Combined type hollow camshaft and machining process thereof

A camshaft, combined technology, applied in the direction of cam, belt/chain/gear, mechanical equipment, etc., can solve the problems of poor control of the pressing angle of the signal wheel, insufficient cam strength, and complex production process. , to improve the NVH situation, reduce the development and design cost, and achieve the effect of accurate signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

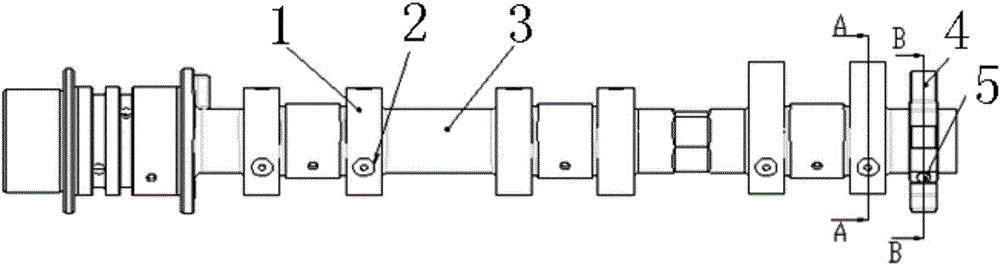

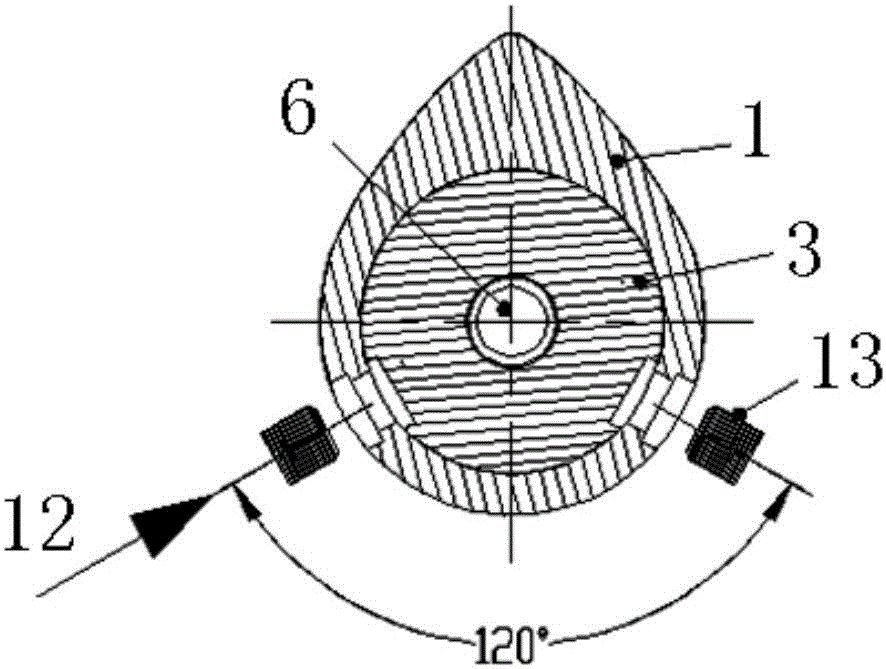

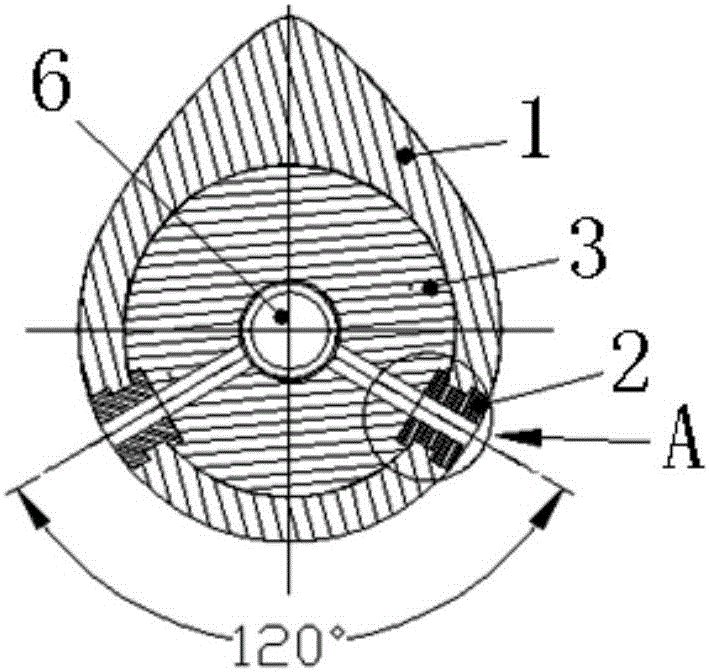

[0039] Such as Figure 1 to Figure 8 As shown, the combined hollow camshaft includes a combined cam 1, a signal wheel 4, a camshaft main body 3, a cam rivet 2 and a tapered pin 5, wherein the combined cam 1 and the signal wheel 4 are provided with a The assembly hole on the camshaft main body 3, the combined cam and the signal wheel are located on the camshaft main body.

[0040] The camshaft main body 3 is a hollow camshaft, and a hollow main oil passage hole 6 is formed in the camshaft main body; the hollow camshaft can be a cast hollow camshaft or a machined hollow camshaft. Cast hollow camshafts are preferred.

[0041] The journal on the main body of the camshaft connected to the combined cam is provided with two holes with a diameter of 6.5mm and a depth of 3mm at an angle of 110°-125°; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com