EPS lightweight aggregate thermal-insulation decorative all-in-one board, and preparation method thereof

An integrated board and light aggregate technology, applied in the field of building insulation materials, can solve the problems of reduced construction strength, insufficient strength, and inability to guarantee the bonding strength of the insulation board and the outer hardened insulation layer, so as to simplify on-site construction and make it difficult Shrinkage deformation, easy mass production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

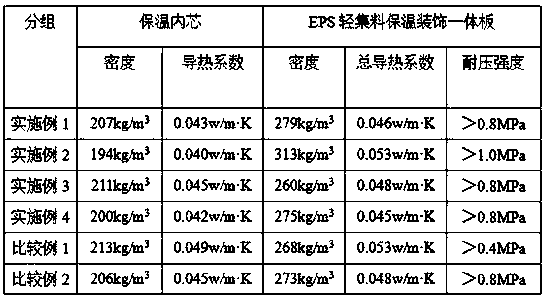

Embodiment 1

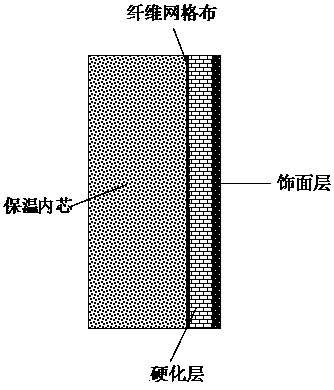

[0033] The preparation of an EPS light aggregate thermal insulation and decoration integrated board, in parts by weight, comprises the following steps:

[0034] 1) Stir and mix 30 parts of EPS foam particles, 40 parts of iron tailings sand, 200 parts of ordinary portland cement, 10 parts of rubber powder, 10 parts of hydroxymethyl cellulose and 250 parts of water to obtain a mixed slurry;

[0035] 2) Transfer the mixed slurry obtained in step 1) to a mold, and dry it naturally for 3 days, so that the water in the mixed slurry evaporates and the mixed slurry forms a solid in the mold. core;

[0036] 3) Mix 20 parts of iron tailings sand, 65 parts of ordinary portland cement, 2 parts of rubber powder, 2 parts of hydroxymethyl cellulose and 120 parts of water to obtain a bonding mortar;

[0037] 4) Cut the fiber mesh cloth according to the size of the thermal insulation core to the corresponding area size. Step 2) After attaching a layer of fiber mesh cloth to the outer surface ...

Embodiment 2

[0041] The preparation of an EPS light aggregate thermal insulation and decoration integrated board, in parts by weight, comprises the following steps:

[0042] 1) Stir and mix 50 parts of EPS foam particles, 80 parts of iron tailings sand, 300 parts of ordinary portland cement, 20 parts of rubber powder, 20 parts of hydroxymethyl cellulose and 300 parts of water to obtain a mixed slurry;

[0043] 2) Transfer the mixed slurry obtained in step 1) to a mold, and let it dry naturally for 7 days, so that the water in the mixed slurry evaporates and the mixed slurry forms a solid in the mold, and the mold is demoulded to obtain a solid plate-shaped insulation inner core;

[0044] 3) Mix 30 parts of iron tailings sand, 75 parts of ordinary Portland cement, 3 parts of rubber powder, 3 parts of hydroxymethyl cellulose and 150 parts of water to obtain a bonding mortar;

[0045]4) Cut the fiber mesh cloth according to the size of the thermal insulation core to the corresponding area si...

Embodiment 3

[0048] The preparation of an EPS light aggregate thermal insulation and decoration integrated board, in parts by weight, comprises the following steps:

[0049] 1) Stir and mix 40 parts of EPS foam particles, 60 parts of iron tailings sand, 270 parts of ordinary portland cement, 25 parts of rubber powder, 25 parts of hydroxymethyl cellulose and 270 parts of water to obtain a mixed slurry;

[0050] 2) Transfer the mixed slurry obtained in step 1) to a mold, and let it dry naturally for 5 days, so that the water in the mixed slurry evaporates and the mixed slurry forms a solid in the mold. core;

[0051] 3) Mix 25 parts of iron tailings sand, 70 parts of ordinary Portland cement, 2 parts of rubber powder, 3 parts of hydroxymethyl cellulose and 130 parts of water to obtain a bonding mortar;

[0052] 4) Cut the fiber mesh cloth according to the size of the thermal insulation core to the corresponding area size. Step 2) After attaching a layer of fiber mesh cloth to the outer surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com