Flame-retardant organosilicon powder encapsulating material for electronic component

A technology of organosilicon powder and electronic components, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of coating film cracking and falling off, solder joint falling off, unable to achieve heating self-leveling, etc., and achieve low curing temperature and electrical insulation. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

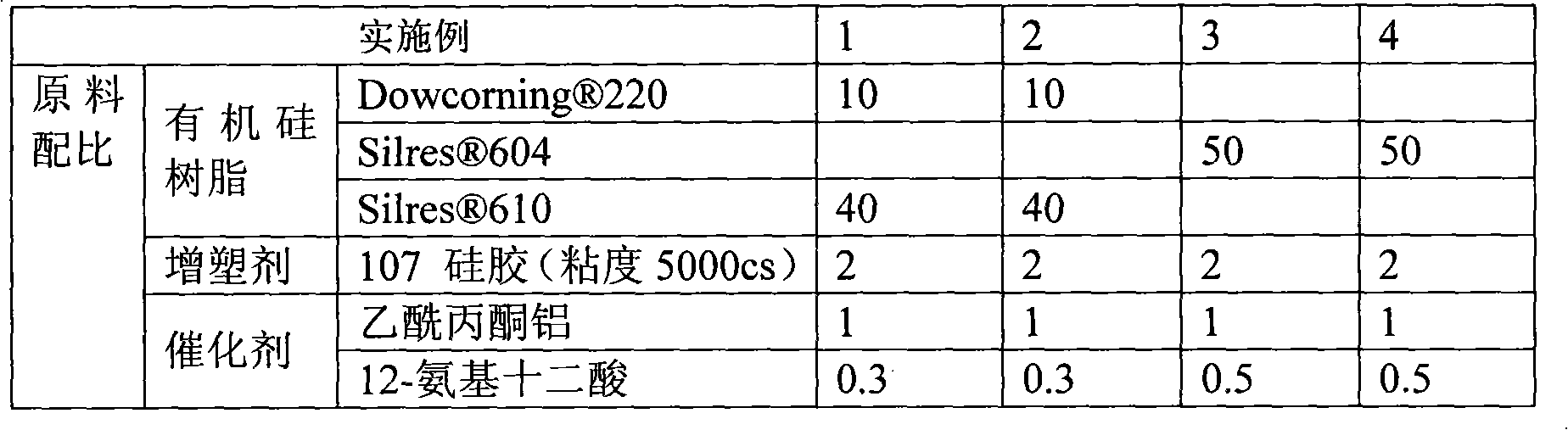

Embodiment 1

[0050] A flame-retardant silicone powder packaging material for electronic components, the components and parts by weight are respectively:

[0051] Dowcorning 220 10 copies

[0052] Silres 610 40 copies

[0053] 107 silicone oil (viscosity 5000cs) 2 parts

[0054] Aluminum acetylacetonate 1 part

[0055] 0.3 parts of 12-aminododecanoic acid

[0056] Silica powder (325 mesh) 50 parts

[0057] Dowcorning Z-6040 0.1 parts

[0058] Oxymelt A-4 0.5 parts

[0059] Resiflow P-67 1 part

[0060] Carbon black 0.1 parts.

[0061] The preparation method is:

[0062] Disperse all the above components evenly in a high-mixing pot, melt and extrude them in a twin-screw extruder, and then cool and press into tablets to make the finished product. The extruder is used to control the temperature of two zones, 60°C in zone I, 80°C in zone II, and the screw speed is 180rpm. It should be noted that if the temperature is too high or the screw speed is too slow, it is easy to cause a...

Embodiment 2

[0064] A flame-retardant silicone powder packaging material for electronic components, the components and parts by weight are respectively:

[0065] Dowcorning 220 10 copies

[0066] Silres 610 40 copies

[0067] 107 silicone oil (viscosity 5000cs) 2 parts

[0068] Aluminum acetylacetonate 1 part

[0069] 0.3 parts of 12-aminododecanoic acid

[0070] Silica powder (325 mesh) 30 parts

[0071] Mica powder (325 mesh) 20 parts

[0072] Dowcorning Z-6040 0.1 parts

[0073] Oxymelt A-4 0.5 parts

[0074] Resiflow P-67 1 part

[0075] Carbon black 0.1 parts.

[0076] Its preparation method is the same as embodiment 1.

Embodiment 3

[0078] A flame-retardant silicone powder packaging material for electronic components, the components and parts by weight are respectively:

[0079] Silres 604 50 copies

[0080] 107 silicone oil (viscosity 5000cs) 2 parts

[0081] Aluminum acetylacetonate 1 part

[0082] 0.5 parts of 12-aminododecanoic acid

[0083] Silica powder (325 mesh) 30 parts

[0084] Mica powder (325 mesh) 20 parts

[0085] Dowcorning Z-6040 0.1 parts

[0086] Oxymelt A-4 0.5 parts

[0087] Resiflow P-67 1 part

[0088] Carbon black 0.1 parts.

[0089] Its preparation method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com