Automobile engine cooling system

A technology of automobile engine and cooling system, which is applied in the direction of engine cooling, engine components, machine/engine, etc. It can solve the problems that the turbocharger cannot be effectively cooled, the performance requirements of the water pump are high, and the combustion efficiency is low, so as to save fuel consumption , Reduce the performance requirements of the water pump and improve the combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

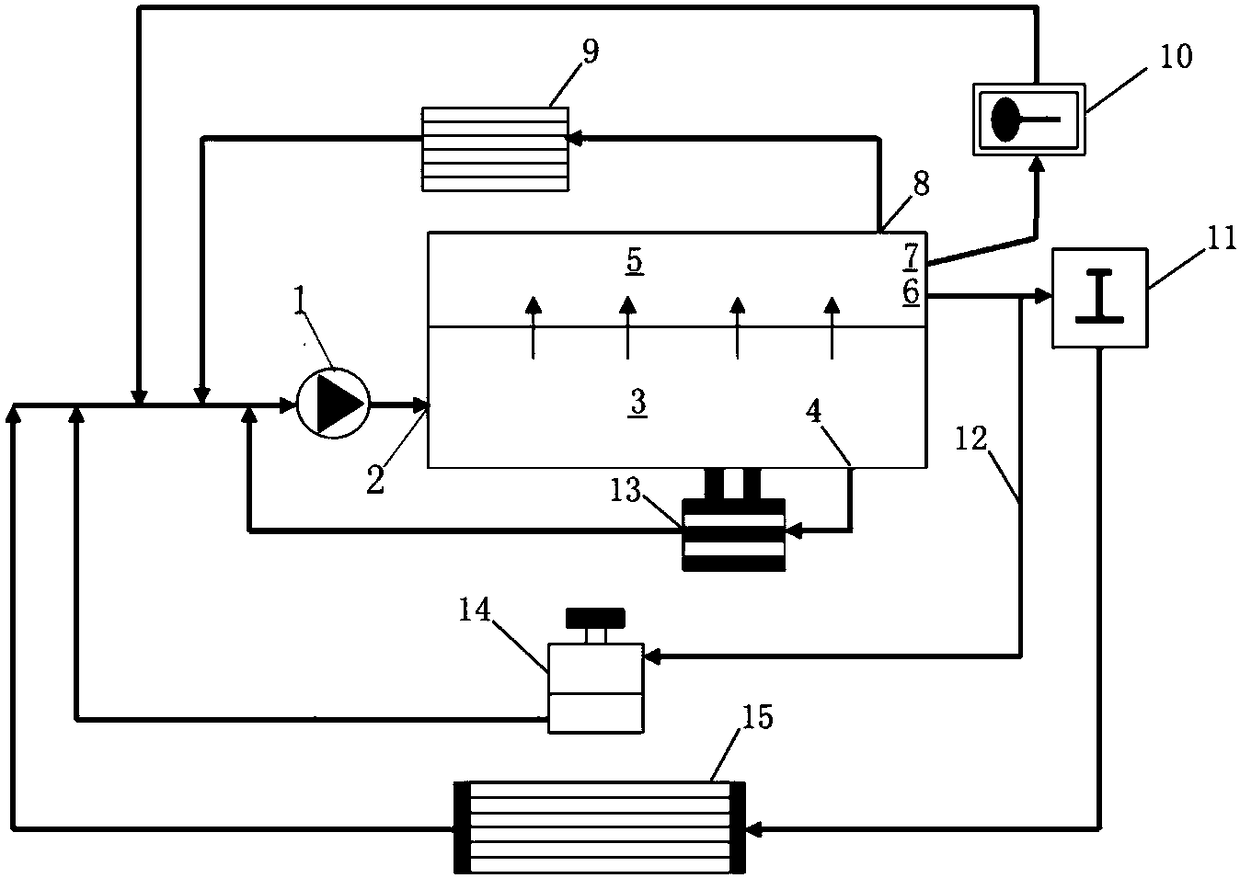

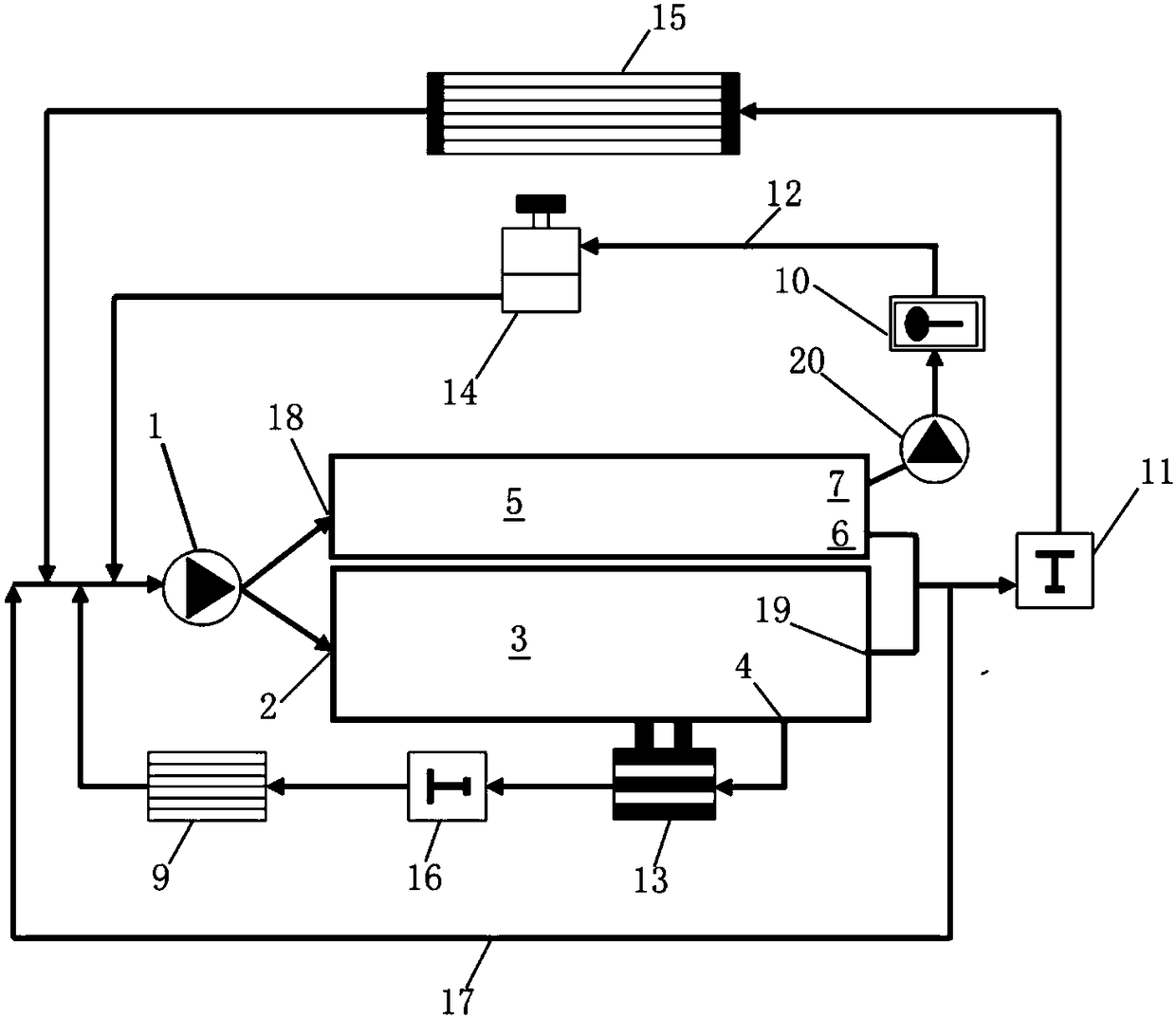

[0024] Such as figure 2 A kind of automobile engine cooling system provided by the present invention comprises water pump 1, cylinder head water jacket 5, cylinder body water jacket 3, first thermostat 11, radiator 15, electronic water pump 20, supercharger 10, Expansion water tank 14, engine oil cooler 13, second thermostat 16, heater 9 and engine degassing pipeline 12, wherein, the opening and closing of the corresponding pipelines of engine oil cooler 13 and heater 9 are controlled by second thermostat 16 Control; the supercharger 10 is cooled by the electronic water pump 20 after the engine stops; the flow rate of one circuit is about 30L / min, and the needs of the oil cooler 13 and the heater 9 are met at the same time. The application of the second thermostat 16 in the above structure avoids unnecessary heat loss during the warm-up period, makes the engine reach the working temperature quickly, improves combustion efficiency and reduces friction work, and saves fuel cons...

Embodiment 2

