Production process of special highly-flame-retardant wire harness for rail transit

A technology of rail transit and production technology, applied in the direction of conductors, climate change adaptation, insulating cables, etc., can solve the problems of cable performance service life impact, heat increase, cable heating, etc., to improve heat conduction and heat dissipation capabilities, and improve wear resistance Sex and elasticity, speed up the effect of absorbing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

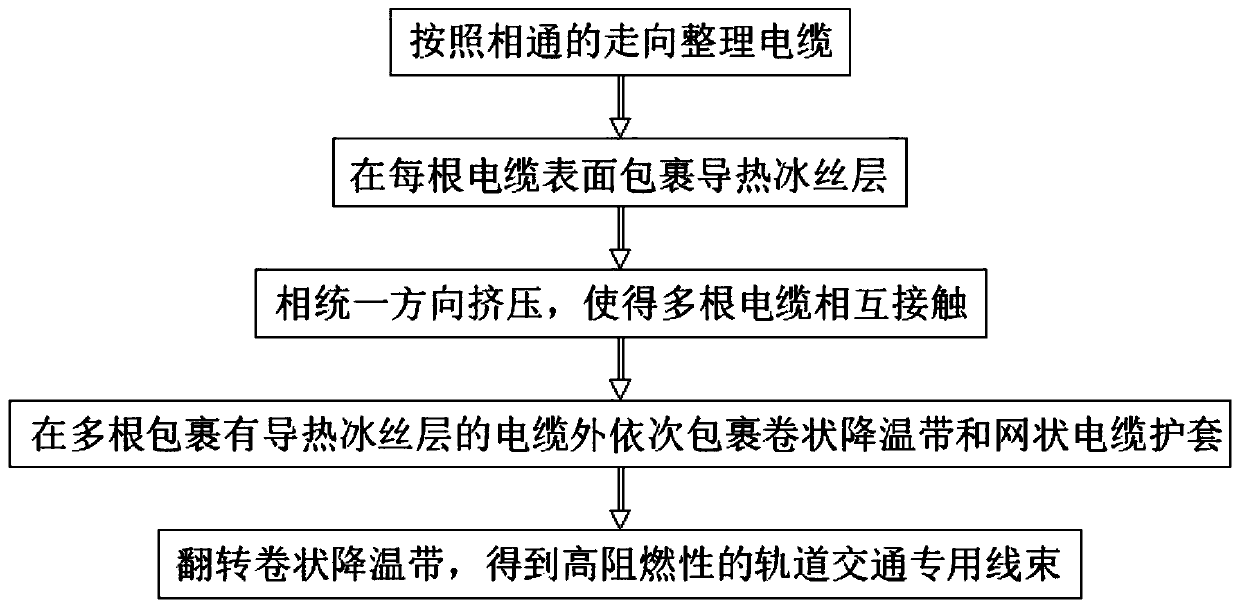

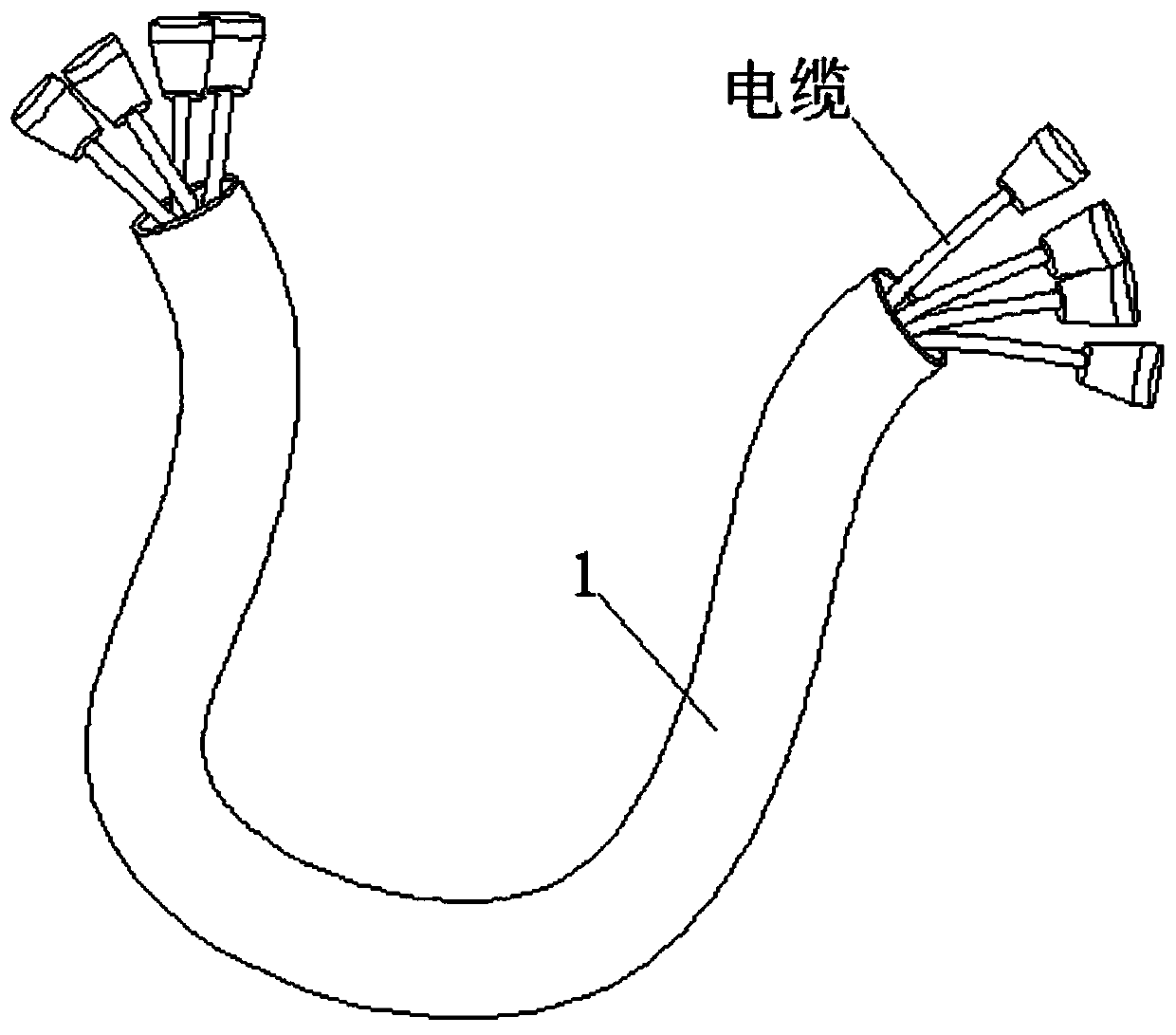

[0038] as attached figure 1 The production process of a special wire harness for high flame-retardant rail transit described in the present invention includes the following steps:

