Cooling waterway cycle structure of automobile engine

A technology of automobile engine and cooling water circuit, which is applied in the direction of engine cooling, engine components, combustion engine, etc., can solve the problems of reducing energy consumption, lack of comprehensive analysis and optimization of cylinder block water jacket and cylinder head water jacket, and difficulty in achieving results. , to reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

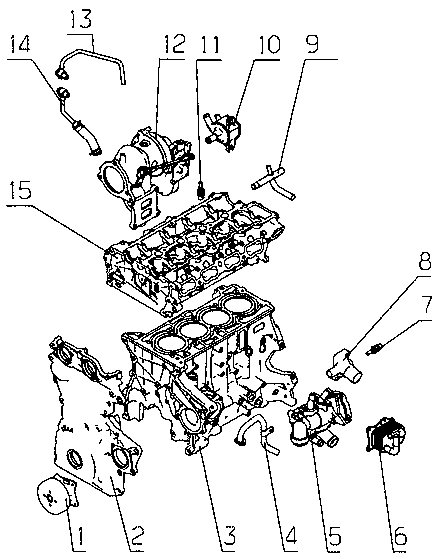

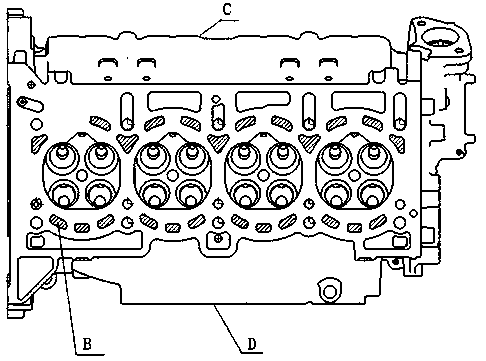

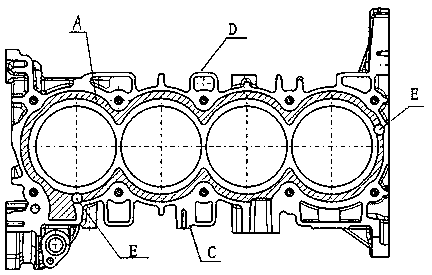

[0032] Referring to the accompanying drawings, an automobile engine cooling water circuit circulation structure includes an engine main water pump 1, a timing sprocket housing integrated water jacket 2, a cylinder block 3, a cylinder block water outlet pipe 4, a multi-channel coolant control valve 5, and an oil cooler 6. Water temperature sensor 7, cylinder block water outlet 8, cylinder head outlet pipe 9, electronic water pump 10, water temperature sensor 11, supercharger 12, supercharger return pipe 13, supercharger water inlet pipe 14, cylinder head 15, heat dissipation 16, expansion water tank 17, warm air heat exchanger 18, timing sprocket housing integrated water jacket 2 and engine main water pump 1 are arranged on the front face of cylinder block 3, and fixed by bolts, timing sprocket housing integrated water jacket 2 and the water inlet of the cylinder block 3 form the inner cavity of the engine main water pump 1, and the timing sprocket shell water jacket boss 19 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com