Waterborne polyurethane containing silicon and boron and preparation method thereof

A technology of water-based polyurethane and boric acid, which is applied in the chemical field, can solve the problems of reducing the mechanical properties of water-based polyurethane materials, achieve the effects of reducing the generation of flammable emissions, ensuring mechanical properties, and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

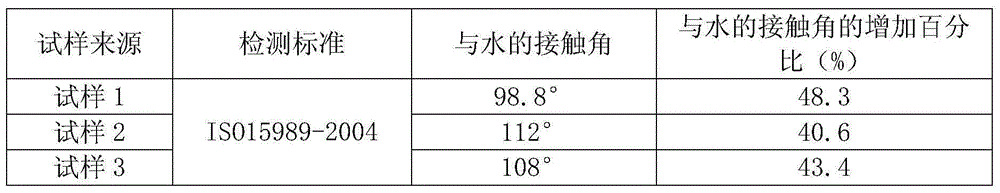

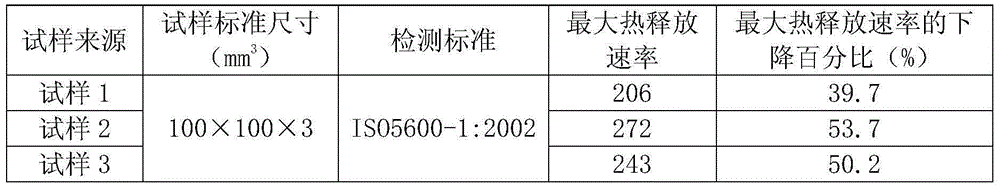

Examples

Embodiment 1

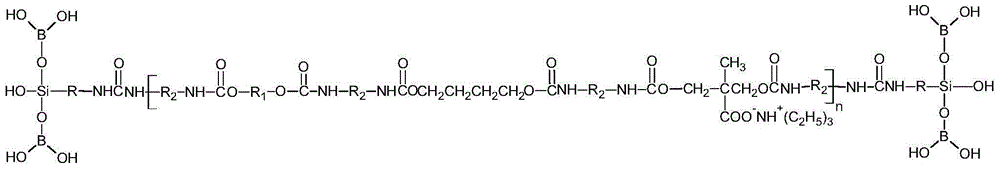

[0019] Example 1: Preparation of silicon-containing boron-containing waterborne polyurethane

[0020] 1) Weigh polyethylene adipate diol with an average molecular weight of 1000 and TDI in a molar ratio of 1:2.2 and add them to a dry four-neck round bottom flask. 2 Under protection, the temperature was raised to 80°C and reacted for 2h, then DMPA was added to react for 1h, then BDO was added for chain extension reaction for 2h, and the temperature was reduced to 60°C. Then 3-aminopropyltriethoxysilane was added dropwise to react for 0.5h, and the temperature was reduced to At 40°C, a siloxane-terminated polyurethane was obtained. Acetone was added dropwise to adjust the viscosity of the system during the reaction. The molar ratio of DMPA, BDO, 3-aminopropyltriethoxysilane and TDI was 0.23:0.27:0.08:1 , The added mass of acetone is 150% of the mass of polyethylene adipate glycol;

[0021] 2) Put the siloxane-terminated polyurethane synthesized in step 1 under the condition of 1500rp...

Embodiment 2

[0023] Example 2: Preparation of silicon-containing boron-containing waterborne polyurethane

[0024] 1) Weigh polytetrahydrofuran ether glycol with an average molecular weight of 2000 and TDI in a molar ratio of 1:2.6 and add them to a dry four-neck round bottom flask. 2 Under protection, the temperature was raised to 90℃, reacted for 1h, then DMPA was added to react for 1.5h, then BDO was added for chain extension reaction for 3h, the temperature was reduced to 70℃, and then N-(2-aminoethyl)-3-aminopropyl was added dropwise. The trimethoxysilane was reacted for 1.5h, and the temperature was lowered to 50°C to obtain a siloxane-terminated polyurethane. During the reaction, acetone was added to adjust the viscosity of the system. The DMPA, BDO, and N-(2-aminoethyl)-3-ammonia The molar ratios of propyltrimethoxysilane and TDI are 0.28:0.23:0.21:1 respectively, and the mass addition amount of acetone is 150% of the mass of the polytetrahydrofuran ether glycol;

[0025] 2) Put the sil...

Embodiment 3

[0027] Example 3: Preparation of silicon-containing boron-containing waterborne polyurethane

[0028] 1) Weigh the polyoxypropylene ether glycol with an average molecular weight of 1750 and TDI in a molar ratio of 1:3 and add them to a dry four-necked round bottom flask. 2 Under protection, the temperature was raised to 70°C and reacted for 3h, then DMPA was added to react for 2h, then BDO was added for chain extension reaction for 1h, and the temperature was lowered to 65°C, then diethylenetriaminopropyltrimethoxysilane was added dropwise to react for 0.5h, and the temperature was lowered. At 40°C, a siloxane-terminated polyurethane is obtained. During the reaction, acetone is added dropwise to adjust the viscosity of the system. The molar ratio of DMPA, diethylenetriaminopropyltrimethoxysilane and TDI is 0.34:0.25:0.15:1 , The mass addition amount of acetone is 100% of the mass of the polyoxypropylene ether glycol;

[0029] 2) Put the siloxane-terminated polyurethane synthesized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com