[0039] S1. First arrange the cables that need to be integrated together in the same direction;

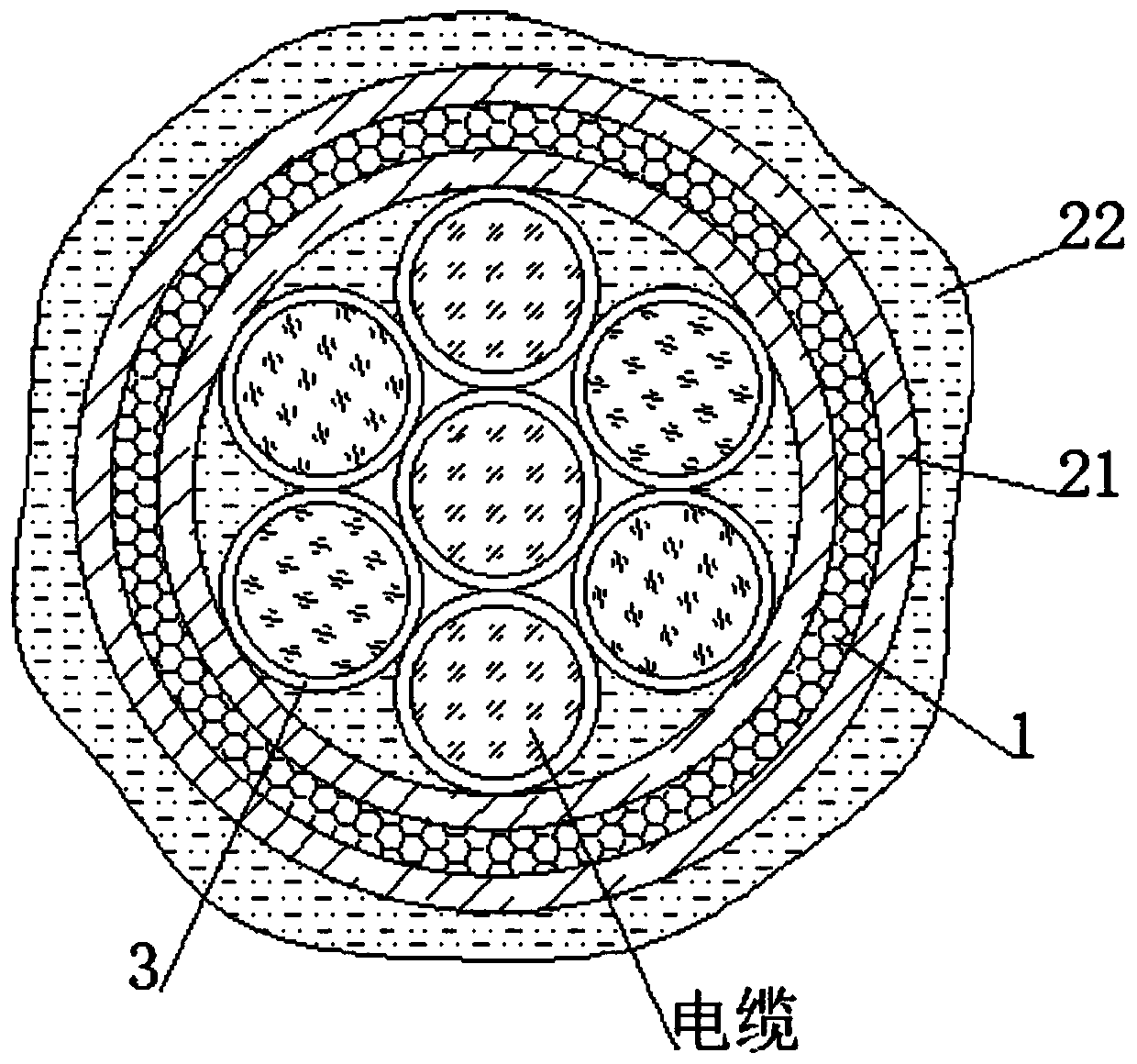

[0040] S2, as attached figure 2 , wrapping a layer of thermally conductive ice silk layer 3 on the surface of each cable;

[0041] S3, then extruding a plurality of cables in the same direction, so that the cables and the heat-conducting ice silk layer 3 are in contact with each other;

[0042] S4. Wrap coil-shaped cooling tapes on multiple cables wrapped with heat-conducting ice silk layers. The ends of the coil-shaped cooling tapes have magnetic suction parts, and then coat a layer of mesh cable sheath on the coil-shaped cooling tapes. 1;

[0043] S5. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com