Polyvinyl chloride/graphene nanocomposite and preparation method thereof

A nano-composite material and polyvinyl chloride technology are applied in the field of conductive polyvinyl chloride/graphene nano-composite materials and their preparation, which can solve the problems of difficult and uniform dispersion of graphene, achieve good electrical conductivity, improve flame retardant performance, and resist The effect of thermal performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

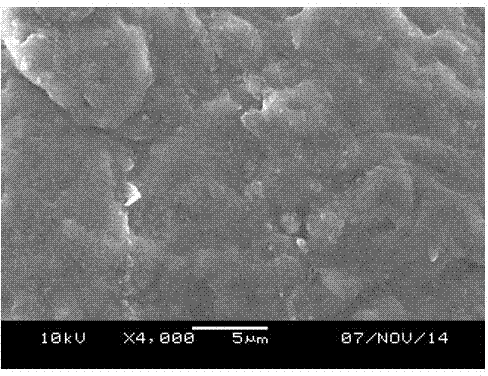

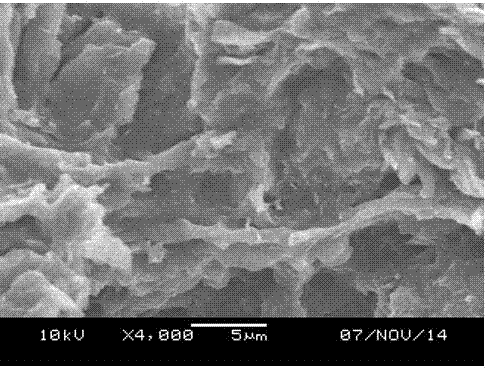

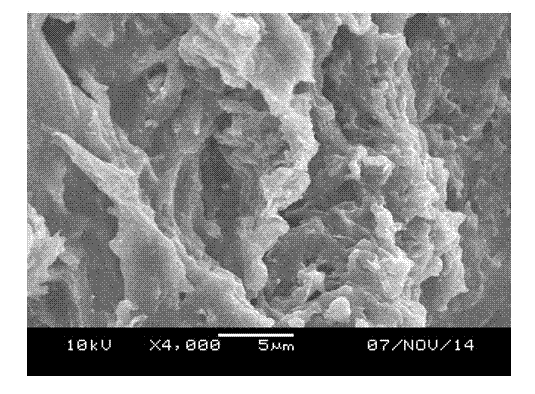

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention is described in detail below through specific examples, but the protection scope is not limited thereto. The raw materials used in the present invention can be purchased from the market.

[0028] The invention proposes a polyvinyl chloride / graphene nanocomposite material and a preparation method thereof. The materials used in it include: PVC resin, a plasticizer, a thermal stabilizer and a lubricant.

[0029] The PVC resin is SG-5 type resin, and the requirements for various performance indicators are: apparent density: ≥0.4g / ml; viscosity number: 107-118ml / g; volatile content: ≤0.5%.

[0030] The thermal stabilizer refers to an auxiliary agent that can improve the thermal stability of PVC. Its function is to prevent or inhibit the release of hydrogen chloride during the production process of special materials, and at the same time maintain sufficient thermal stability during the use of the product to prolong the service l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com