Patents

Literature

51results about How to "Increase the amount of carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

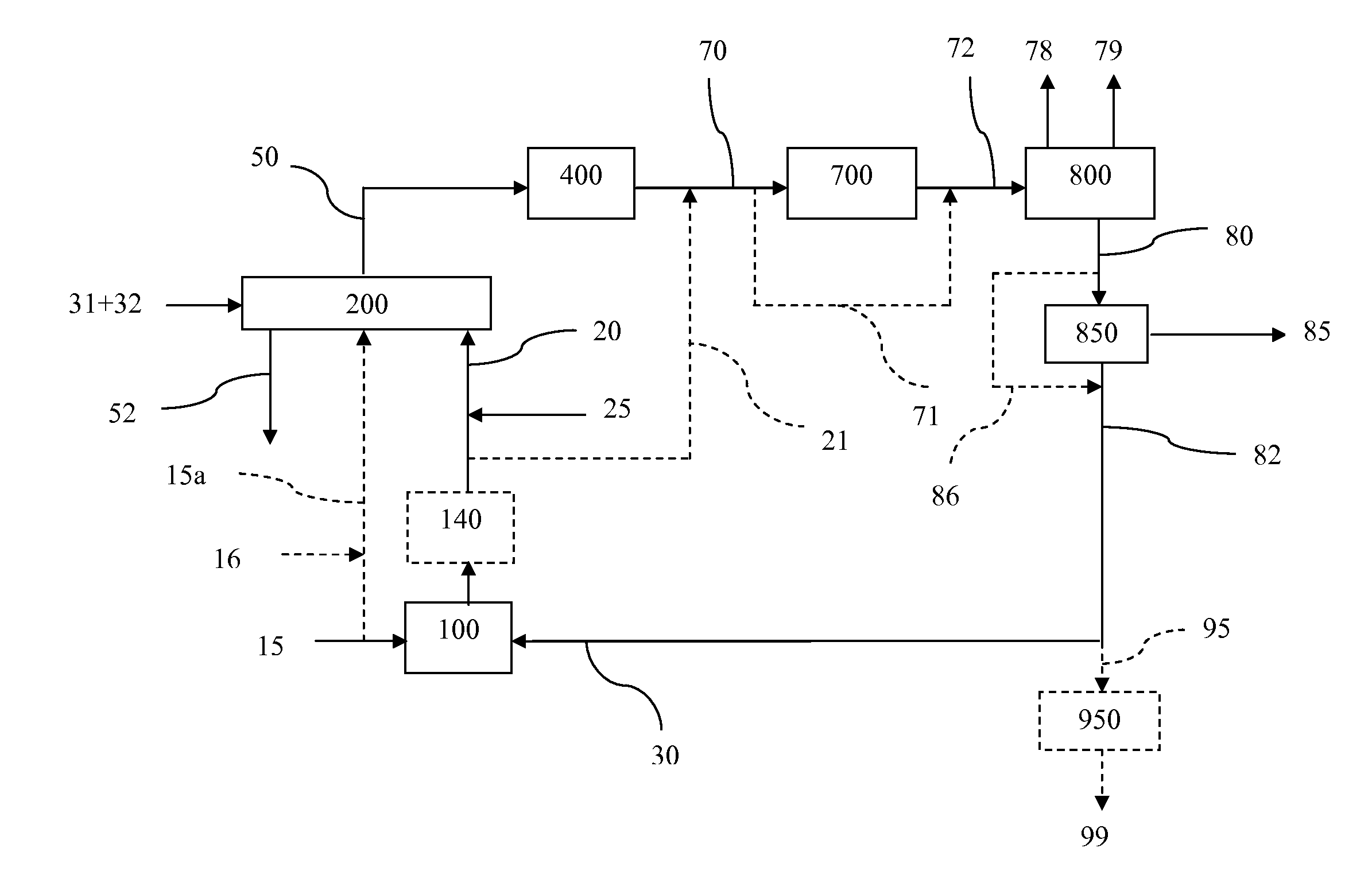

Processes for hydromethanation of a carbonaceous feedstock

InactiveUS20110031439A1Increase the amount of carbonIncrease volumeCombustible gas chemical modificationHydrocarbon from carbon oxidesPtru catalystPhysical chemistry

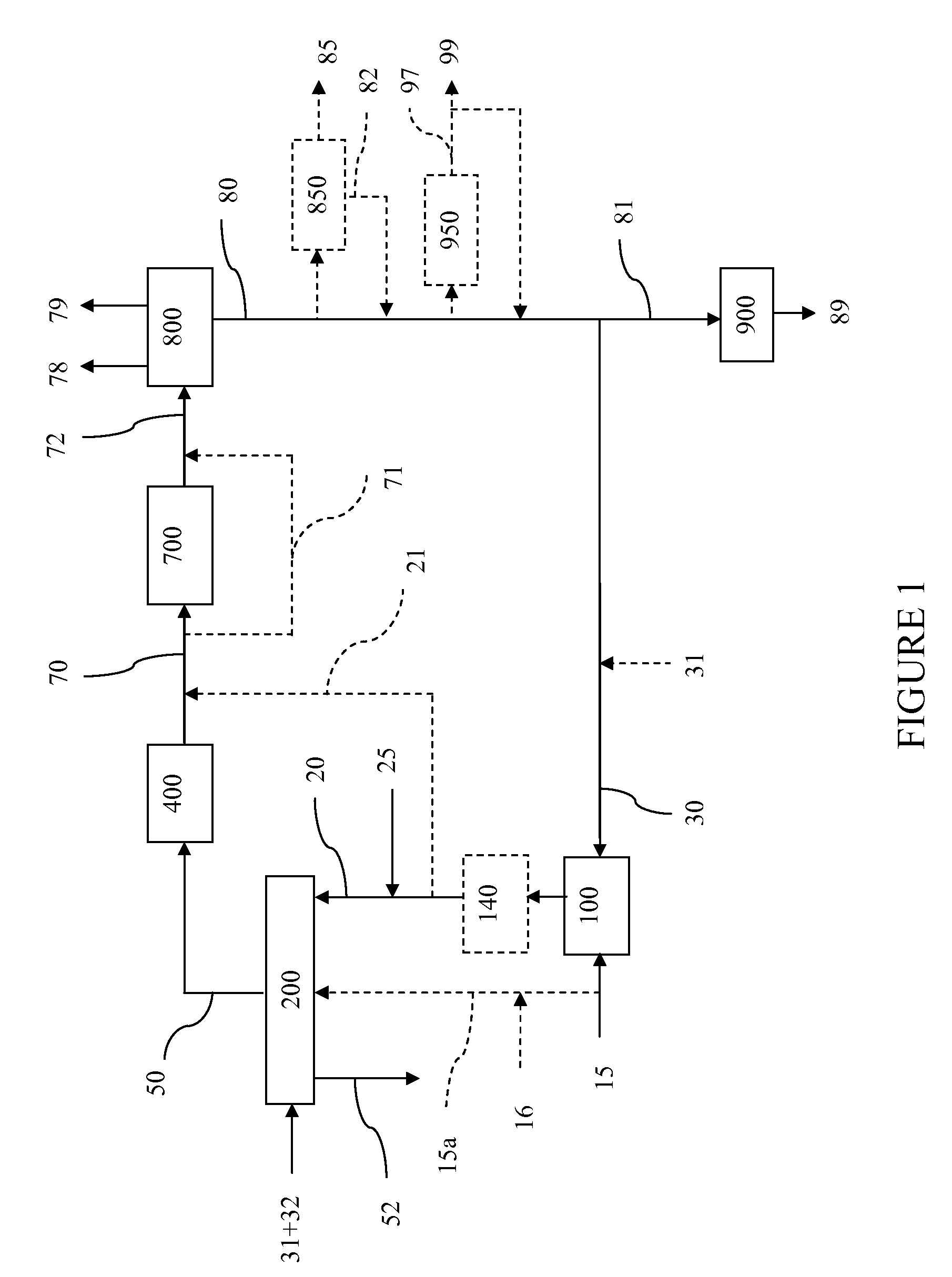

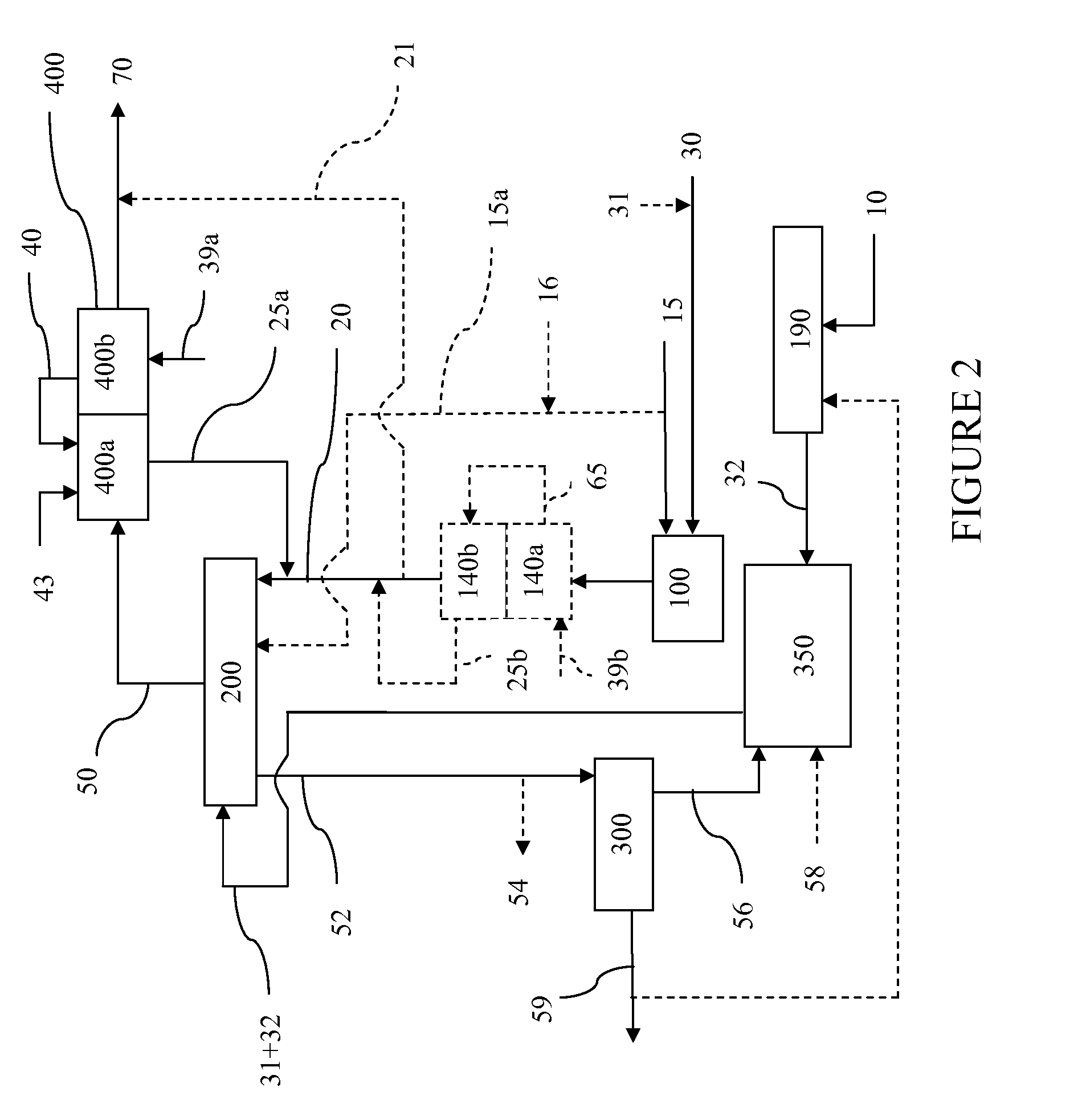

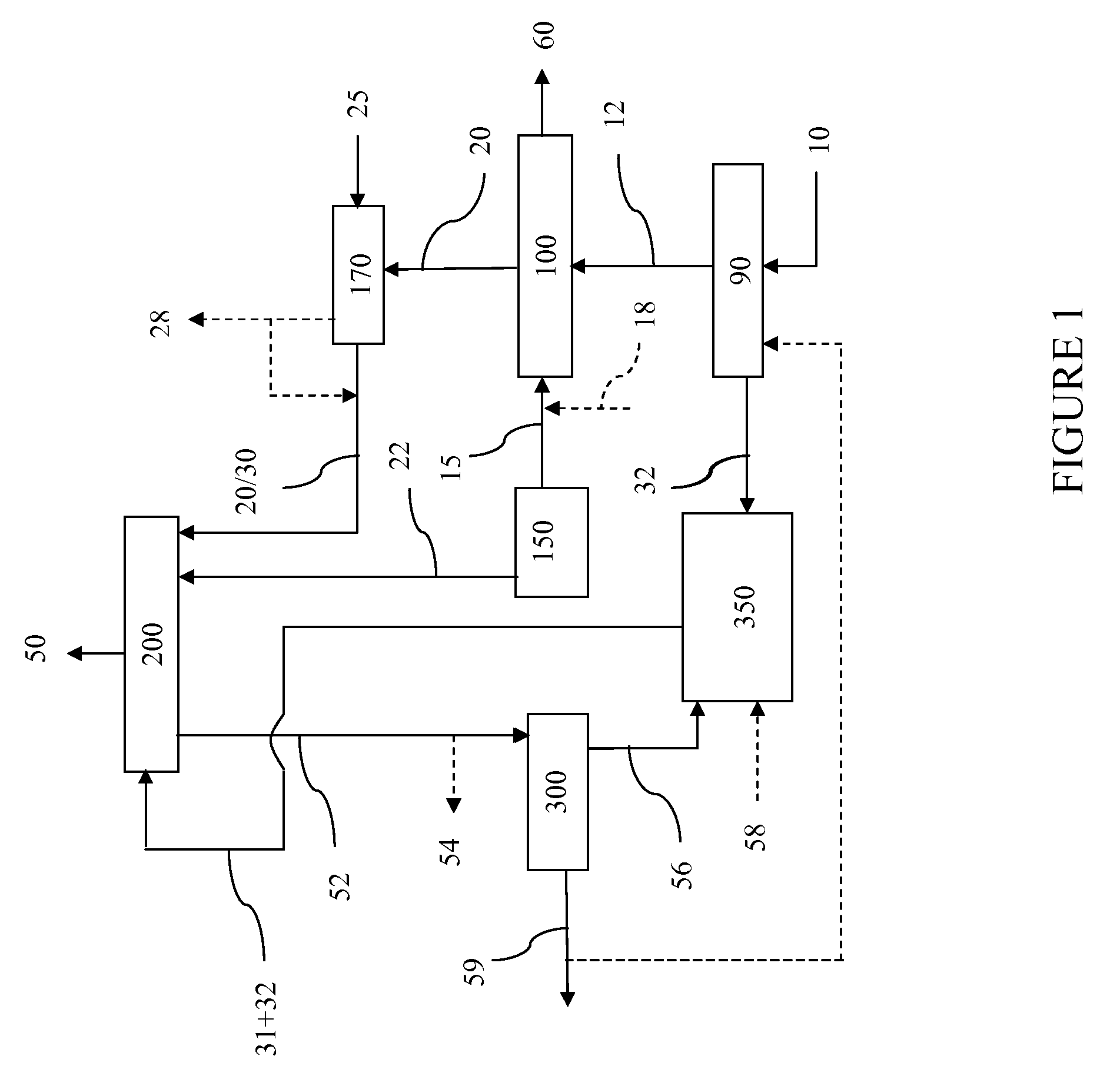

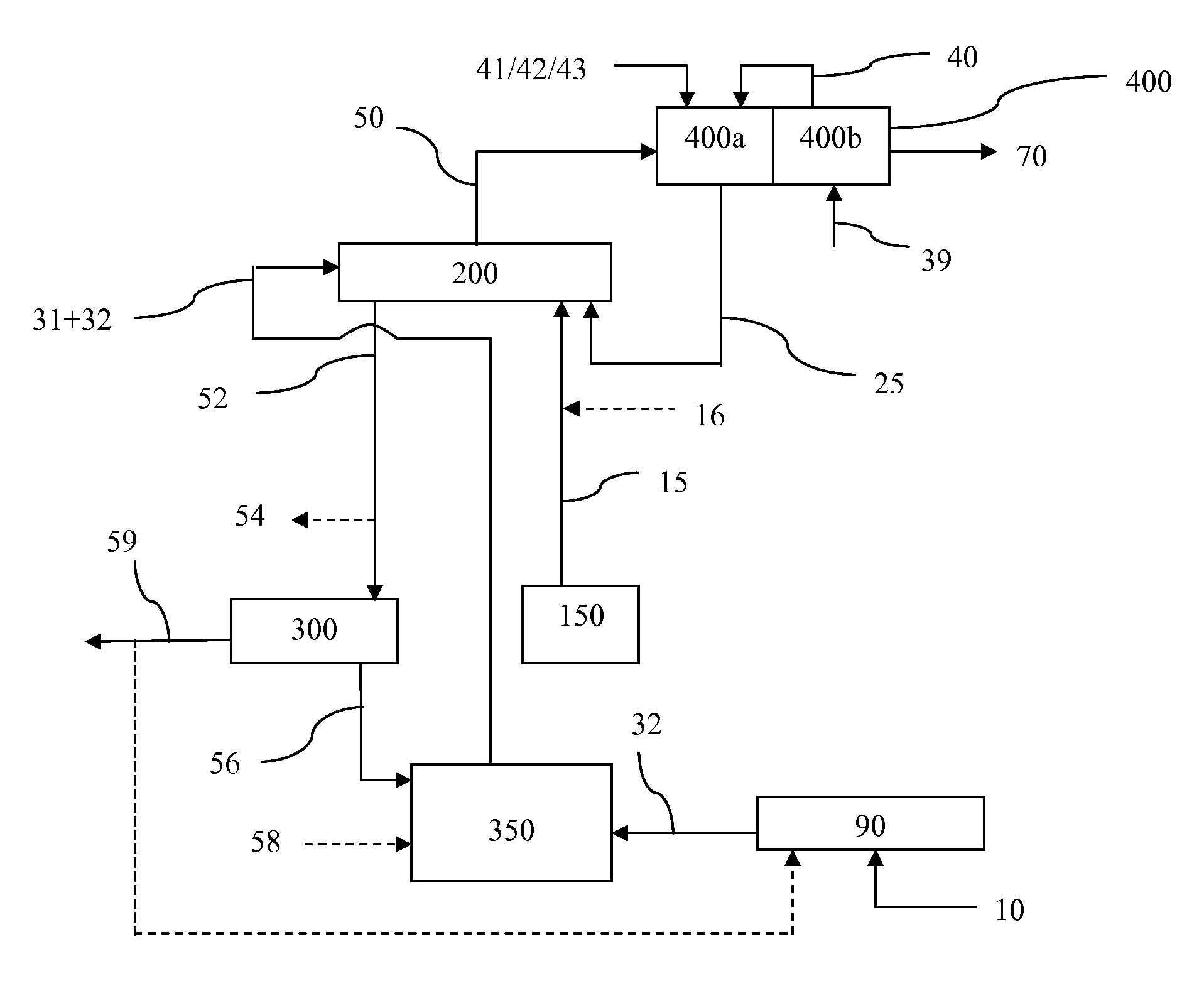

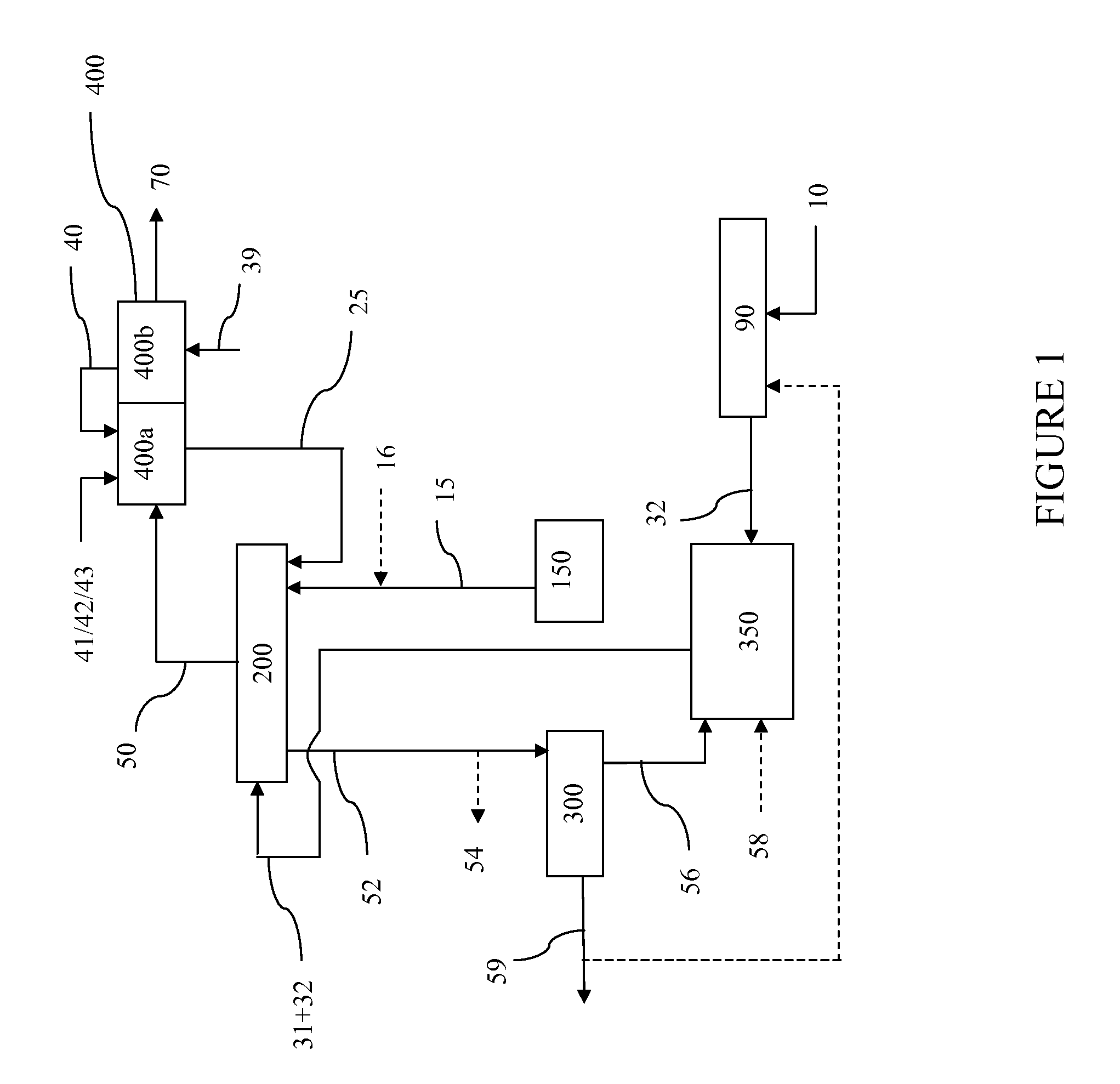

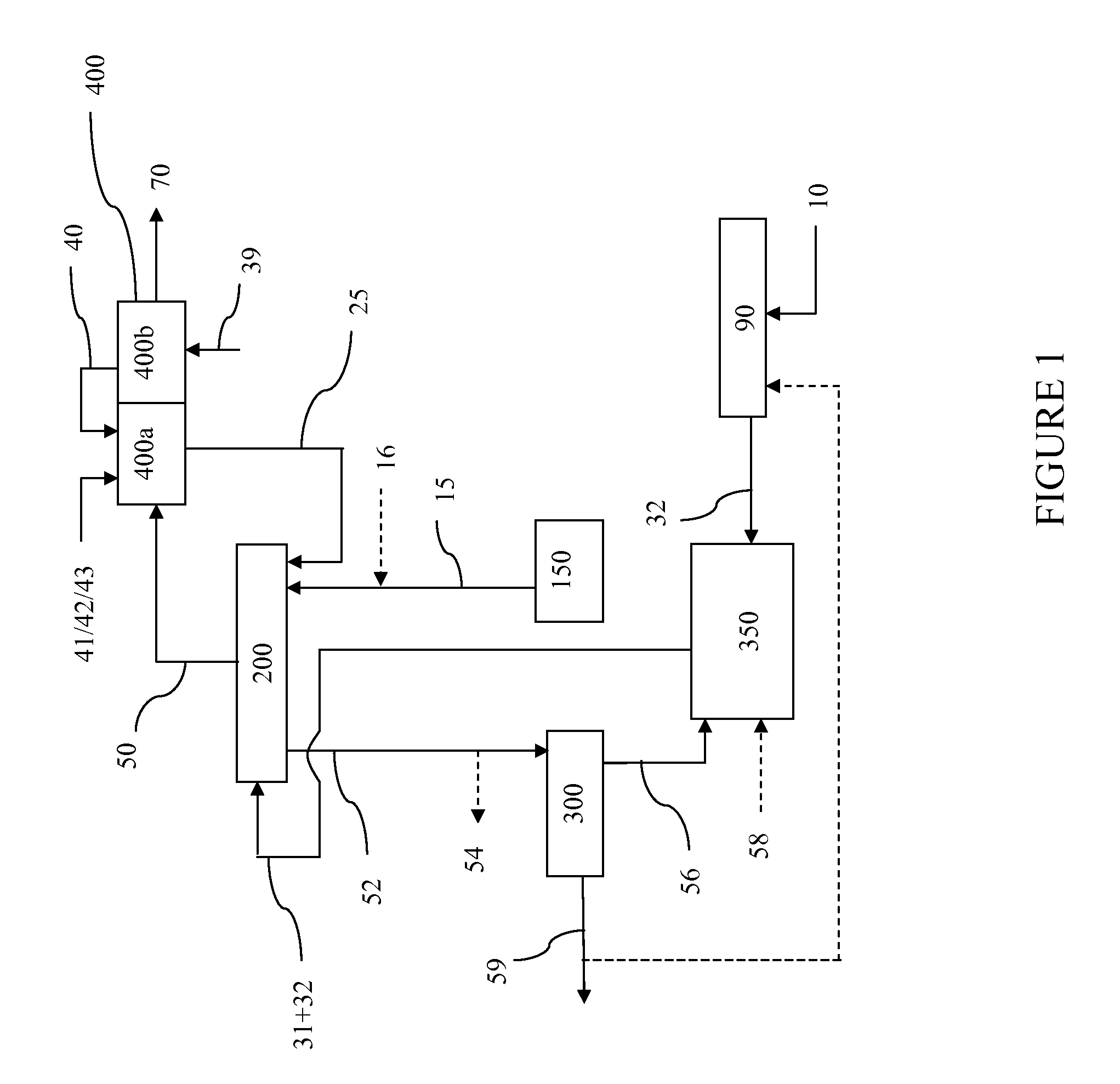

The present invention relates to processes for preparing gaseous products, and in particular a hydrogen product stream and optionally a methane product stream, via the hydromethanation of carbonaceous feedstocks in the presence of steam, carbon monoxide, hydrogen and a hydromethanation catalyst.

