Preparation method of nanometer bismuth hydroxide/polyethylene flame-retardant composite material

A technology of nano-bismuth hydroxide and flame-retardant composite materials, which is applied in the direction of plastic/resin/wax insulators, organic insulators, conductors, etc., can solve problems such as uneven growth, and achieve simple equipment, low cost, and increased carbon formation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

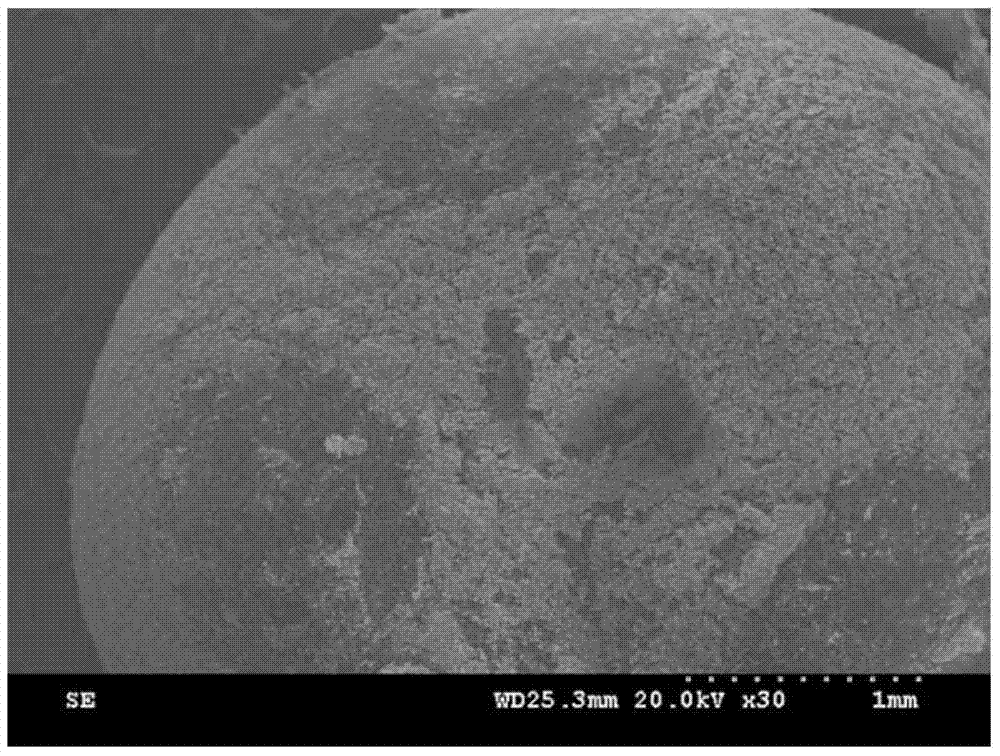

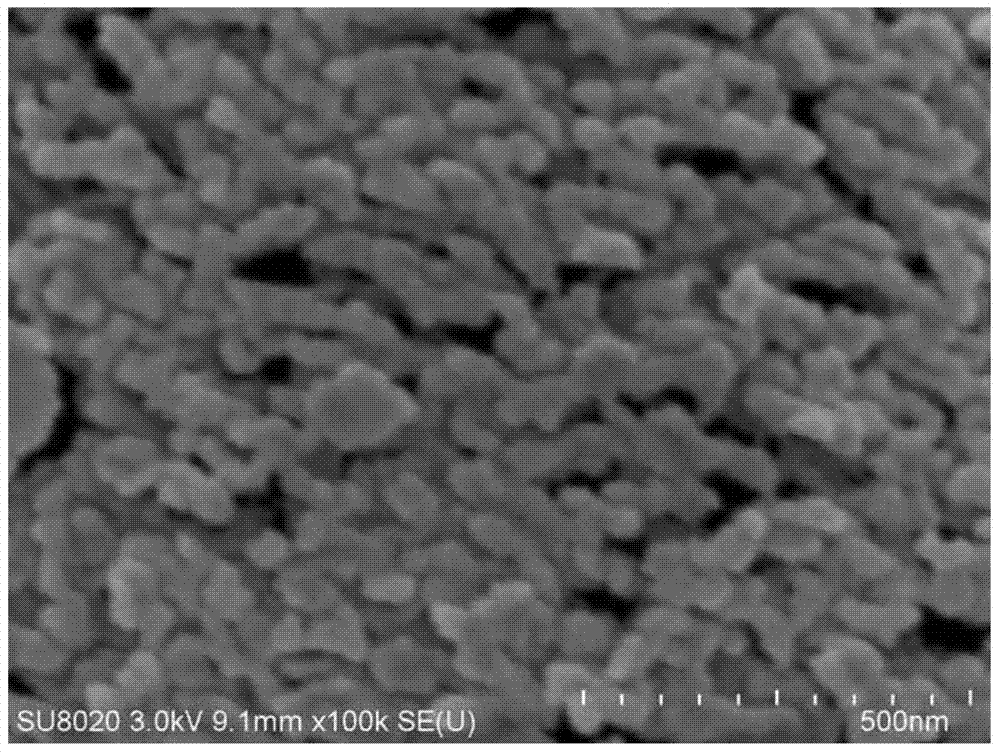

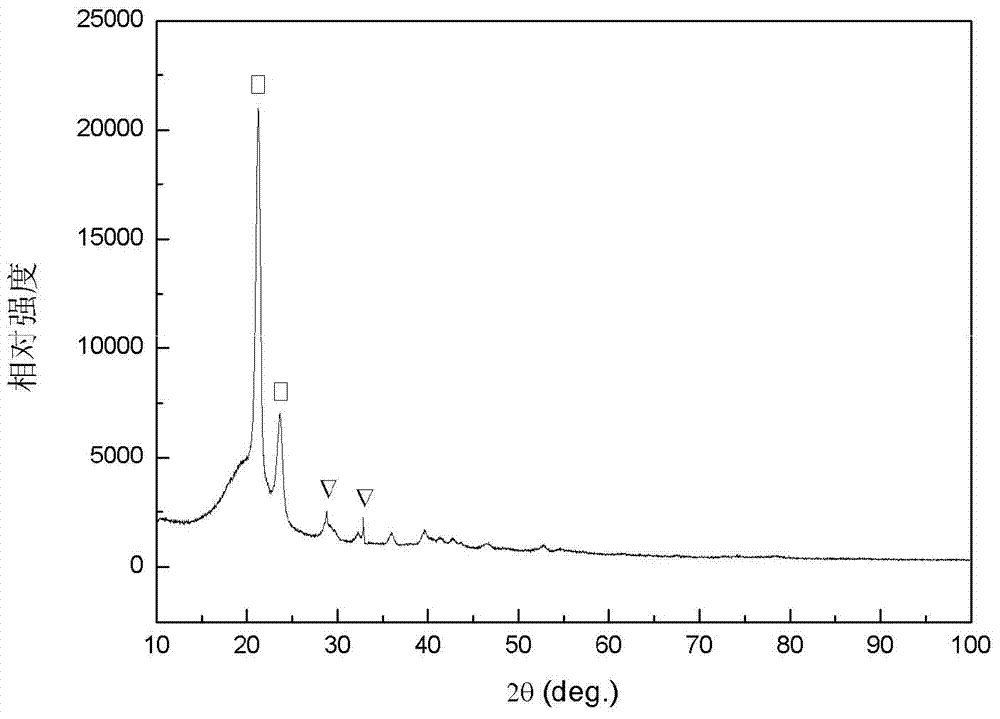

[0015] Specific embodiment one: In this embodiment, the preparation method of nano bismuth hydroxide / polyethylene flame retardant composite material is carried out according to the following steps:

[0016] 1. Dissolve bismuth hydroxide and polyethylene in alcohol and mix them to obtain a mixed solution. The mass ratio of polyethylene to bismuth hydroxide in the mixed solution is 3 to 40:1, and the concentration of bismuth hydroxide in the mixed solution is 1 to 40:1. 300g / L;

[0017] 2. Pour the mixed solution obtained in step 1 into a ball mill tank, the mass ratio of balls to materials is 15:1, and ball mill at a speed of 50-300r / min for 1-30 hours;

[0018] 3. Adjust the pH value of the mixed solution treated in step 2 to 7-14 with ammonia water, then pour it into the hydrothermal synthesis reaction kettle, and keep it warm at a filling ratio of 70-85% and a temperature of 100-140°C 1~24h;

[0019] 4. Pour out the powder from the hydrothermal synthesis reaction kettle, w...

specific Embodiment approach 2

[0021] , Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the mass ratio of polyethylene to bismuth hydroxide in the mixed solution described in step 1 is 90:10.74. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the mass ratio of polyethylene to bismuth hydroxide in the mixed solution described in step 1 is 85:16.12. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com