Metal bipolar plate flow field runner structure of fuel cell

A metal bipolar plate, fuel cell technology, applied in the direction of fuel cells, fuel cell components, circuits, etc., can solve the problems of increased cost, increased performance requirements of booster equipment, and higher equipment selection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

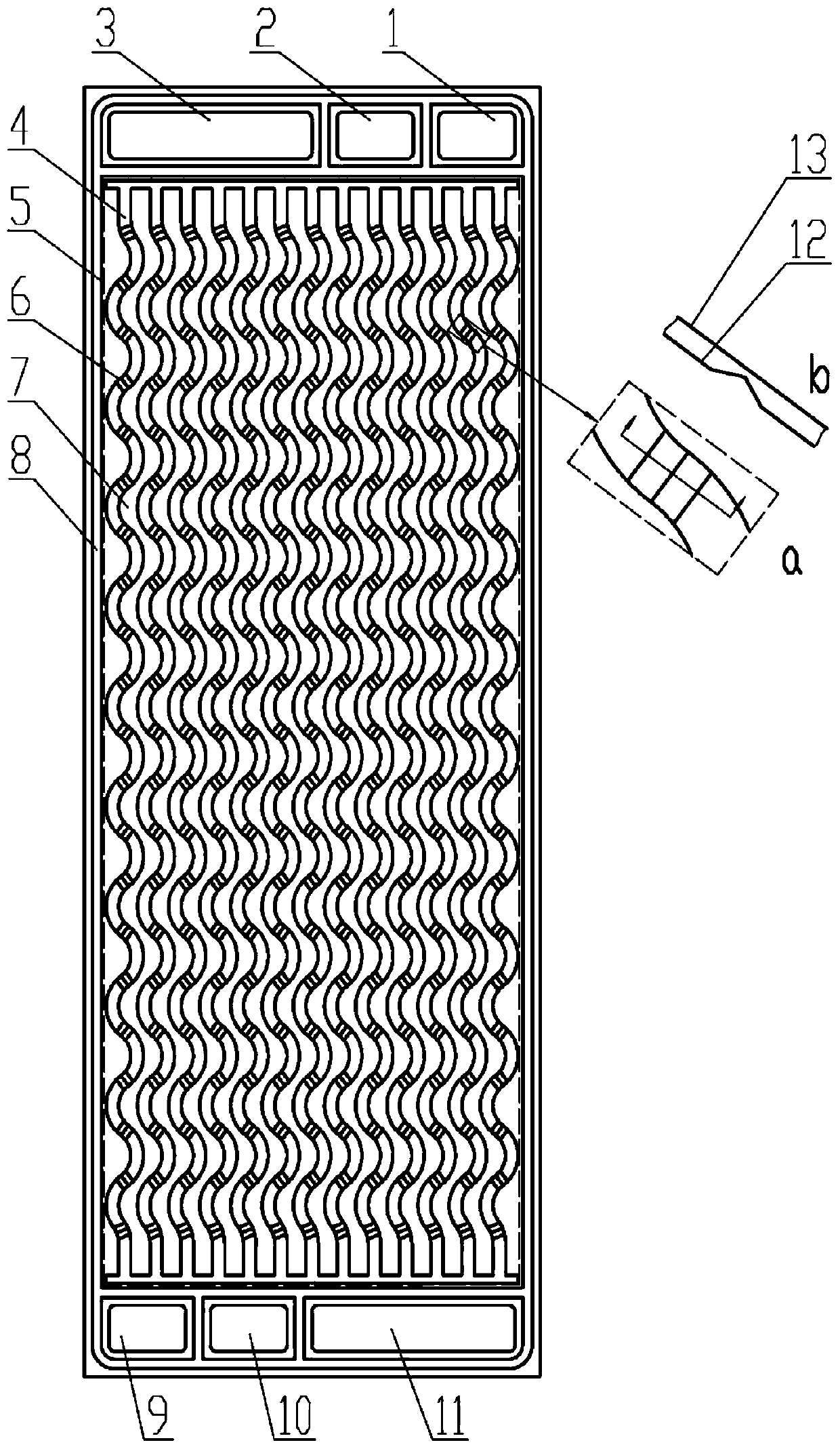

[0050] Embodiment 1: a kind of fuel cell metal bipolar plate ( figure 1 ), the bipolar plate includes a fuel gas inlet 9, a fuel gas outlet 1, an oxidant inlet 3, an oxidant outlet 11, a coolant inlet 2, a coolant outlet 10, an oxidant flow field and a fuel flow field, and the oxidant flow field and The fuel gas flow field is respectively located on the left and right sides of the bipolar plate, the oxidant inlet 3 and the oxidant outlet 11 are connected through the flow channel in the oxidant flow field, and the fuel gas inlet 9 and the fuel gas outlet 1 are connected through the flow channel in the fuel gas flow field. The flow channels are connected;

[0051] The oxidant inlet 3 and the oxidant outlet 11 are centrosymmetric with the center of the bipolar plate as the center point; the fuel gas inlet 9 and fuel gas outlet 1 are centrosymmetric with the center of the bipolar plate as the center point; the The coolant inlet 2 and the coolant outlet 10 are centrally symmetric...

