Miniature ultra-hard drilling and milling cutter special for machining ceramic materials and machining method thereof

A ceramic material, drilling and milling cutter technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of difficult to obtain economic effect and surface processing quality, achieve good processing effect, fast drilling speed, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

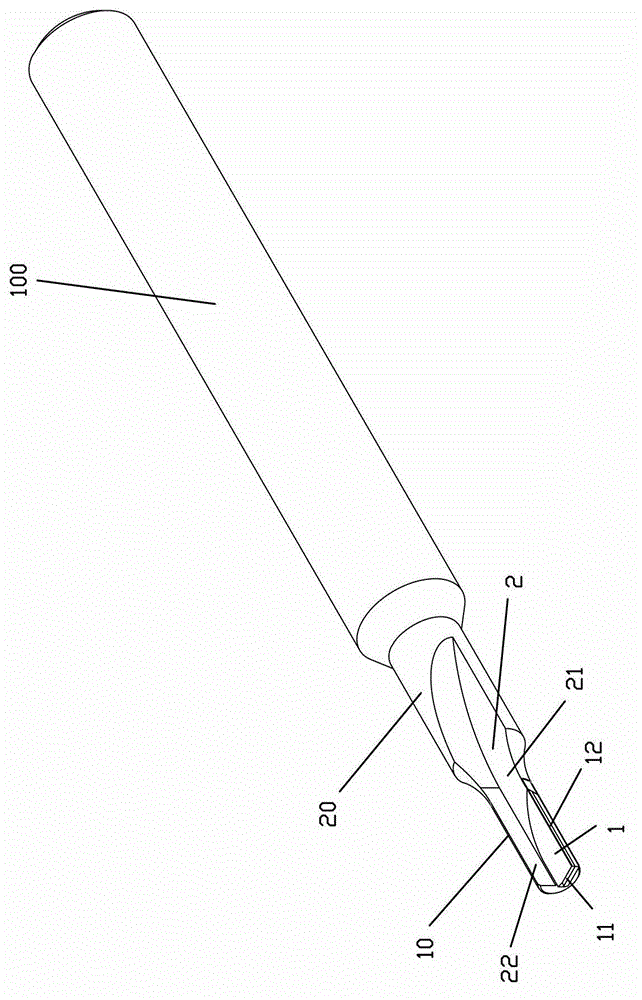

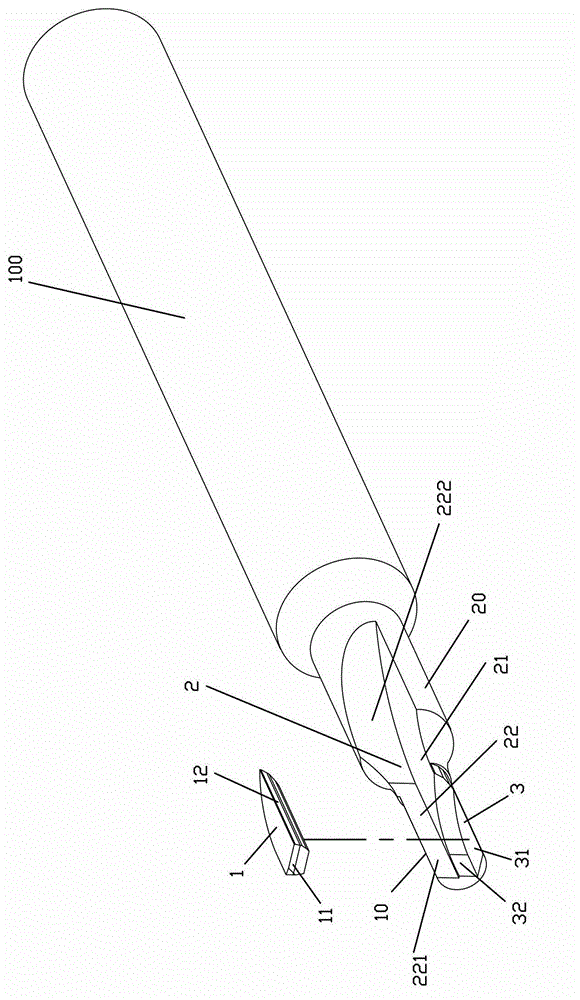

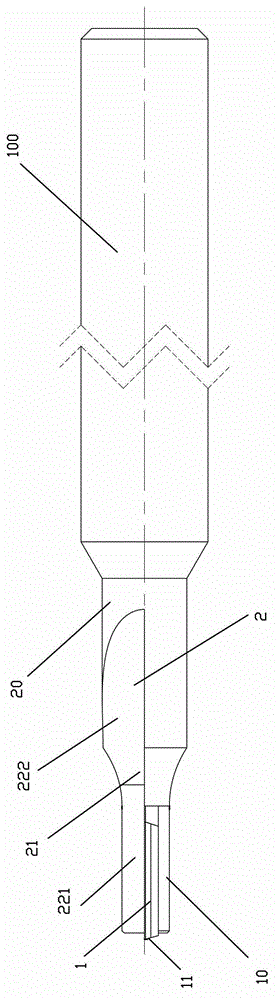

[0028] Embodiment, referring to the accompanying drawings, the miniature superhard drill and milling cutter specially used for processing ceramic materials of the present invention includes a round rod 100 made of cemented carbide; the diameter of the round rod 100 is 6 millimeters, circular The end of one end of the rod 100 is provided with a first circular rod part 10 and a second circular rod part 20 successively from the end to the end, and the diameter of the first circular rod part 10 is less than or equal to 2.5 millimeters, and the second The diameter of circular rod part 20 is 4 millimeters; The end portion at one end of described circular rod 100 is provided with a chip removal groove 2 by end head and extends to the second circular rod part; This chip removal groove 2 Consist of groove bottom wall 21 and groove side wall 22, wherein, groove bottom wall 21 is set as plane and passes through the center line of circular rod, groove bottom wall 21 and groove side wall 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com