Preparation method of dust-free-level lithium hydroxide monohydrate

A technology of lithium hydroxide and lithium sulfate monohydrate, applied in the direction of lithium oxide;/hydroxide, etc., can solve the problems of low main content and inability to meet the requirements of the product, and achieve high lithium recovery rate, low product cost and equipment investment. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

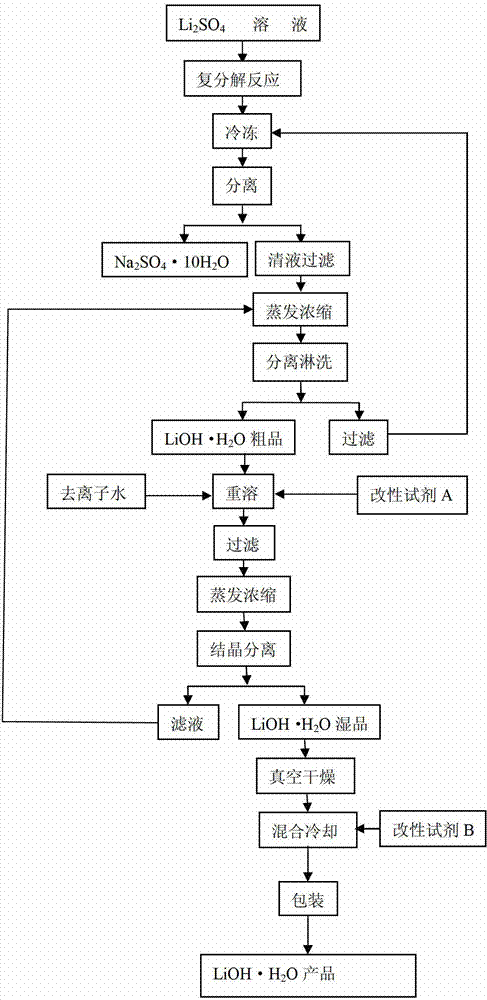

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Dust-free LiOH·H 2 Preparation of O

[0036] (1) Take Li 2 Li with an O concentration of 38 g / L 2 SO 4 Leaching solution 3m 3 , to which Ca(OH) is added 2 Adjust pH=11, filter to obtain lithium sulfate primary purification solution;

[0037] (2) Add 33kg of sodium hydroxide to the lithium sulfate primary purification solution obtained in step (1), stir well to dissolve it completely, then cool it to -3°C under stirring, and the solution contains S0 4 2- When the concentration is 30g / l, it is separated by filtration to obtain LiOH solution and Na 2 SO 4 10H 2 O solid;

[0038] (3) Filter the LiOH solution obtained in step (2) to obtain a pure LiOH solution; evaporate the LiOH pure liquid until the liquid-solid phase volume ratio is about 1:1, then filter and centrifuge it to obtain LiOH·H 2 O crude product;

[0039] (4) To the LiOH·H obtained in step (3) 2 Add deionized water to the O crude product, stir to dissolve it completely, and make Li in th...

Embodiment 2—36

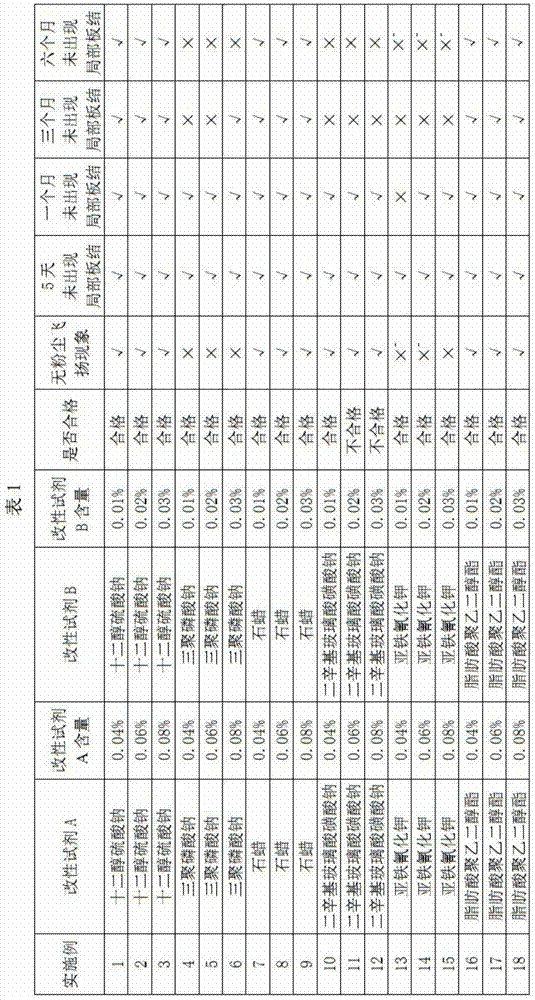

[0043] Example 2-36 Dust-free LiOH·H 2 Preparation of O

[0044] The preparation process is the same as in Example 1, except that the types and contents of the modifying reagents added in steps (4) and (6) are different. The specific implementation results are shown in Table 1.

[0045]

[0046]

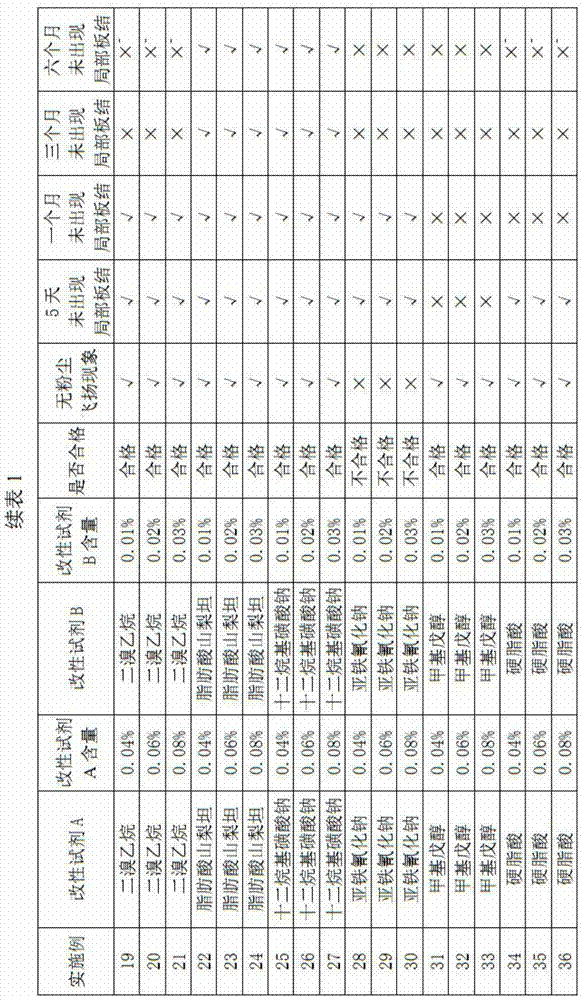

[0047] In Table 1, √ means no hardening, × means hardening, × + Indicates that the agglomerate is very hard. "Qualified" in Table 1 means that the obtained product meets the index of dust-free lithium hydroxide monohydrate product. The specific indicators are as follows:

[0048] Table 2

[0049]

Main content%

Fe%

Na+K%

Ca%

Cl - %

SO 4 2- %

CO 2 %

acid insoluble matter

Water insoluble matter

Example 1

56.7

0.0012

0.008

0.006

0.0013

0.015

0.23

0.002

0.006

Example 2

56.5

0.0010

0.012

0.005

0.0010

0.016

0.26

0.002

0.008

Example 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com