Online detection device and method for thin film solar cell photovoltaic conversion layer

A technology for a photoelectric conversion layer and a solar cell, which is applied in the field of solar cells, can solve the problems of wasting materials, increasing production costs, and having complex structures, and achieves the effects of avoiding waste of materials, saving production costs, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

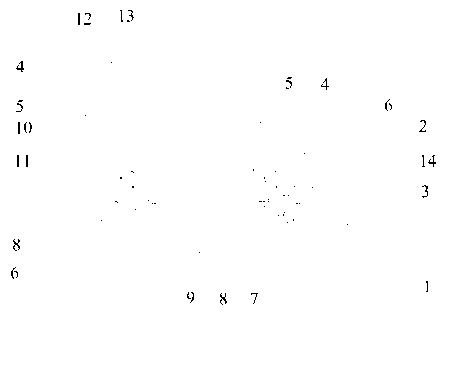

[0031] See figure 1 , the test device that the present embodiment adopts is made up of test platform 1, moving frame 2, linear motor 3, cylinder 4, guide post 5, probe fixed plate 6, moving probe, fixed probe, fastening screw 9, fixed frame 10 , DC power supply 12 and adjustable resistance 13, the moving probe is composed of probe rod 8 and moving probe head 7, the fixed probe is composed of probe rod 8 and fixed probe head 11, and the fixed frame 10 is fixedly installed in the test One end of the platform 1, the fixed frame 10 cannot be moved, the probe rod 8 for fixing the probe is installed on the probe fixed plate 6, and is tightened by the fastening screw 9, and the probe fixed plate 6 is mounted on the fixed frame The cylinder 4 on the crossbeam of 10 is connected, and the guide post 5 on the probe fixing plate 6 is installed on the crossbeam of the fixing frame 10, and the probe fixing plate 6 can drive the fixed probe to move up and down under the push of the cylinder ...

Embodiment 2

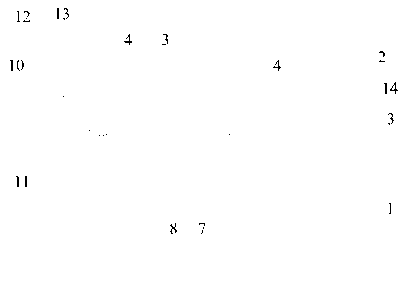

[0041] See figure 2 , the moving probe of this embodiment is one, and the moving probe can realize the X-axis motion through the linear motor 3 under the moving frame 2, realize the Y-axis motion through the linear motor 3 on the side of the moving frame 2, and then realize it through the cylinder 4 For the movement of the Z axis, the coordinate positioning of the test position of the moving probe is carried out by the control system before the measurement, and the measurement data is respectively measured for each test position during the test.

[0042] The implementation manner of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

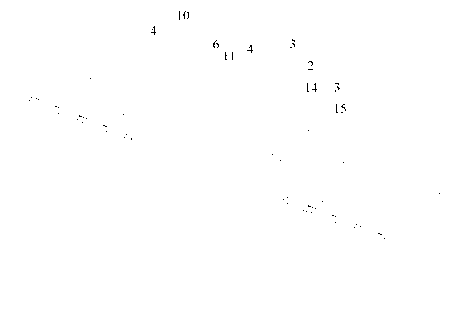

[0044] See image 3 , the present invention is applied to a continuous production line. The solar cell 14 is placed on the transmission roller 15 on the transmission system, and the transmission system drives the solar cell 14 from the previous station to the corresponding position of the test station for measurement.

[0045] During the measurement, the solar cell 14 with the photoelectric conversion layer deposited is placed in a fixed position, the cylinder 4 on the fixed frame 10 first presses the fixed probe head 11 on the film leaving the front electrode layer, and the moving frame 2 drives the moving probe to In the test position of the first row, the cylinder 4 on the moving frame 2 presses the moving probe head 7 on the photoelectric conversion layer. The cylinder 4 on the 2 presses the moving probe head 7 on the photoelectric conversion layer until all positions of the test are completed, the probes on the fixed frame of the test device and the moving frame are disco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com