Composite material and manufacturing method thereof

A technology for composite materials and raw materials, applied in the field of composite materials and their preparation, can solve the problems of unenvironmental protection and poor fire resistance of flame retardant materials, and achieve the effects of reducing thermal conductivity, maintaining thermal stability, and improving flame retardant ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, PET / GF / CHP5: polyethylene terephthalate (PET) content is 65%; Cerium hypophosphite (CHP) content is 5%; Glass fiber (GF) content is 30%;

Embodiment 2

[0017] Embodiment 2, PET / GF / CHP10: polyethylene terephthalate (PET) content is 60%; Cerium hypophosphite (CHP) content is 10%; Glass fiber (GF) content is 30%;

Embodiment 3

[0018] Embodiment 3, PET / GF / CHP15: polyethylene terephthalate (PET) content is 55%; Cerium hypophosphite (CHP) content is 15%; Glass fiber (GF) content is 30%;

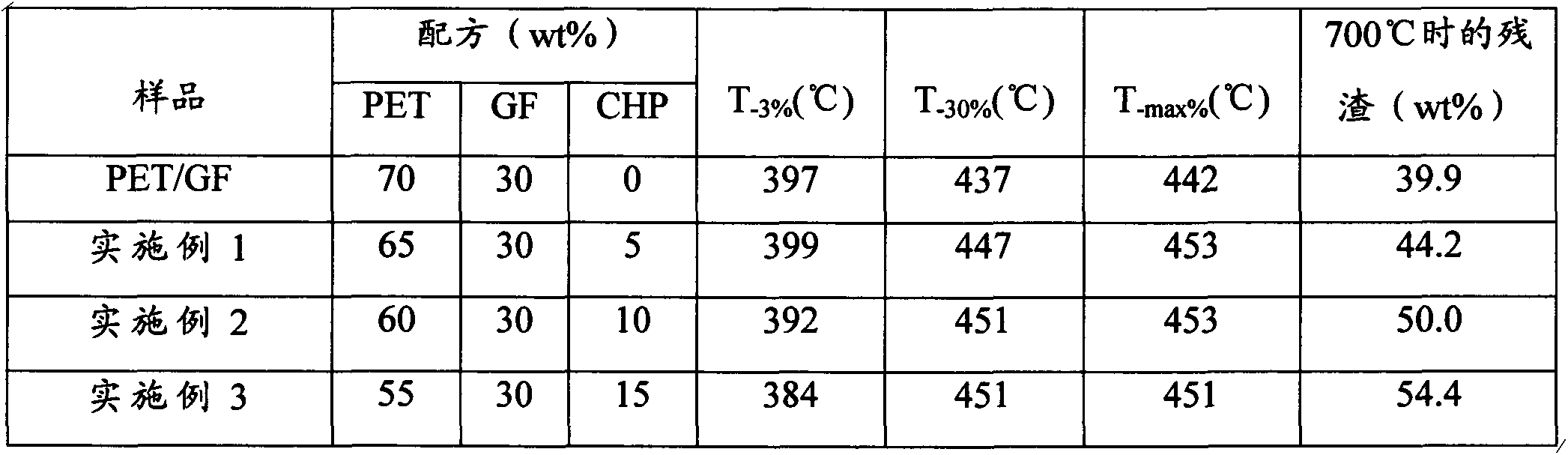

