Fluorosilicone rubber cable material for coal mine cable and preparation method of cable material

A technology of fluorosilicone rubber and cable material, which is applied in the field of fluorosilicone rubber cable material for coal mine cables and its preparation, which can solve the properties of loss of performance, cable rubber surface damage, wear-resistant collision, temperature resistance, medium resistance, aging resistance and flame retardancy Can not meet the demand and other problems, to achieve the effect of improving performance, long service life, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

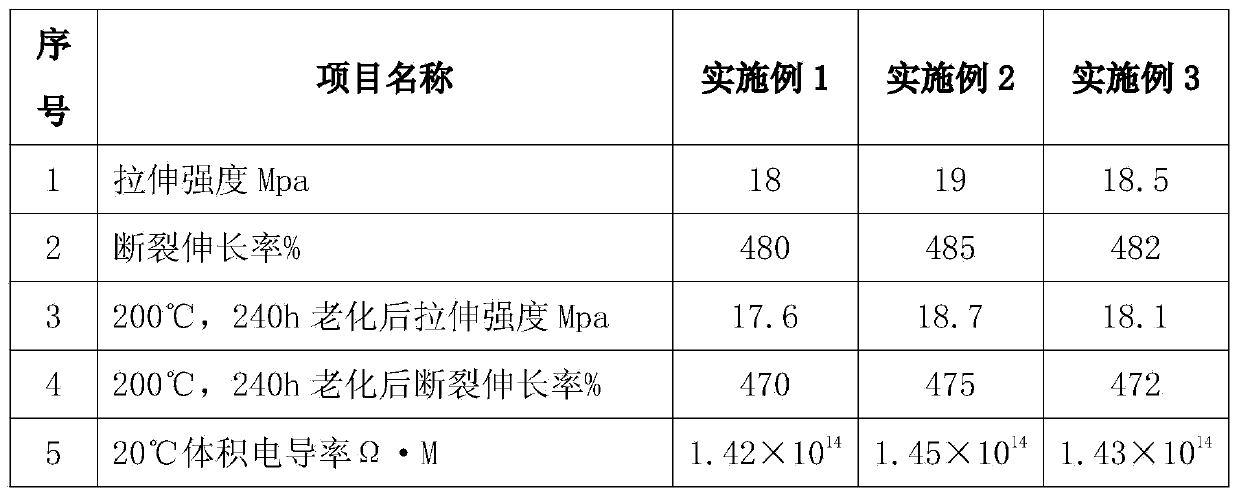

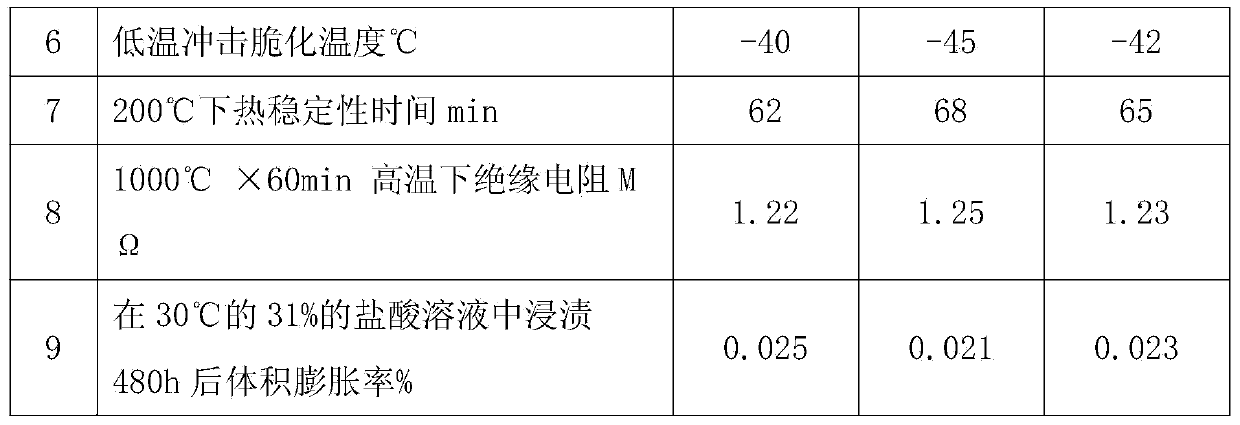

Embodiment 1

[0049] The fluorosilicone rubber cable material for coal mine cable according to the present invention has the distribution ratio of each group in parts by weight,