Owner:SURE CHAMPION INVESTMENT LTD

Integrated hydromethanation combined cycle process

InactiveUS20110062722A1Increase the amount of carbonIncrease volumeCombustible gas catalytic treatmentHydrogen/synthetic gas productionChemistryElectric energy

The present invention relates to an integrated process for preparing combustible gaseous products via the hydromethanation of carbonaceous feedstocks in the presence of steam, carbon monoxide, hydrogen, a hydromethanation catalyst and optionally oxygen, and generating electrical power from those combustible gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

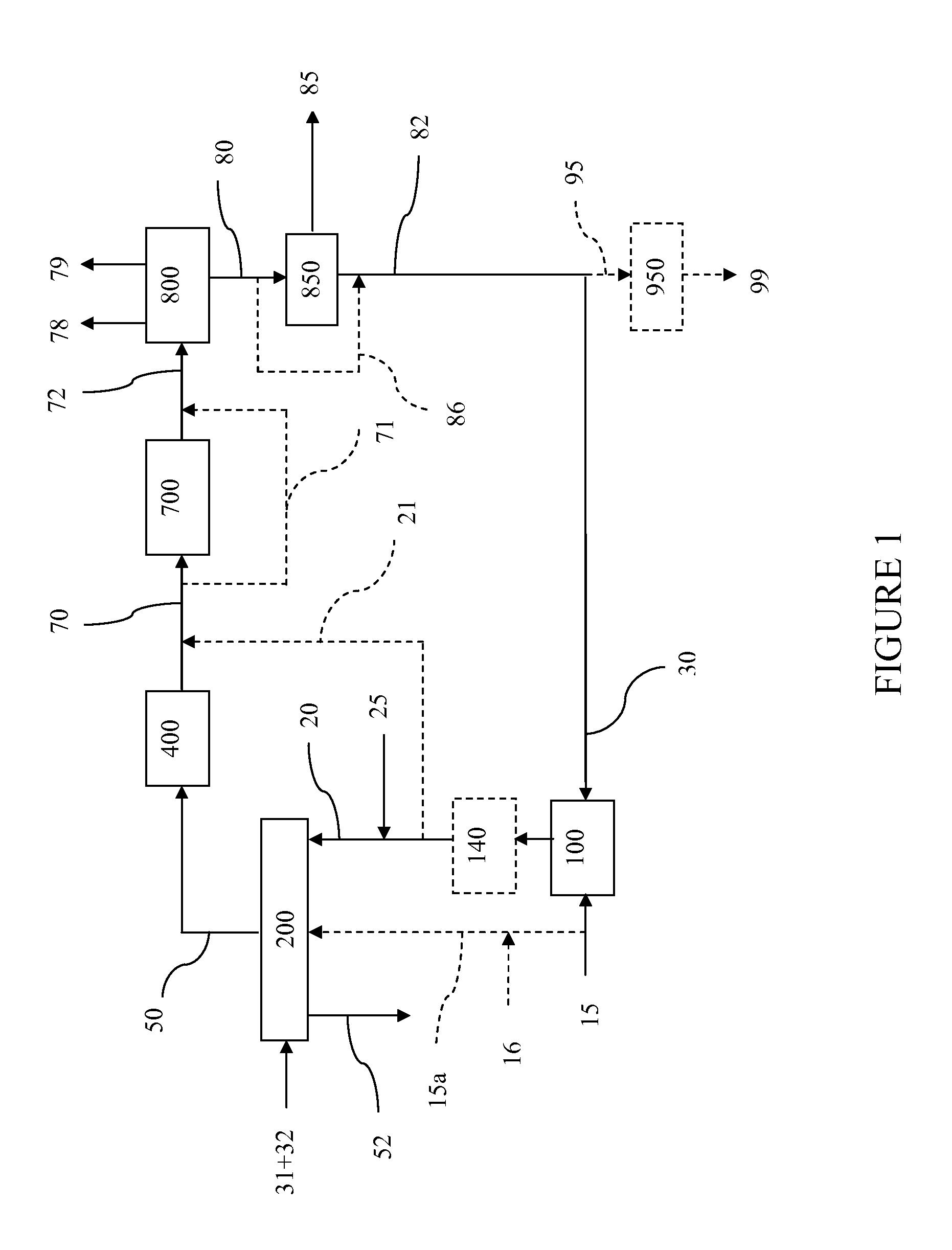

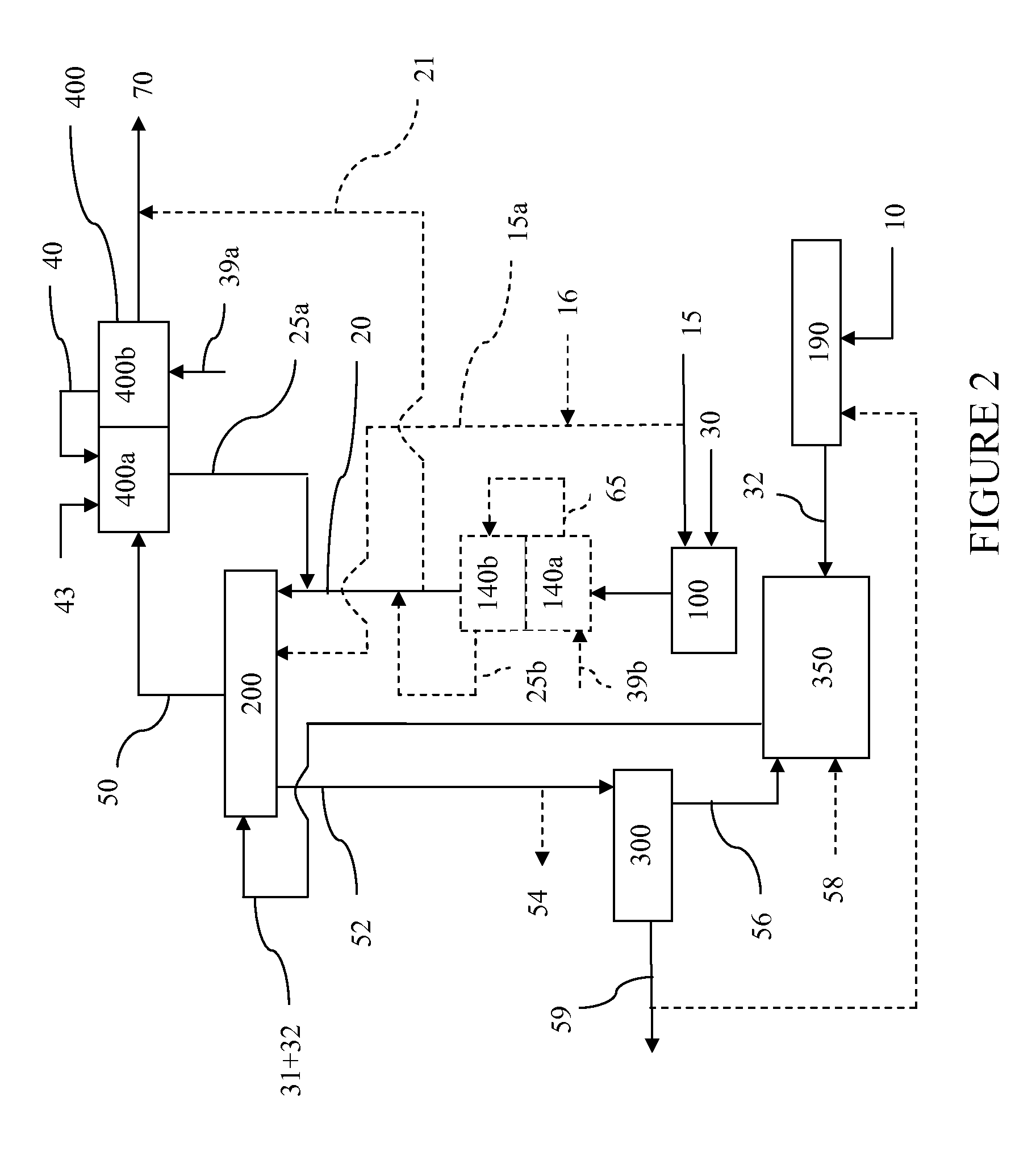

Processes For Hydromethanation Of A Carbonaceous Feedstock

ActiveUS20100292350A1Increase oxygenIncrease the amount of carbonOrganic compound preparationCombustible gas catalytic treatmentPhysical chemistryProcess engineering

The present invention relates to processes for preparing gaseous products, and in particular methane, via the catalytic hydromethanation of a carbonaceous feedstock in the presence of steam, syngas and an oxygen-rich gas stream.

Owner:SURE CHAMPION INVESTMENT LTD

Processes for Hydromethanation of a Carbonaceous Feedstock

ActiveUS20100287835A1Increase the amount of carbonIncrease volumeHydrocarbon by isomerisationHydrogen separationMethanationOrganic chemistry

The present invention relates to processes for preparing gaseous products, and in particular methane, via the hydromethanation of a carbonaceous feedstock in the presence of steam, syngas, a hydromethanation catalyst and an oxygen-rich gas stream.

Owner:SURE CHAMPION INVESTMENT LTD

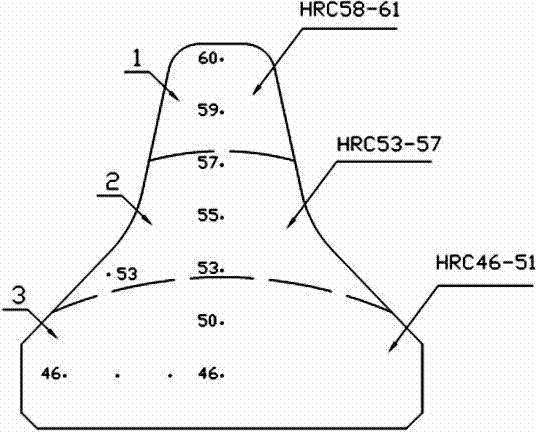

Disk-shaped roller cutter ring and manufacture method thereof

ActiveCN102517502AGuaranteed hardenabilityImprove toughnessFurnace typesHeat treatment furnacesMedium frequencyHardness

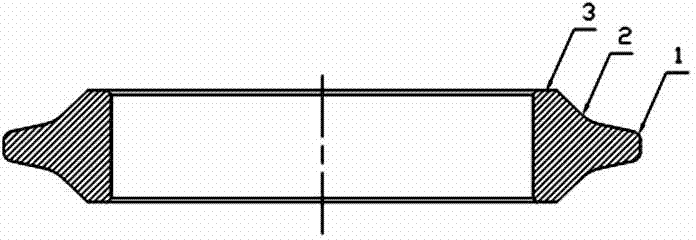

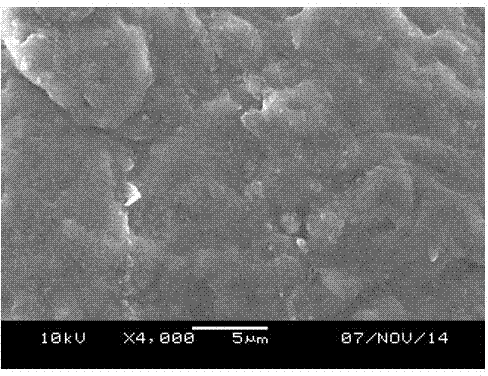

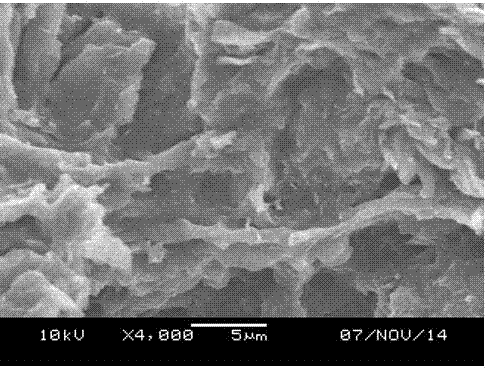

The invention discloses a disk-shaped roller cutter ring with high hardness, good toughness and excellent comprehensive performance. The disk-shaped roller cutter ring comprises the following ingredients of: 0.46-0.56% of C, 0.80-1.20% of Si, 0.20-0.65% of Mn, 5.00-5.80% of Cr, 1.15%-1.55% of Mo, 0.85-1.40% of V and the balance Fe and impurities, wherein the content of P is no more than 0.02%, and the content of S is no more than 0.01%; and the overall hardness of the cutter ring is HRC55-61 (Rockwell Hardness C55-61), or the hardness is of graded distribution, i.e. the hardness of a working edge area is HRC55-61, the hardness of a transition surface area is HRC50-57, and the hardness of a step assembly surface area and an inner ring is HRC44-51. A preparation method of the disk-shaped roller cutter ring comprises the following steps of: smelting the raw materials in an electric furnace; carrying out electroslag remelting; preforging; carrying out die forging; carrying out slow cooling; annealing; carrying out rough machining to obtain a disk-shaped roller cutter ring rough blank; carrying out high-temperature vacuum hardening and two-time high-temperature tempering on the cutter ring rough blank; carrying out low-temperature destressing treatment; carrying out fine finishing to obtain the cutter ring with the overall hardness of HRC55-61, wherein the cutter ring with the overall hardness of HRC55-61 is applicable to the tunneling of a hard rock formation by a shield tunneling machine; or carrying out medium-frequency induction tempering treatment prior to the low-temperature destressing treatment to obtain the cutter ring with graded-distribution hardness, wherein the cutter ring with the graded-distribution hardness is applicable to the tunneling of a rock formation with an upper soft part and a lower hard part.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