Embodiment 2

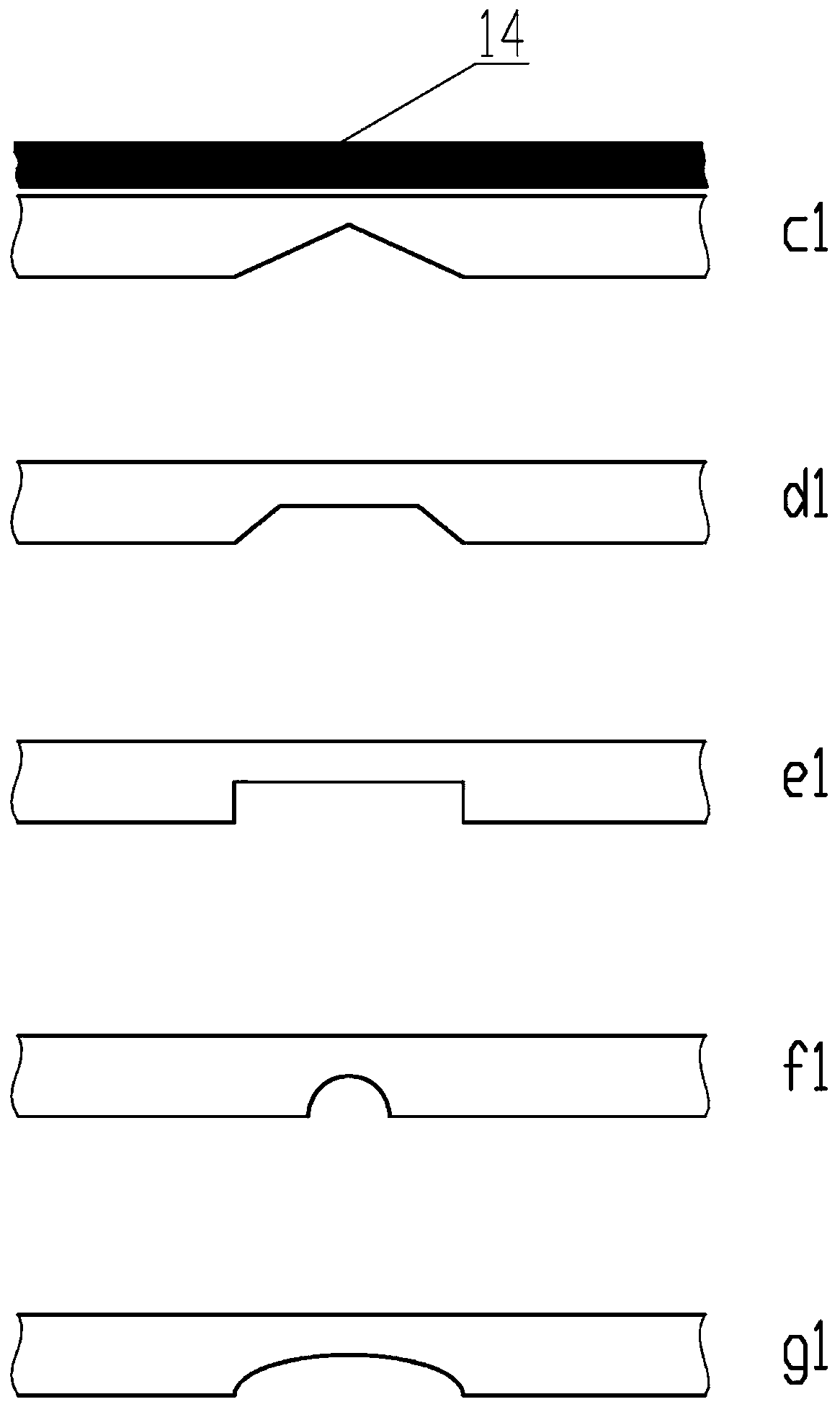

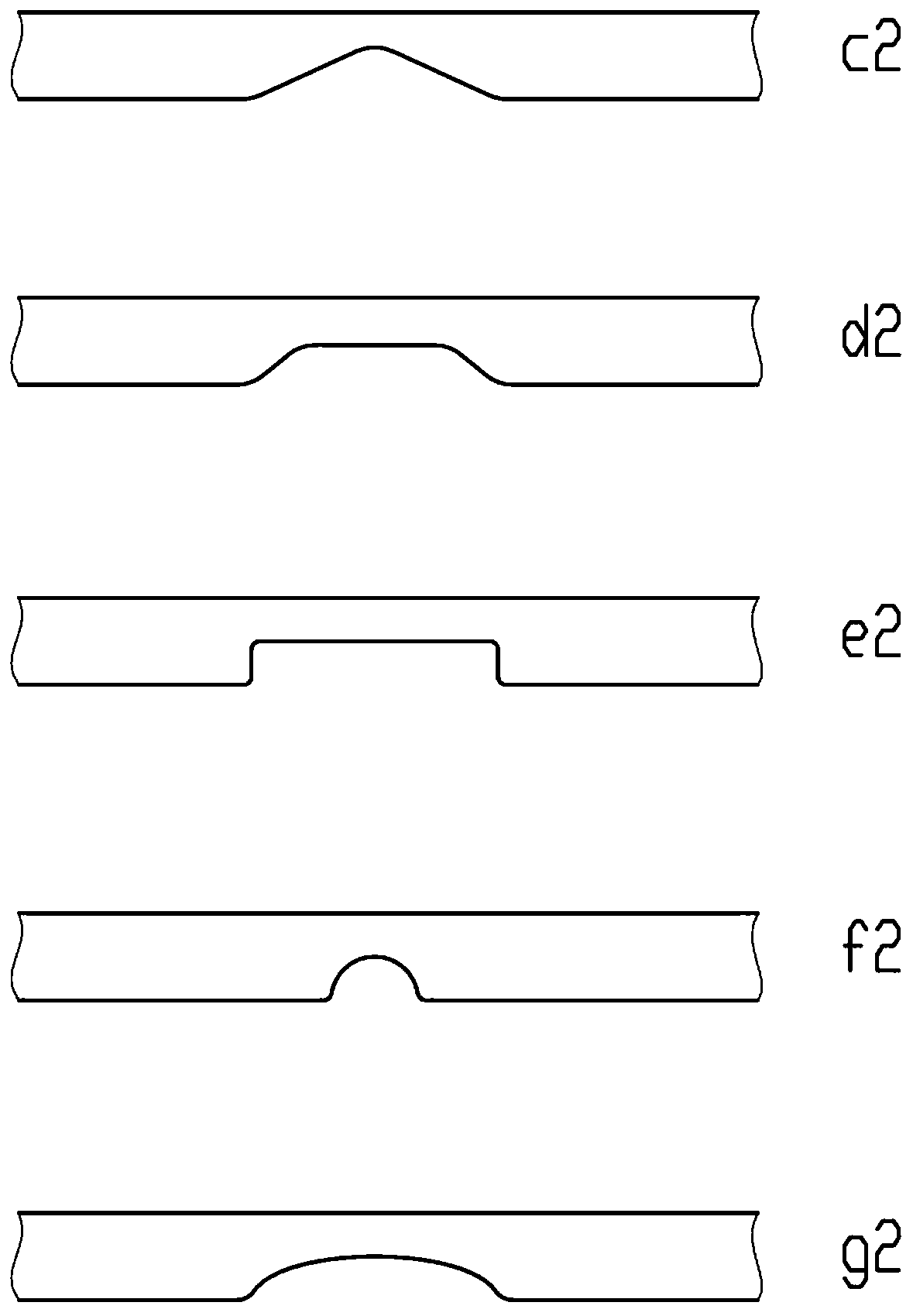

[0056] Embodiment 2: Based on the bipolar plate described in Embodiment 1, only the structural size of the raised portion is adjusted, and the specific adjustment is as follows: the length of the raised portion is adjusted to 35 mm, and the distance between the raised portion in each flow channel is 40 mm. Layout, the rest of the size and structure remain unchanged.

Embodiment 3

[0057] Embodiment 3: Based on the bipolar plate described in Embodiment 1, only the structural size of the raised portion is adjusted, and the specific adjustments are as follows: the length of the raised portion is adjusted to 2 mm, the height of the raised portion is 0.4 mm, and the raised portion is at The inner spacing of each flow channel is 8 mm, and the arrangement is uniform, and the other dimensions and structures remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com