high polymer materials. The low-gloss halogen-free flame-retardant alloy material is prepared from the following raw materials in parts by weight: 50-90 parts of polypropylene resin, 10-30 parts of polycarbonate resin, 6-12 parts of a compound flame retardant and 0.3-0.6 part of a lubricant. When the compound flame retardant is formed by compounding a nitrogen flame retardant, a hypophosphite flame retardant, a phosphate flame retardant and a flame retardant synergist, the mass ratio of the nitrogen flame retardant to the hypophosphite flame retardant to the flame retardant synergist to the phosphate flame retardant is (30-60: 15-30): (0.5-1.5: 0-20). The low-gloss halogen-free flame-retardant alloy material prepared from the compound flame retardant disclosed by the invention has good flame retardancy, mechanical properties and low gloss, and can be used for preparing a table lamp key shell; and the preparation method is simple and suitable for industrial production.

Owner:GUANGDONG JUSHI CHEM CO LTD

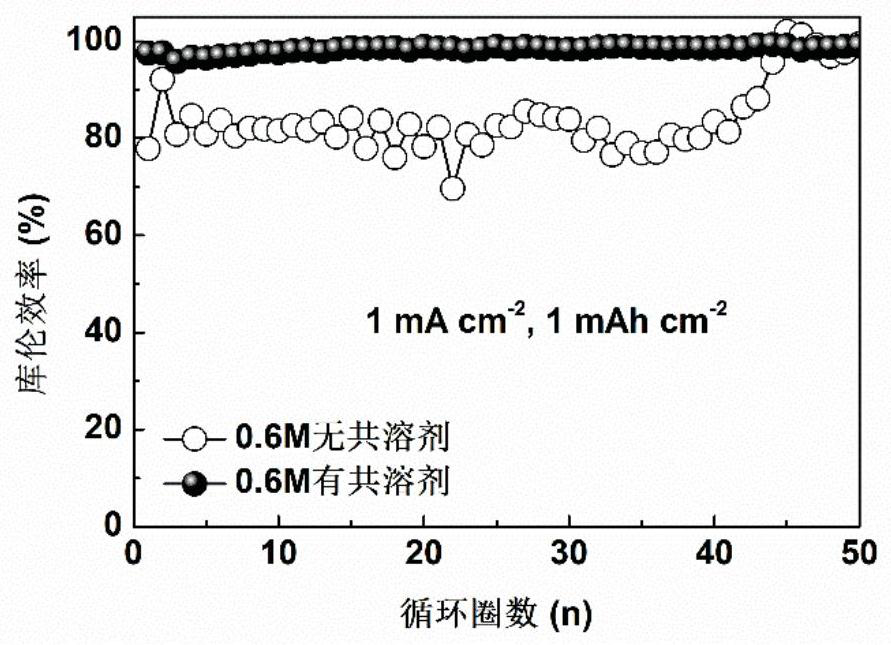

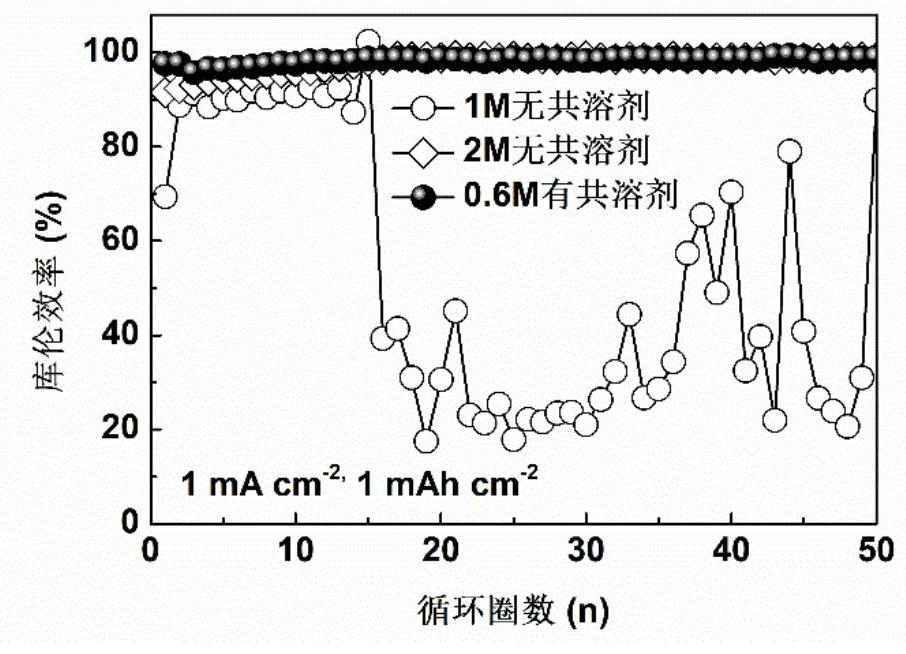

Safe low-concentration electrolyte for lithium battery and application of safe low-concentration electrolyte

PendingCN113948771AAdjust the solvation structureImprove cycle stabilityLi-accumulatorsOrganic electrolytesElectrolytic agentPhysical chemistry

The invention discloses a safe low-concentration electrolyte for a lithium battery and application of the safe low-concentration electrolyte, and belongs to the field of secondary batteries. The electrolyte contains lithium salt, a solvent for dissolving the lithium salt and a non-solvated cosolvent, the lithium salt is a mixed lithium salt rich in fluorine element, the overall concentration of the lithium salt does not exceed 0.6 mol / L, the solvent is a single solvent or a mixed solvent, the cosolvent is a fluorinated solvent, and the electrolyte has a flame-retardant effect. The problem that in the prior art, a low-concentration electrolyte cannot give consideration to high performance and high safety at the same time is solved, the low-concentration electrolyte capable of enabling a lithium battery to stably circulate and be safe is achieved by reasonably designing the components of the lithium salt, the solvent and the cosolvent, and compared with a traditional electrolyte, the electrolyte has the advantages that the lithium salt concentration is lower, the cost of the electrolyte can be remarkably reduced, and the electrolyte for the lithium battery, which is low in cost, high in performance and high in safety, is finally obtained.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com