Hydraulic parallel driving system for fore-and-aft lifting of forging manipulator

A technology for forging manipulators and hydraulic systems, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, mechanical equipment, etc., to achieve good motion stability and avoid changes in mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

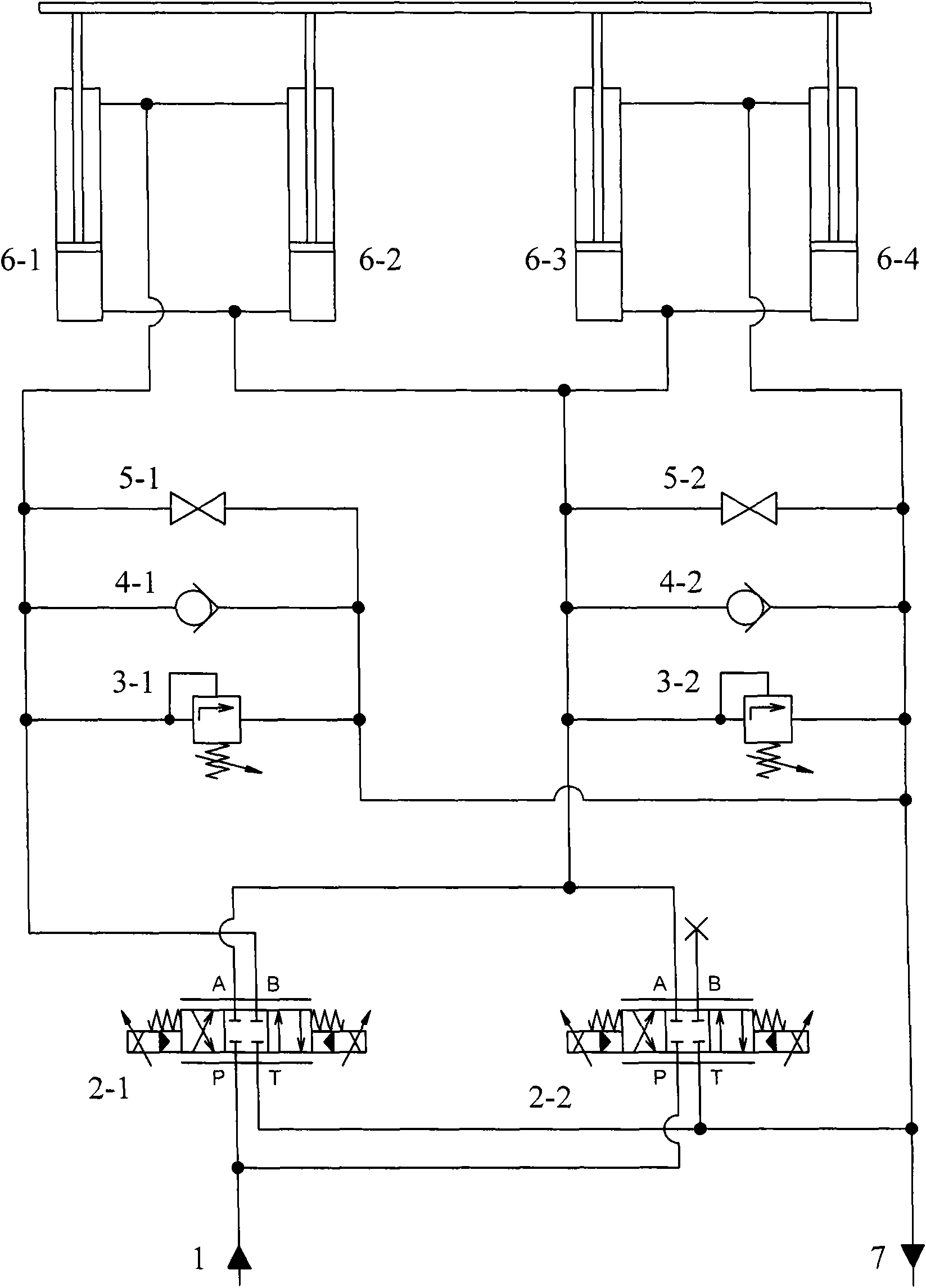

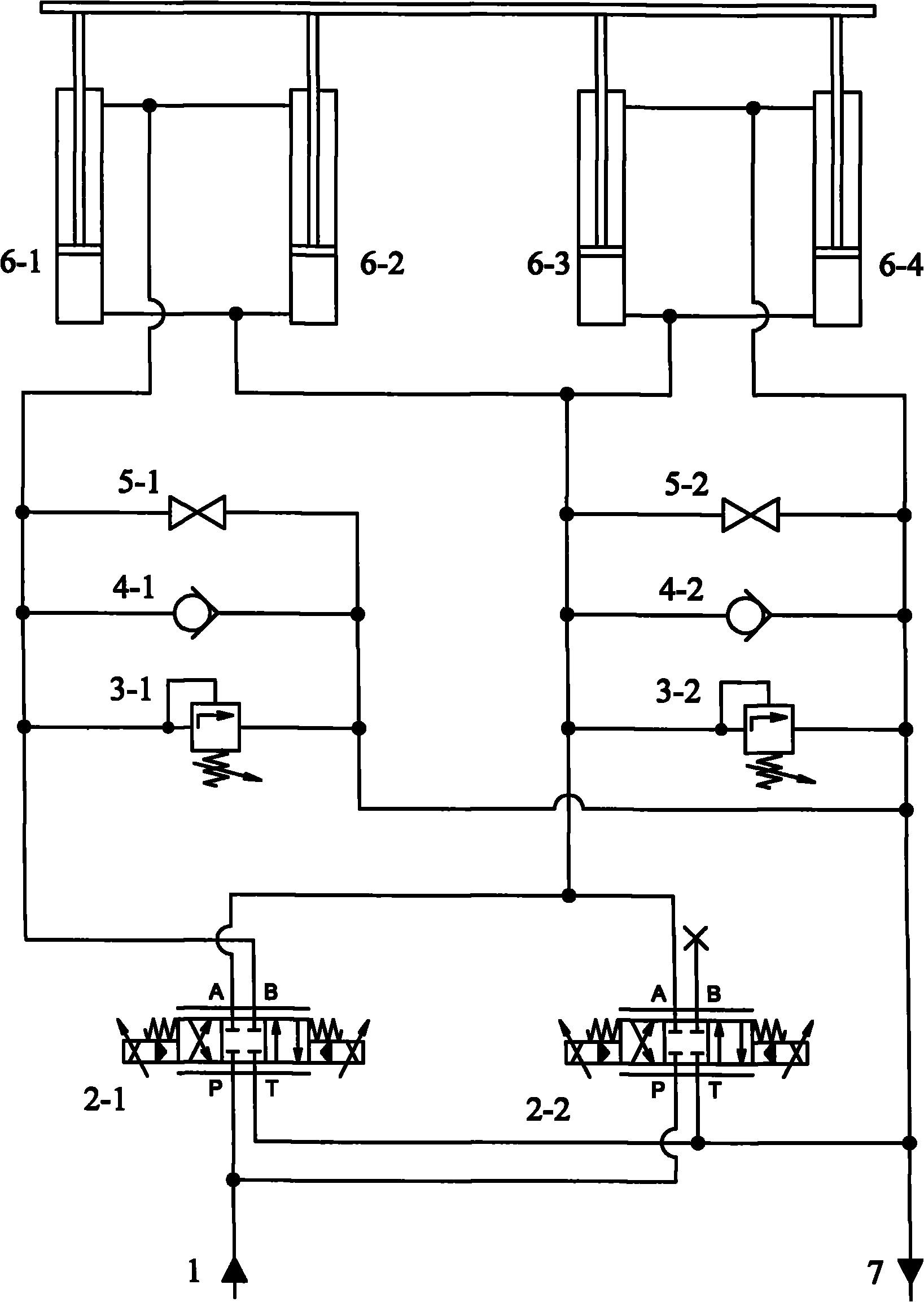

[0017] figure 1 A forging manipulator is given a front and rear lifting parallel drive hydraulic system, which consists of asymmetric proportional servo valve 2-1, symmetrical proportional servo valve 2-2, upper cavity safety valve 3-1, lower cavity safety valve 3-2, upper cavity Chamber check valve 4-1, lower chamber check valve 4-2, upper chamber stop valve 5-1, lower chamber stop valve 5-2, left rear lift cylinder 6-1, right rear lift cylinder 6-2, left front Lift cylinder 6-3, right front lift cylinder 6-4 form.

[0018] The P port of the asymmetric proportional servo valve 2-1 is respectively connected to the oil supply port 1 and the P port of the symmetrical proportional servo valve 2-2; the A port of the asymmetrical proportional servo valve 2-1 is respectively connected to the symmetrical proportional servo valve 2- A port of 2, lower chamber safety valve 3-2 inlet, lower chamber one-way valve 4-2 outlet, lower chamber stop valve 5-2 inlet, left front lifting cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com