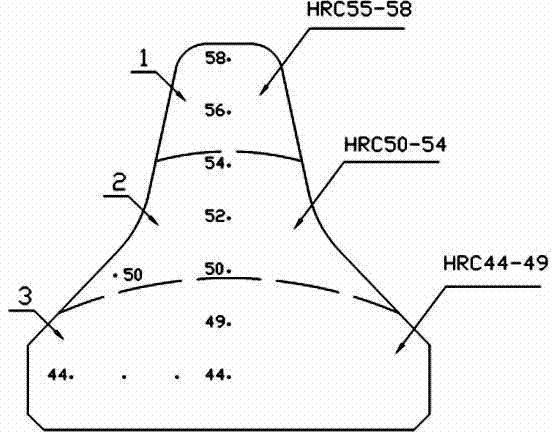

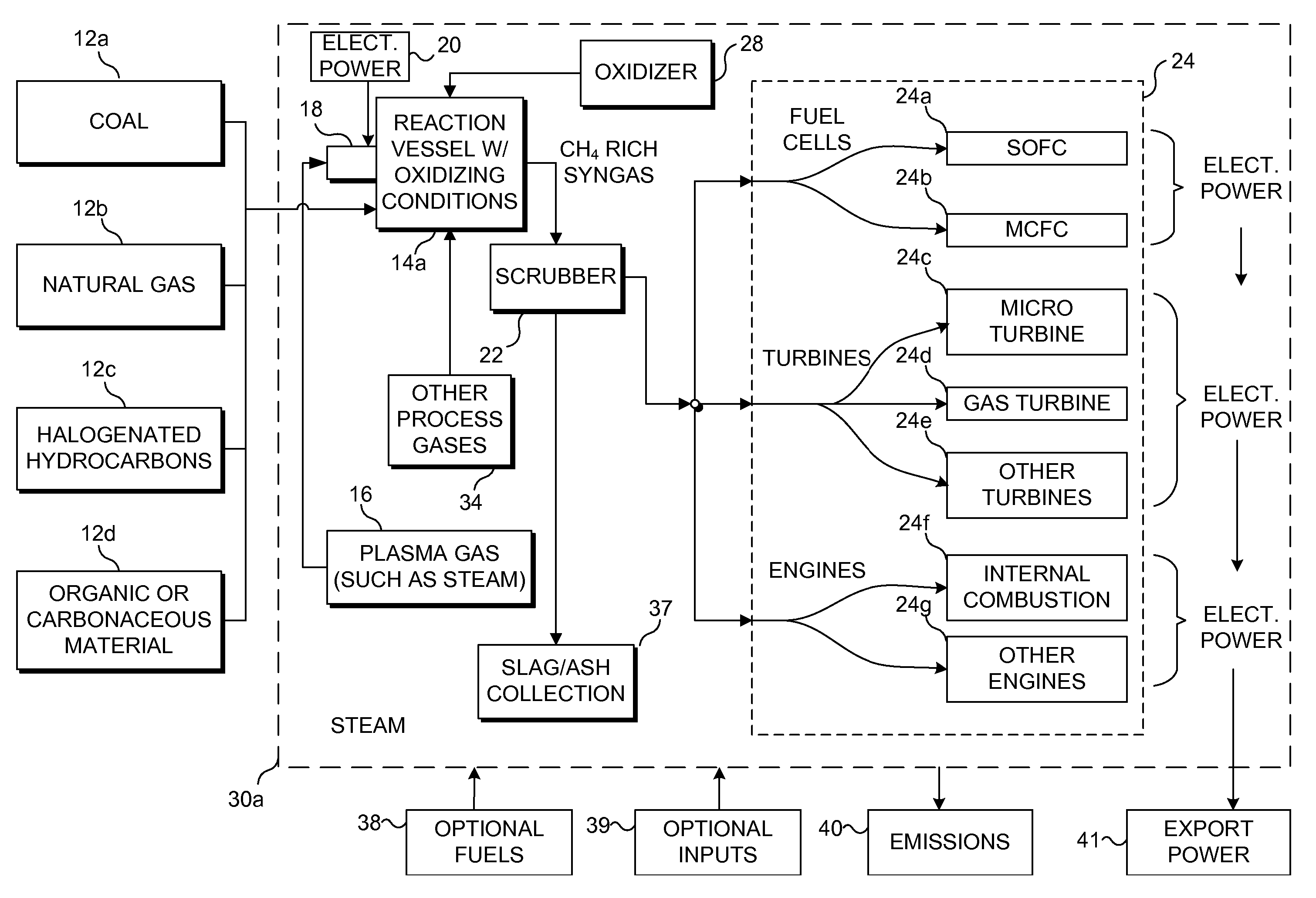

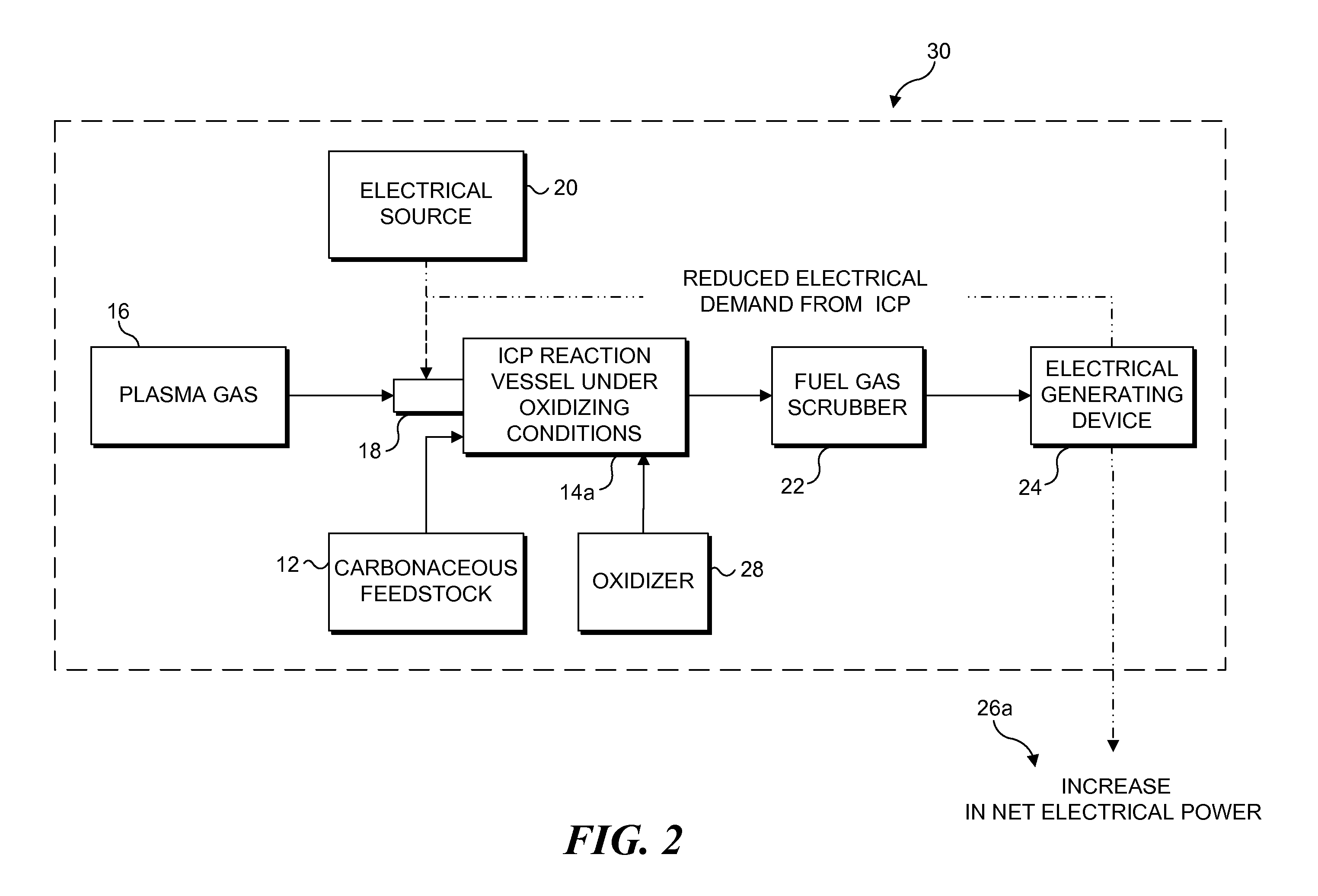

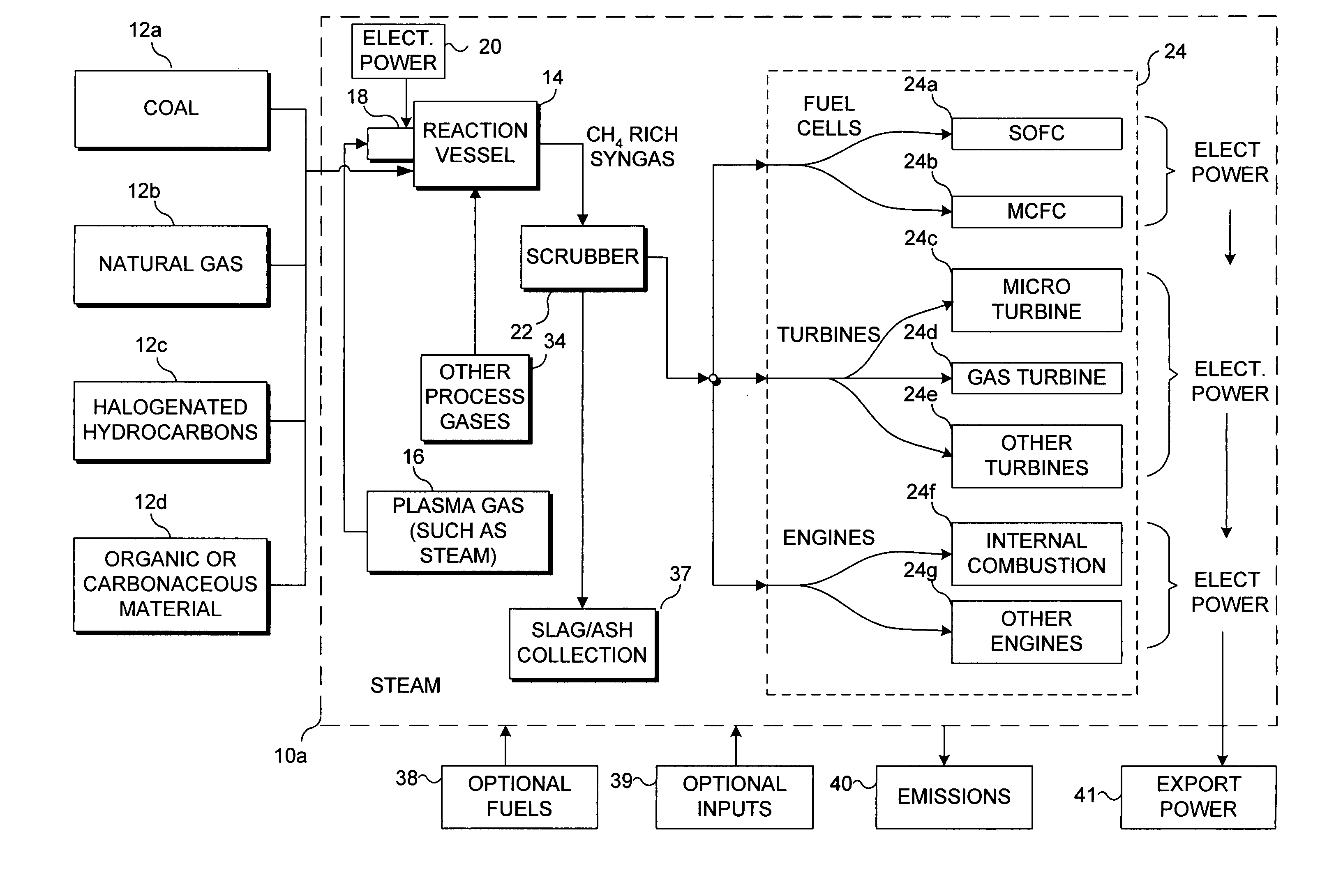

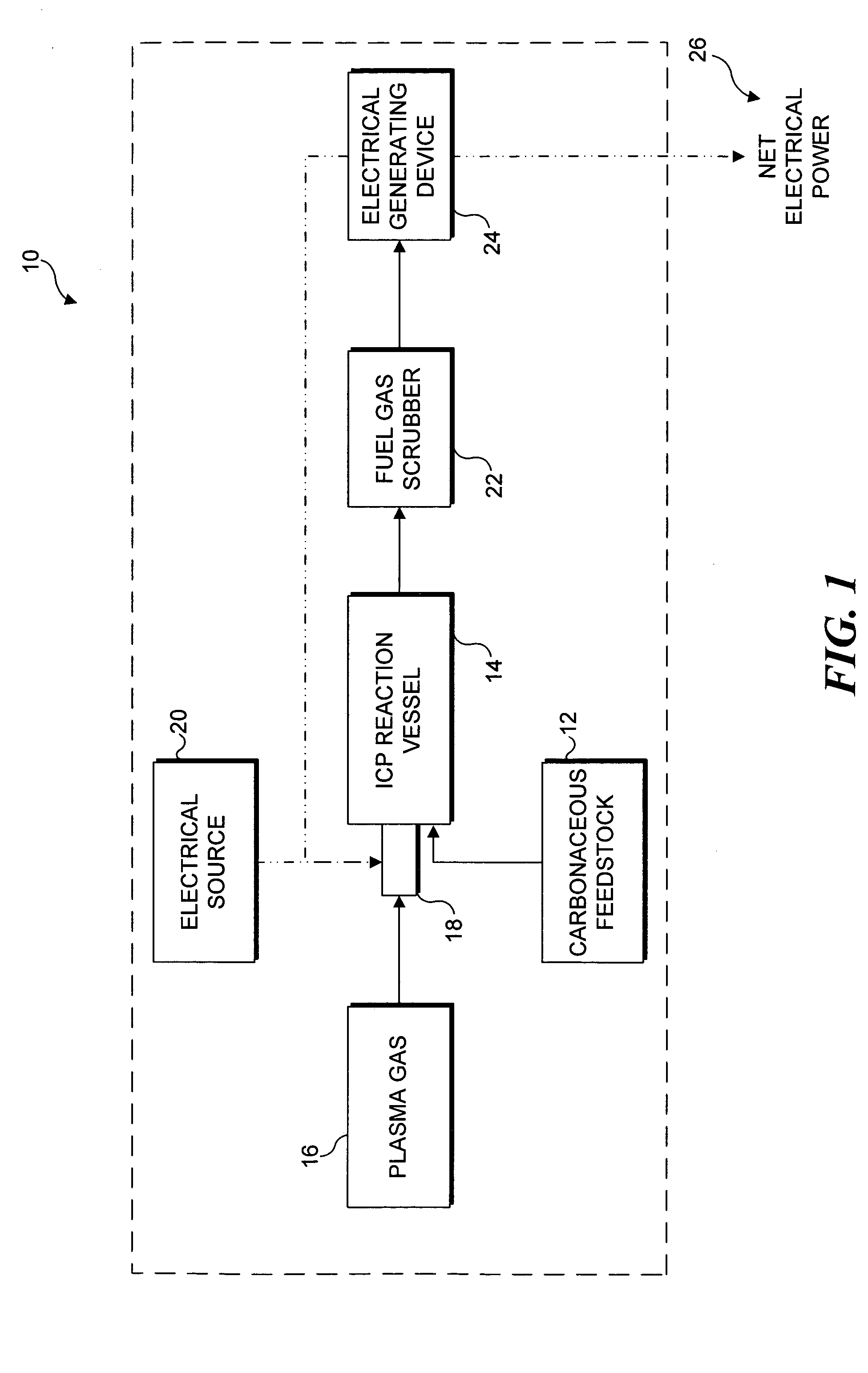

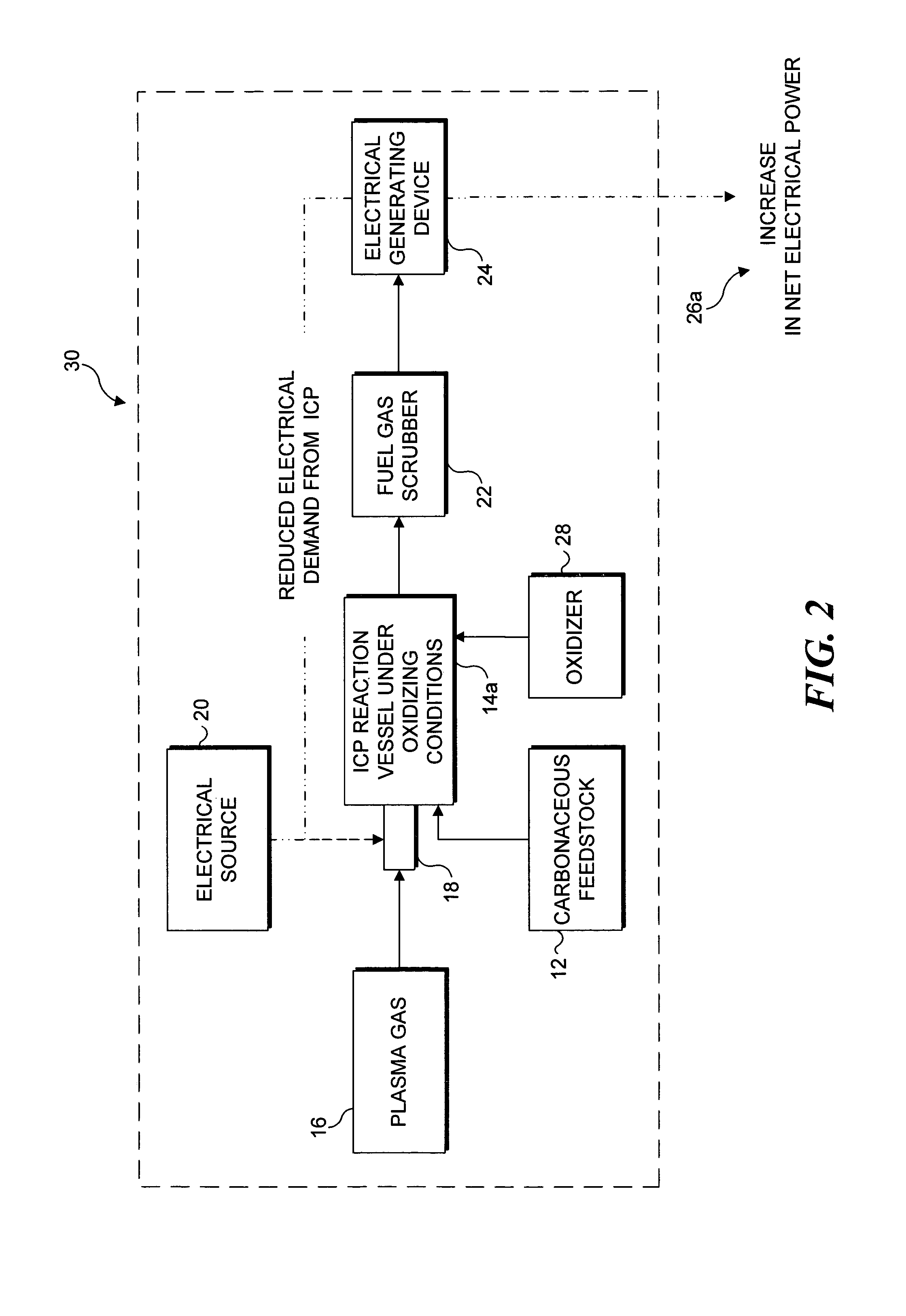

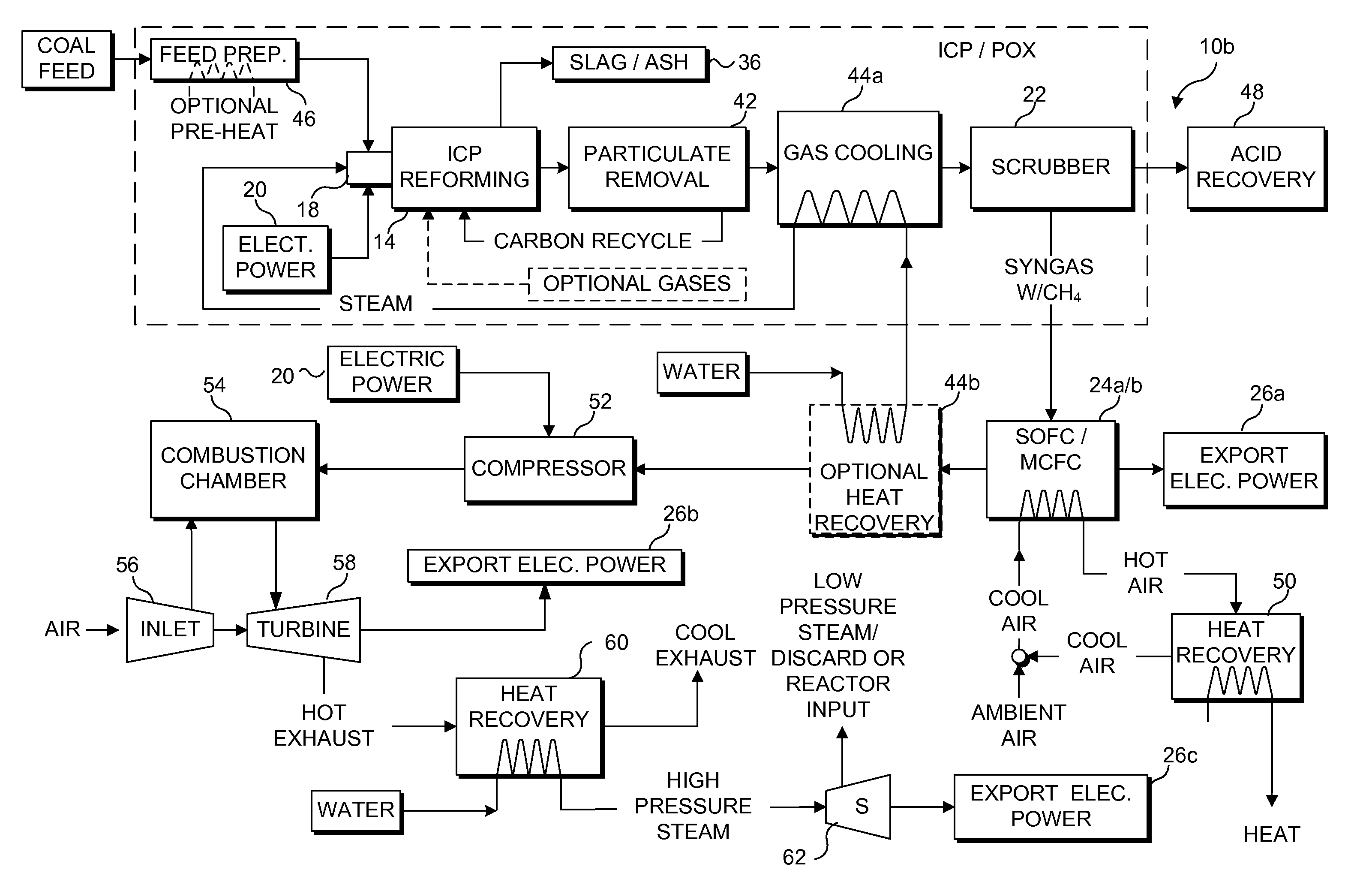

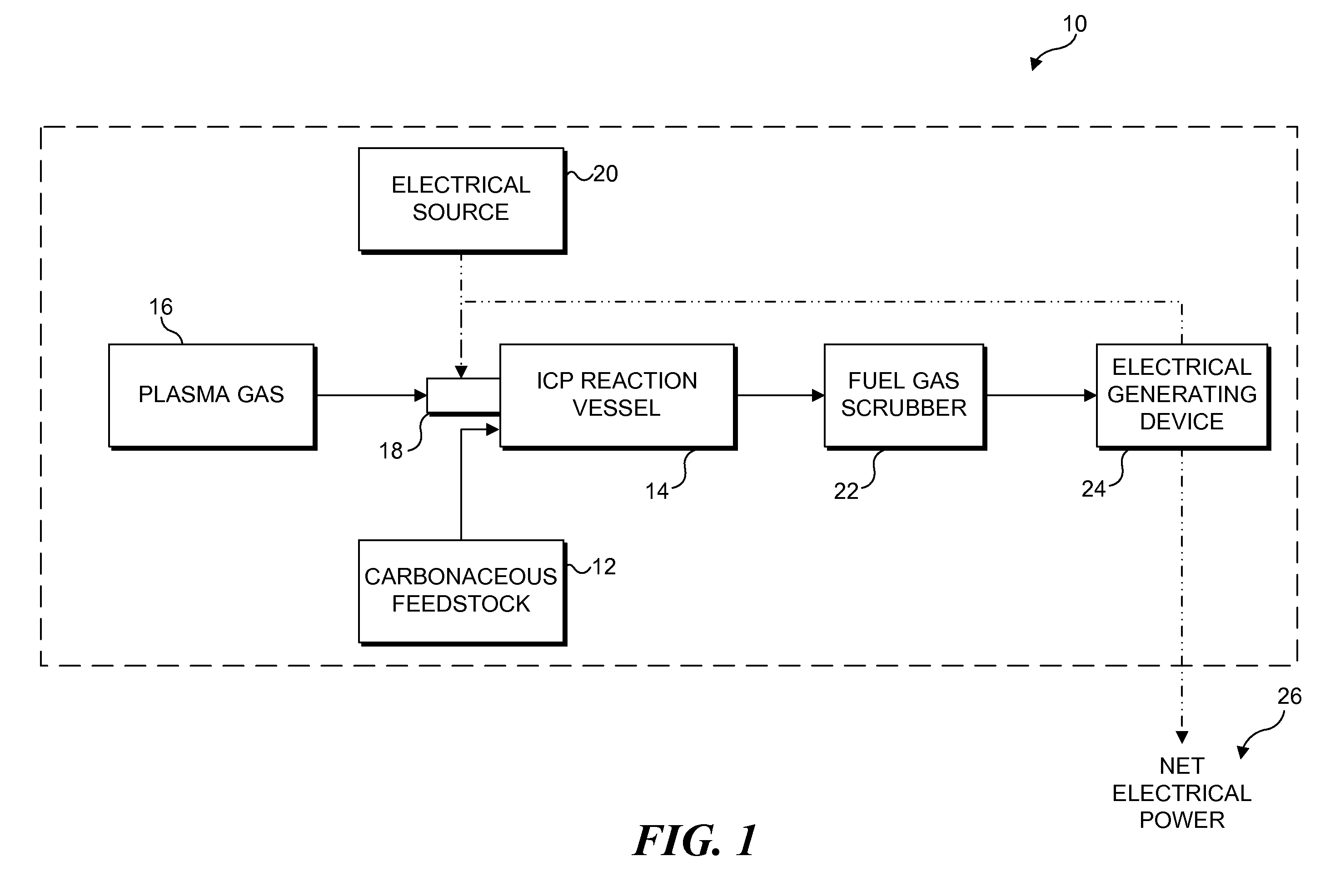

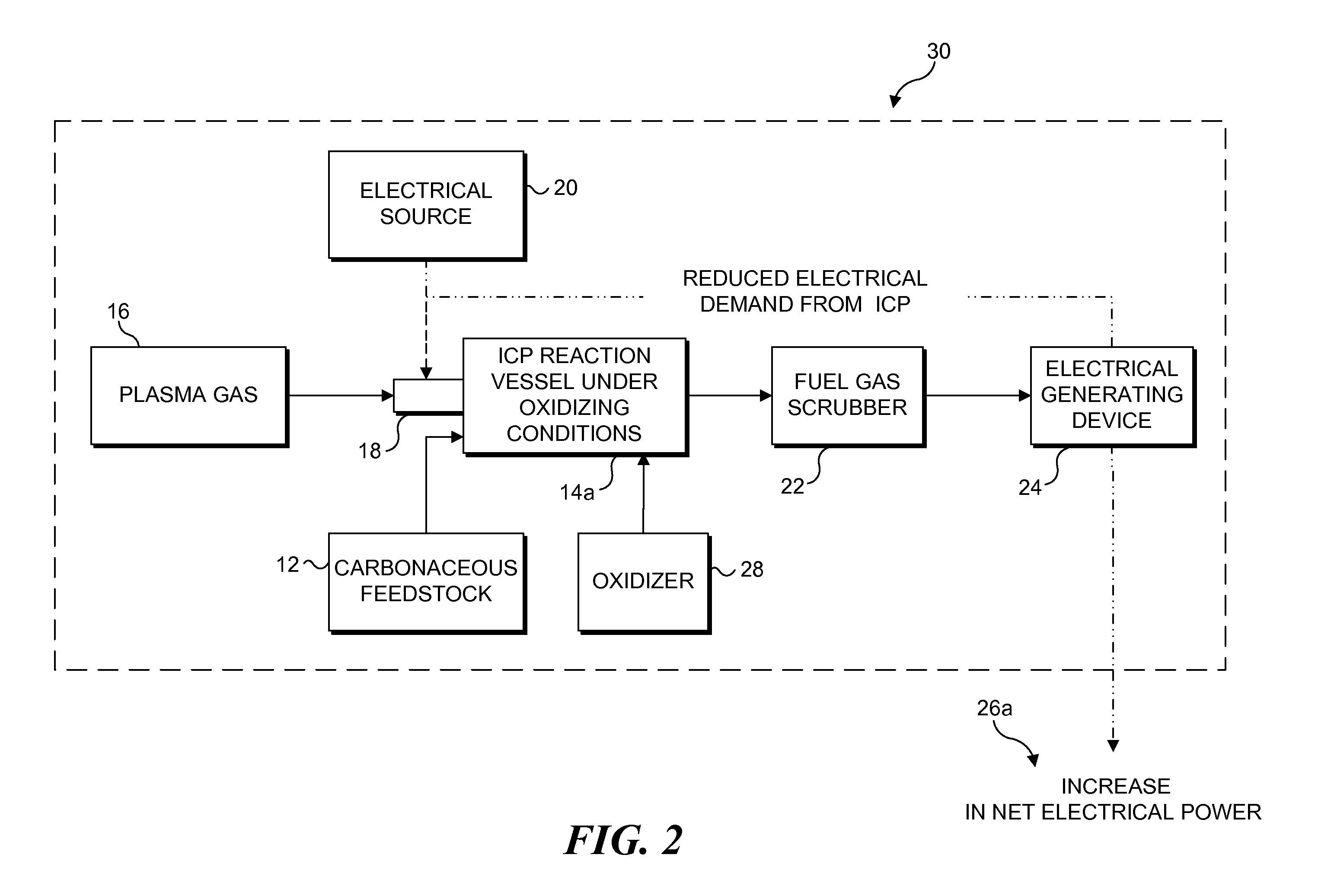

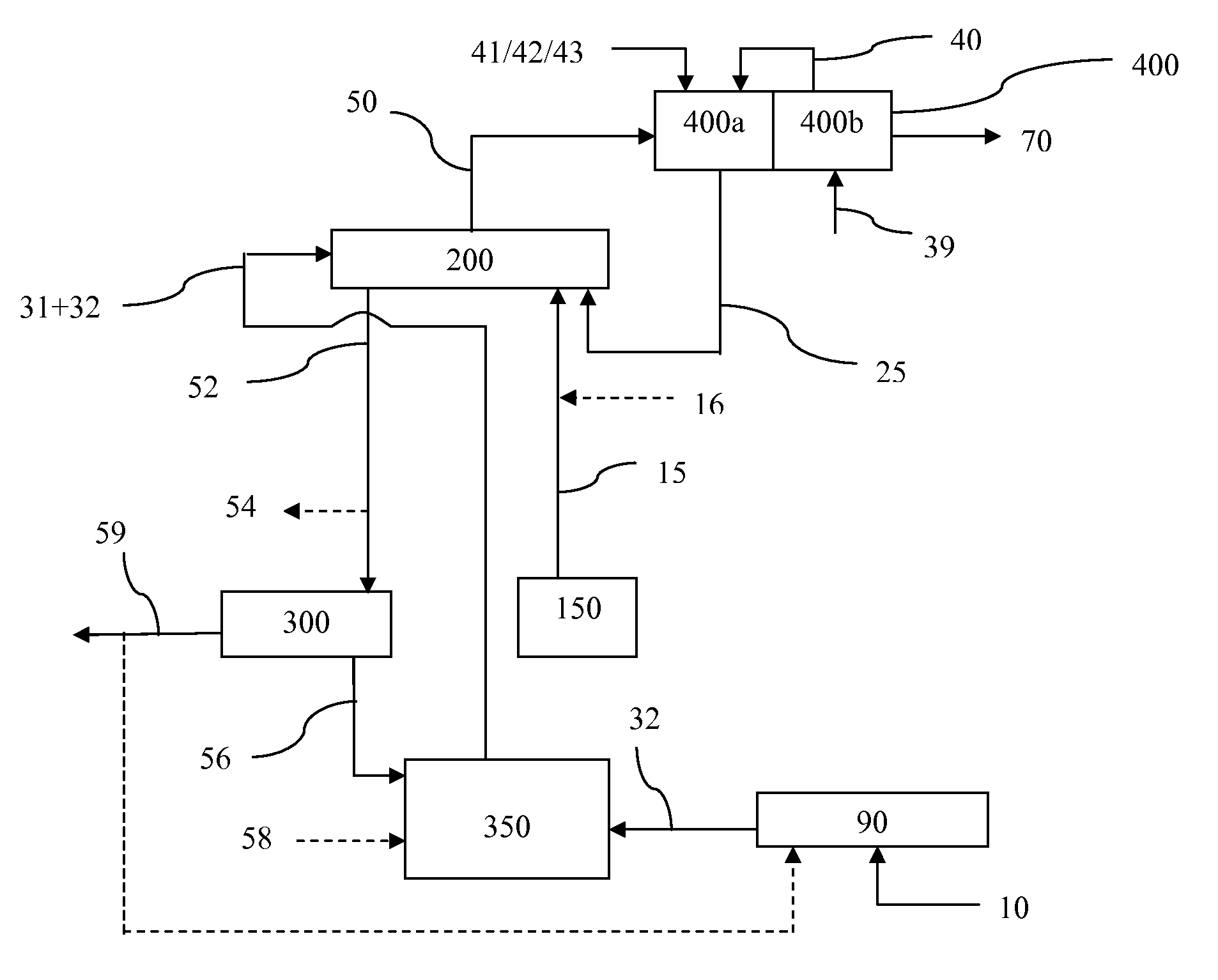

Inductively coupled plasma/partial oxidation reformation of carbonaceous compounds to produce fuel for energy production

InactiveUS20080041829A1Increase the amount of carbonMore electricityElectricity cogenerationFuel cell auxillariesThermal energyPartial oxidation

Owner:SEQUOYAH FINANCE ONE

Inductively coupled plasma/partial oxidation reformation of carbonaceous compounds to produce fuel for energy production

InactiveUS7279655B2Emission reductionMore electricityElectricity cogenerationFuel cell auxillariesThermal energyPartial oxidation

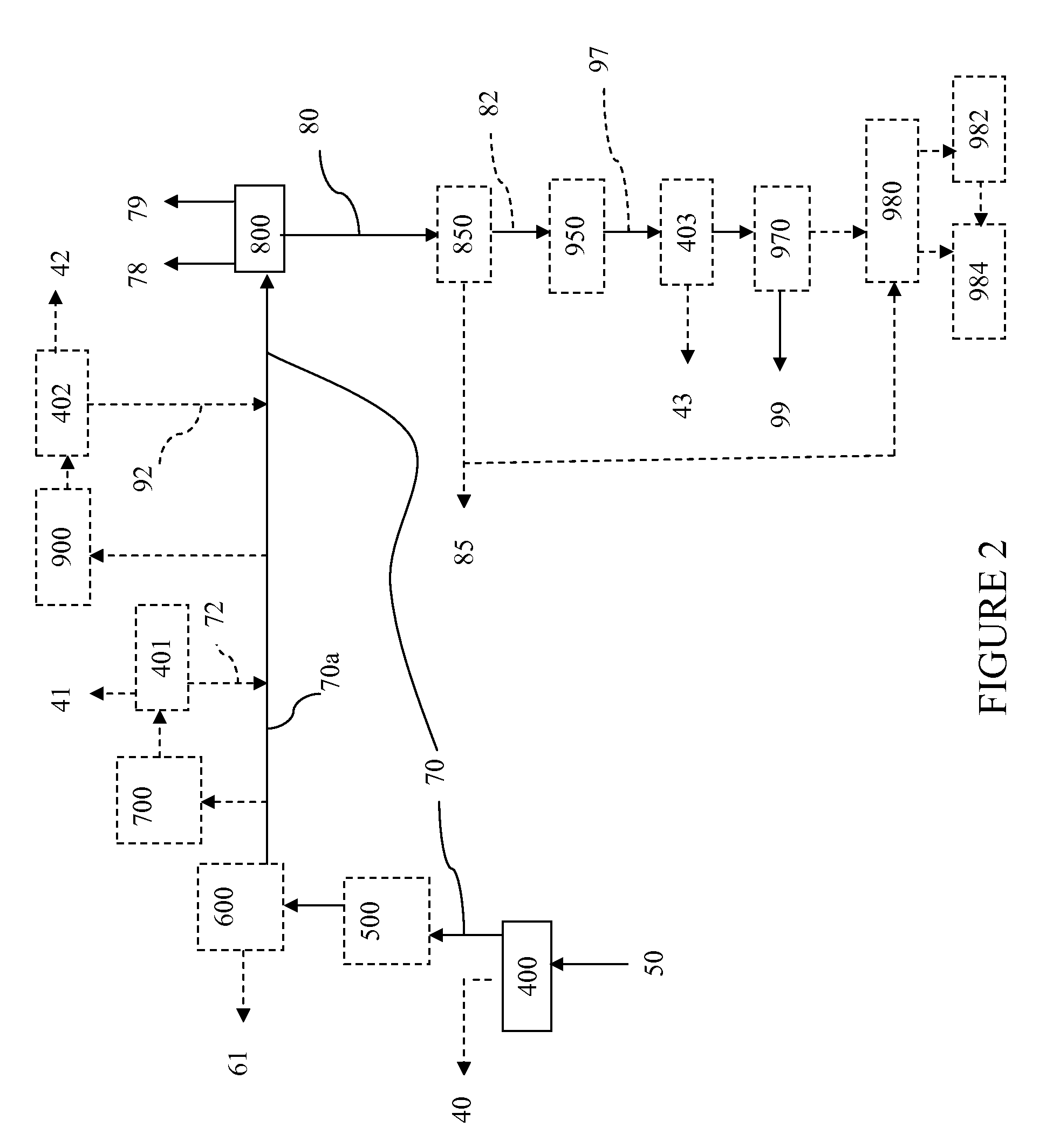

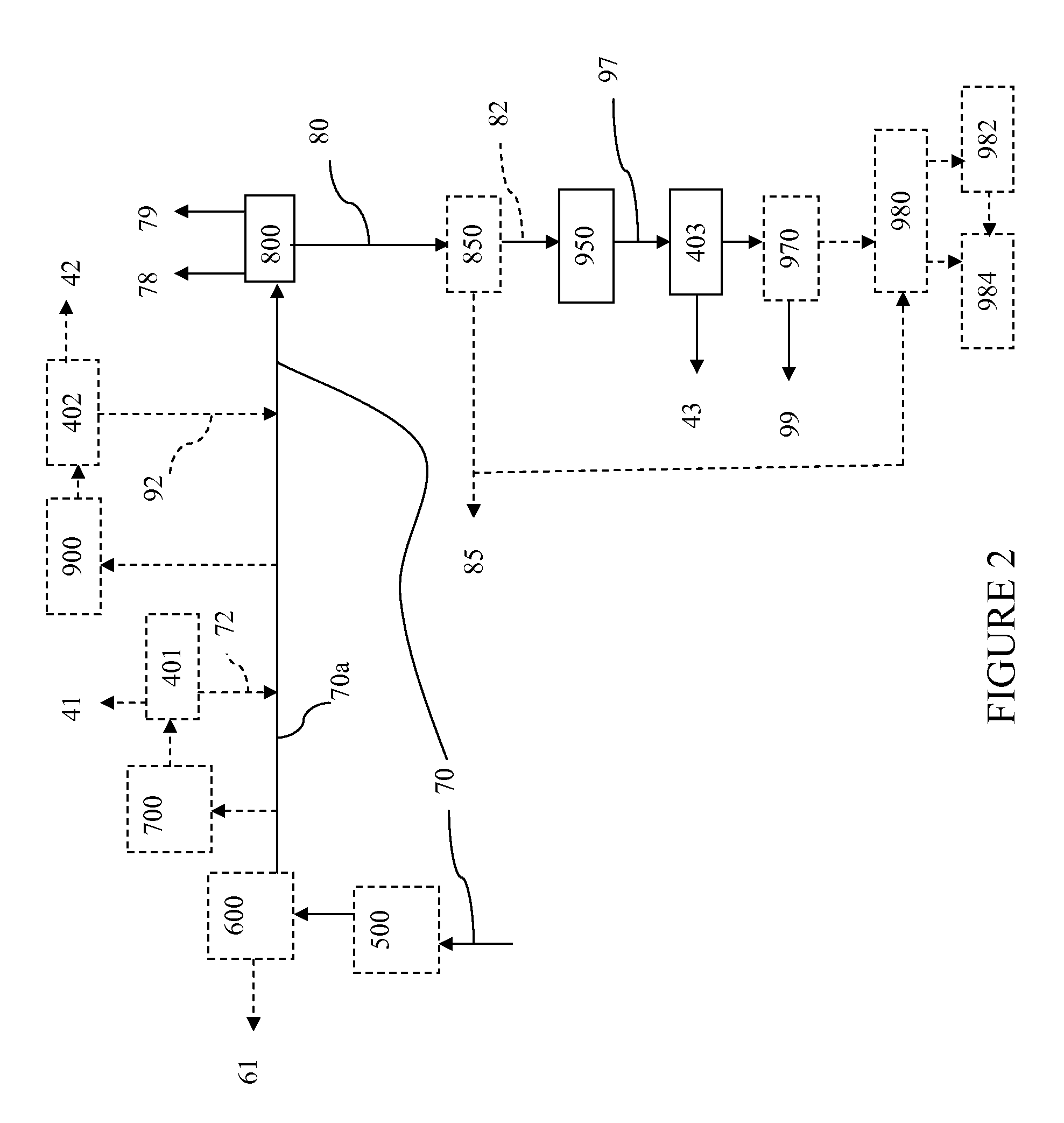

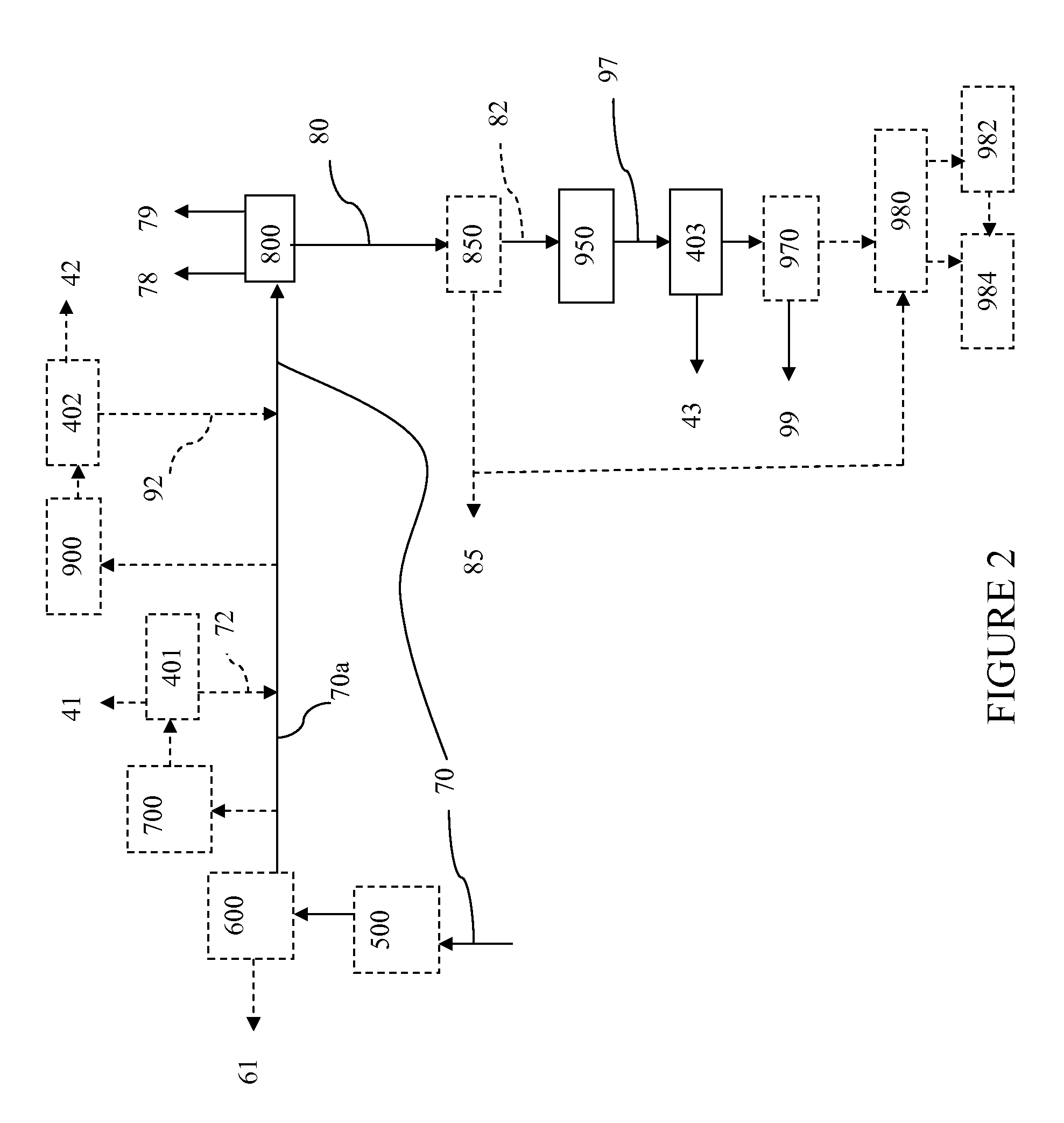

Inductively coupled plasma (ICP) reforming converts carbonaceous compounds into a fuel for use in generating electrical power. Energy rich hydrocarbon fuels, such as coal, marine diesel, oils, and hydrocarbon wastes are employed as a feedstock for the ICP, which transforms the feedstock into a fuel that can be used by fuel cells and gas turbines for the production of electricity. The overall efficiency of an ICP-based electrical power system can be increased by providing partial oxidation within the reaction vessel. The partial oxidation conditions consume a small amount of the reformed fuel gas, thereby liberating sufficient thermal energy to reduce the electrical power requirements of the ICP to maintain desired reactor temperatures, and providing an increase in the overall net electrical power production. The integrated power production system can also adjust to meet an increased requirement for process heat and steam by balancing the effect of partial oxidation.