[0050] (1) 25 parts of fluorosilicone rubber

[0051] (2) 55 parts of methyl vinyl silicone rubber

[0052] (3) 20 parts of white carbon black

[0053] (4) 20 parts of light calcium carbonate

[0054] (5) 2 parts of zinc oxide

[0055] (6) 2 parts of magnesium oxide

[0056] (7) 4 parts of stearic acid

[0057] (8) 0.4 parts of accelerator

[0058] (9) 1.8 parts of antioxidant

[0059] (10) 0.8 parts of vulcanizing agent

[0060] (11) 6 parts of flame retardant

[0061] (12) 1.5 parts of diphenyl silicon diol

[0062] (13) 1.5 parts of talcum powder

[0063] (14) 5 parts of Vaseline.

[0064] The white carbon black is precipitation method white carbon black.

[0065] The light calcium carbonate is ultrafine active light calcium carbonate, and its particle size is above 1000 mesh.

[0066] The accelerator is N,N-tetramethyldithiodithioc...

Embodiment 2

[0077] The fluorosilicone rubber cable material for coal mine cable according to the present invention has the distribution ratio of each group in parts by weight,

[0078] (1) 35 parts of fluorosilicone rubber

[0079] (2) 45 parts of methyl vinyl silicone rubber

[0080] (3) 25 parts of white carbon black

[0081] (4) 16 parts of light calcium carbonate

[0082] (5) 2.5 parts of zinc oxide

[0083] (6) 1.5 parts of magnesium oxide

[0084] (7) 4.5 parts of stearic acid

[0085] (8) 0.5 parts of accelerator

[0086] (9) 2 parts of antioxidant

[0087] (10) 1 part of vulcanizing agent

[0088] (11) 8 parts of flame retardant

[0089] (12) 2 parts of diphenyl silicon diol

[0090] (13) 2 parts of talcum powder

[0091] (14) 4 parts of Vaseline.

[0092] The white carbon black is precipitation method white carbon black.

[0093] The light calcium carbonate is ultrafine active light calcium carbonate, and its particle size is above 1000 mesh.

[0094] The accelerator is N,N-tetramethyldithiodithiocarb...

Embodiment 3

[0105] The fluorosilicone rubber cable material for coal mine cable according to the present invention has the distribution ratio of each group in parts by weight,

[0106] (1) 45 parts of fluorosilicone rubber

[0107] (2) 35 parts of methyl vinyl silicone rubber

[0108] (3) 30 parts of white carbon black

[0109] (4) 12 parts of light calcium carbonate

[0110] (5) 3 parts of zinc oxide

[0111] (6) 1 part of magnesium oxide

[0112] (7) 5 parts of stearic acid

[0113] (8) 0.6 parts of accelerator

[0114] (9) 2.5 parts of antioxidant

[0115] (10) 1.2 parts of vulcanizing agent

[0116] (11) 10 parts of flame retardant

[0117] (12) 3 parts of diphenyl silicon glycol

[0118] (13) 3 parts of talcum powder

[0119] (14) 3 parts of Vaseline.

[0120] The white carbon black is precipitation method white carbon black.

[0121] The light calcium carbonate is ultrafine active light calcium carbonate, and its particle size is above 1000 mesh.

[0122] The accelerator is N,N-tetramethyldithiodithiocar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com