Squeeze film damper with novel outer ring structure

A technology of extruding oil film damping and damper, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problems of high maintenance cost, increase the complexity of damper structure, etc., and achieve the reduction of oil film stiffness and structure Simple, the effect of increasing the working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

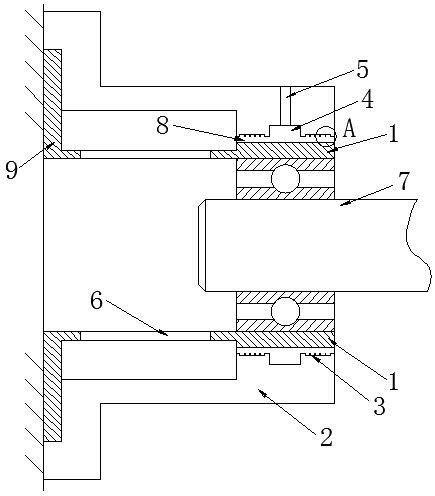

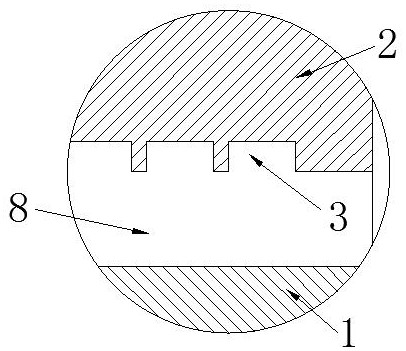

[0033] like Figure 1~6 As shown, a squeeze film damper with a novel outer ring structure of the present invention includes a fixed outer ring 2 of the damper, a fixed elastic support base 9 and an inner ring of the damper installed on the inner ring of the outer ring 2 of the damper 1. The outer ring 2 of the damper is fixed on the frame. The outer ring 2 of the damper is a ring structure with a round hole inside. The inner ring 1 of the damper is a ring structure and is installed inside the outer ring 2 of the damper. The inner ring 1 is concentric with the outer ring 2 of the damper.

[0034] The elastic support base 9 and the damper outer ring 2 are affixed to the frame together, and the damper inner ring 1 is connected to the elastic support base 9 through the elastic support 6, and the elastic support 6 is a cage structure, so The elastic support 6 is provided with several cage bars along the circumferential direction, and the two ends of the cage bars are respectively ...

Embodiment 2

[0047] like Figure 1~7 As shown, the difference between this embodiment and embodiment 1 is:

[0048] The oil film counterbore 3 is a circular counterbore, and the circular hole structure is simpler than the honeycomb structure, and the processing technology is less difficult.

[0049] The diameter of the oil film counterbore 3 is 1mm, and the depth of the oil film counterbore 3 is 0.1mm. A plurality of oil film counterbores 3 are arranged in a straight line in the axial direction of the damper outer ring 2 and arranged in a staggered manner in the circumferential direction of the damper outer ring 2 .

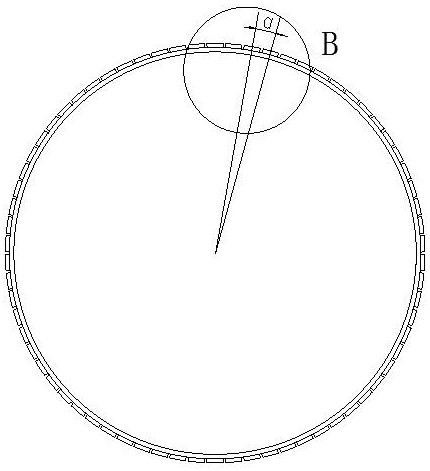

[0050] The distance h between the centers of the adjacent oil film counterbore 3 along the axial direction of the damper outer ring 2 is 1.08mm, and the linear distance d between the centers of the adjacent oil film counterbore 3 in the circumferential direction is 0.93mm. Any two phases in the circumferential direction The included angle a between the center of the adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com