Owner:SEQUOYAH FINANCE ONE

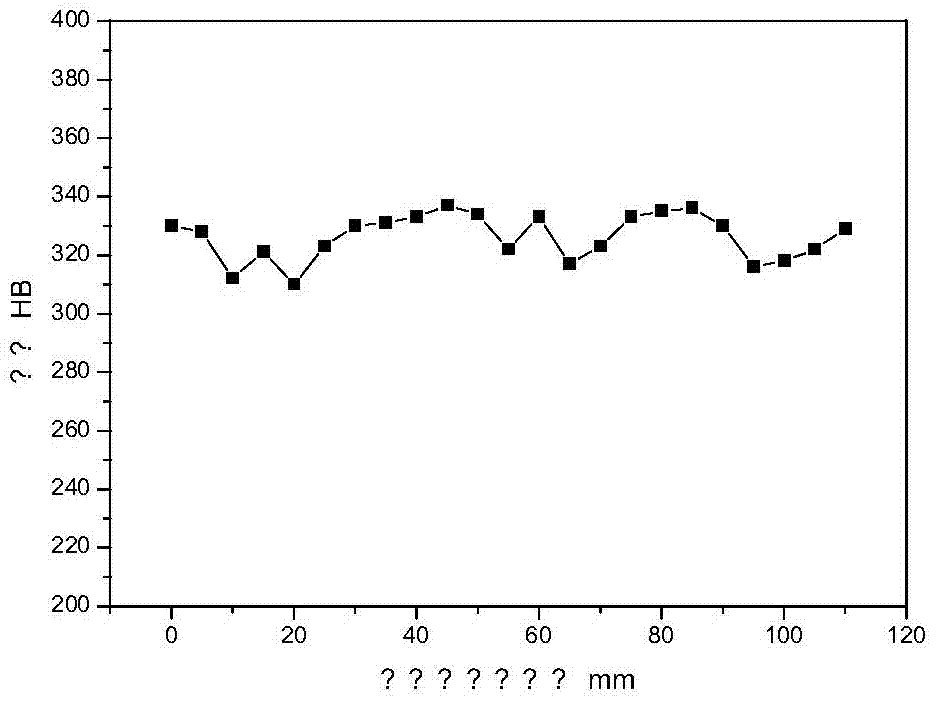

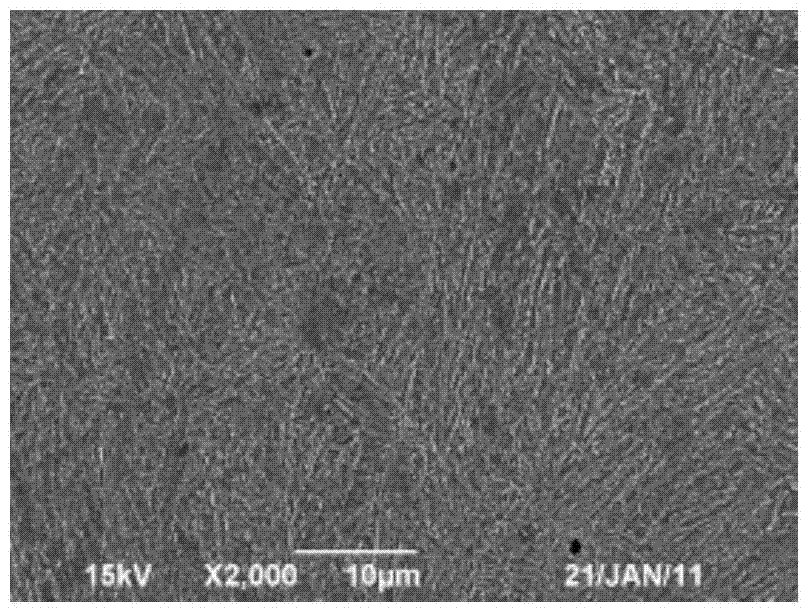

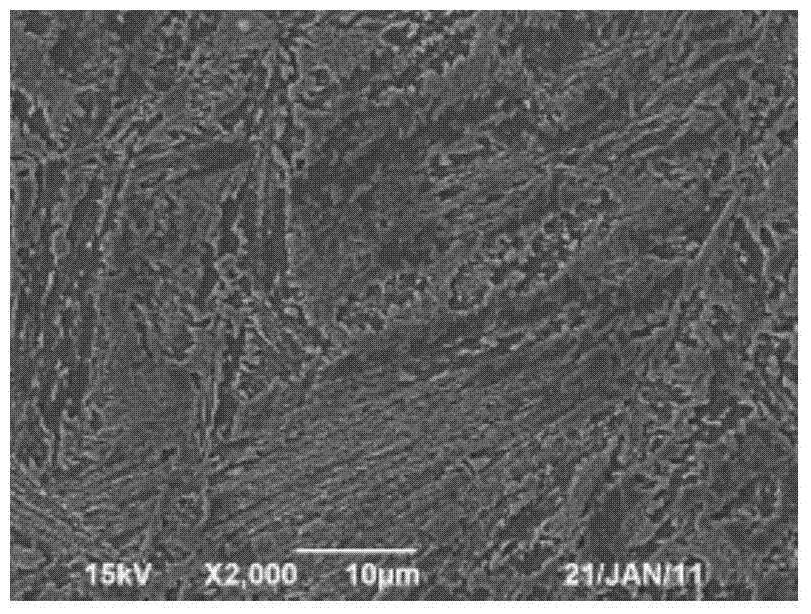

Economical non-quenched and non-tempered micro-alloyed plastic die steel plate and making method thereof

The invention discloses an economical non-quenched and non-tempered micro-alloyed plastic die steel plate and a making method thereof. The economical non-quenched and non-tempered micro-alloyed plastic die steel plate comprises 0.32-0.40wt% of C, 0.20-0.50wt% of Si, 1.00-1.50wt% of Mn, 1.20-1.70wt% of Cr, 0.20wt% or less of Mo, 0.0025wt% or less of B, 0.03wt% or less of Ti, 0.03wt% or less of Nb, and the balance Fe. The making method comprises the following steps: carrying out converter smelting, LF+RH refining and continuous slab casting; heating the obtained slab at 1200-1230DEG C, carrying out precision rolling at 900-950DEG C, and carrying out finishing rolling at 870-920DEG C; carrying out controlled cooling after the steel plate rolling; and tempering the steel plate obtained after the controlled rolling and controlled cooling at 550-600DEG C to obtain the finished pre-hardened plastic die steel plate having a bainite structure. The yield strength, the normal temperature impact toughness and the cross section hardness of the steel plate are above 800MPa, above 20J and 310-350HB respectively. The making method is suitable for the production of pre-hardened plastic die steel plates with the specification of below 120mm from 320mm continuous casting blanks.

Owner:NANJING IRON & STEEL CO LTD +1

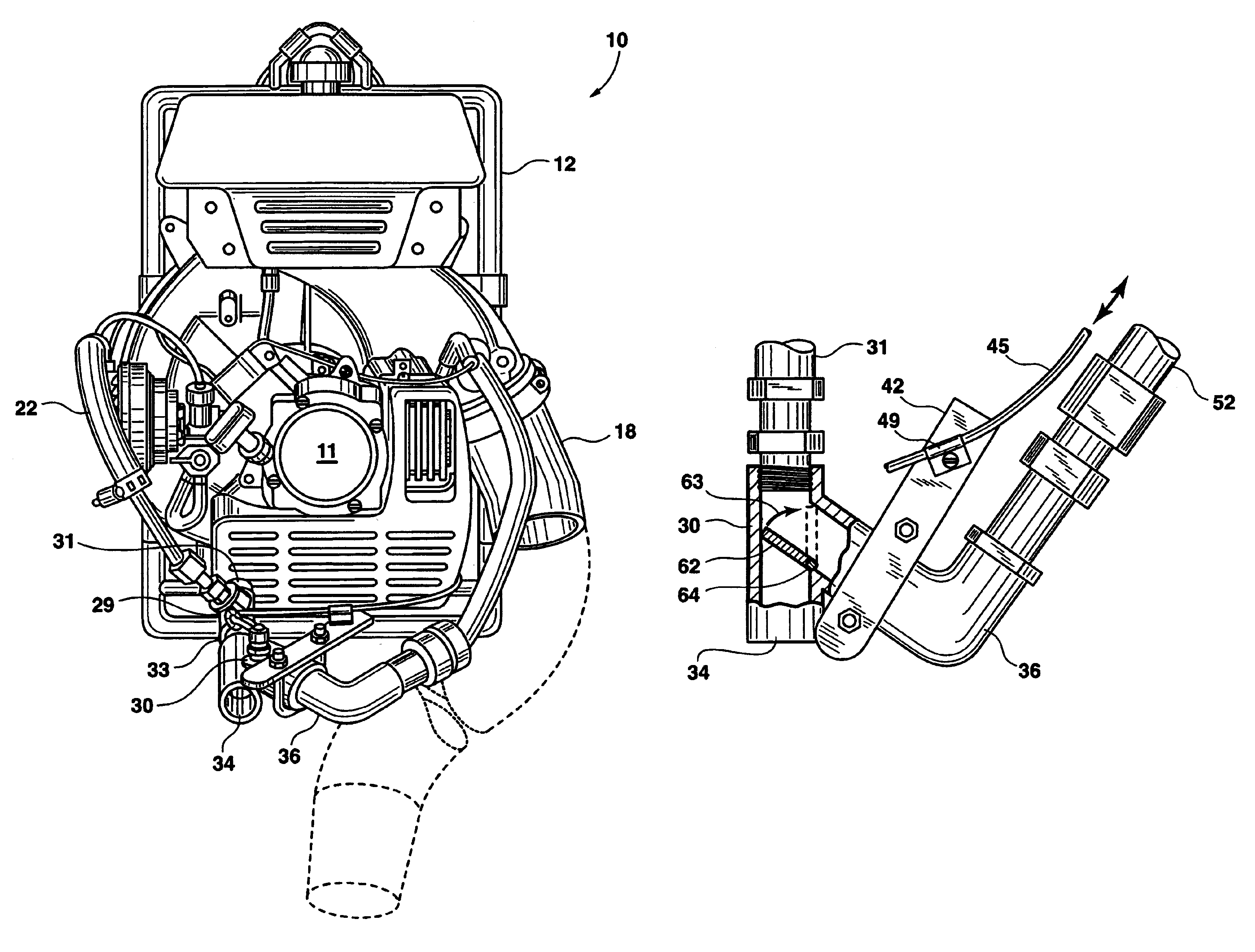

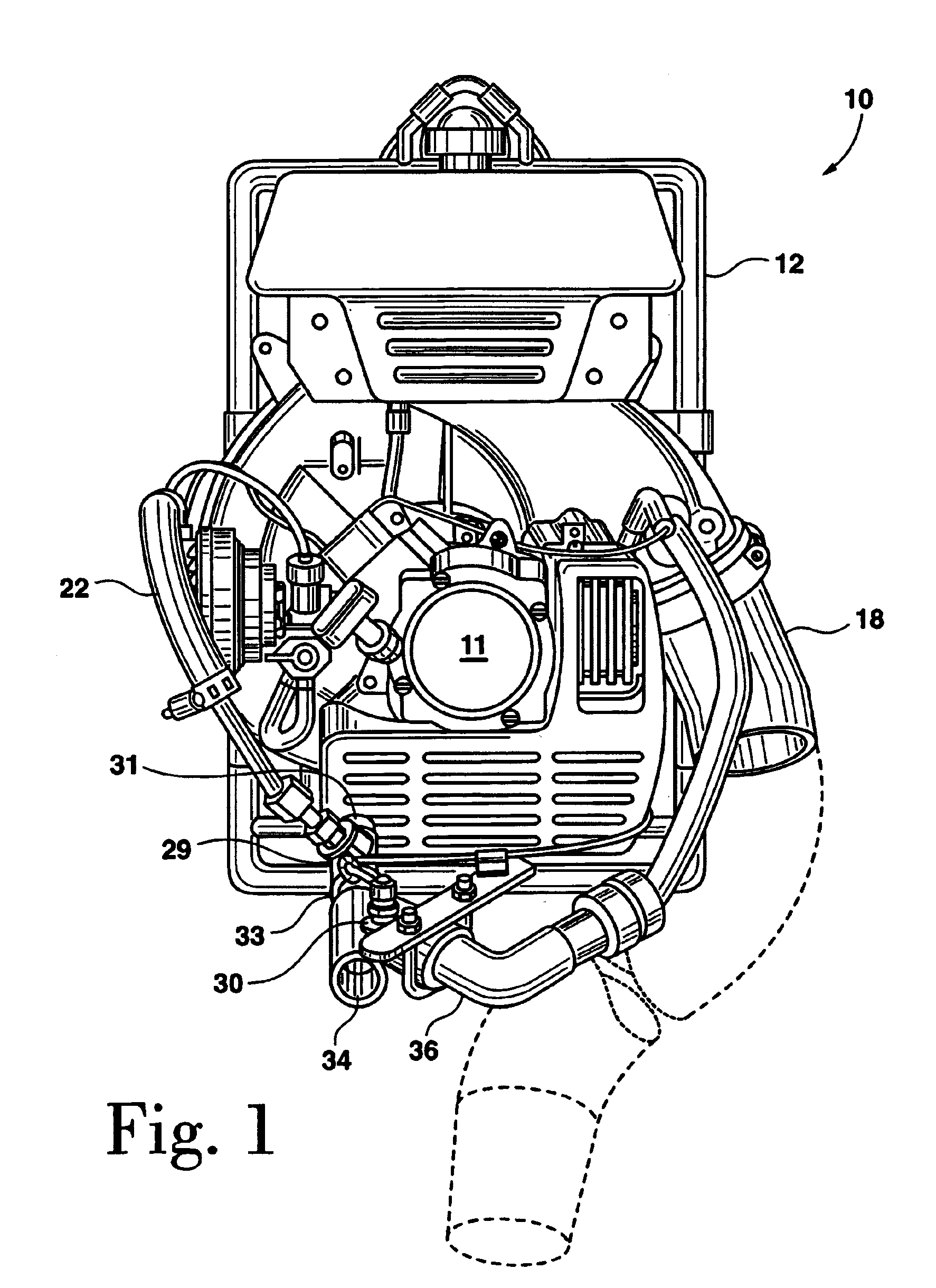

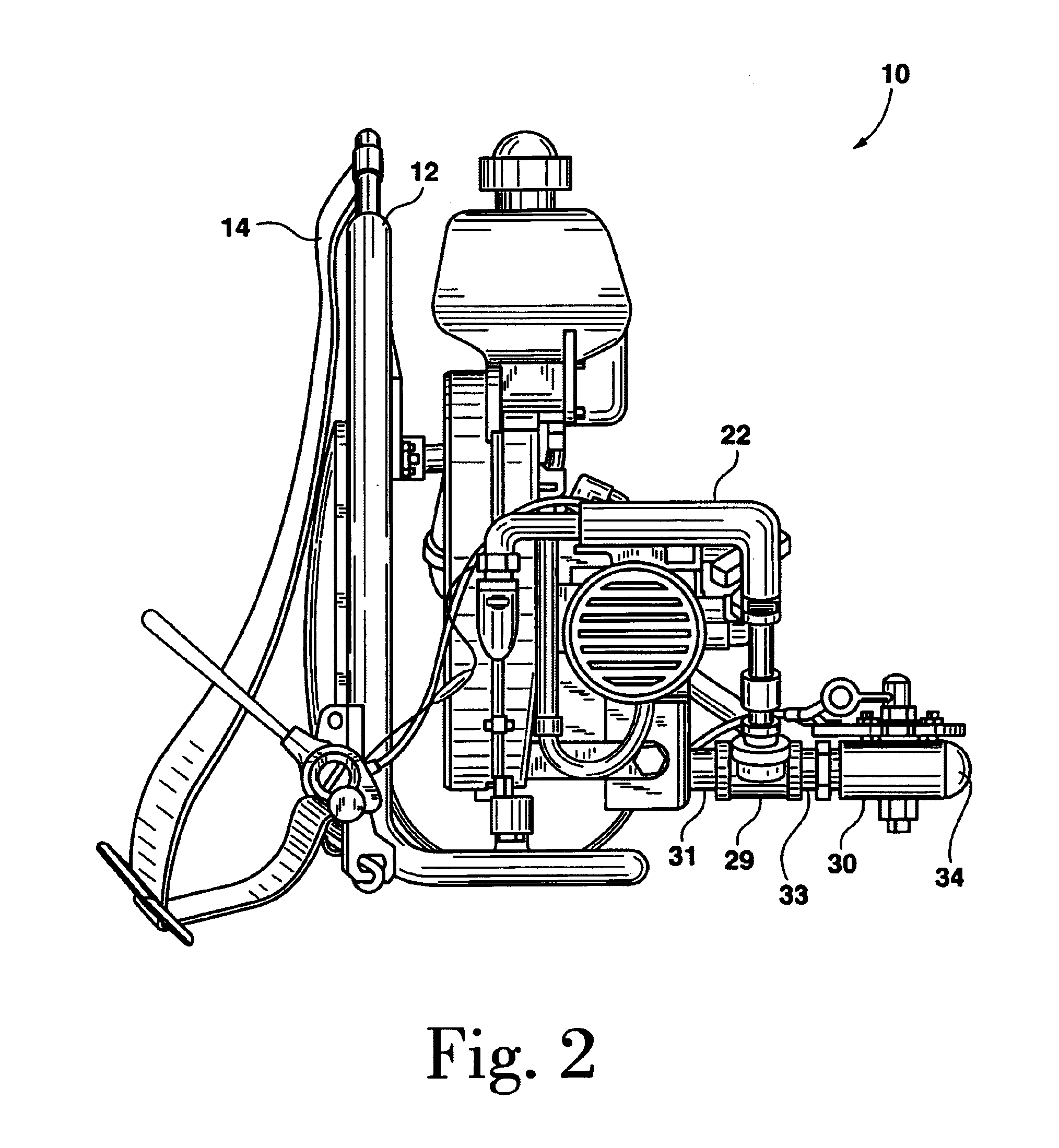

Air blower for extinguishing fires and method for extinguishing fires

The invention employs a blower of the type used by commercial landscapers. The device has an engine mounted on a frame. Shoulder straps attached to the frame allow the user to wear the device on his back leaving the hands of the operator free to operate other tools such as a chain saw or perform other tasks. Also, wearing the device on the back makes it easier to transport the device over long distances to the source of the fire or backfire to be started.The device's blower generates a stream of air at high speeds. This stream of air can be used to feed a fire when the air is directed at a fire. When used to extinguish a fire, air from the blower is tapped from a point 180 degrees removed from the blower output and mixed with exhaust from the engine. This mixture is diverted through a Y-shaped valve into the airstream coming out of the blower. When the device is used to start backfires a fire is started. The airstream, without the mixture of air and engine exhaust can be used to both encourage the propagation of the fire and direct the fire towards the main wild fire. The ability to quickly spread the backfire in the proper direction is imperative because a sudden change in wind direction or other weather conditions could cause the backfire to become as big a problem as the original fire.

Owner:EBNER EDWIN D

Polyvinyl chloride/graphene nanocomposite and preparation method thereof

InactiveCN104710709ASolve the problem of difficult dispersionImprove mechanical propertiesGraphene nanocompositesPlasticizer

The invention discloses a conductive polyvinyl chloride / graphene nanocomposite with good mechanical property and thermal stability and a preparation method thereof. The conductive polyvinyl chloride / graphene nanocomposite comprises the following raw materials in parts by weight: 100 parts of a polyvinyl chloride resin, 10-50 parts of a plasticizer, 1-10 parts of a thermal stabilizer, 0.1-5 parts of a lubricant and 0-8 parts of graphene. The conductive polyvinyl chloride / graphene nanocomposite solves the problem that the conductivity of the PVC is poor, and remarkably improves the mechanical property and thermal stability of the PVC; the conductivity is up to 1.06*10<-6> S / cm; and the tensile strength is increased by 40.66%.

Owner:LIAOCHENG UNIV

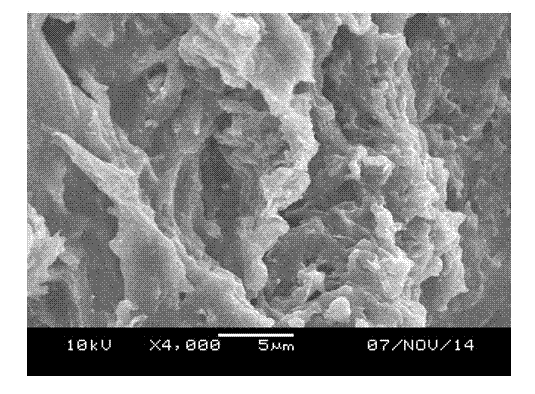

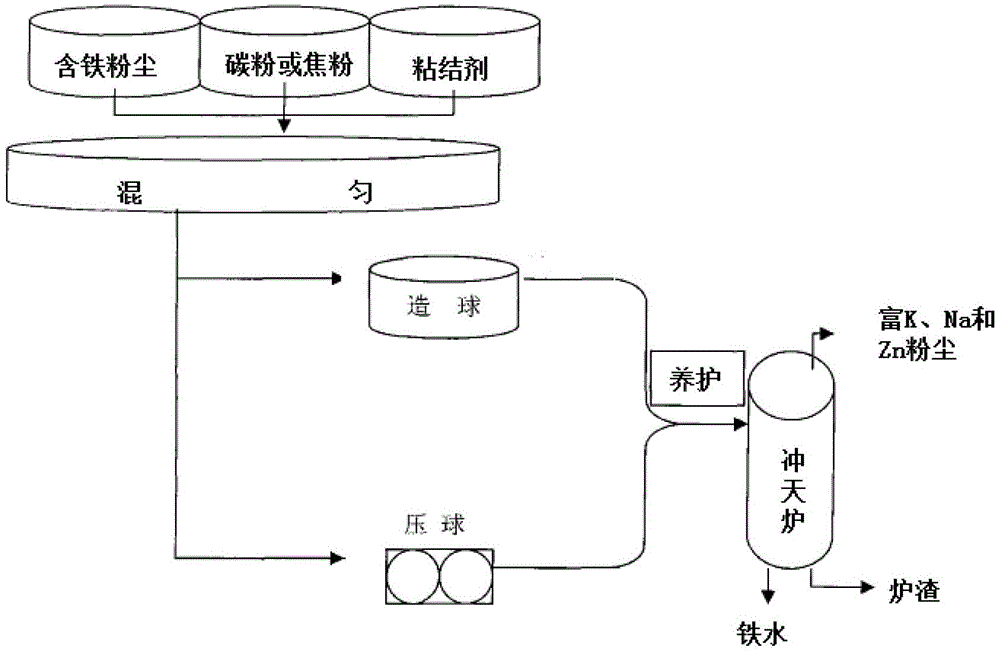

Method for treating iron-containing dust of iron and steel plant by using cupola furnace

The invention discloses a method for treating iron-containing dust in an iron and steel plant by using a cupola furnace, belonging to the technical field of iron making. The method is characterized by comprising the following steps of: blending, uniformly mixing, briquetting and maintaining raw materials including dust in the iron and steel plant, a carbonaceous reducing agent, a bonder and an additive, and then putting the raw materials into the cupola furnace for iron making, wherein the carbon content of carbon-containing pellets prepared by briquetting raw materials of various iron-containing dust in the iron and steel plant is about 10%, the compressive strength of the maintained pellets is greater than 1000N per each pellet, and the pellets are distributed into the cupola furnace for iron making through a material distribution system; and preheating blast through a hot blast furnace, preheating the wind temperature from a normal temperature to about 500-1200 DEG C, and enriching oxygen by 1-5% in the blast to achieve the aims of improving the smelting strength, increasing the output and reducing the coke ratio. By adopting the method, the dust of the iron and steel plant can be recycled to achieve the aims of saving energy, reducing emission and reducing environmental pollution, so that the method has good economic and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

Electrode mixture, electrode, and lithium secondary battery

InactiveUS20120315530A1High outputHigh rateFinal product manufactureConductive materialWater soluble polymersElectrically conductive

An electrode mixture containing a lithium mixed metal oxide having a BET specific surface area of 2 to 30 m2 / g, a water-soluble polymer having an acid functional group, water and an electrically conductive material. An electrode produced by applying the electrode mixture on an electrode current collector, and then drying the applied current collector. A lithium secondary battery comprising the electrode as a positive electrode.

Owner:SUMITOMO CHEM CO LTD

Graphene-oxide-modified polypropylene composite material

The invention discloses a graphene-oxide-modified polypropylene composite material which is prepared from graphene-oxide-modified polypropylene, ethylene propylene diene monomer rubber, a butadiene-acrylonitrile copolymer, a silane coupling agent, zinc borate, magnesium hydroxide, pentaerythritol, epoxy soybean oil, tritolyl phosphate, pentaerythritol stearate, yttrium oxide, nano mica powder, talcum powder, silicon micropowder, 1,3,2,4-di(3,4-dimethylbenzylidene)sorbitol, an ethylene-octylene copolymer and 2-hydroxy-4-n-octyloxy diphenyl ketone. The graphene-oxide-modified polypropylene composite material has the advantages of high strength, excellent heat resistance, excellent flame retardancy and favorable heat stability.

Owner:ANHUI LANTONG TECH CO LTD

Aqueous solution capable of absorbing and collecting carbon dioxide in exhaust gas with high efficiency

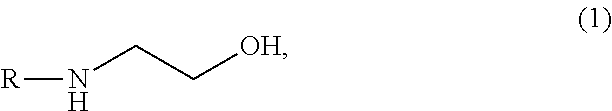

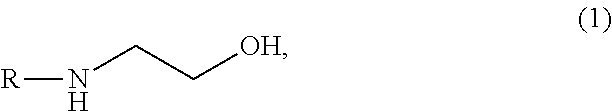

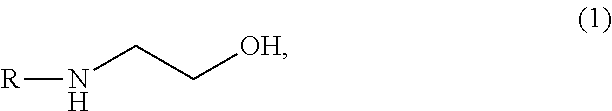

InactiveUS20130101493A1Increase the amount of carbonReduce the amount requiredGas treatmentOther chemical processesExhaust fumesProduct gas

Disclosed is an aqueous solution for absorbing and recovering carbon dioxide from a carbon dioxide-containing gas, the aqueous solution containing 50 to 70 wt % of a secondary amine compound represented by Formula (1):wherein R represents a straight- or branched-chain alkyl group having 3 to 5 carbon atoms; and a surfactant. Also disclosed is a method for absorbing and recovering carbon dioxide using the aqueous solution.

Owner:RES INST OF INNOVATIVE TECH FOR THE EARTH +1

Preparation method of nanometer bismuth hydroxide/polyethylene flame-retardant composite material

InactiveCN103788459AImprove flame retardant performanceEvenly dispersedPlastic/resin/waxes insulatorsInsulated cablesWater bathsSynthesis methods

The invention relates to a preparation method of a nanometer bismuth hydroxide / polyethylene flame-retardant composite material, and relates to a flame-retardant composite material which contains an inorganic flame retardant and a preparation method of the flame-retardant composite material. The invention aims at solving the technical problem that the bismuth hydroxide is nonuniformly grown on the surface of polyethylene in a water bath synthetic method. The method comprises the following steps of dissolving the bismuth hydroxide and the polyethylene into alcohol, mixing, and then pouring into a ball milling jar for ball milling, wherein the mass ratio of mill balls to materials is 15:1; then regulating a pH value, pouring into a hydro-thermal synthesis reaction kettle for heat preservation; pouring powder from the hydro-thermal synthesis reaction kettle, washing the powder by using alcohol, drying, then placing the powder into a flat vulcanizing machine for hot press forming, and cooling to room temperature to obtain the nanometer bismuth hydroxide / polyethylene flame-retardant composite material. According to the invention, the generated bismuth hydroxide is coated on the surface of the polyethylene through a solvent thermal synthesis method, nanometer particles contained in the prepared nanometer particle / polyethylene composite material are uniformly dispersed, the bismuth hydroxide outstandingly enhances the flame-retardant property of the polyethylene, and the carbon forming amount of the polyethylene is greatly increased. The invention belongs to the field of preparation of flame-retardant composite materials.

