Long-span cable stayed bridge steel truss girder mounting method

A cable-stayed bridge steel and installation method technology, applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as low construction efficiency, high construction difficulty, and large capital investment, so as to improve work efficiency and construction conditions , The effect of reducing the segmental lifting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

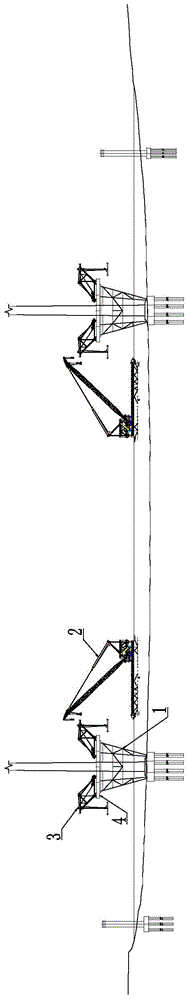

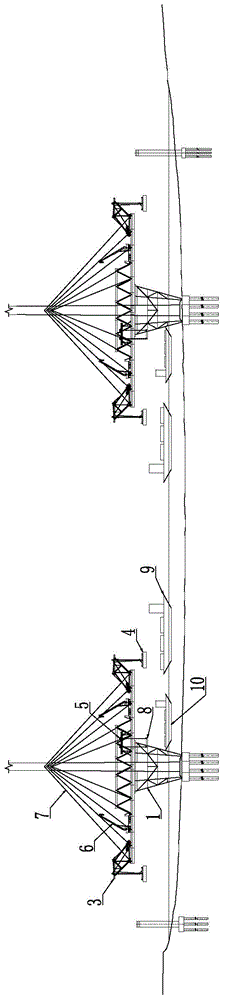

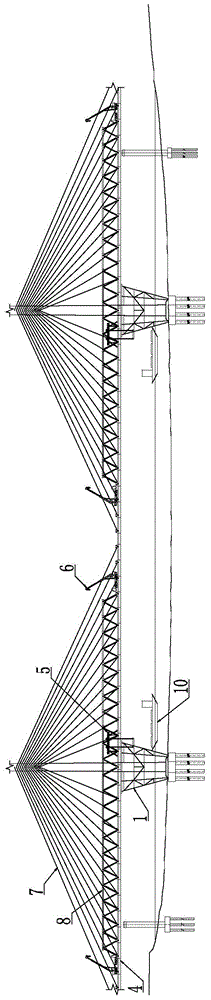

[0037] Such as figure 1 As shown in -3, a method for installing steel truss girders of long-span cable-stayed bridges includes the following steps:

[0038] Step 1: After the construction of the lower beam of the main tower is completed, set up the bracket 1 beside the pier, and install the lower chord 42 of the steel truss girder at the top of the pier and the bridge deck 41 on the bracket 1 beside the pier by using 2 parts of the floating crane to form a section Inter-section bridge deck 4; after completing the assembling of the inter-node bridge deck 4 between four nodes, install the girder crane 3 on the inter-node bridge deck 4.

[0039] Step 2: Assemble the lower chord 42 of the single internode steel truss girder and the bridge deck 41 in the factory to form the internode bridge deck 4; use the first water transport ship 9 to transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com