Preparation process of high-rigidity antistatic modified hollow wall winding pipe

A preparation process and anti-static technology, which is applied in the field of preparation process of high-stiffness anti-static modified hollow-wall winding pipe, can solve the problems of damaging the mechanical properties of the pipe, difficult migration of static charges, fire chemicals, etc., and achieves the environmental protection of the preparation process, Facilitates decentralized, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the embodiments.

[0026] The invention discloses a preparation process of a high-rigidity antistatic modified hollow-wall wound pipe, which comprises the following steps:

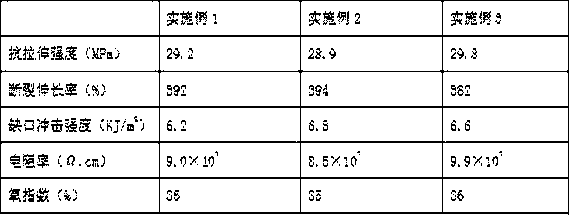

[0027] (1) In terms of weight fraction, weigh 100-120 parts of high-density polyethylene, 10-20 parts of linear low-density polyethylene, 10-20 parts of chlorinated polyethylene, and 8- 12 parts, 6-12 parts of compatibilizer, 1-3 parts of lubricant, 3-9 parts of flame retardant, 0.5-1.5 parts of antioxidant, 1-3 parts of coupling agent, 1-5 parts of nano calcium carbonate, 1-3 parts of processing aid, 4-6 parts of initiator;

[0028] (2) Mix the low-density polyethylene, chlorinated polyethylene, antioxidant, and 1 / 2 of the total amount of coupling agent in the high-speed mixer first, and then add the initiator to mix after plasticizing Mixture A is obtained evenly;

[0029] (3) Mix the high-density polyethylene, nano-zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com