Owner:HARBIN UNIV OF SCI & TECH

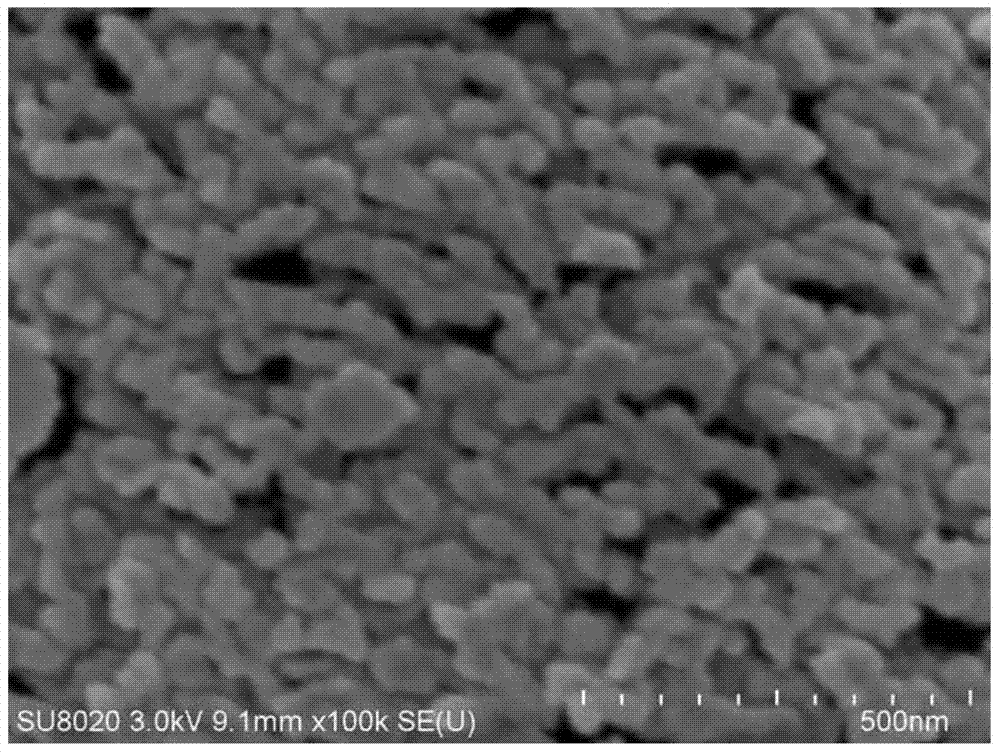

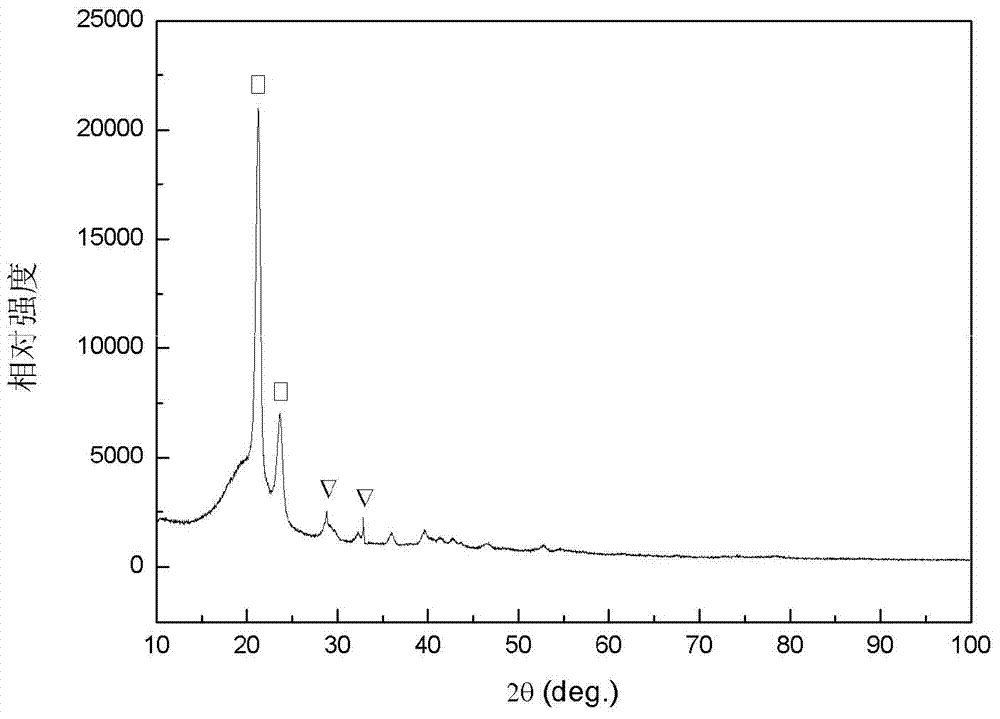

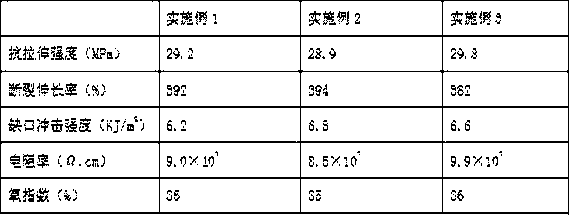

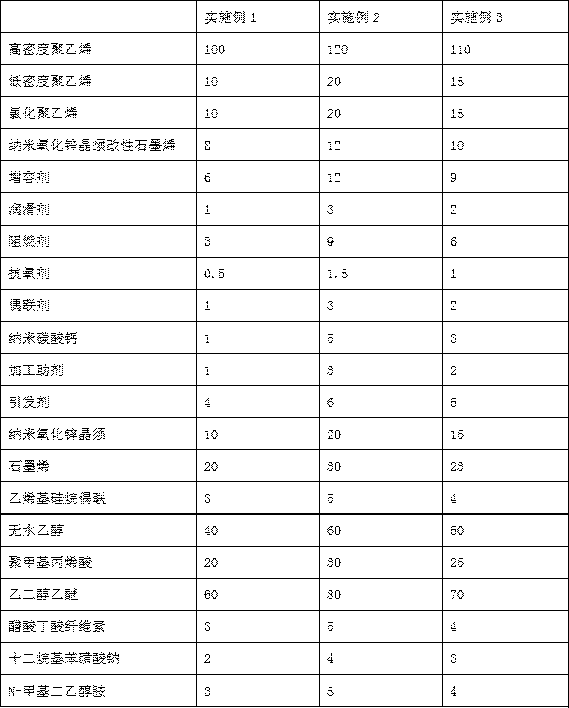

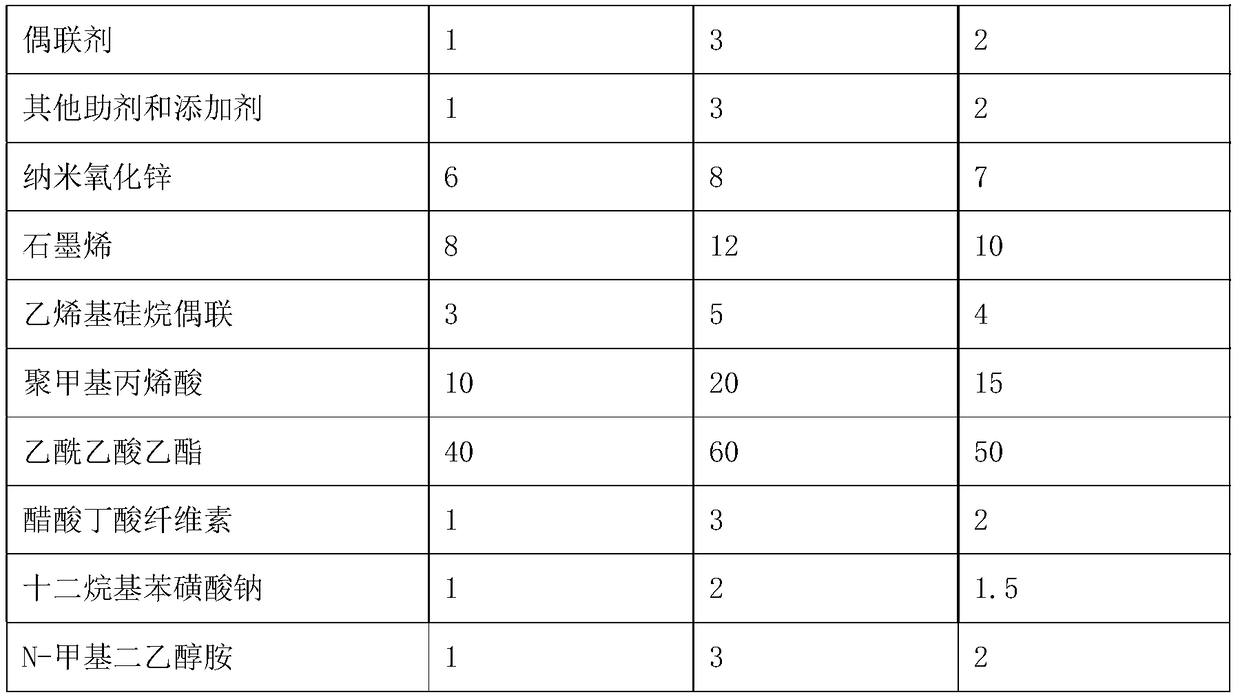

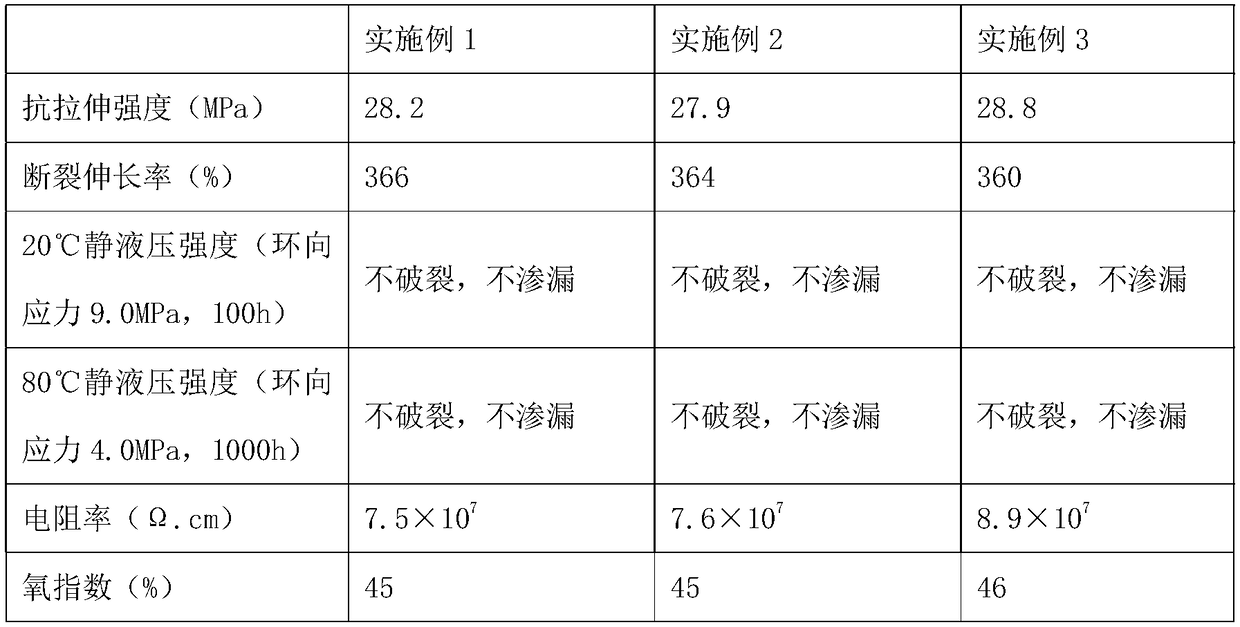

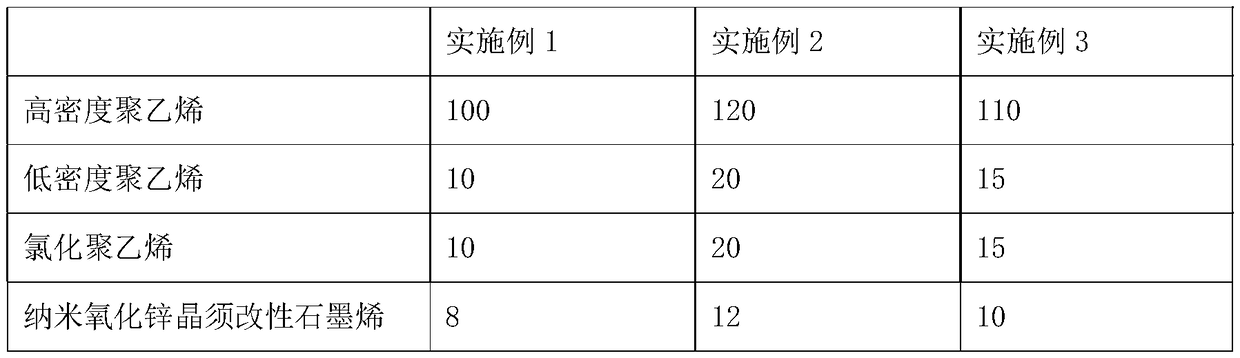

Preparation process of high-rigidity antistatic modified hollow wall winding pipe

The invention relates to a preparation process of a high-rigidity antistatic modified hollow wall winding pipe. The modified nano-zinc oxide whisker is used to modify graphene to combine nano-zinc oxide whiskers, a vinyl silane coupling agent and graphene, the vinyl silane coupling agent and the nano zinc oxide whisker are uniformly dispersed between the graphene surface and a sheet layer, which improves the surface properties of the grapheme, the process effectively promotes the dispersion of the nano zinc oxide whiskers and graphene, prevents the agglomeration, promotes the effect of high-density polyethylene resin, improves the compatibility between the systems, and improves the mechanical properties and toughness and rigidity of the pipe; on the one hand, the carbon content of the pipeis improved and the thermal stability of the pipe is improved; and on the other hand, the nano-zinc oxide whiskers and graphene cooperate to form a continuous conductive path between the systems, which greatly improves the electrical conductivity of the pipe and improves the antistatic flame retardant effect of the pipe. The preparation method is simple and scientific, the cost is low, the preparation process is environmentally friendly, and the environment is not polluted.

Owner:JIANGSU QIANLONG NEW MATERIAL

Inductively coupled plasma/partial oxidation reformation of carbonaceous compounds to produce fuel for energy production

InactiveUS7781695B2Increase the amount of carbonMore electricityElectricity cogenerationFuel cell auxillariesThermal energyPartial oxidation

Inductively coupled plasma (ICP) reforming converts carbonaceous compounds into a fuel for use in generating electrical power. Energy rich hydrocarbon fuels, such as coal, marine diesel, oils, and hydrocarbon wastes are employed as a feedstock for the ICP, which transforms the feedstock into a fuel that can be used by fuel cells and gas turbines for the production of electricity. The overall efficiency of an ICP-based electrical power system can be increased by providing partial oxidation within the reaction vessel. The partial oxidation conditions consume a small amount of the reformed fuel gas, thereby liberating sufficient thermal energy to reduce the electrical power requirements of the ICP to maintain desired reactor temperatures, and providing an increase in the overall net electrical power production. The integrated power production system can also adjust to meet an increased requirement for process heat and steam by balancing the effect of partial oxidation.

Owner:SEQUOYAH FINANCE ONE

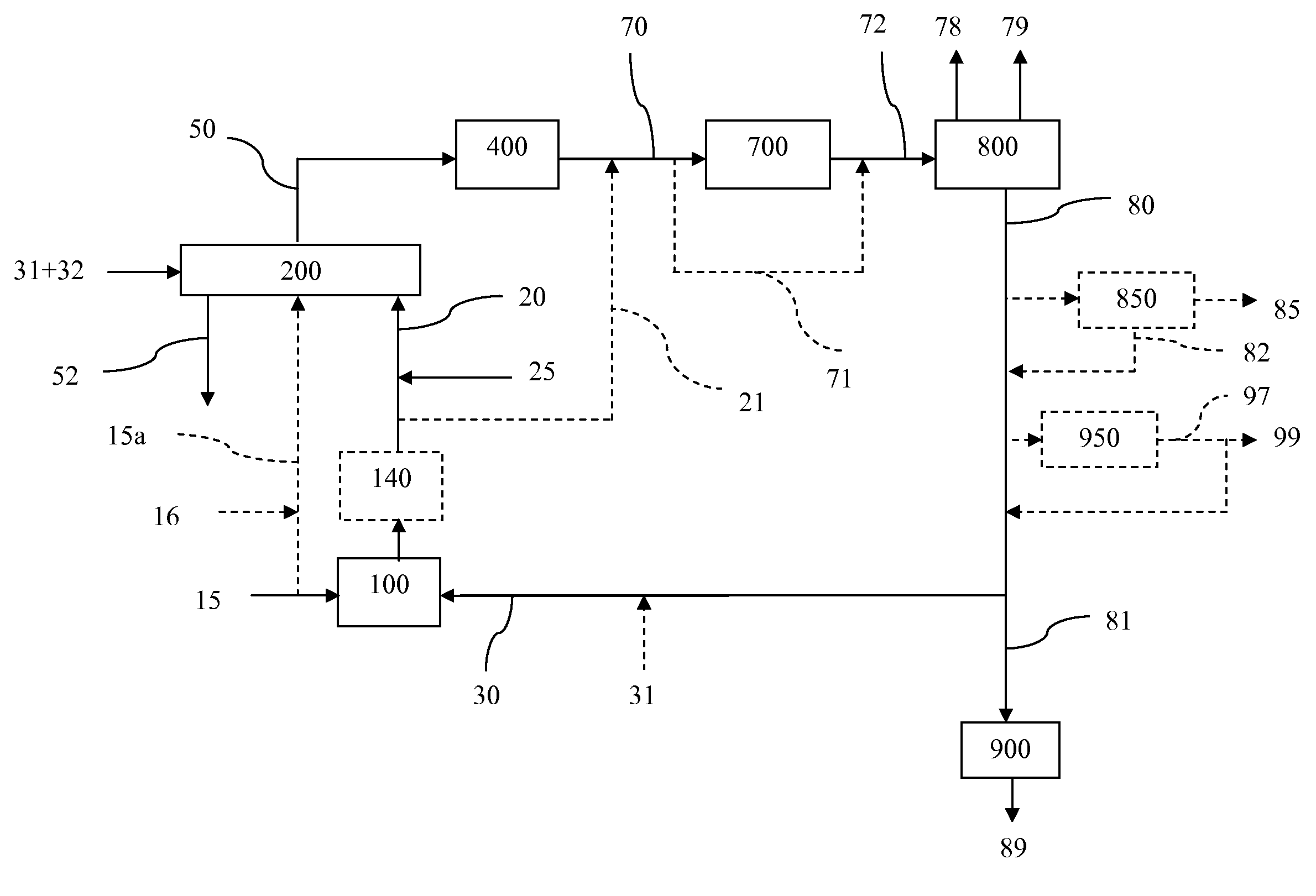

Processes for hydromethanation of a carbonaceous feedstock

ActiveUS8728183B2Increase the amount of carbonIncrease volumeHydrocarbon by isomerisationHydrogen separationThermodynamicsPtru catalyst

The present invention relates to processes for preparing gaseous products, and in particular methane, via the hydromethanation of a carbonaceous feedstock in the presence of steam, syngas, a hydromethanation catalyst and an oxygen-rich gas stream.

Owner:SURE CHAMPION INVESTMENT LTD

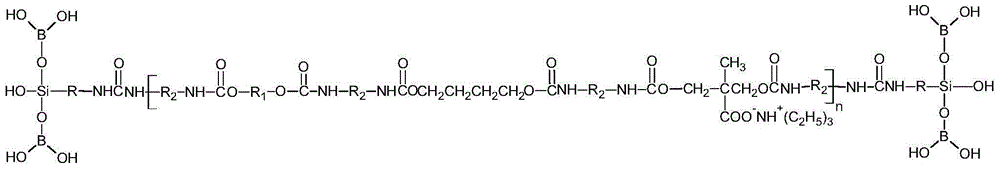

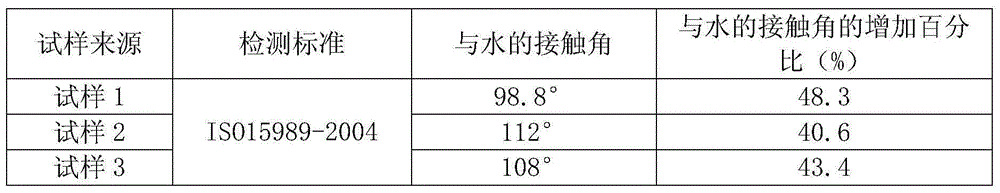

Waterborne polyurethane containing silicon and boron and preparation method thereof

The invention primarily aims to provide waterborne polyurethane containing silicon and boron further aims to provide a preparation method thereof. The preparation method comprises the following steps: 1 weighing macromolecule dibasic alcohol for being mixed with TDI, raising the temperature to be within 70-90 DEG C under the protection of N2, conducting the reaction for 1-3 hours, firstly adding in DMPA for reacting for 1-2 hours, then adding in BDO for reacting for 1-3 hours, lowering the temperature to be within 60-70 DEG C, subsequently, dropwise adding siloxane with the end capped by amino for reacting for 0.5-1.5 hours, lowering the temperature to be within 30-50 DEG C, and obtaining polyurethane with the end capped by the siloxane; 2 conditioning the polyurethane with the end capped by the siloxane at the rotation speed of 1500-2000 rpm, firstly adding in TEA for conducting the emulsification and neutralization for 20-30 minutes, then adding in boric acid for conducting the emulsification continuously for 10-20 minutes, conducting the reduced pressure distillation, and obtaining the waterborne polyurethane which contains the silicon and the boron and is 25-35% in solid content. The waterborne polyurethane obtained through the preparation method has good dewatering, inflaming retarding and smoke suppressing performance, and in the practical application, the mechanical properties of materials can be effectively guaranteed.

