Combined anti-loosening fastener

An anti-loosening and combined technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of difficulty and trouble in processing wedge-shaped teeth, difficulty in mass production, etc., and achieve assembly process convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

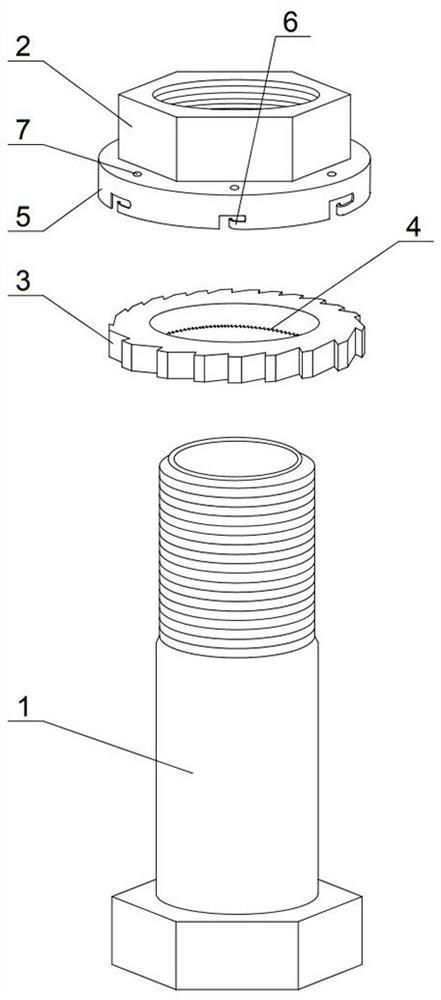

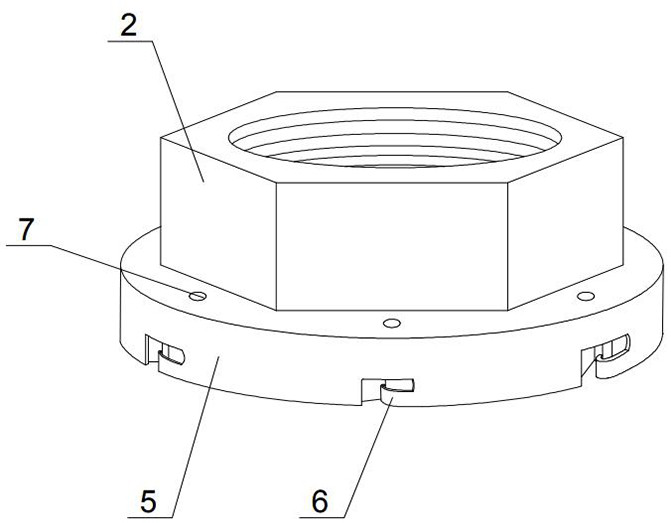

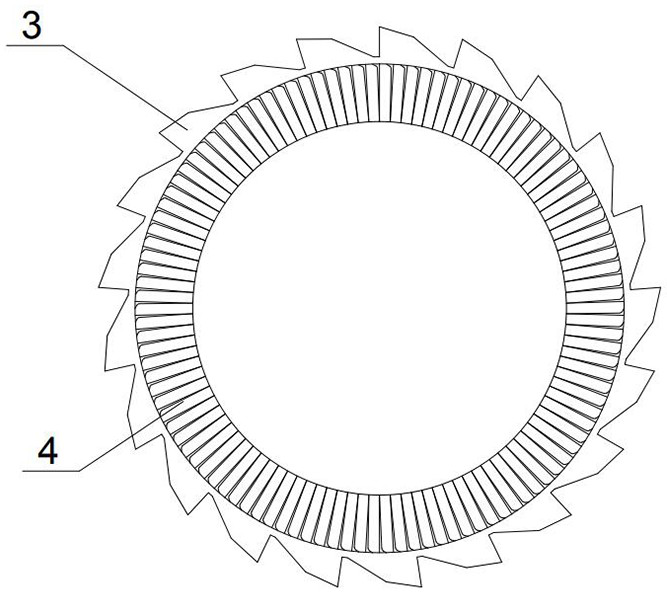

[0027] like Figure 1-3 As shown, the combined anti-loosening fastener includes a bolt 1, a nut 2 and a ratchet 3. The lower end surface of the ratchet 3 is arranged with radial wedge-shaped teeth 4 along a ring. The direction is the same, the bottom end of the nut 2 is fixedly connected with a female cover 5, the female cover 5 can cover the ratchet 3 and the inner top end of the female cover 5 can be pressed on the upper end surface of the ratchet 3, and the side wall of the female cover 5 is provided with multiple One pawl 6 for matching the ratchet 3, one end of the shank of the bolt 1 can pass through the workpiece, the ratchet 3, the female cover 5 and the nut 2 in order to fasten the connected workpiece.

[0028] When the combined anti-loosening fastener provided by the above embodiment is used, such as Figure 4 As shown, first, the bolt 1 can be passed through the workpiece B, the workpiece A, the ratchet 3, the female cover 5 and the nut 2 in sequence, and then the ...

Embodiment 2

[0040] In addition to the methods provided by the above-mentioned embodiments, an embodiment can also be provided, which differs from Embodiment 1 only in the form of the ratchet 6 on the side of the mother cover 5, specifically, as Figure 5 As shown, the direction of one end of the ratchet 6 is opposite to that of the ratchet 6 in Embodiment 1, and there is no need to set a hook-shaped end structure, it only needs to be bent at a certain angle, and this structure can also play the role of locking the ratchet 5. As a result, different mother cover 5 structures can be selected according to requirements during actual use, so that the difficulty of repairing after disassembly will also be different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com