Oil pipe joint

A technology for oil pipe joints and fixed pipes, which is applied in the field of pipe joints, can solve the problems of high processing precision of parts, difficulty in meeting the requirements of processing equipment, and unsuitability for rapid production, etc., and achieve low processing difficulty, simple structure, and low processing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

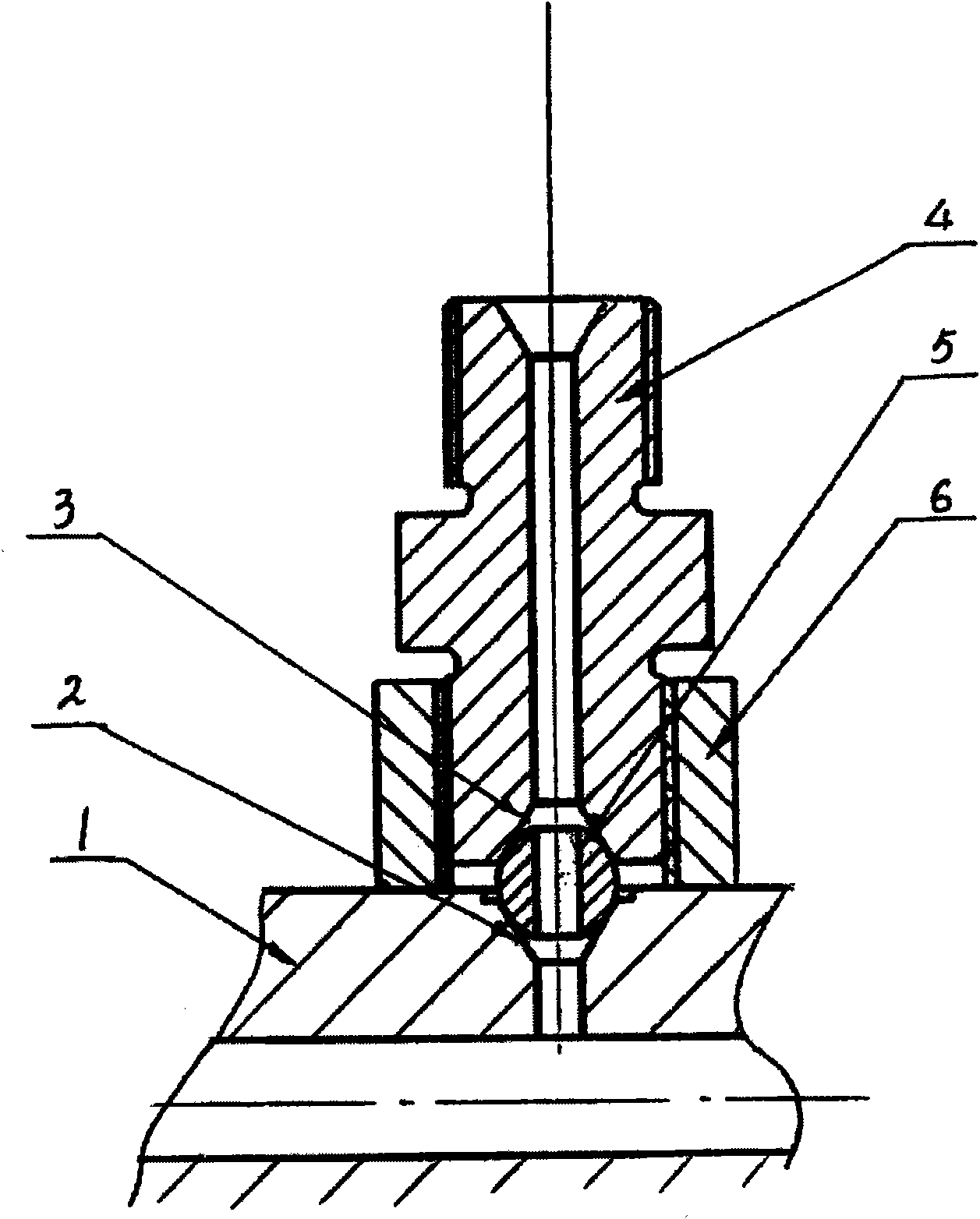

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as figure 1 In the shown embodiment, the tapered sealing surfaces 3 and 2 are processed at the central part of the bottom surface of the joint 4 and the corresponding part where the rail pipe 1 and the joint 4 are connected; then the fixing sleeve 6 is set on the rail pipe 1, and then, Put the sealing ball 5 with a through hole on the tapered sealing surface 2 of the rail pipe 1, and then tighten the thread provided on the lower part of the joint 4 and the thread provided on the fixed sleeve 6, and seal the ball 5 before tightening. The through hole of the joint is connected with the through hole of the rail pipe at the lower end.

[0014] The oil pipe joint installed on the common rail pipe is used to install the high-pressure oil pipe. The common rail pipe is connected with the high-pressure pump and the fuel injector through the high-pressure oil pipe to rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com