Preparation method of tetrakis hydroxymetyl phosphonium sulfuric-urea polymer

A technology of tetrakis hydroxymethyl phosphorus sulfate and initial shrinkage, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, textiles and papermaking, etc., which can solve the problems of slow reaction speed and achieve non-tearing The effect of breaking, reducing impurity content and enhancing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

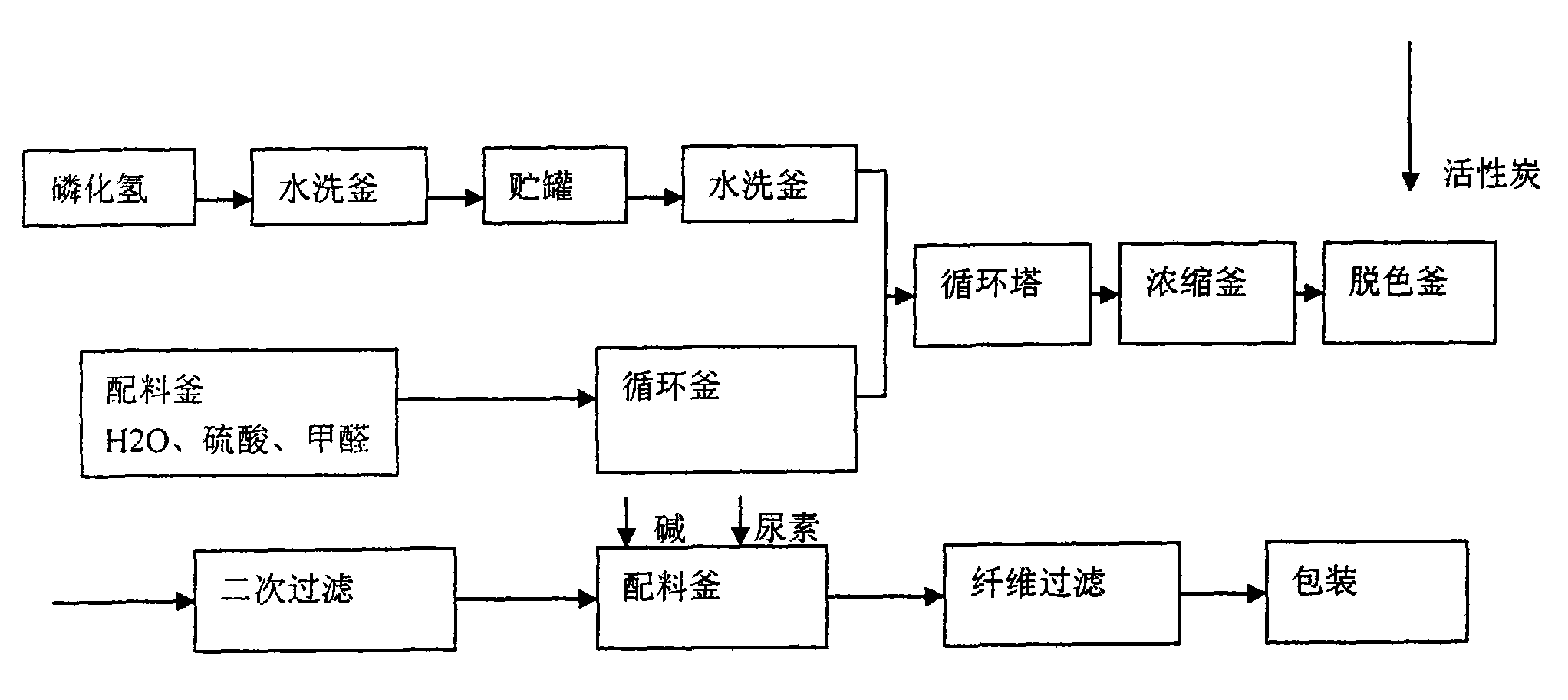

Image

Examples

Embodiment 1

[0017] 1. After the phosphine gas is washed in the inlet water washing tank, it is collected into the storage tank, and then washed into the circulation tower through the outlet gas washing tank.

[0018] 2. Add 300 kg of ion-free water to the batching kettle, and suck in sulfuric acid while stirring, and suck in formaldehyde after cooling in the kettle (according to the molar ratio of formaldehyde and sulfuric acid 8.5:1).

[0019] 3. Pour the feed liquid into the circulating kettle. When the temperature is ≥40°C, open the air valve and circulation pump, and gradually heat the jacket to 55°C to close the air valve. The feed liquid absorbs phosphine gas and the main content is 40% through laboratory tests. , discharge into the storage tank.

[0020] 4. When there are two tanks for the circulating feed liquid, pump it into the concentration tank. When the vacuum is at 0.06Mpa, the jacket is heated. When the concentrated content test tetrakis hydroxymethyl phosphorus sulfate con...

Embodiment 2

[0024] 1. After the phosphine gas is washed in the inlet water washing tank, it is collected into the storage tank, and then washed into the circulation tower through the outlet gas washing tank.

[0025] 2. Add 300 kg of ion-free water to the batching kettle, and suck in sulfuric acid while stirring, and suck in formaldehyde after cooling in the kettle (according to the molar ratio of formaldehyde and sulfuric acid 8.7:1).

[0026] 3. Pour the feed liquid into the circulating kettle. When the temperature is ≥40°C, open the air valve and circulation pump, gradually heat the jacket to 55°C and close the air valve. The feed liquid absorbs phosphine gas and the main content is 40% through laboratory tests. , discharge into the storage tank.

[0027] 4. When there are two tanks for the circulating feed liquid, pump it into the concentration tank. When the vacuum is at 0.06Mpa, the jacket is heated. When the concentrated content test tetrakis hydroxymethyl phosphorus sulfate conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com