An automatic retractable water diversion device

A water diversion device, automatic retractable technology, applied in industrial buildings, building components, buildings, etc., can solve the problems of high manufacturing cost, rain leakage, complicated installation of the transmission device of the flap, etc., and achieve low manufacturing cost and quick installation , The effect of processing is not difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

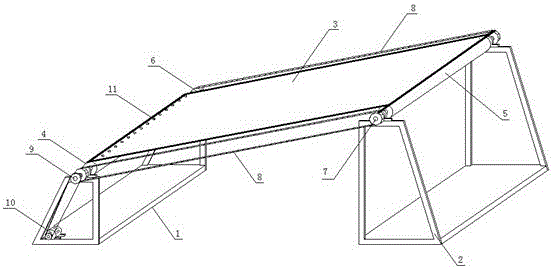

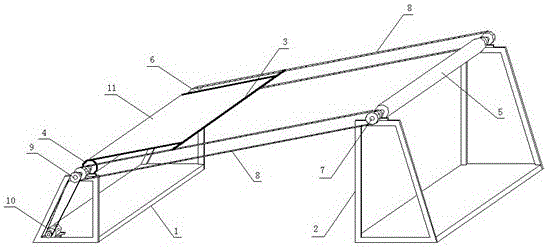

[0009] Attached below figure 1 And attached figure 2 A further description will be given to an automatic retractable water diversion device of the present invention.

[0010] An automatic retractable water diversion device of the present invention is composed of a front-end bracket 1, a tail-end bracket 2 and a cord 3, and the front-end bracket 1 is fixedly connected with a rotating roller I4 and a bearing on the tail-end bracket 2 through a bearing. The rotating roller II5 is fixedly connected, the rotating roller I4 and the rotating roller II5 are in the same plane and parallel to each other, the two ends of the rotating roller I4 are provided with transmission wheels I6, and the two ends of the rotating roller II5 are equipped with transmission wheels II7. The driving wheel I6 and the driving wheel II7 on the same side of the roller I4 and the rotating roller II5 are connected by a chain 8, and a driven wheel 9 is provided on one side of the rotating roller I4, and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com