Non-contact power supply of automatic carriage

A contactless power supply, bicycle technology, applied in circuit devices, circuits, inductors, etc., can solve the problems of low reliability and stability of bicycle operation, inconvenient layout design, and potential safety hazards, and achieve easy upgrades. And modular expansion, avoid harm to human body, reduce the effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

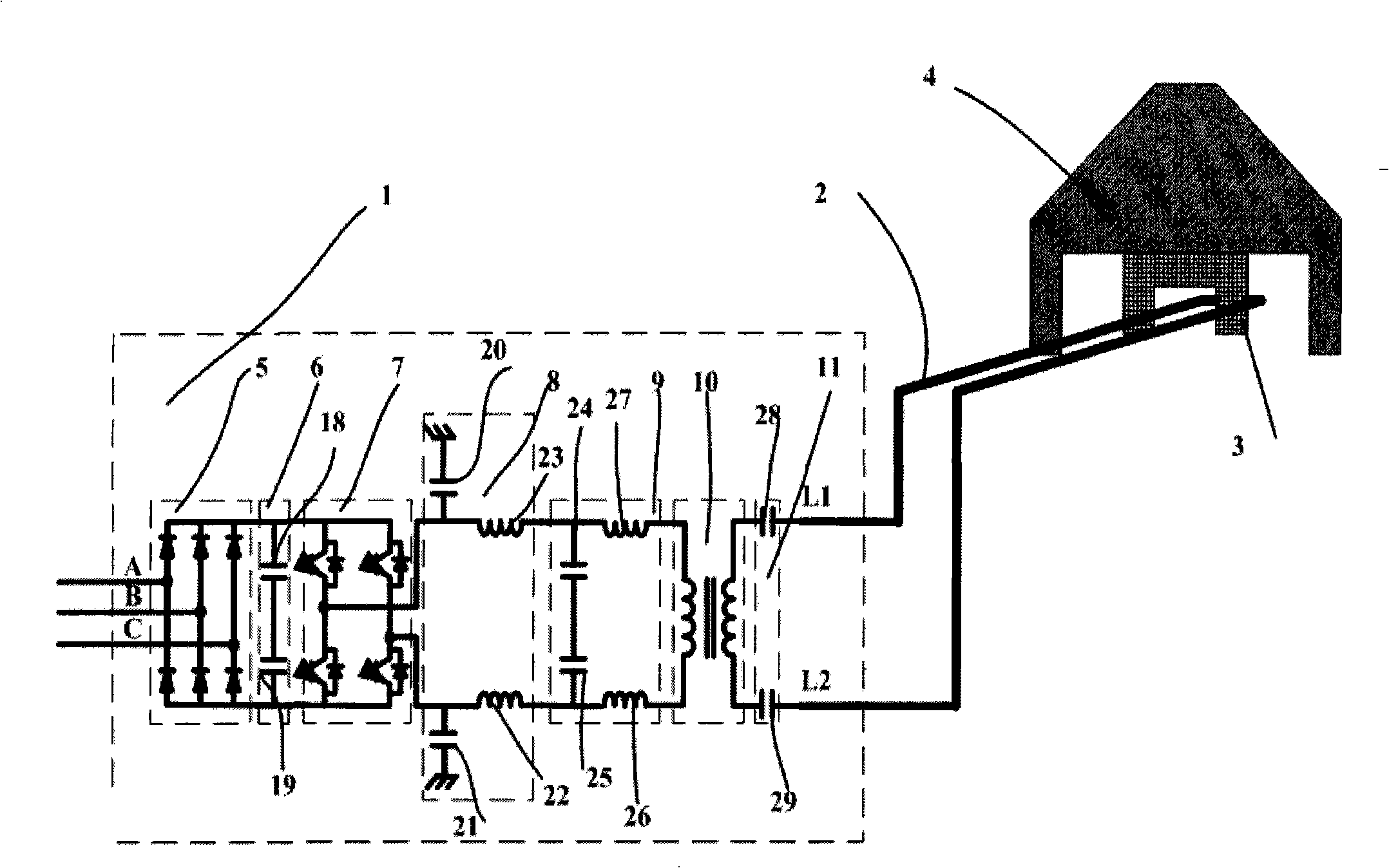

[0023] as attached figure 1 As shown, the present invention includes the following main components: a transformer cabinet 1, a primary cable 2, a pick-up component 3, and a self-propelled trolley 4. These modules are introduced respectively below in conjunction with each accompanying drawing.