Owner:安徽省金越亨通交通装备有限公司

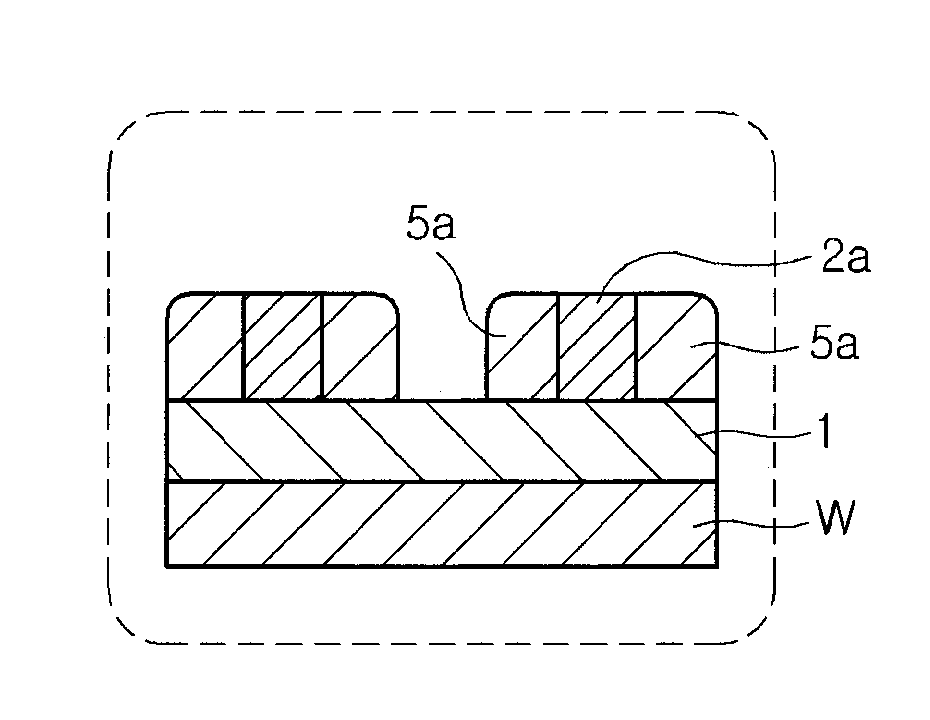

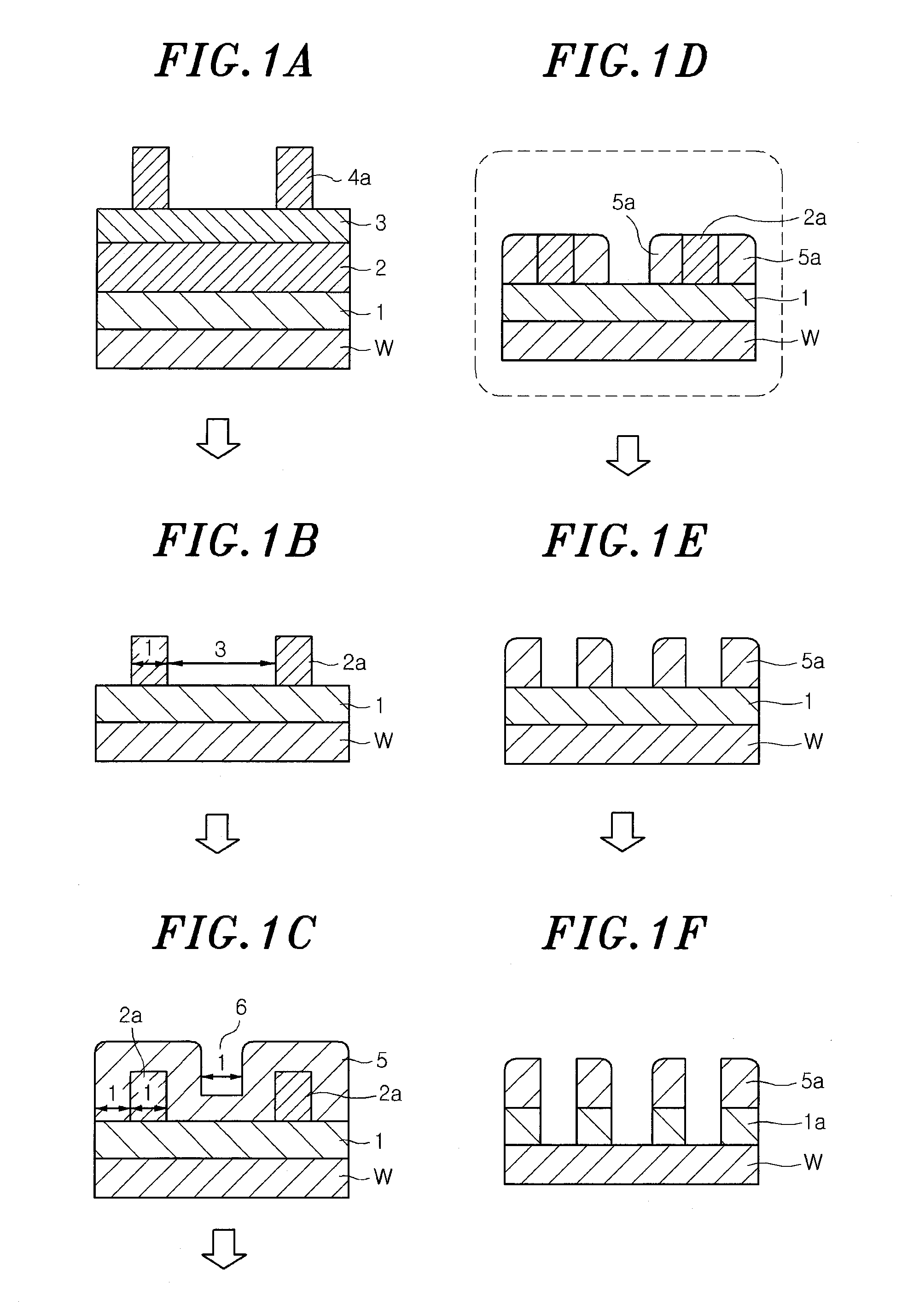

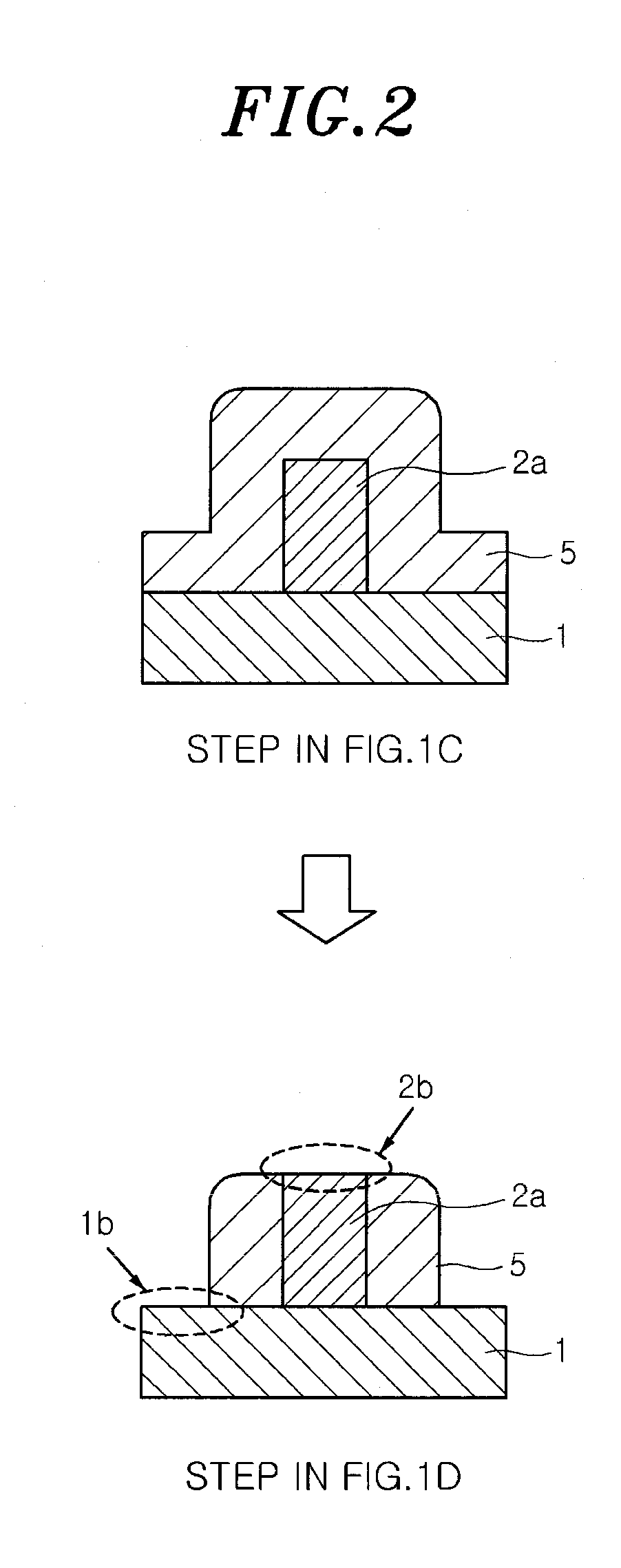

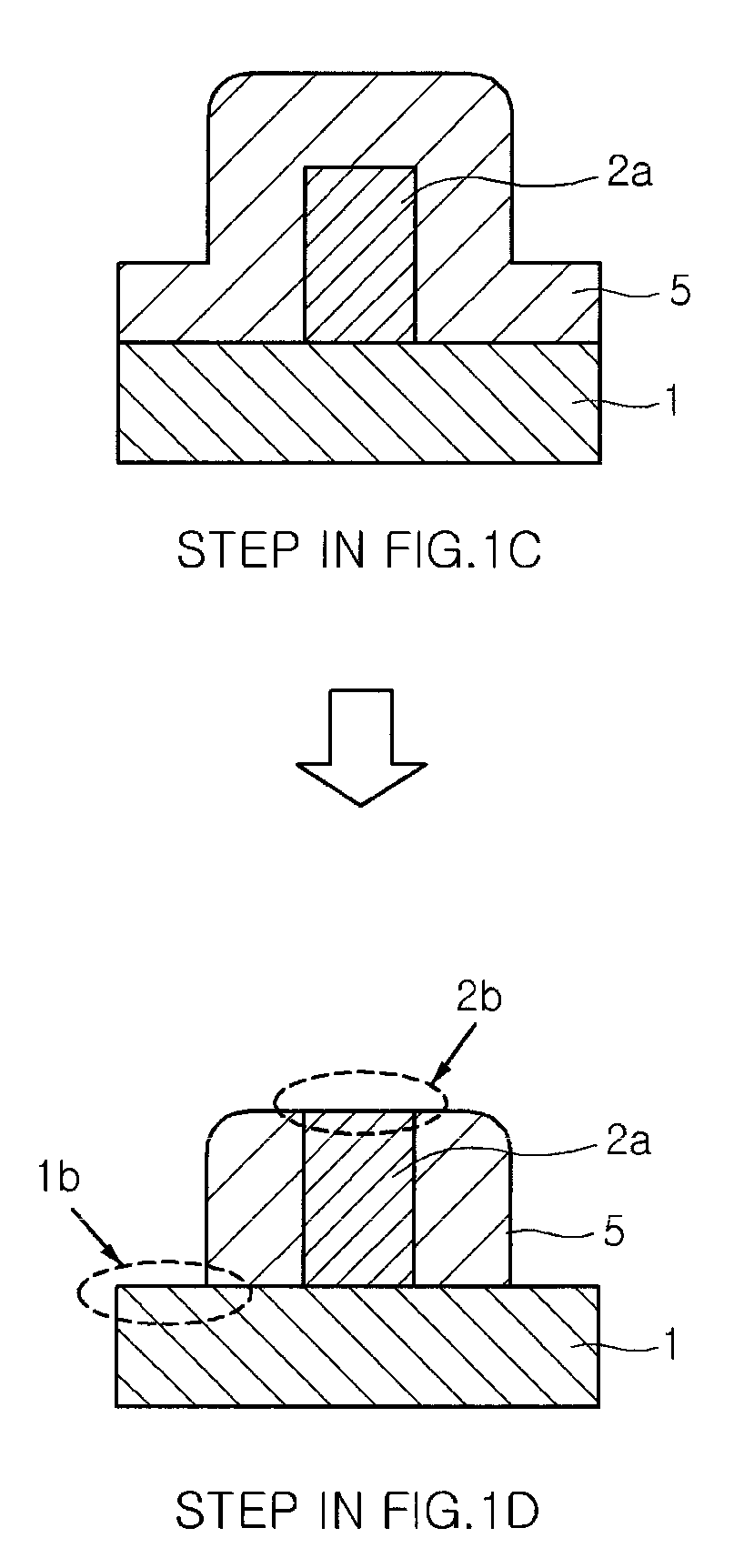

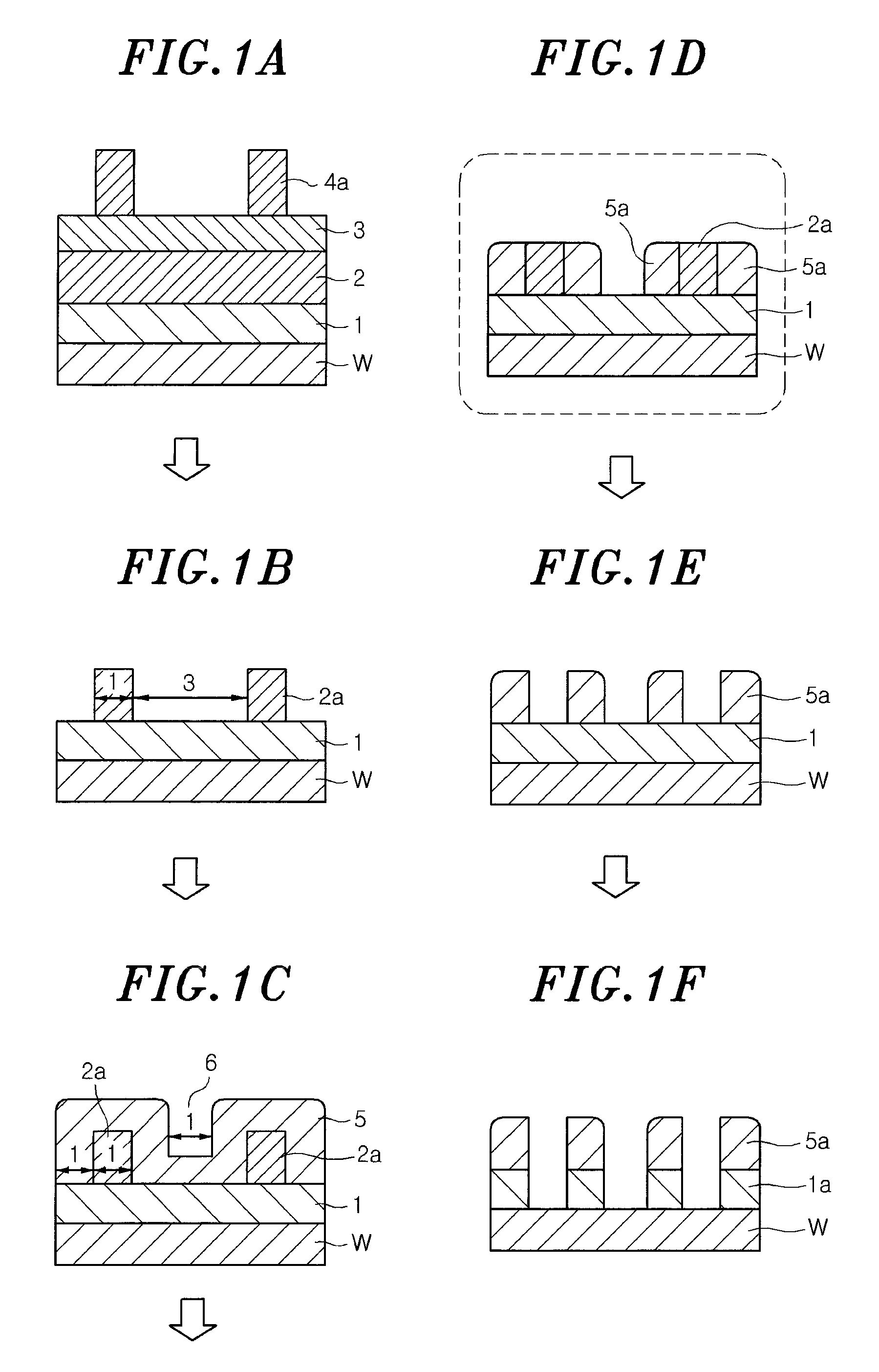

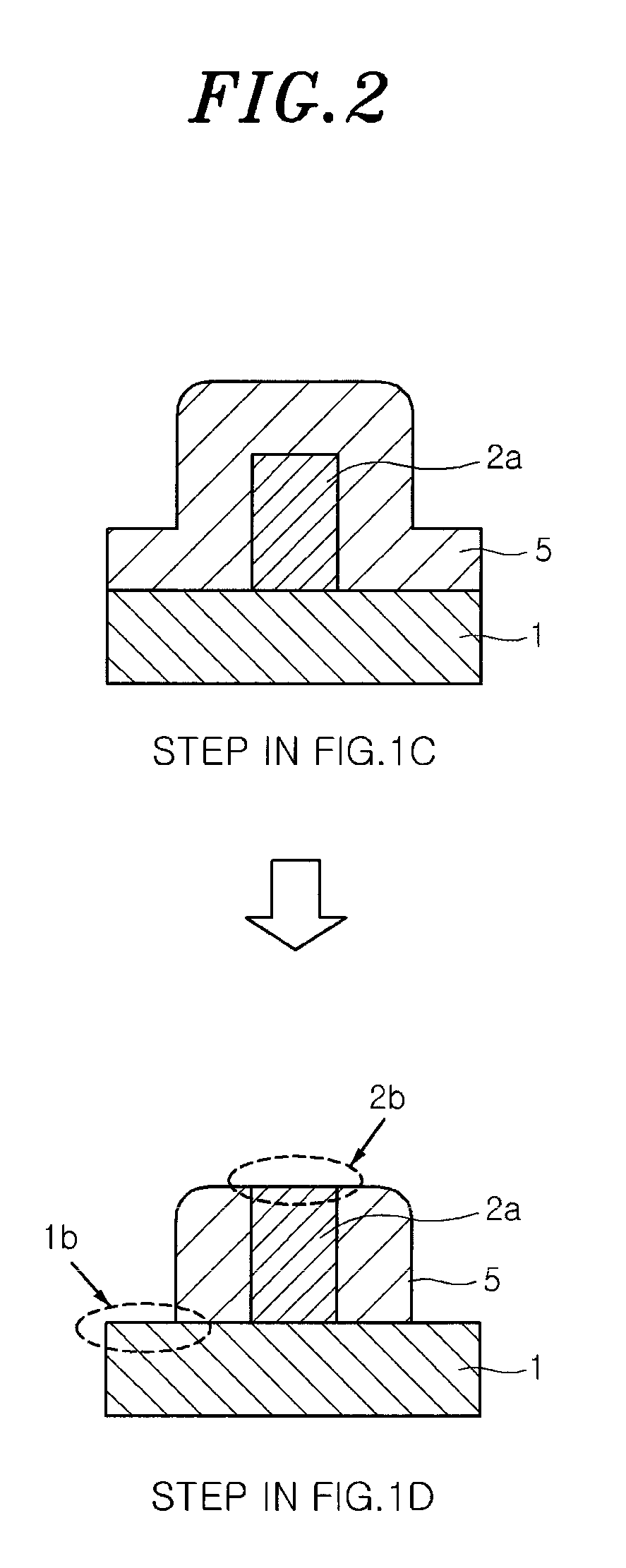

Etching method and apparatus

ActiveUS20140302684A1Increase the amount of carbonIncrease etch rateElectric discharge tubesSemiconductor/solid-state device manufacturingSilicon oxideMaterials science

An etching method and apparatus for etching a silicon oxide film selectively with respect to a silicon nitride film formed on a substrate are provided. A processing gas containing a plasma excitation gas and a CHF-based gas is introduced into a processing chamber such that a flow rate ratio of the CHF-based gas to the plasma excitation gas is 1 / 15 or higher. By generating a plasma in the processing chamber, the silicon oxide film is etched selectively with respect to the silicon nitride film formed on the substrate in the processing chamber.

Owner:TOKYO ELECTRON LTD

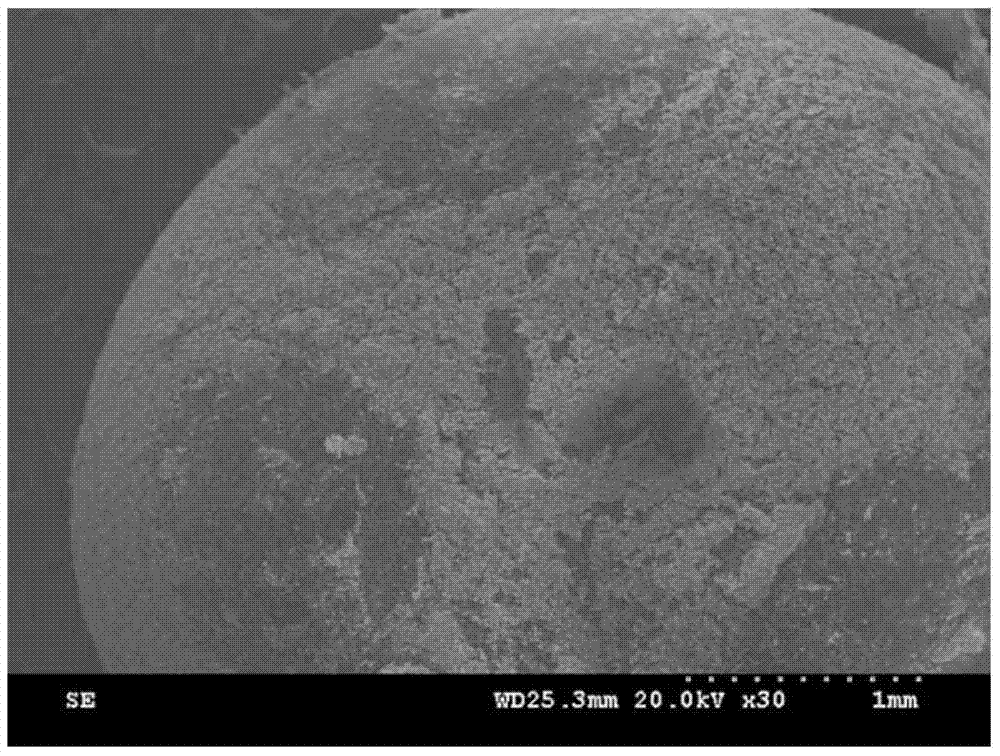

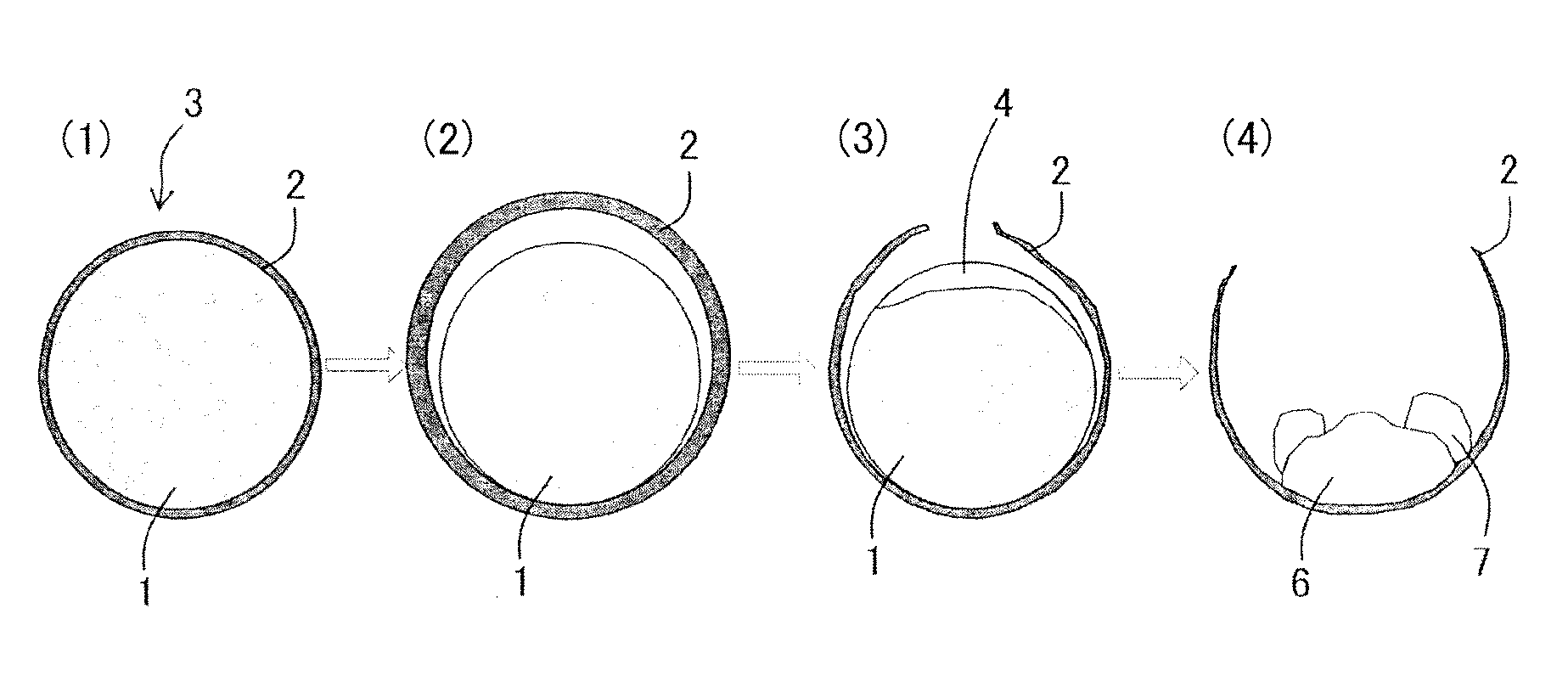

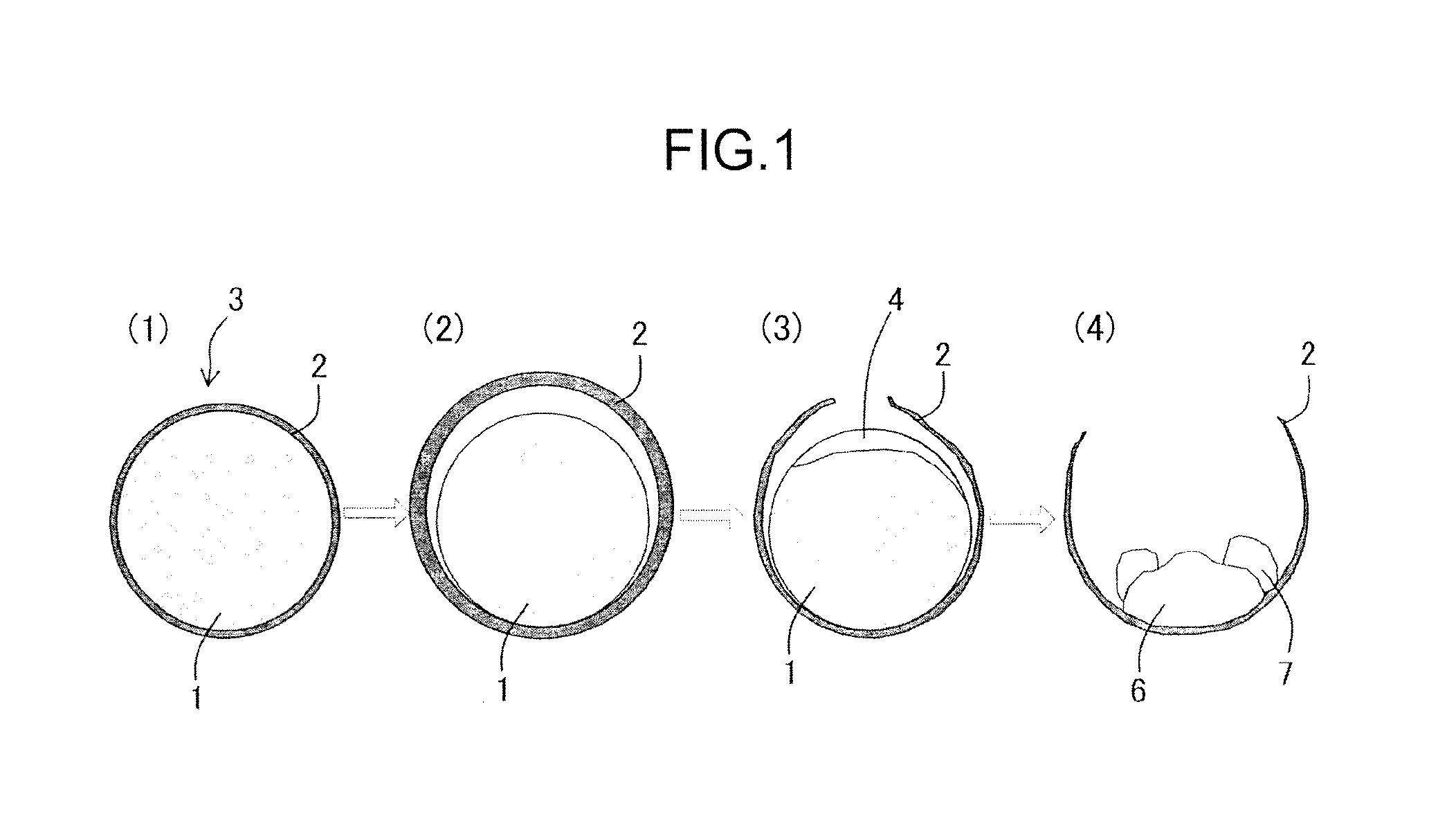

Method for manufacturing iron nuggets

InactiveUS20160237514A1Quality improvementIncrease volumeSteel manufacturing process aspectsGas emission reductionHearthHeating furnace

Provided is a method for manufacturing iron nuggets by which reduced iron obtained by heating and reducing agglomerates, or iron nuggets obtained by melting and aggregating the reduced iron can be prevented from reoxidation inside a movable hearth heating furnace and quality of the reduced iron can be improved. The method involves charging and heating agglomerates including iron oxide and a carbonaceous reducing agent on a hearth of a movable hearth heating furnace, reducing and melting the iron oxide in the agglomerates, and then discharging obtained iron nuggets to the outside of the furnace and recovering the iron nuggets. The agglomerates have a coating layer, including a fluid carbonaceous material, on the surface.

Owner:KOBE STEEL LTD

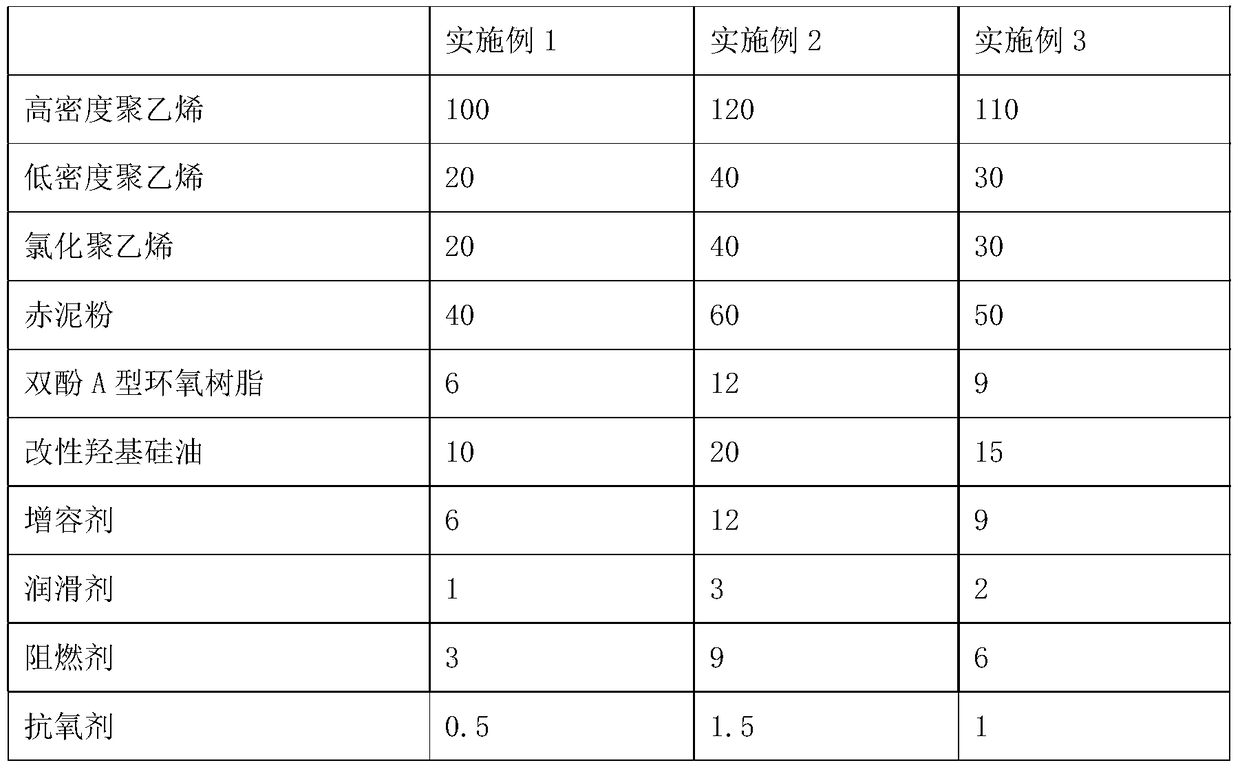

Preparation method of high toughness PE hollow wall twined pipe based on red mud modification

InactiveCN109021358AGood compatibilityIncrease the amount of carbonTubular articlesRed mudVolumetric Mass Density

The invention relates to a preparation process of a high toughness PE hollow wall twined pipe based on red mud modification. The process utilizes nano-zinc oxide and graphene for modification to improve the mechanical properties, toughness and rigidity of the pipe; nano-zinc oxide and graphene cooperate to form a continuous conductive path between systems, thus greatly improving the pipe conductivity; red mud is utilized for blending modification of a PE composite material, while the rigidity is improved, the PE pipe also has strong toughness, waste is turned into wealth, and the cost is greatly saved. Hydroxyl silicone oil can migrate on the PE surface and form a flame retardant layer to achieve flame retardant effect. Moreover, addition reaction can be carried out on the hydroxyl in themodified hydroxyl silicone oil and the epoxy group in a bisphenol A epoxy resin structure to enhance the crosslinking density and mechanical strength of the pipe. At the same time, hydroxyl silicone oil has low surface energy and endows the PE pipe with excellent waterproof performance. The preparation method is simple and scientific, the cost is low, the preparation process is environment-friendly, and has no pollution to the environment.

