High-limit oxygen index halogen-free flame-retardant PP material and preparation method thereof

A technology of limiting oxygen index and flame retardant synergist, applied in the field of halogen-free flame retardant PP materials, can solve the problems of poor water resistance, poor mechanical properties, and reduced flame retardant effect of polymer materials, and achieves simple processing technology, Simple preparation method and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also discloses a preparation method of the above-mentioned high limiting oxygen index halogen-free flame-retardant PP material, which includes the following steps:

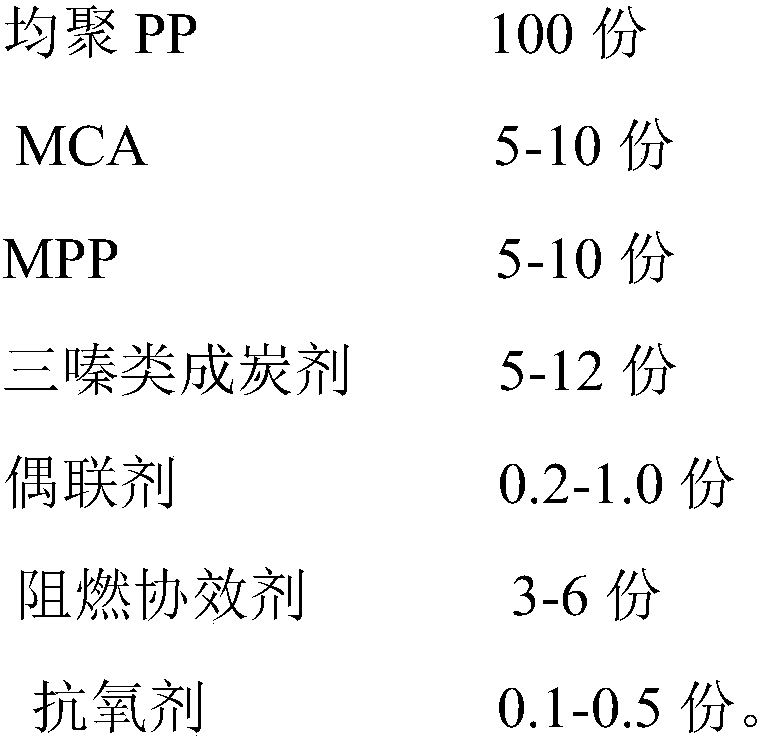

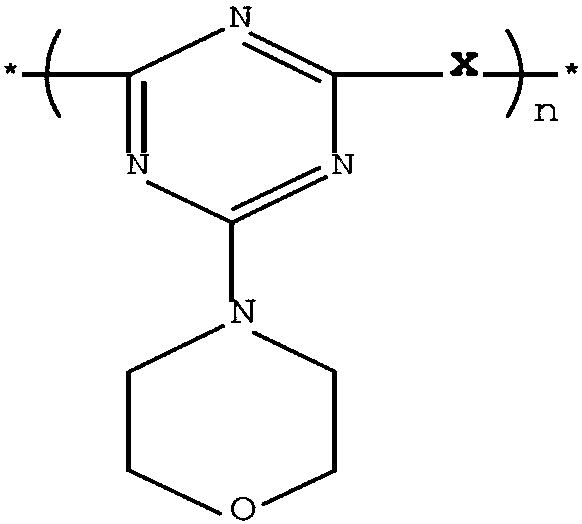

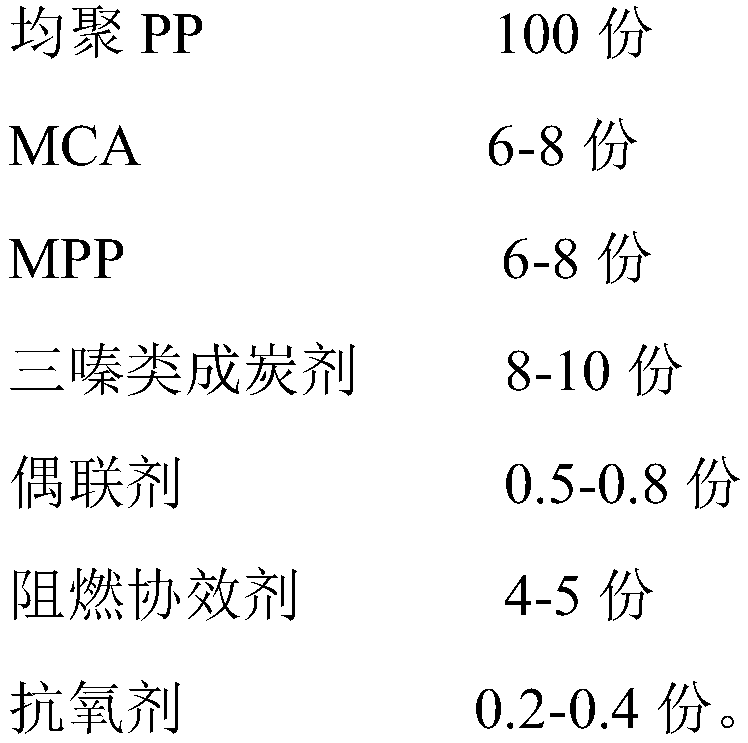

[0038] (1) In parts by weight, weigh 5-10 parts of MCA, 5-10 parts of MPP, 5-12 parts of triazine char-forming agents, 3-6 parts of flame retardant synergists and 0.2-1.0 parts of even Coupling agent; first add twice the amount of absolute ethanol to the coupling agent to dilute, and then add the above-mentioned MCA, MPP, triazine char-forming agent and flame retardant synergist into the high mixer Mix evenly, and after mixing, use a double-roller kneading temperature of 50°C and an oven drying temperature of 80°C to obtain a mixture;

[0039] (2) Add 100 parts of homopolymerized PP and 0.1-0.5 parts of antioxidant to the mixture, and mix it in the high mixer for 5 minutes;

[0040] (3) Extrude and granulate with a twin-screw extruder to obtain a high limiting oxygen index halogen-fre...

Embodiment 1

[0050] (1) Weigh 100 parts of homopolymerized PP, 6 parts of MCA, 6 parts of MPP, 8 parts of triazine char-forming agent, 4 parts of aluminum hypophosphite, 0.2 part of antioxidant and 0.5 part of KH-550;

[0051] (2) Dilute KH-550 with 2 times the mass of absolute ethanol, mix the flame retardant, flame retardant synergist and diluted KH-550 in a high mixer for 5 minutes, and knead the mixture with double rollers , and the twin-roll temperature was set to 50 °C. The kneaded mixture is dried in an oven at 80°C;

[0052](3) Mix the homopolymer PP, the antioxidant and the mixture in step (2) in a high mixer for 5 minutes;

[0053] (4) The mixture in the step (3) is extruded and granulated with a twin-screw extruder.

Embodiment 2

[0055] (1) Weigh 100 parts of homopolymerized PP, 7 parts of MCA, 7 parts of MPP, 9 parts of triazine char-forming agent, 5 parts of zinc borate, 0.3 part of antioxidant and 0.6 part of KH-560;

[0056] (2) Dilute KH-560 with 2 times the mass of absolute ethanol, mix the flame retardant, flame retardant synergist and diluted KH-560 in a high mixer for 5 minutes, and knead the mixture with double rollers , and the twin-roll temperature was set to 50 °C. The kneaded mixture is dried in an oven at 80°C;

[0057] (3) Mix the homopolymer PP, the antioxidant and the mixture in step (2) in a high mixer for 5 minutes;

[0058] (4) The mixture in the step (3) is extruded and granulated with a twin-screw extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com