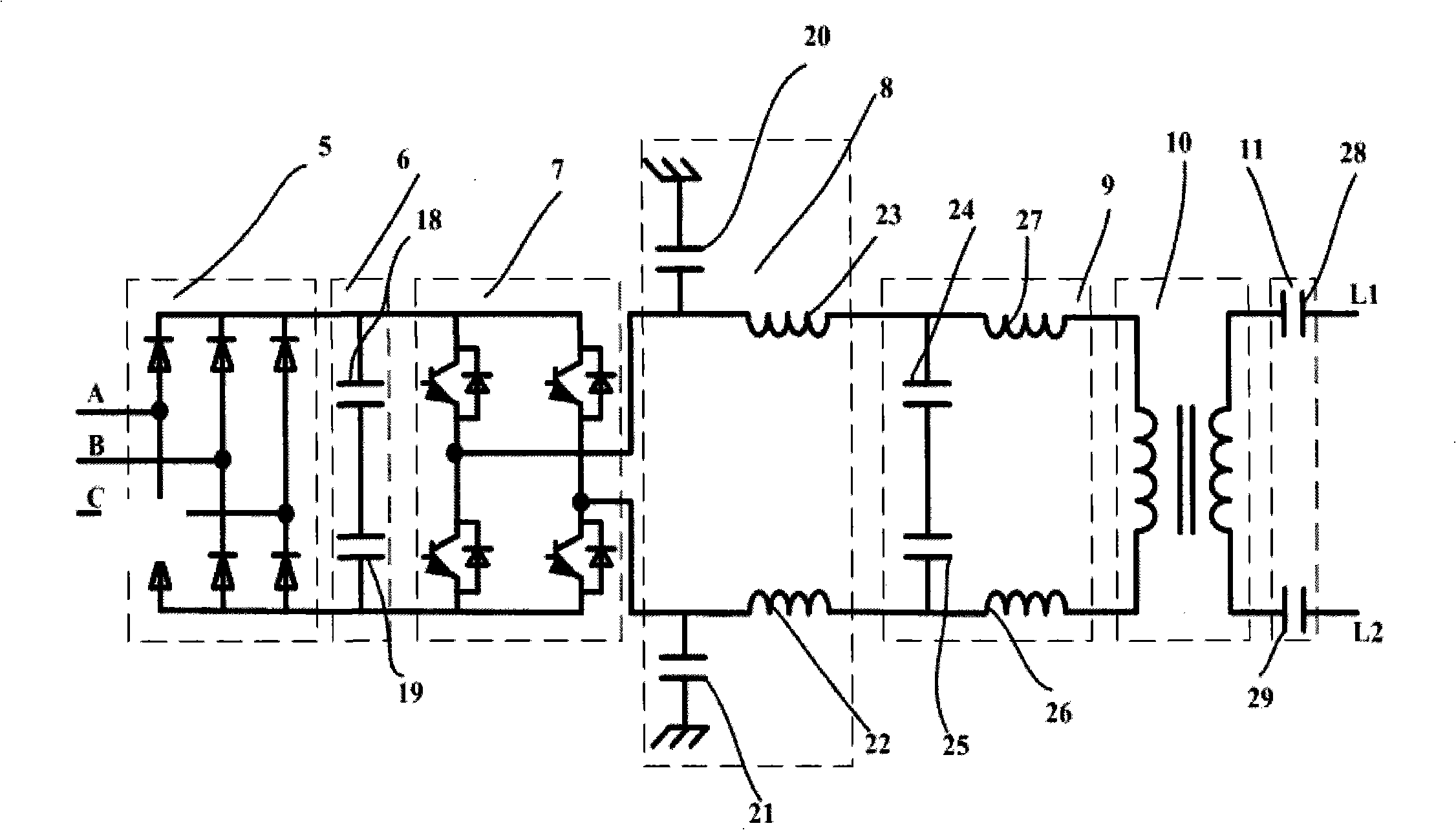

[0024] Transformer cabinet 1: refer to the attached figure 2 -Structure diagram of transformer cabinet

[0025] The transformer cabinet 1 is mainly used to realize the transformation from input power frequency power to output high frequency sinusoidal alternating current. It mainly includes a rectification module 5 , a filter module 6 , a high-frequency inverter module 7 , a frequency selection module 8 , a resonant conversion module 9 , an isolation module 10 , and a compensation module 11 .

[0026] 1. Rectification module 5: The functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com