[0029] A kind of automobile engine cooling system provided by this embodiment, such as figure 2 As shown, the devices contained therein and the connection structure between the devices are the same as those in the first embodiment.

[0030]When the engine is in the normal working stage, the temperature has reached the opening temperature of the first thermostat 11 and the second thermostat 16, the first thermostat 11 and the second thermostat 16 are in the open state, and the bypass line 17 is closed, the coolant in the water pump is divided into two paths and enters the mutually independent cylinder body water jacket 3 and cylinder head water jacket 5 in a ratio of 3:7 to cool the cylinder body and cylinder head. Compared with the prior art , cooling according to this ratio can achieve the best cooling effect, so that the temperature of the cylinder block can be increased appropriately, thereby reducing friction, saving fuel consumption, and the temperature of the cylinder h...

Embodiment 3

[0032] A kind of automobile engine cooling system provided by this embodiment, such as figure 2 As shown, the devices contained therein and the connection structure between the devices are the same as those in the first embodiment.

[0033] When the engine is shut down (i.e., stopped), the oil pressure drops to zero rapidly, and the water pump 1 also stops working. At this time, the electronic water pump 20 enters the working state to provide circulating power for the coolant, and continues to delay the cooling of the supercharger 10, thereby The reliability of the supercharger 10 is guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com