Electrolytic copper-clad plate by taking polymethyl methacrylate as medium, printed circuit board and manufacturing method thereof

A printed circuit board and manufacturing method technology, which is applied in the secondary processing of printed circuits, chemical instruments and methods, improvement of metal adhesion of insulating substrates, etc. Problems such as poor ability, to achieve the effect of less difficulty in processing, good insulation and mechanical strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

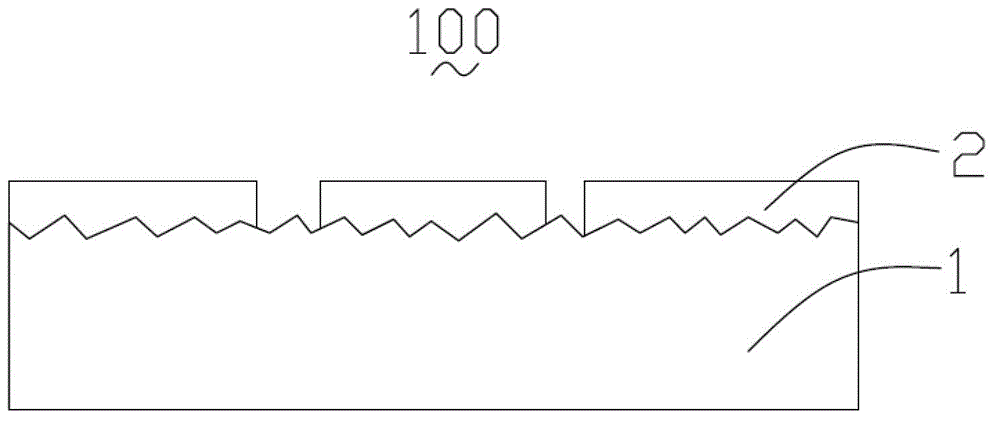

[0031] see figure 1 , figure 1 It is a schematic cross-sectional structure diagram of a printed circuit board (Printed Circuit Board, PCB) of the present invention. The printed circuit board 100 includes a substrate 1 and a patterned copper layer 2 disposed on the substrate 1 .

[0032] Specifically, the substrate 1 is made of polymethyl methacrylate (Polymethyl Methacrylate, PMMA) material, and its surface is roughened to form a roughness of 50 microns to 150 microns, which is beneficial to the patterned metal layer. 2. It is tightly combined with it to prevent the metal layer from falling off and warping.

[0033] The patterned copper layer 2 can also be replaced by a common conductive material such as an aluminum layer, a silver layer, or a gold layer according to actual needs, which is not specifically limited here. The patterned coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com