Owner:徐州辛辛那提新型材料有限公司

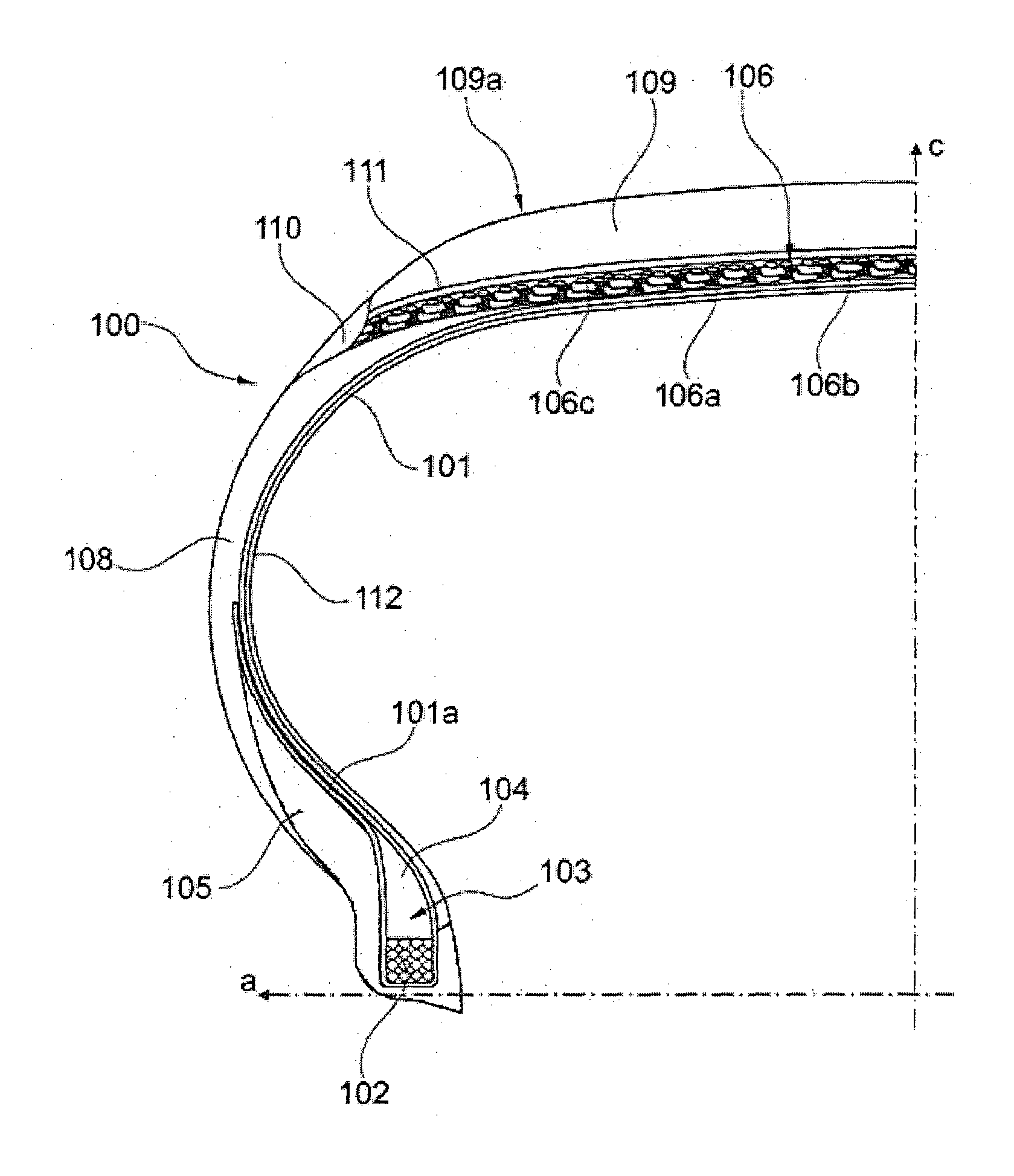

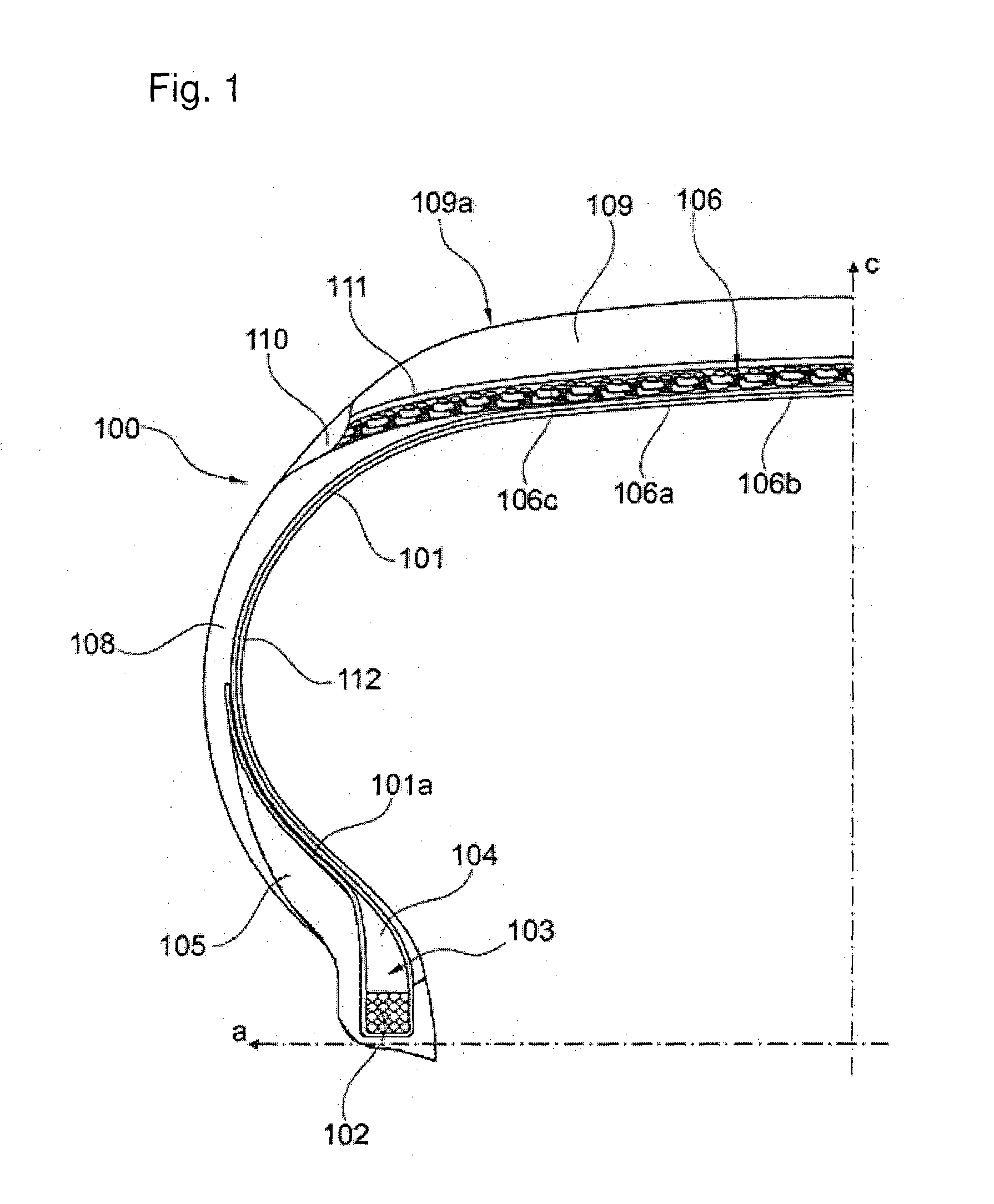

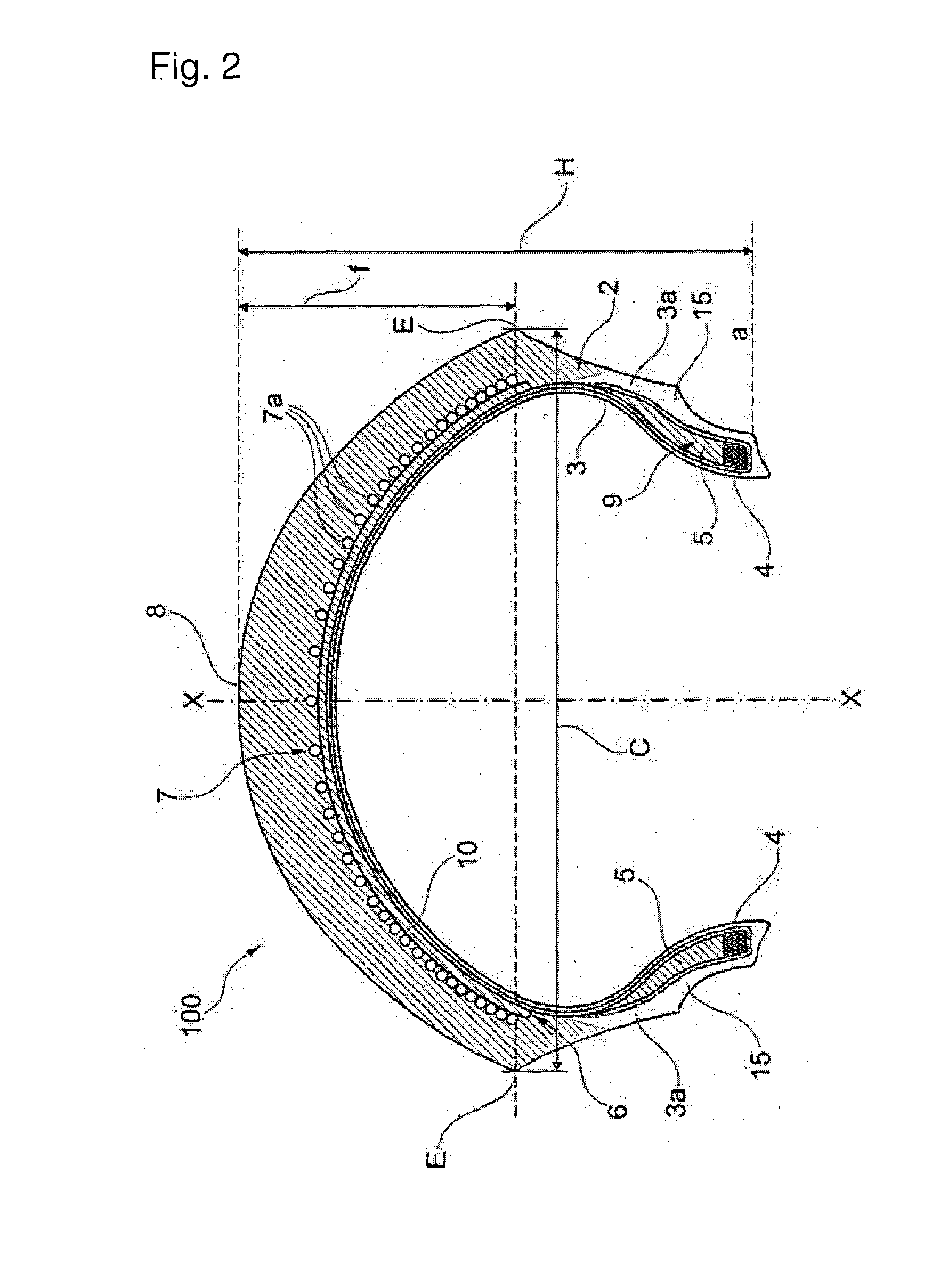

Tire for vehicle wheels

InactiveUS20150266344A1Decrease performance of tireImprove deformationSpecial tyresPneumatic tyre reinforcementsFiberElastomer

A tire for vehicle wheels, includes a carcass structure including at least one carcass layer having opposed side edges associated with relative annular reinforcing structures, a tread band applied in a radially outer position with respect to the carcass structure, and a pair of sidewalls laterally applied onto opposite sides with respect to the carcass structure; wherein the annular reinforcing structures include a crosslinked elastomeric material obtained by the crosslinking of a crosslinkable elastomeric composition including inorganic fibres of magnesium and / or aluminium silicates having nanometric dimensions, wherein the crosslinked elastomeric material has an elastic dynamic modulus E′, at 70° C. and a frequency of 10 Hz, higher than about 55 MPa.

Owner:PIRELLI TYRE SPA

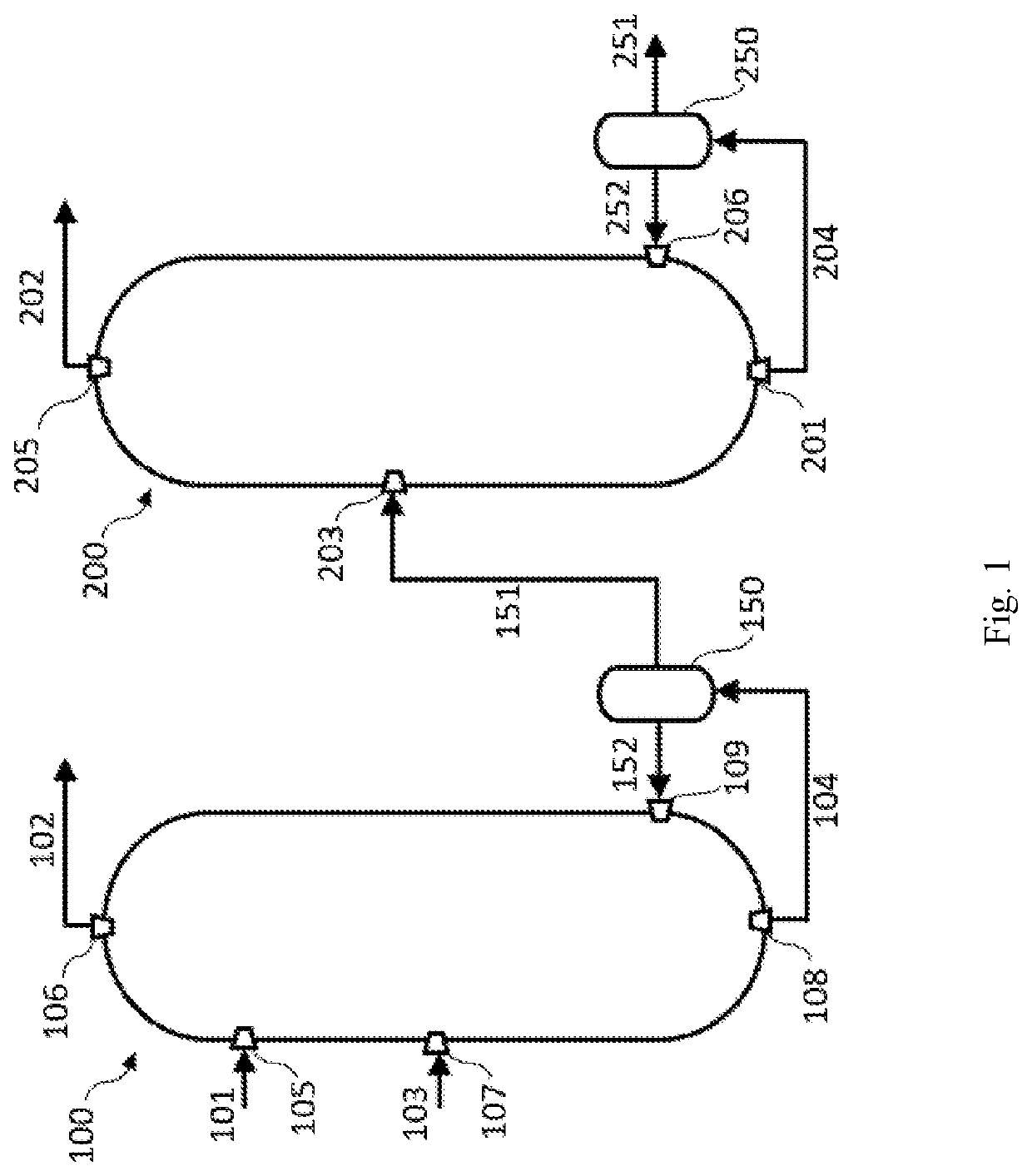

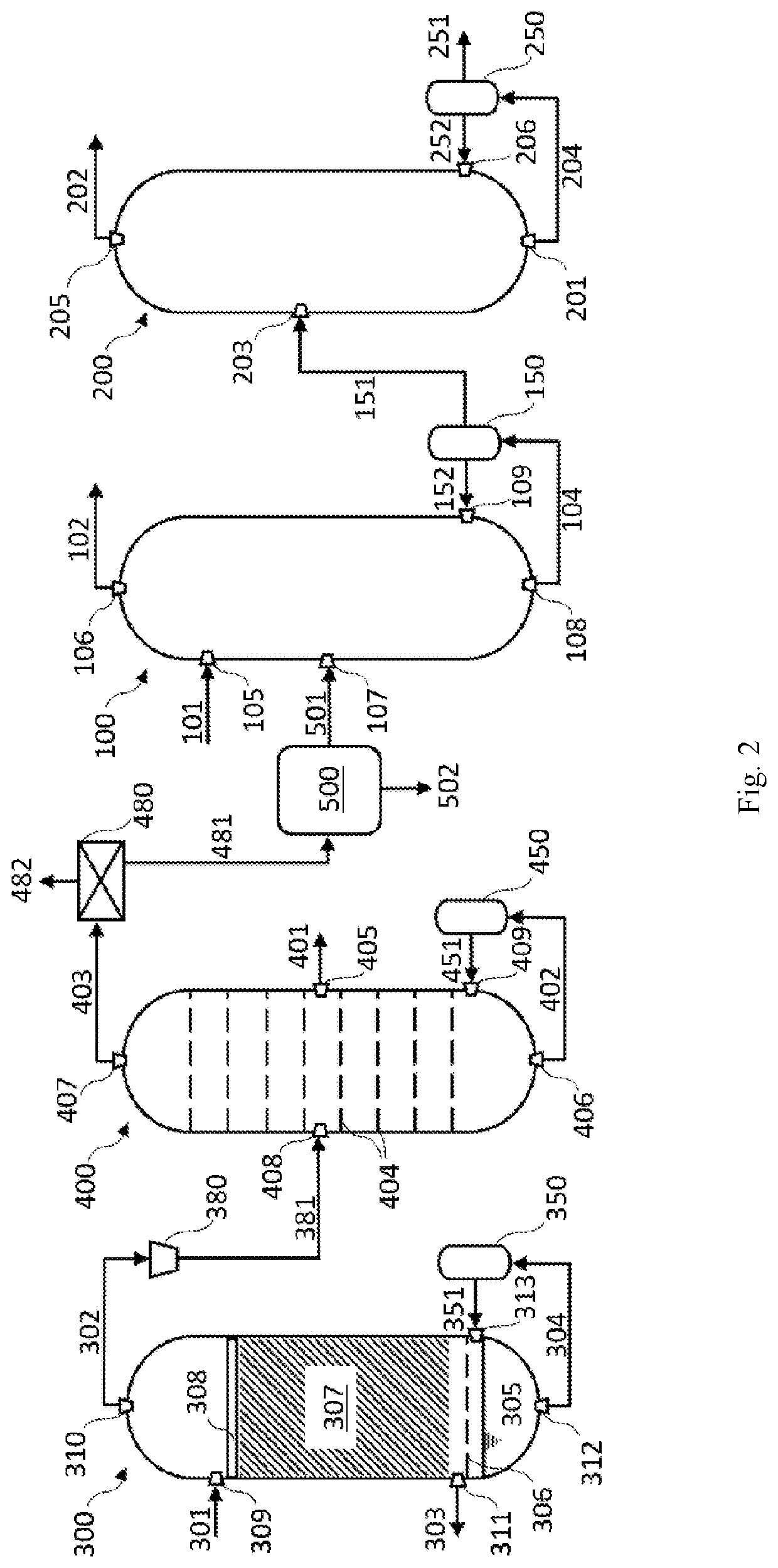

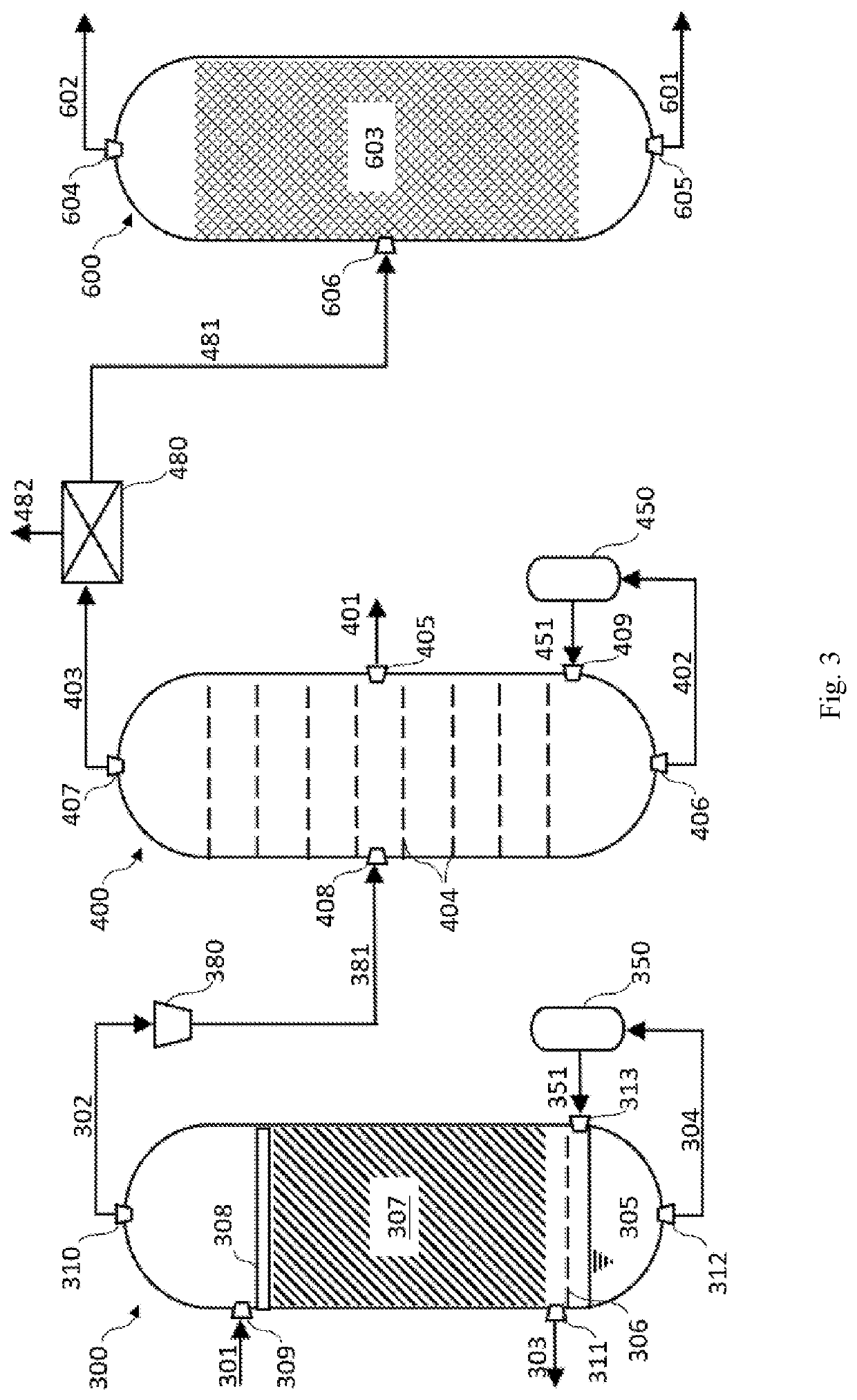

Process for recovering close boiling products

ActiveUS20200255362A1Increase relative volatilityHigh affinityPhysical/chemical process catalystsOrganic compound preparationMicroorganismExtractive distillation

The disclosure is directed to a method for recovering products from a fermentation broth. The disclosure relates to the use of extractive distillation and / or dehydration to recover products which have close boiling points, such as ethanol and isopropanol, from a fermentation broth. In an embodiment, the recovery of product is completed in a manner that minimizes stress on the microbial biomass, such that it remains viable, at least in part, and may be recycled and reused in the fermentation process, which may result in increased efficiency in the fermentation process. The extractive distillation vessel and / or dehydration reactor may be used downstream of a distillation vessel. To minimize stress on the microbial biomass the distillation vessel may be under vacuum. The extractive distillation vessel may be used alongside a separation vessel such that the separation vessel is capable of recycling extractive distillation agent.

Owner:LANZATECH INC

Preparation process of high-rigidity anti-static modified hollow wall winding pipes

ActiveCN109027444AGood dispersionImprove surface propertiesRigid pipesPipe protection against damage/wearZno nanoparticlesVinylsilane

The invention relates to a preparation process of a high-rigidity anti-static modified hollow wall winding pipes. Graphene is modified by using modified nano zinc oxide whisker, and the nano zinc oxide whisker, vinyl silane coupling agent and the graphene are combined into a whole; the vinyl silane coupling agent and the nano zinc oxide whisker are uniformly dispersed on the surface and between sheets of the graphene, so that the surface performance of the graphene is improved, the dispersion of the nano zinc oxide whisker and the graphene is effectively promoted, and the agglomeration is prevented; and the compatibility between systems is improved by acting with high-density polyethylene resin, and the mechanical performance, toughness and rigidity of pipes are improved. On the one hand,the carbon content of the pipes is increased, and the thermal stability of the pipes is improved; and on the other hand, the nano zinc oxide whisker and graphene cooperate to form a continuous conductive path between the systems,the conductivity of the pipes is greatly improved, and the anti-static flame retardant effect of the pipes is improved. The preparation process of the high-rigidity anti-static modified hollow wall winding pipes is simple and scientific, the cost is low, the preparation process is environmentally friendly and does not pollute the environment.

