Preparation process of high-rigidity anti-static modified hollow wall winding pipes

A preparation process and antistatic technology, which is applied in the field of preparation technology of high-rigidity antistatic modified hollow-wall winding pipes, can solve the problems of destroying the mechanical properties of pipes, difficult migration of static charges, fire chemicals, etc. Promotes decentralized, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the embodiments.

[0026] The invention discloses a preparation process of a high-rigidity antistatic modified hollow-wall wound pipe, which comprises the following steps:

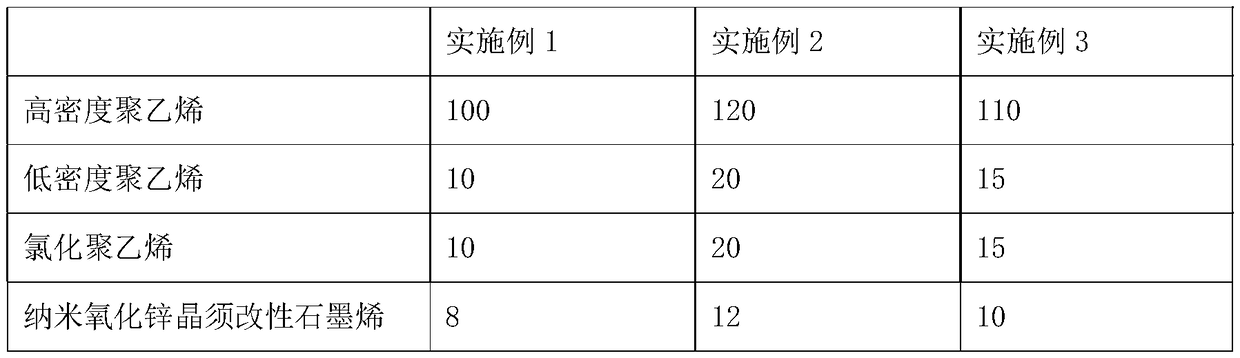

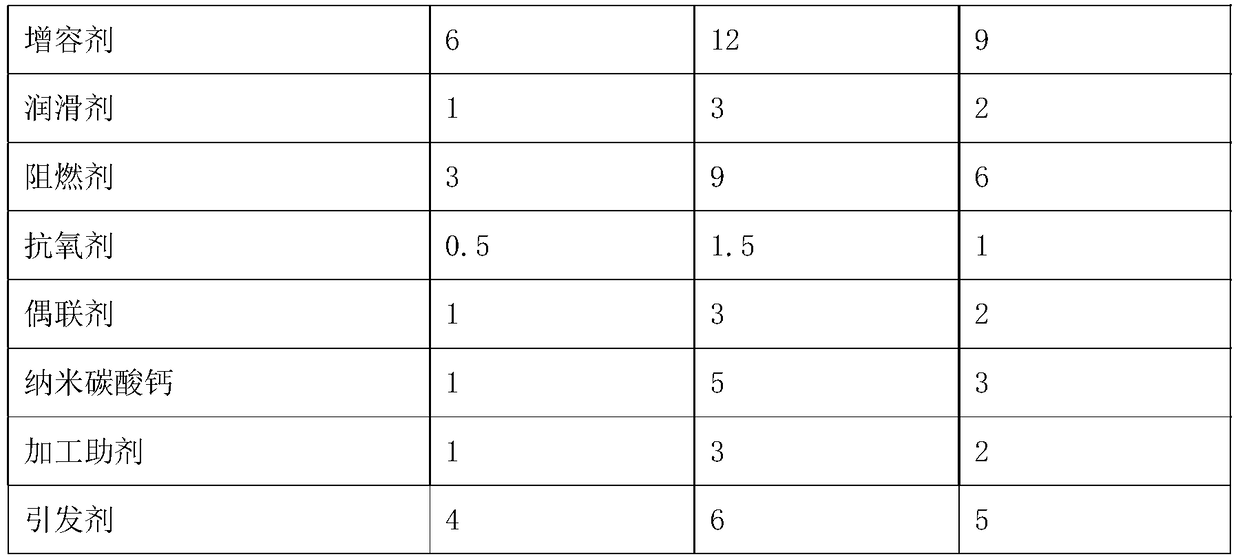

[0027] (1) In terms of weight fraction, weigh high-density polyethylene, linear low-density polyethylene, chlorinated polyethylene, nano-zinc oxide whisker modified graphene, compatibilizer, lubricant, flame retardant, antioxidant Agents, coupling agents, nano calcium carbonate, processing aids, initiators;

[0028] (2) Mix the low-density polyethylene, chlorinated polyethylene, antioxidant, and 1 / 2 of the total amount of coupling agent in the high-speed mixer first, and then add the initiator to mix after plasticizing Mixture A is obtained evenly;

[0029] (3) The high-density polyethylene, nano-zinc oxide whisker-modified graphene, compatibilizer, lubricant, flame retardant, antioxidant, remaining 1 / 2 coupling agent, nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com