Low-gloss halogen-free flame-retardant alloy material and preparation method thereof

An alloy material and low-gloss technology, which is applied in the field of low-gloss halogen-free flame retardant alloy materials and their preparation, can solve the problems of corrosiveness of screws, inability to achieve halogen-free flame retardant, etc., and achieves good chemical corrosion resistance and processing plasticity. Good, strong hydrogen abstraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

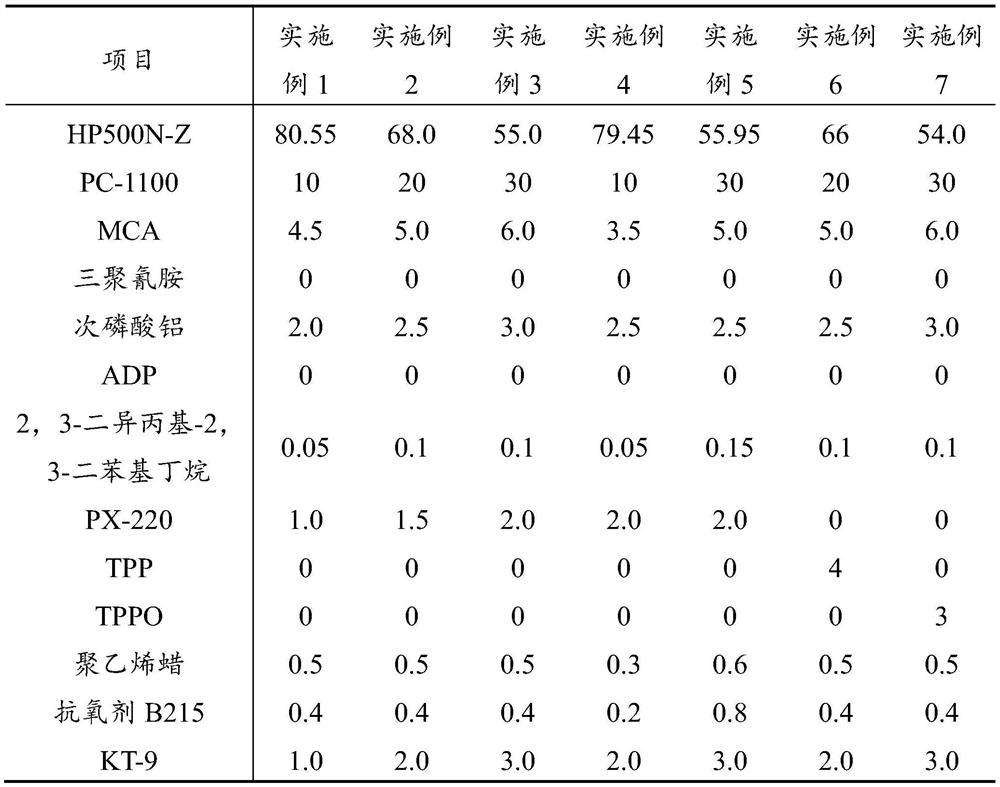

[0030] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

[0031] The raw materials used in the examples and comparative examples are as follows:

[0032] Homopolypropylene: Homopolypropylene HP500N-Z (12g / 10min, 230℃ / 2.16kg), China Sea Shell

[0033] Polycarbonate resin: PC-1100 (10g / 10min, 300℃ / 1.2kg), Lotte Chemical

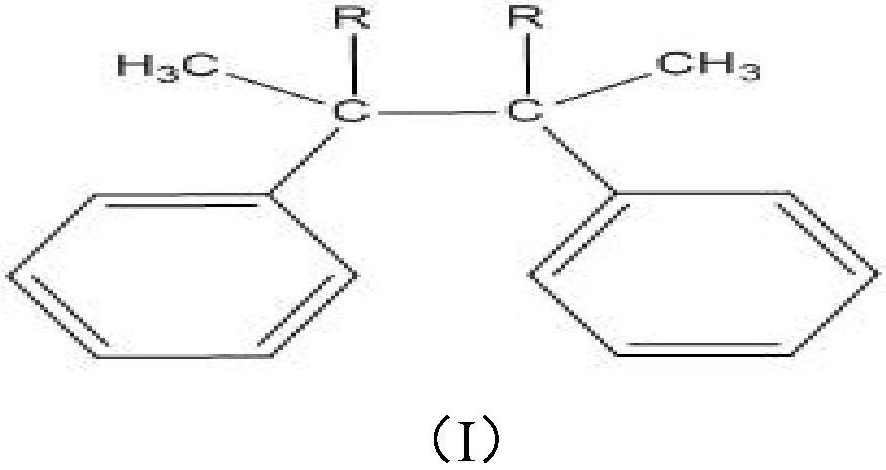

[0034] Compound flame retardant: melamine cyanurate (MCA), Sichuan Fine Chemical Research Institute; aluminum hypophosphite, Suzhou Lianxiong Technology Chemical Co., Ltd.; flame retardant synergist 2,3-diisopropyl-2,3 -Diphenylbutane, commercially available; phosphate ester flame retardant PX-220, triphenyl phosphate (TPP), Zhejiang Wansheng Co., Ltd., triphenylphosphine oxide (TPPO), Shouguang Puer Chemical Co., Ltd.

[0035] Flame retardant: melamine, commercially available; aluminum diethylphosphinate (ADP), c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com