Owner:徐州辛辛那提新型材料有限公司

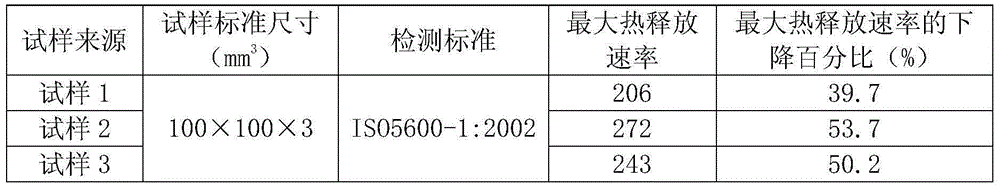

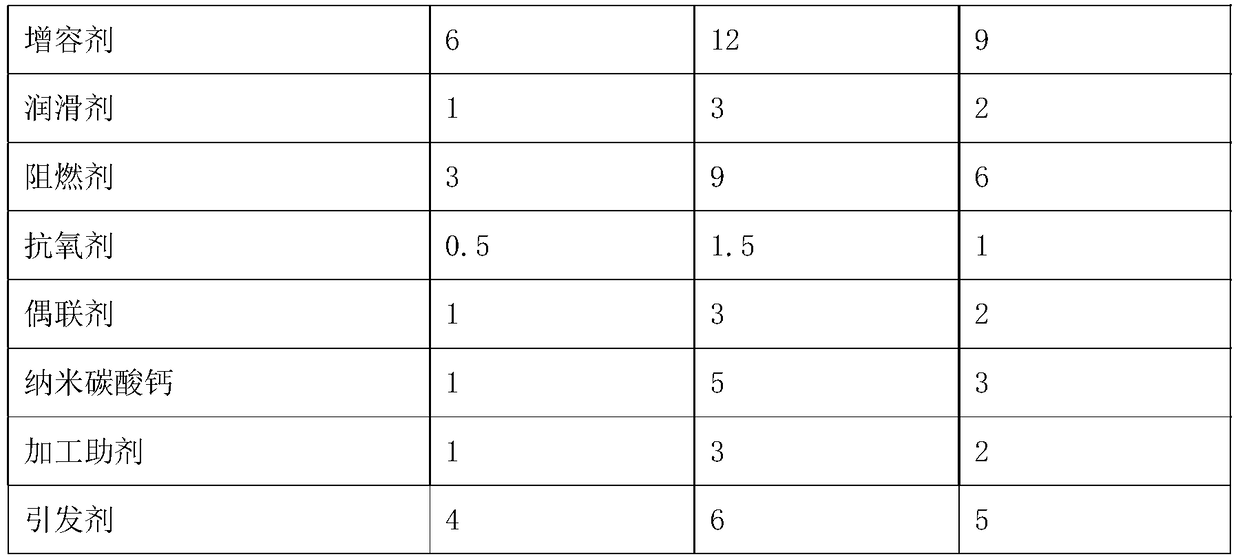

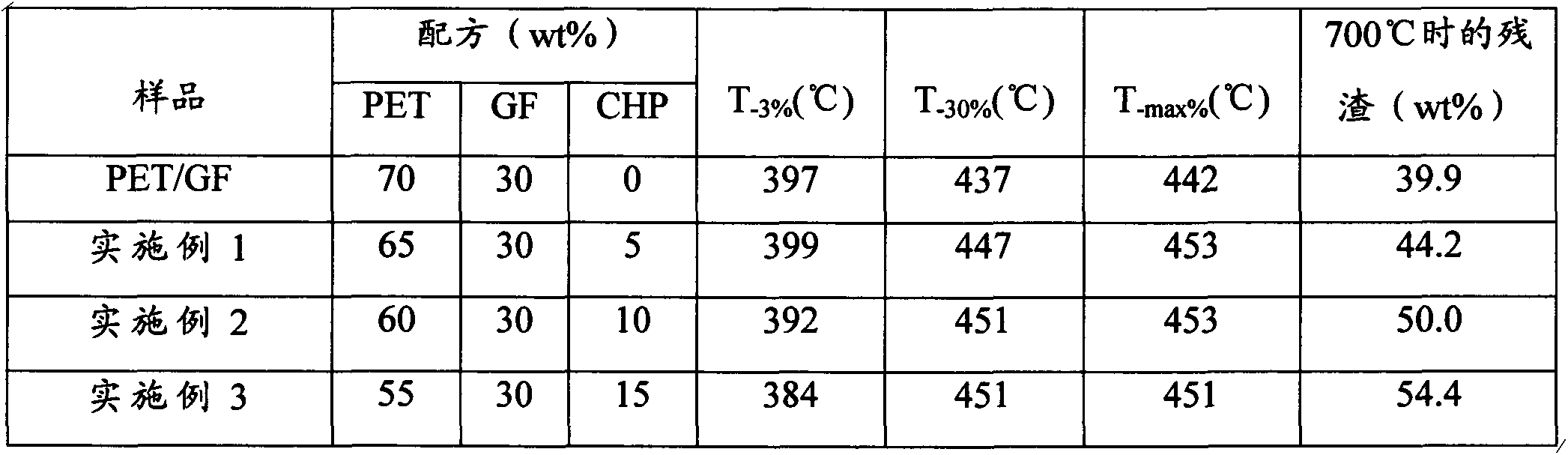

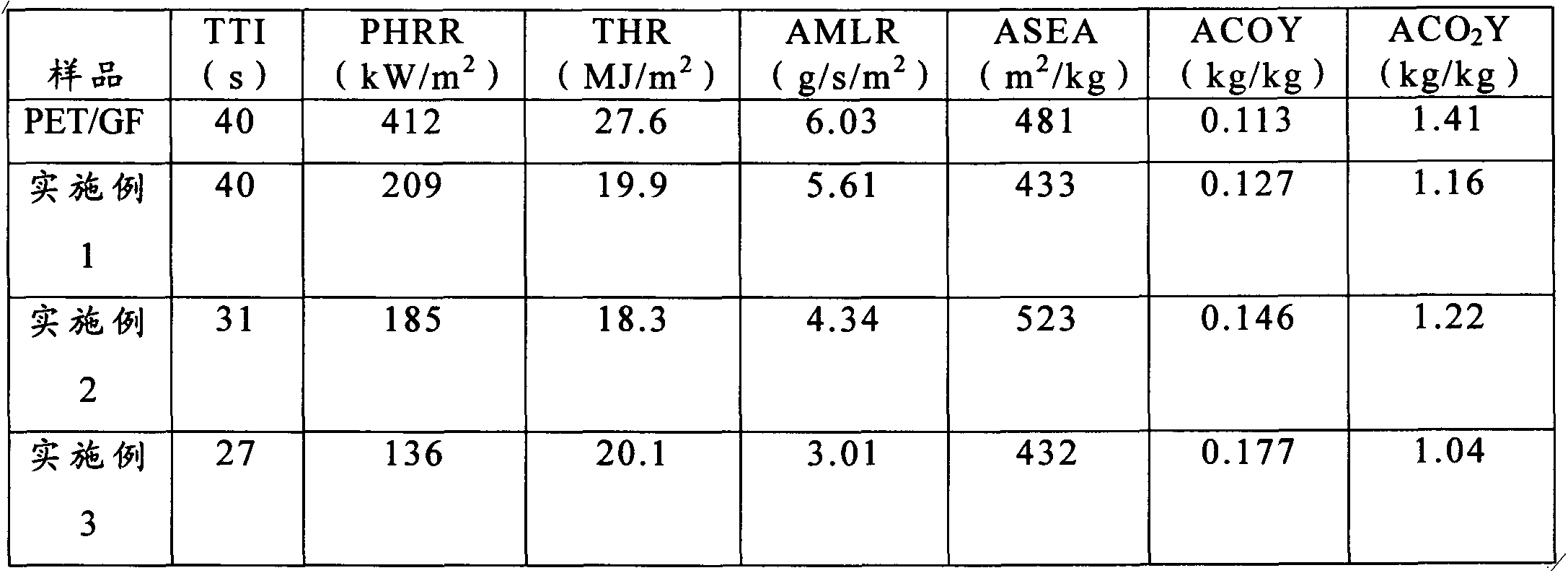

Composite material and manufacturing method thereof

The invention discloses a composite material and a manufacturing method of the composite material. Polyethylene glycol terephthalate of 55%-70%, ceroushypophosphate of 5%-15% and glass fibers of 30% are dried for 24 hours in a drying oven of 80 DEG C and then are mixed for 10 minutes in an internal mixer of 265 DEG C, wherein the rotation speed of the internal mixer in the mixing process is 100 rpm; the mixed sample is pressed to be in a sheet shape in a press vulcanizer of 270 DEG C, wherein the sheet is 3.2 mm thick. By means of the mode, the composite material and the manufacturing method are provided, and as the ceroushypophosphate is introduced into the raw materials of the composite material, not only is the thermal stability of the composite material kept, but also the carbon forming amount of the material in the high temperature area is increased. By the addition of the ceroushypophosphate, a large number of compact carbon residues are generated after burning to cover the surface of the glass fibers, thermal conductivity of the glass fibers is reduced, and the inflaming retarding capacity of the material is improved.

Owner:田聪 +1

Etching method and apparatus

ActiveUS9263283B2High selectivityIncrease etch rateElectric discharge tubesSemiconductor/solid-state device manufacturingOptoelectronicsSilicon oxide

An etching method and apparatus for etching a silicon oxide film selectively with respect to a silicon nitride film formed on a substrate are provided. A processing gas containing a plasma excitation gas and a CHF-based gas is introduced into a processing chamber such that a flow rate ratio of the CHF-based gas to the plasma excitation gas is 1 / 15 or higher. By generating a plasma in the processing chamber, the silicon oxide film is etched selectively with respect to the silicon nitride film formed on the substrate in the processing chamber.

Owner:TOKYO ELECTRON LTD

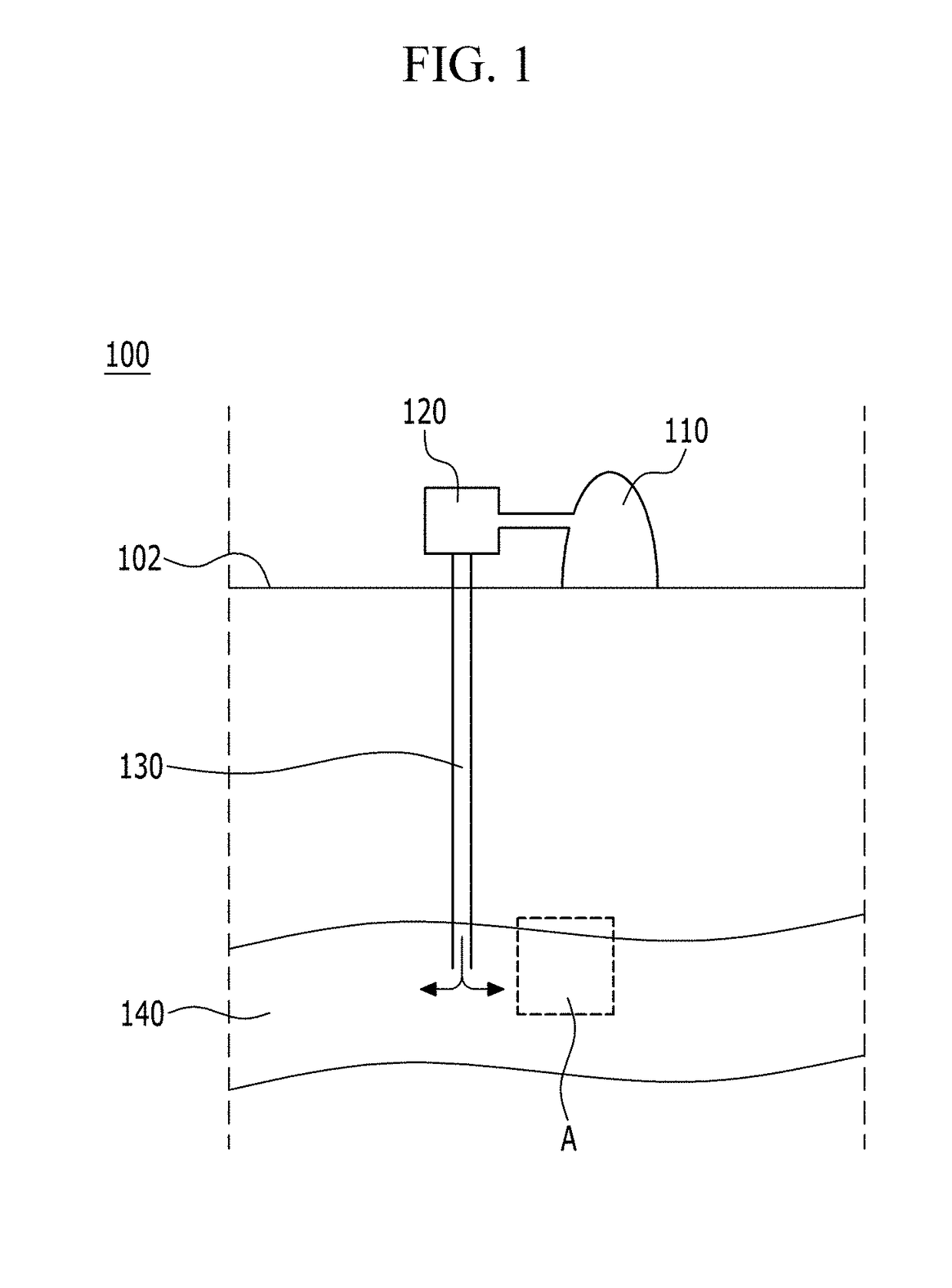

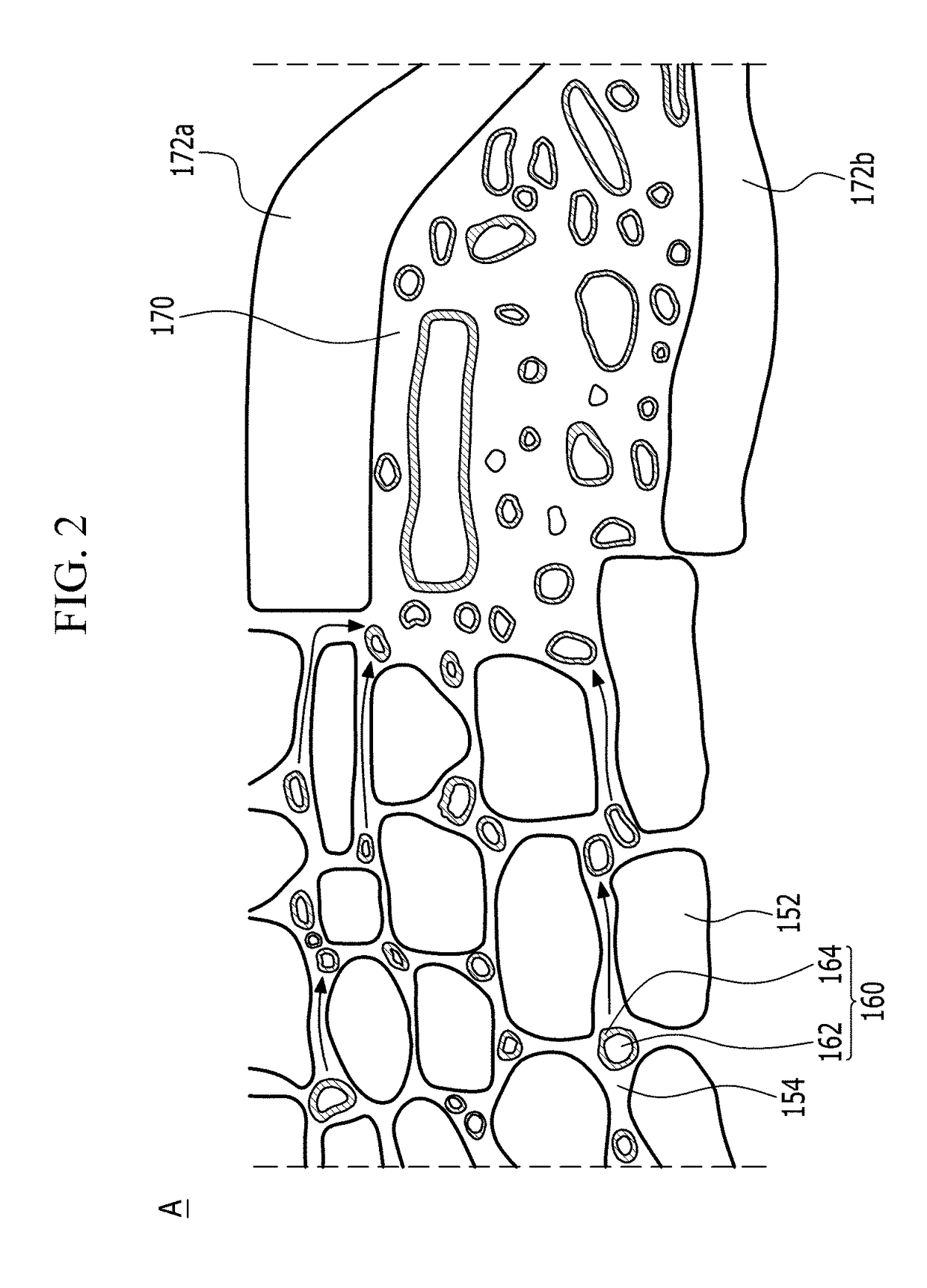

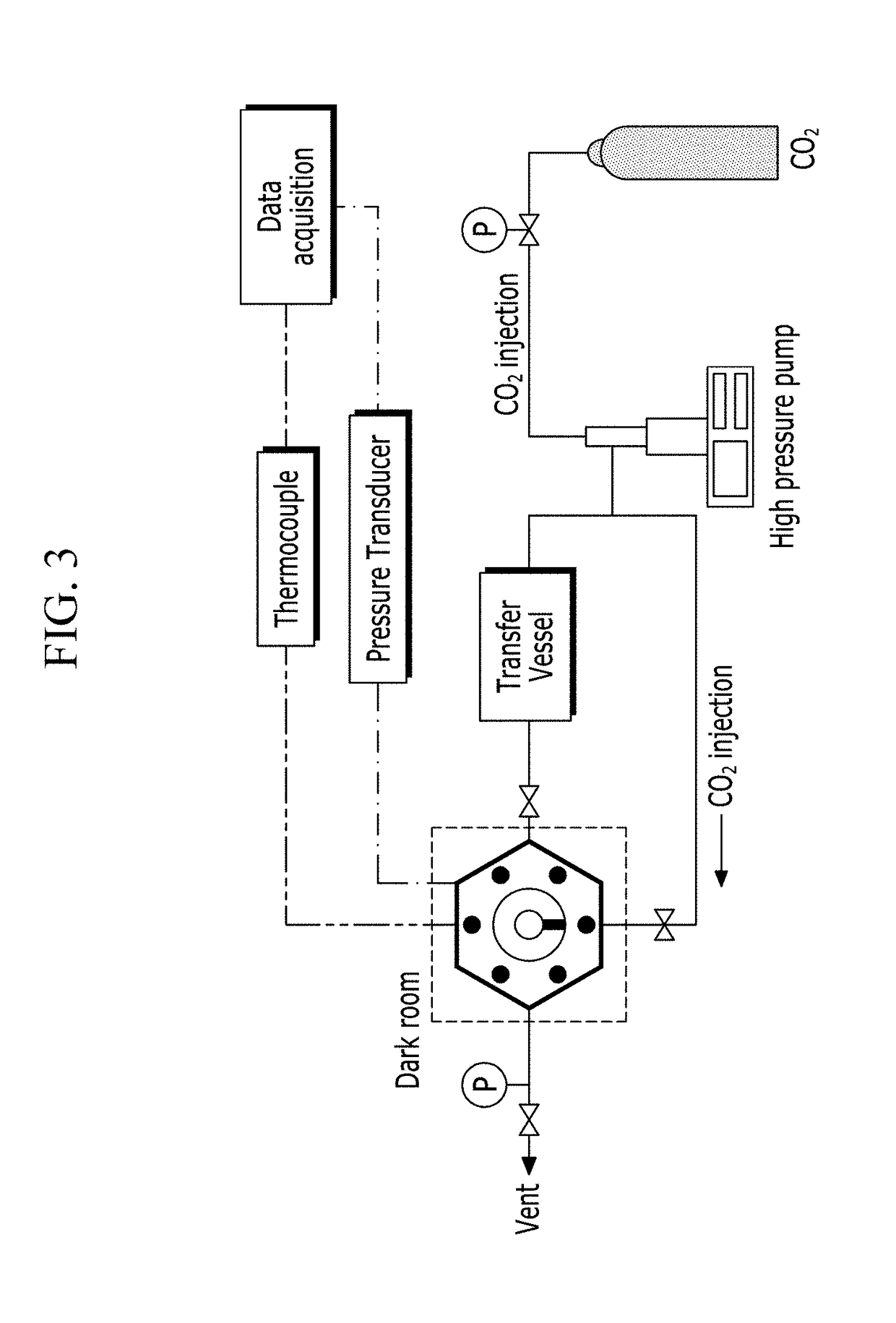

Geological storage system of carbon dioxide and process for geological storage of carbon dioxide

ActiveUS20190062059A1Reduce capillary pressureImprove scanning efficiencyGas handling applicationsPeptidesCarbon storageCarbon dioxide flux

A geological storage system of carbon dioxide according to an exemplary embodiment of the present invention includes: an injection pipe that extends to a carbon storage reservoir that includes a plurality of rock grains and brine, from the ground surface, and supplies an injection material that includes carbon dioxide (CO2) to the carbon storage reservoir; a plurality of pores that are disposed between the plurality of rock grains; and a storage structure that is connected with a part of the plurality of pores and where the carbon dioxide reaches through the plurality of pores and then stored.

Owner:KOREA ADVANCED INST OF SCI & TECH

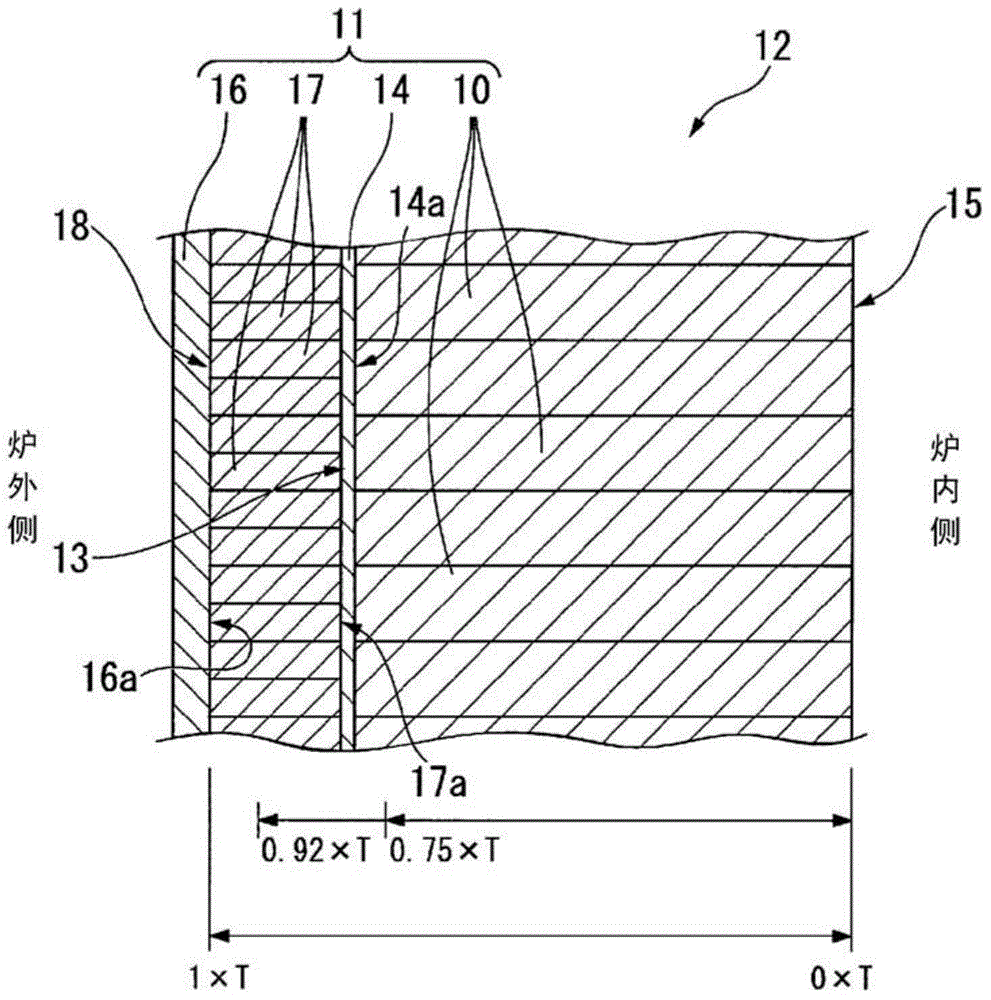

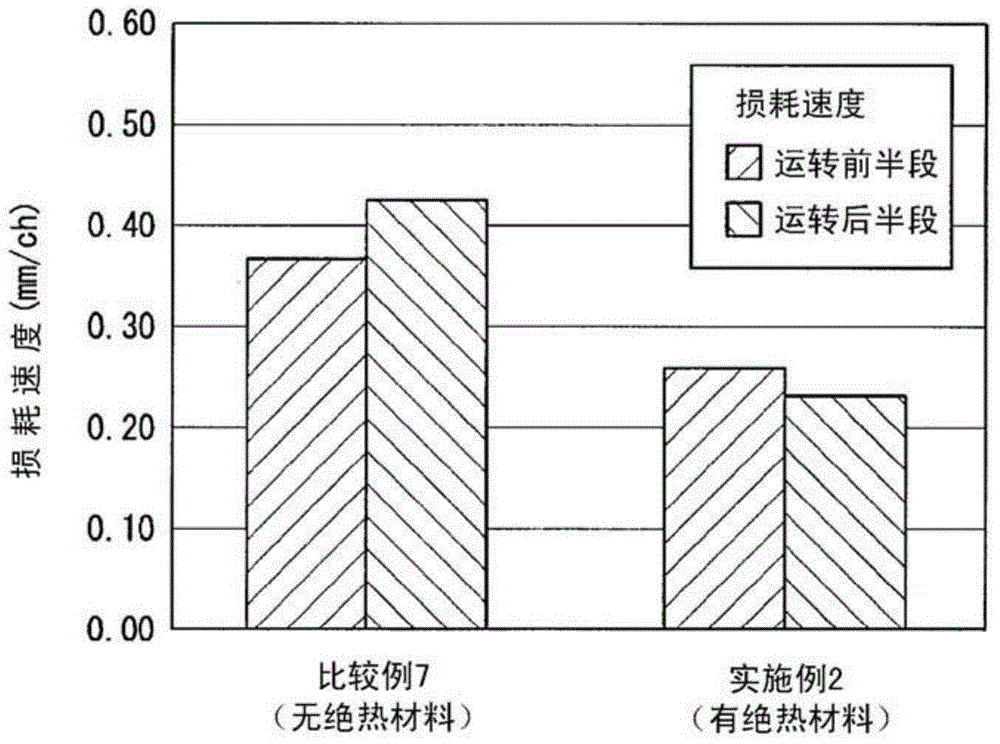

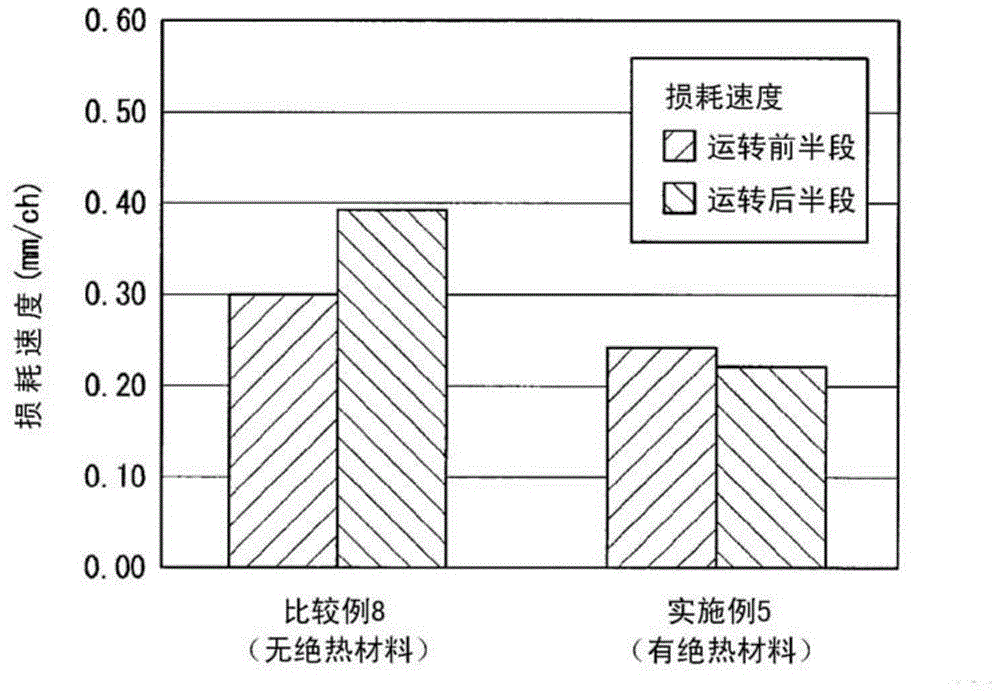

Furnace wall structure of molten metal container and furnace wall construction method of molten metal container

ActiveCN103620332BReduce temperature gradientMinimize thermal expansion differencesManufacturing convertersFurnace liningsRefractoryMolten metal

This furnace wall structure of a molten metal container contains a heat insulation material which exhibits a thermal conductivity of 0.01 to 0.15 W / (m·K) in a temperature range of 25 to 300°C and which has a melting point of 1000 to 1400°C and a thickness of 2 to 10mm in a position in the longitudinal section view, said position being within a thicknesswise region of 0.75×T to 0.92×T (mm) from the inside surface of a magnesia / carbon refractory toward a steel shell. T is the thickness of the furnace wall exclusive of the steel shell.

Owner:NIPPON STEEL CORP

High abrasion resisting centrifugal composite high-speed steel roll

InactiveCN110387506AIncrease the amount of participationImprove wear resistanceFurnace typesRollsHigh-speed steelHigh heat

The invention relates to metallurgy rolls, in particular to a high abrasion resisting centrifugal composite high-speed steel roll. The high abrasion resisting centrifugal composite high-speed steel roll comprises the chemical components of, by mass, an outer layer including, 1.6-1.9% of C, 0.30-0.80% of Si, 0.60-1.2% of Mn, smaller than or equal to 0.035% of P, smaller than or equal to 0.030% of S, 3.50-6.50% of Cr, 0.20-1.0% of Ni, 3.0-6.0% of Mo, 2.0-6.0% of V, 2.0-6.0% of W, 0.5-2.0% of Nb and the balance Fe and impurities, and a middle layer and a core portion including, 2.95-3.4% of C, 2.0-3.0% of Si, 0.4-1.0% of Mn, smaller than or equal to 0.05% of P, smaller than or equal to 0.035% of S, 0.01-0.04% of Re, 0.03-0.08% of Mg, smaller than or equal to 0.15% of Cr, smaller than or equalto 0.5% of Ni, smaller than or equal to 0.1% of Mo, smaller than or equal to 0.1% of Cu, and the balance Fe and impurities. The high abrasion resisting centrifugal composite high-speed steel roll hasthe characteristics of high hardness, high abrasion resistance, high heat intensity and high red hardness.

Owner:唐山市国宗元裕龙重工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com