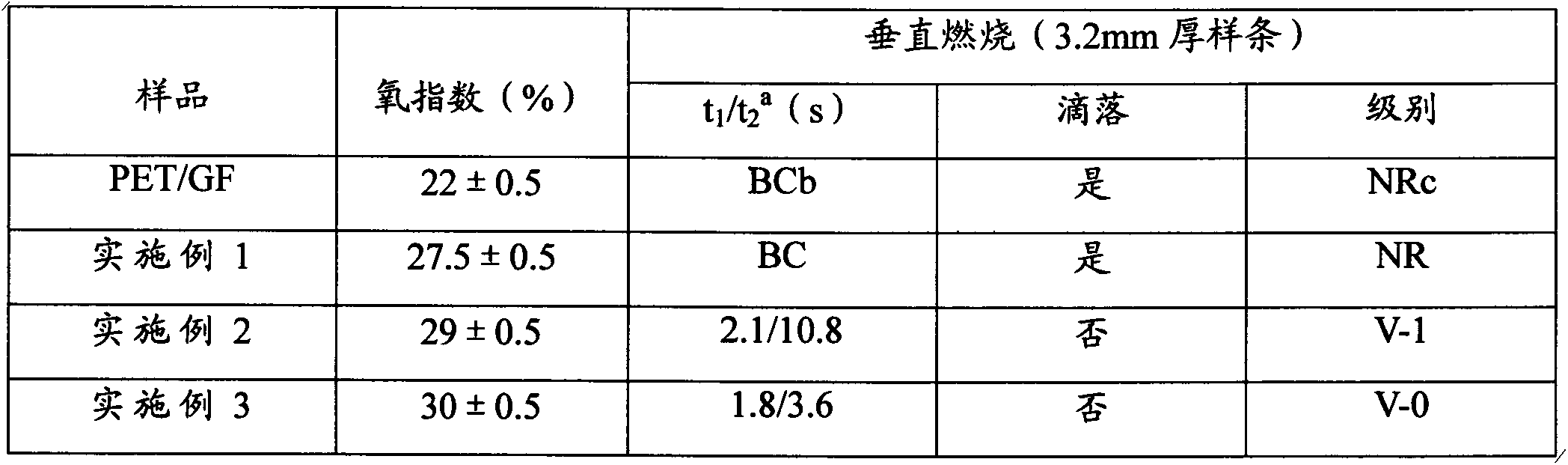

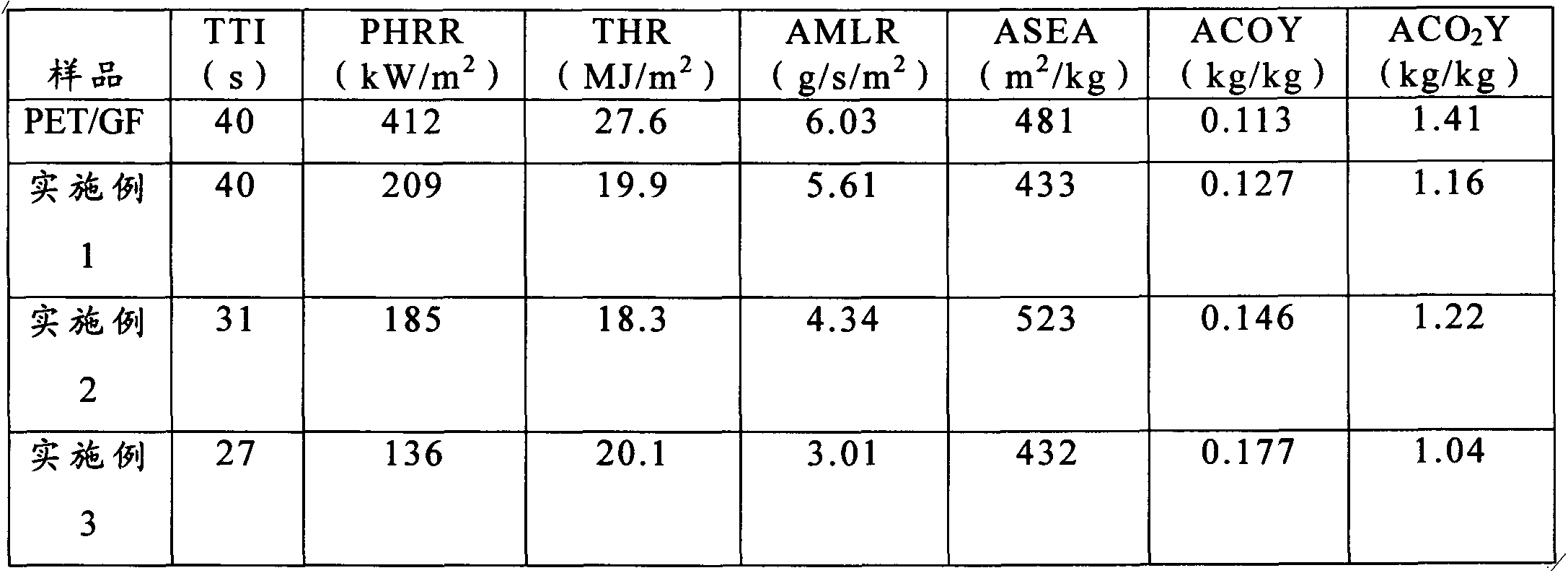

[0019] According to the thermal stability test of the raw material formula of above-mentioned three groups of mass percentages and the glass fiber reinforced polyethylene terephthalate (PET / GF) that does not add cerium hypophosphite (CHP) in nitrogen, its record contrast As shown in the following table:

[0020] Table 1 Formulation and thermogravimetric analysis data of PET / GF and PET / GF / CHP composites

[0021]

[0022] It can be seen from the above table that the thermal decomposition process of glass fiber reinforced polyethylene terephthalate (PET / GF) in nitrogen, at 397°C (T -3% ) began to decompose, and the mass fraction of the residue was 39.9% at 700°C, mainly glass fibers and a small amount of searchlight. With the increase of CHP content, the actual decomposition temperature of PET / GF composites first in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com