Air exhaust brake butterfly valve control system and control method

A technology of exhaust braking and control system, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problem of butterfly valve service life reducing friction power of engine air compressor and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail in conjunction with the accompanying drawings and embodiments.

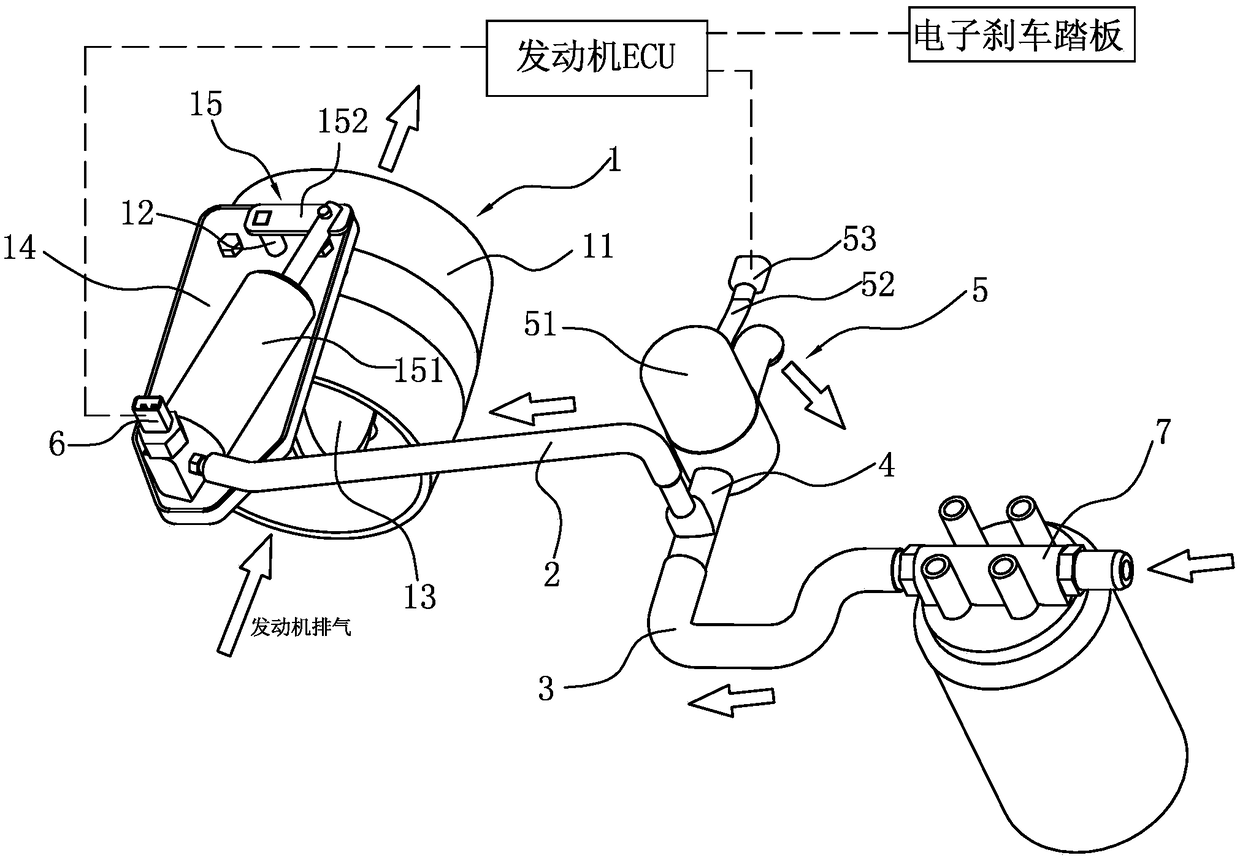

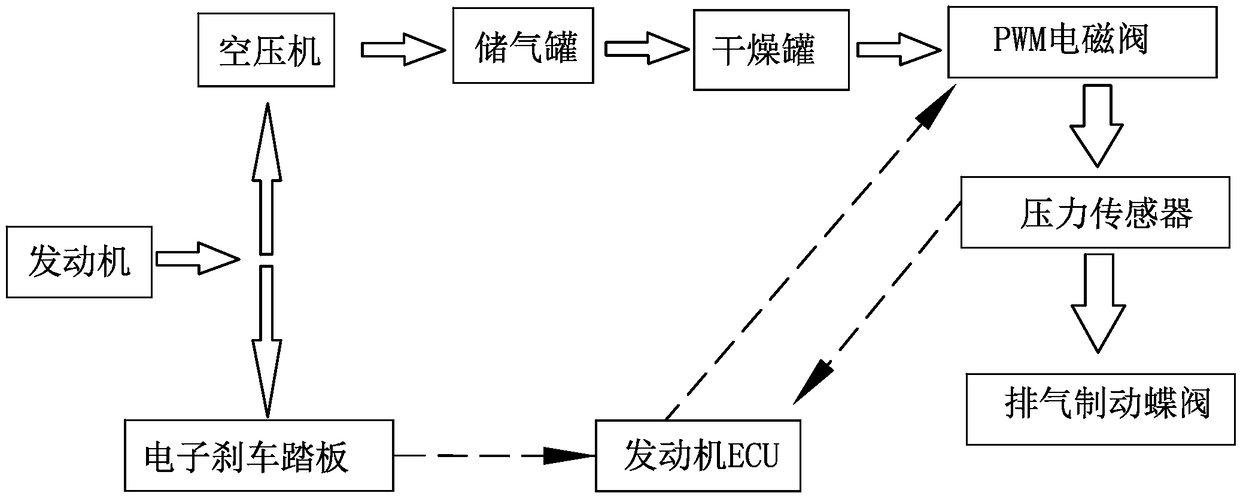

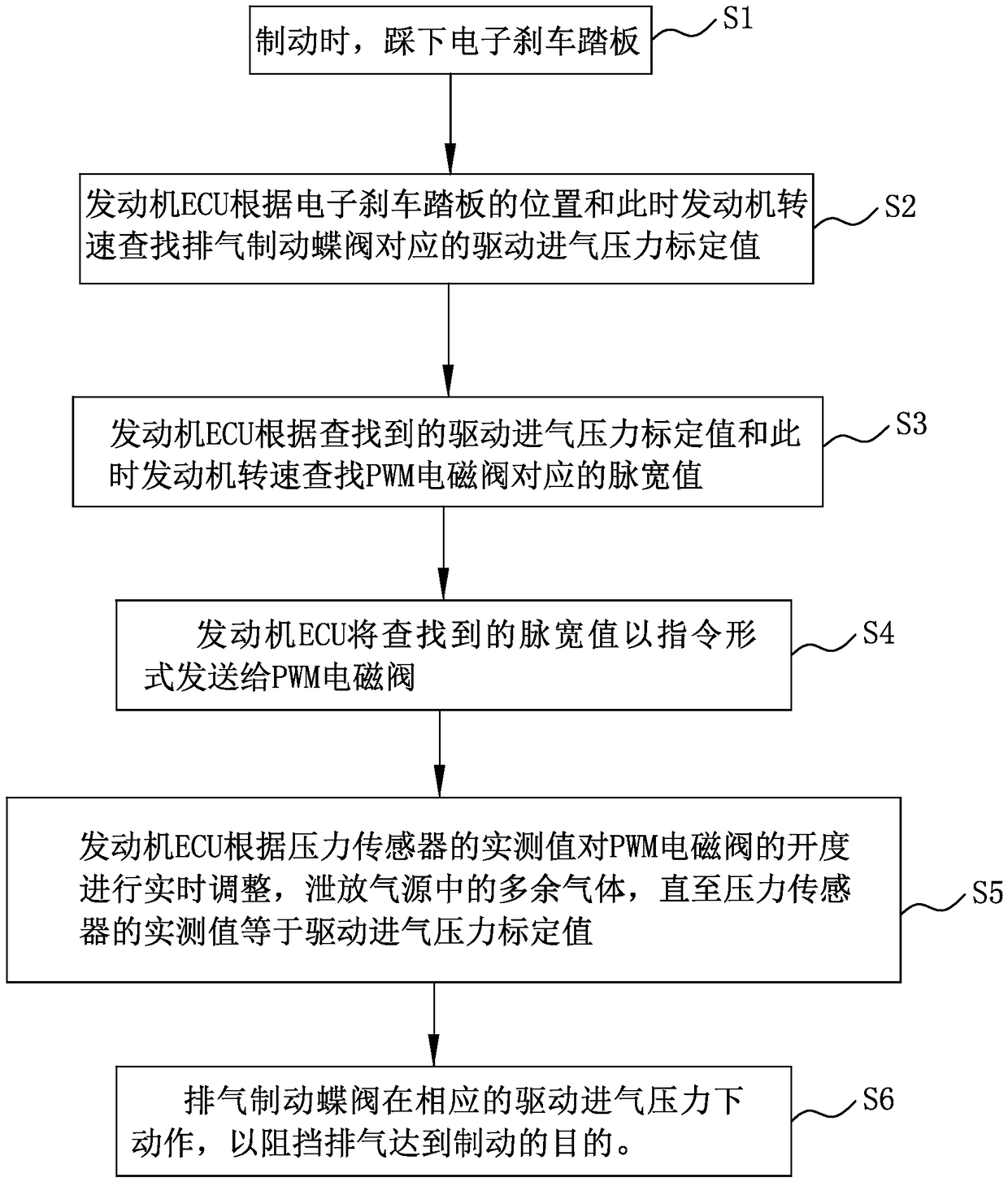

[0032] Such as figure 1 with figure 2 As shown together, the exhaust brake butterfly valve control system is mainly composed of exhaust brake butterfly valve 1, PWM solenoid valve 5 (PWM is the abbreviation of Pulse Width Modulation, representing pulse width modulation) and an electronic brake pedal that provides users with braking needs.

[0033] The valve body 11 of the exhaust brake butterfly valve 1 is arranged on the engine exhaust pipe. The valve shaft 12 is rotatably installed on the valve body 11. One end of the valve shaft 12 passes through the wall surface of the valve body 11 and the butterfly plate 13 inside the valve body 11. Fixedly connected, the valve body 11 is also provided with a mounting plate 14, the other end of the valve shaft 12 (the end outside the wall of the valve body 11) passes through the mounting plate 14, and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com